TAS TA515M Series User manual

GEAR BENDER

TA515M Series

Instruction Manual

1

Thank you for purchasing this product.

Read this Safety Notes and Instruction Manual thoroughly before using the product and ensure

that instructions therein are fully understood.

This manual summarizes “things that needs to be observed” so that the product can be used by

everybody without any concern.

Keep this manual handy for quick reference.

If the product were to be rented or assigned to somebody else, provide thorough instructions and

deliver the product together with this manual.

Contents

1. For Using the Product Safely・・・・・・・・・・・・ 2 - 3

2. Part Name and Function・・・・・・・・・・・・・・・ 4

3. Preparation・・・・・・・・・・・・・・・・・・・・ 5 - 6

4. Usage・・・・・・・・・・・・・・・・・・・・・・・ 6 – 8

5. Primary Specification・・・・・・・・・・・・・・・ 9

Warranty Certificate・・・・・・・・・・・・・・・・・・ 10

Safety Notes

(Should be observed)

Always observe these instructions as they are meant to prevent harms to the operator and other

persons, as well as damages to the properties.

Notes contained in this manual are classified as WARNING and CAUTION.

Instructions given in the WARNING column summarize and refer to those that may result in

a death or serious injury if they are neglected. However, instructions classified as

CAUTION may also lead to serious consequences depending on the

circumstance if

neglected.

Observe all instructions without fail because they refer to important matters concerning safety.

Before using the product, it should be understood that the supplier shall not be held liable for the

product failures, ot

her problems and damages suffered by the customer or a third person, while

using the product erroneously or properly, unless the liability is affirmed legally.

2

Safety Notes

1.For Using the Product Safely

General instructions

WARNING

Do not modify the machine or use it for purposes other than those intended.

[If neglected]

The machine may fail or cause an accident, resulting in an injury of the operator.

WARNING

Wear clothing suitable for the task.

Do not wear the baggy clothes and accessories such as a necklace to prevent them from getting

caught in the moving part.

Put on safety shoes, a helmet, protective eyeglasses, protective clothes, etc. in performing a task.

[If neglected]

The operator may suffer an injury.

WARNING

Do not touch the moving part during work.

[If neglected]

The operator may suffer an injury.

WARNING

Carry out the work on a level place.

[If neglected]

The operator may suffer an injury by moving the machine accidentally.

WARNING

Allow sufficient space for usi

ng the machine in consideration of length of a

copper tube and its rolling.

[If neglected]

It may not only damage the surroundings but also people around the machine may be hurt.

WARNING

Keep the machine in a location where children and animals wou

ld not be

present.

[If neglected]

Children or animals may suffer an injury by touching or moving the machine.

CAUTION

Avoid using the product forcibly so that a work can be performed safely and

efficiently.

[If neglected]

The machine may fail or cause an accident, resulting in an injury of the operator.

CAUTION

Do not sit on and shake the machine.

[If neglected]

The machine may fail or cause an accident, resulting in an injury of the operator.

3

CAUTION

Do not expose the machine to wind and rain.

[If neglected]

It can be a cause of failure.

CAUTION

Keep the workplace clean.

[If neglected]

A workplace or a workbench that is littered can cause an accident.

CAUTION

Do not use parts other than those designated by the supplier fo

r

replacement and other purposes.

[If neglected]

It can be a cause of failure.

4

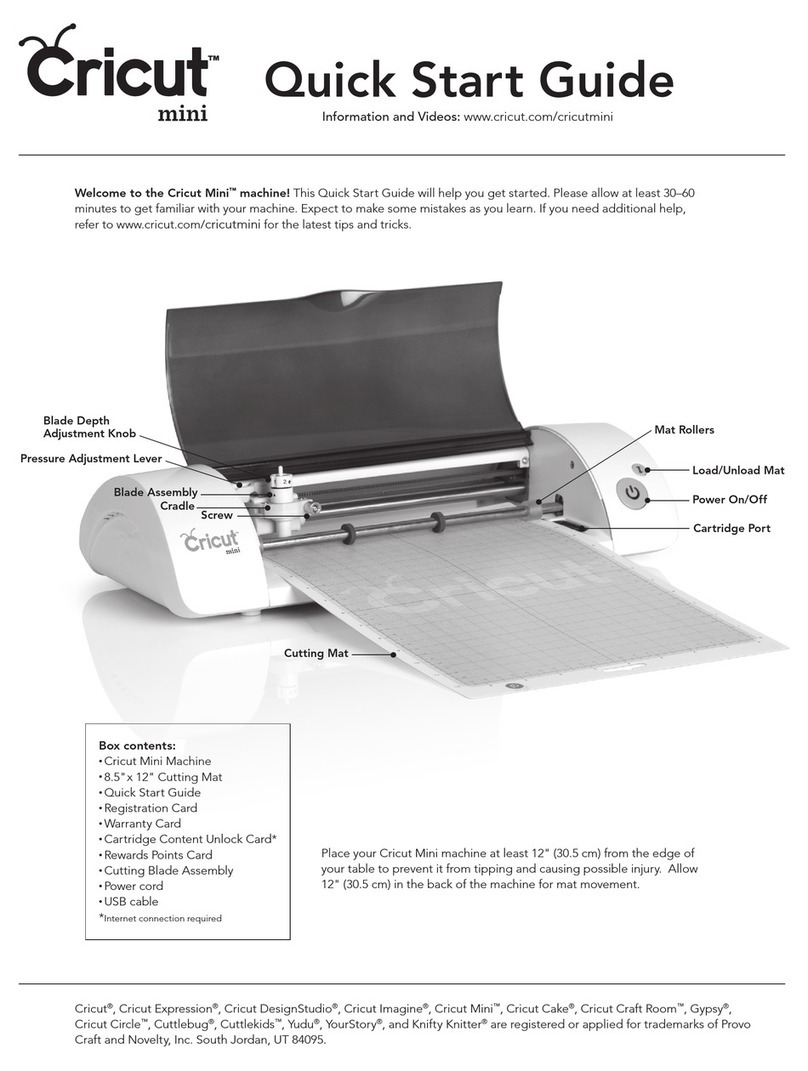

2.Part Name and Function

2.1 Features

■Need no power supply.

■Gears make labor-saving, easy and simple operation.

■Tripod with adjustable and foldable legs.

■Easy to carry and operate at work sites.

2.2 Parts

①

Guide Pin

②

Guide

③

Bender Former

④

Bolt 2 pcs (to fix the former)

⑤

Ratchet Wrench with 17mm Socket

⑥

Tripod

①

②

③

④

⑤

⑥

5

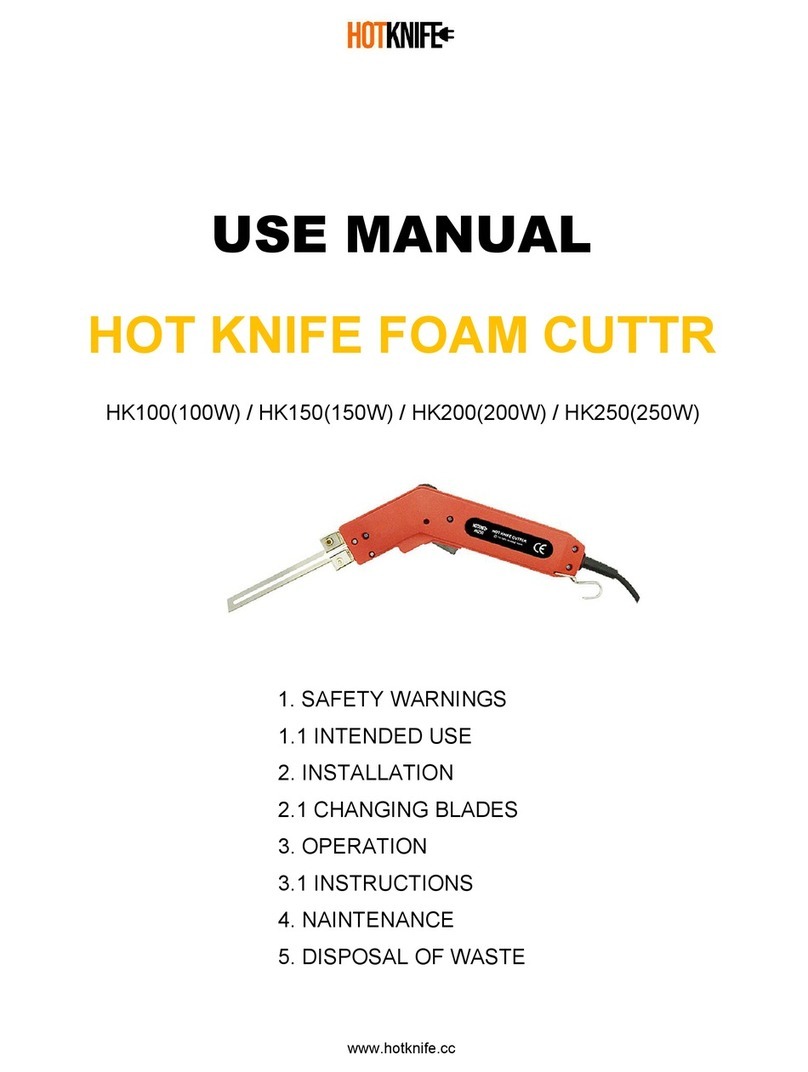

3.Preparation

1. Open up the tripod and turn left to loosen the legs.

Pull out to a desired length and turn right to lock the legs.

※After setting the bender former on the tripod, adjust the length so that

it’s horizontal.

※Do not pull the legs out beyond the yellow line for safety purposes.

※In case the legs doesn’t lock:

(1)By pulling out to the end and turning right,

the leg should lock.

(2)After confirming that the leg can be locked, make sure

to shorten the length of the leg so that the yellow line is

covered.

Then, turn the leg to the right to lock and push the legs

a bit outward.

UNLOCK

LOCK

③LOCK

①

UNLOCK

YELLOW LINE

②PULL OUT TO THE END

②LOCK

①

PUSH OUTWARD

①

PUSH OUTWARD

②LOCK

6

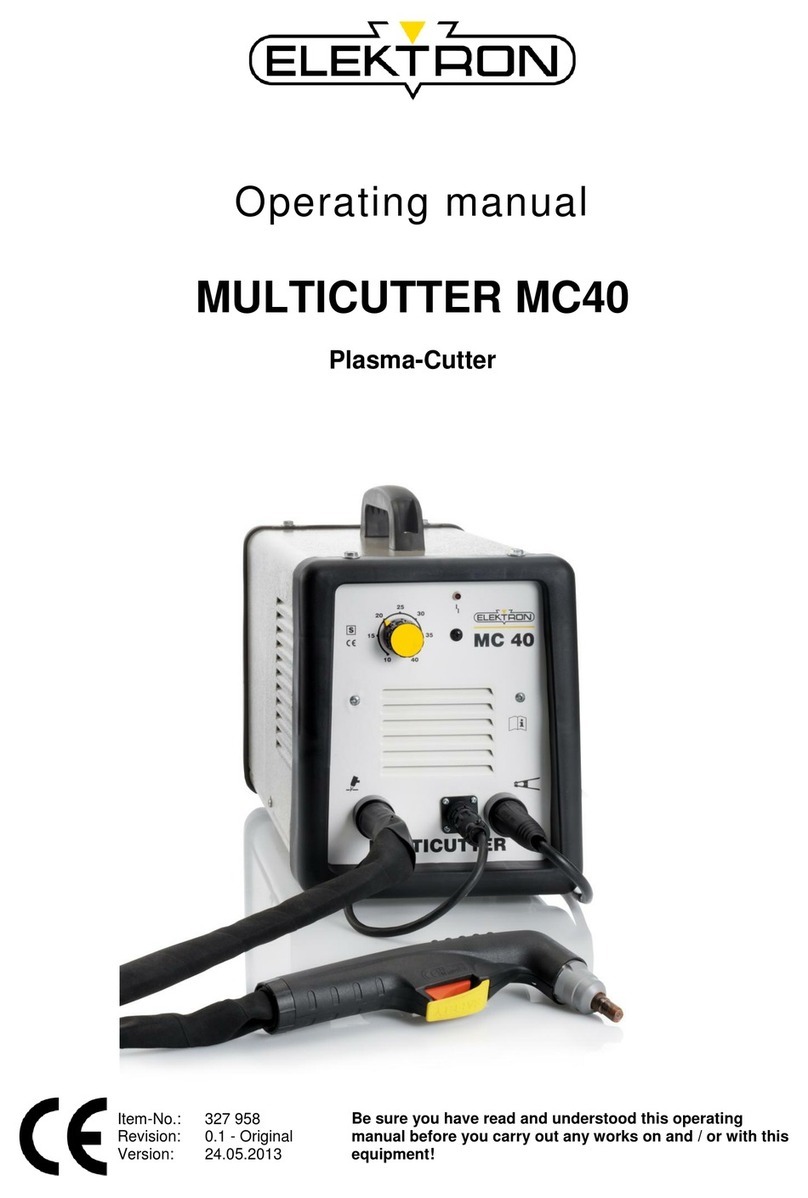

2. Attach the bender former to the tripod with the fixing bolts.

4.

Usage

1. Set the copper tube to the former and fasten the hook. Then put the guide

pin through the former and the guide (arrow mark on the guide should be

pointing upwards) completely.

※The copper tube end should stick out of the hook at least 20mm or more.

※The guide pin should pass completely through the former plate.

2. Set the ratchet wrench to the former and shift the selector bar as per the

picture below.

※Can adjust the length of ratchet handle by turning the grip.

※Do not pull out the handle over the limit line.

(The limit line is shown by the dent on the ratchet tube.)

SELECTOR BAR

UNLOCK

LOCK

HOOK

MORE THAN 20mm

PENETRATE

COMPLETELY

RATCHET HANDLE

ROCK NUT

FIXING BOLT

7

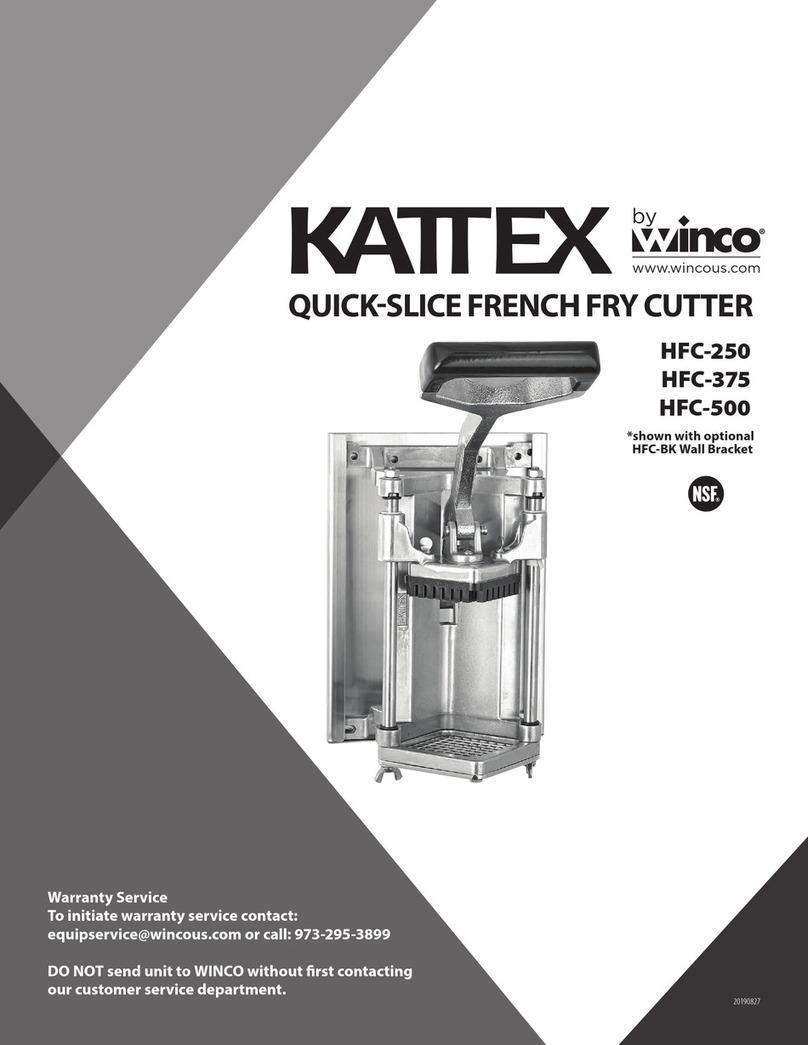

3. Move the ratchet handle forward and backward

widely

so that the former

rotates. In order to apply the ratchet function, hold the socket of the

ratchet wrench and move the handle forward and backward.

Once there is resistance, replace the left hand on the guide pin as shown

in the picture below.

※Do not touch the moving part during operation .

4. Check the angle by the check window and when it reaches the target angle,

stop the operation and shift the selector bar of the ratchet wrench. Then,

move the ratchet handle forward and backward so that the former rotates in

the opposite direction.

※Bending angle is only a guide. Depending on the copper tube, the spring

back (the force to go backwards) will occur.

※Note to take care of the rebound of the copper tube.

5. After the copper tube is released from the fixing, remove the guide pin

from the guide and remove the copper tube from the former.

SOCKET

ANGLE CHECK WINDOW

8

WARNING

Do not bend the copper tube other than the appropriate size.

The machine is only for 1/2 hard copper tube. Do not bend a hard copper tube.

Make sure to attach the guide pin.

【

If neglected

】

The machine may fail or cause an accident, resulting in an injury of the operator.

CAUTION

Make sure to support the copper tube during work.

【If neglected】

The end of the copper tube which is not fixed by the gear bender shall be weighted down

with one’s own weight. If it’s not be supported during work, the copper tube may deform

and the machine may also fail.

Therefore, we strongly recommend you to support the copper tube regardless of the tube

length.

OPTION

Adapter for Impact Driver【TA515M-D】

●Applicable for electric drivers with 45Nm or above.

●Attached with 17mm socket for electric driver.

●Easier to operate than with a ratchet wrench.

Pipe Supporting Stand for Bending Machine【TA515PY】

●Height:860~1200mm●forφ9~100mm copper tube

9

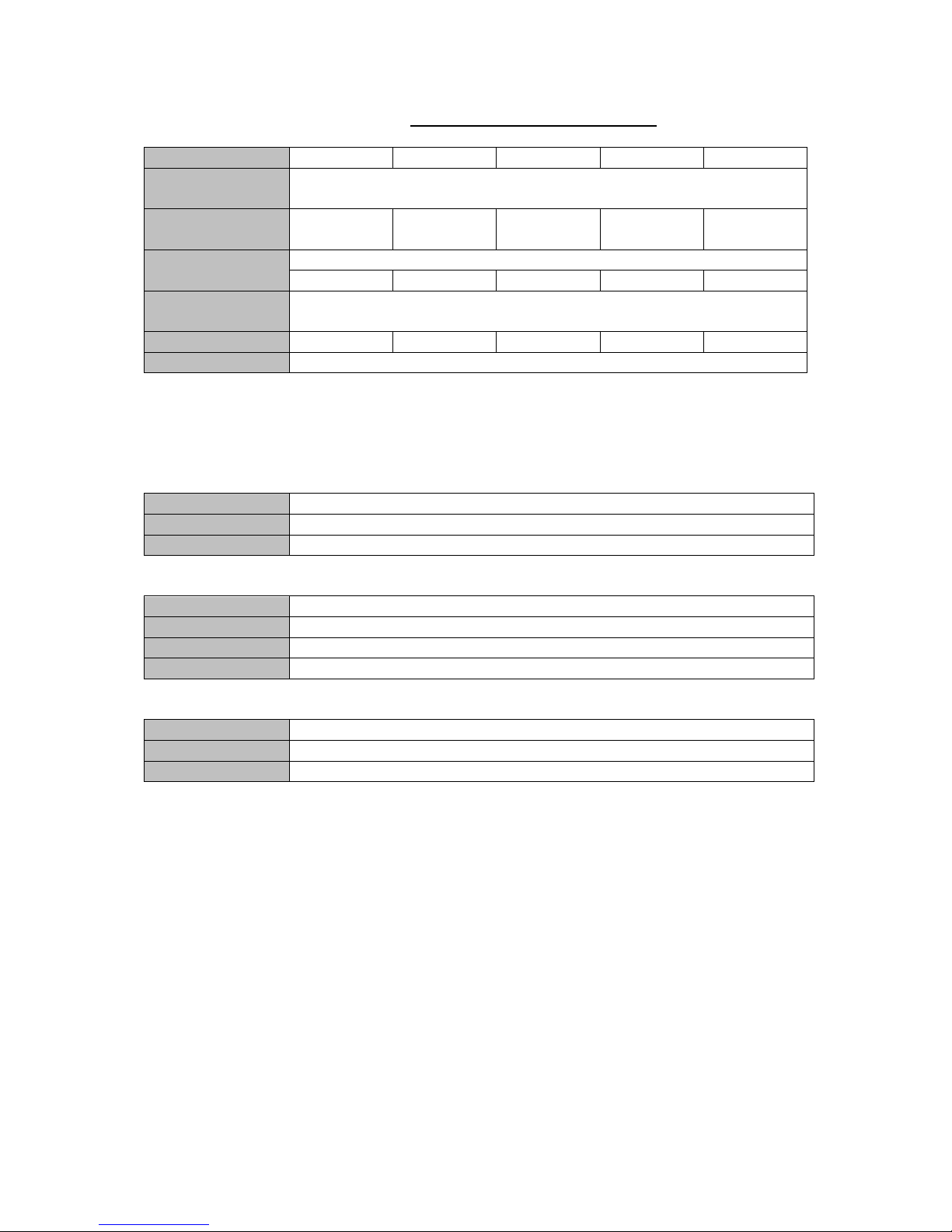

5.

Primary Specification

FORMER

ITEM NO.

TA515M-7 TA515M-8 TA515M-9 TA515M-10 TA515M-12

APPLICABLE COPPER

MATERIAL

1/2HCOPPER TUBE

COPPER TUBE SIZE

7/8”

(22.23mm)

1”

(25.4mm)

1-1/8”

(28.58mm)

1-1/4”※

(31.75mm)

1-1/2”※

(38.1mm)

BENDING RADIUS

R=4D(4 TIMES OF TUBE DIAMETER)

89mm 102mm 114mm 127mm 152mm

MAXIMUM BENDING

ANGLE

180°

WEIGHT

4.5kg 5.0kg 5.4kg 6.9kg 9.0kg

ACCESSORIES

GUIDE、GUIDE PIN、FIXING BOLT

※Depending on the hardness of the copper tube, the spring back function occurs(the force

to return to its original form), which may cause the ratchet action to have no effect.

When this happens, do not use the ratchet action (back and forth), but rotate the handle

360 degrees by hand in order to make the former move and bend the tube.

TRIPOD

ITEM NO.

TA515M-T

HEIGHT

550~790mm

WEIGHT

6.9kg

1/2”RATCHET WRENCH

ITEM NO.

TA515M-W

LENGTH

420~660mm

WEIGHT

1.3kg

SOCKET

INSERTING ANGLE:1/2”(12.7mm)SIZE:17mm

STORAGE BAG

ITEM NO.

TA515M-B

SIZE

W670×D330×H300mm

WEIGHT

3.0kg

10

No.

Warranty

Terms of Warranty

1. This product is to be repaired free of charge if a failure occurs despite proper use during

the period of warranty.

2. This warranty is valid for 1 year starting from the date of purchase.

3. In any of the following cases, this product is to be excluded from free-of-charge repair.

1) Failures incurred by improper use.

2) Failures due to handling and storage beyond its specifications.

3) Failures due to modifications or repairs not done by the manufacturer or its

entrusted technicians.

4) Failures due to consumable components.

5) Other failures not deemed to be the manufacturer’s responsibilities.

Product Name: GEAR BENDER

Model: TA515M series

Date of purchase: M: /D: /Y:

Period of warranty: For 1 year starting from M: /D: /Y:

Customer

Name:

Address:

Phone number:

Dealer

Address and name:

* To the dealer: Kindly take a few minutes and fill out the above form.

11

1-17-20 Inadauemachi, Higashi-Osaka City, Osaka

577-0002, JAPAN

Phone: 81-6-6748-9310 Fax: 81-6-6748-9320

Web Site: http://www.tascojapan.co.jp/

Table of contents