Task Force TF2500 User manual

Questions, problems, missing parts? Before returning to your retailer, please contact our

customer service department at 1-866-393-3968.

ITEM / ARTICULO # 0008862

MODEL / MODELO # TF2500

2500PSI GASOLINE

PRESSURE WASHER

Español p. 38

This product is covered by US patents and other international patents.

Copyright. All Rights Reserved.

READ AND SAVE THESE INSTRUCTIONS

EQUIPO GASOLINA DE

LAVADO CON AGUA A

PRESIÓN DE 2500 PSI

LEA Y GUARDE ESTAS INSTRUCCIONES

¿Consultas, problemas, piezas faltantes? Antes de devolver la unidad a la tienda,

contáctese con nuestro Departamento de Servicio al Cliente llamando al 1-866-393-3968.

Este producto está protegido por patentes de los EE. UU. y otras patentes internacionales.

Derecho de autor. Todos los derechos reservados.

Rev.5 2/097102055

2

TABLE OF CONTENTS

PRODUCT SPECIFICATIONS

Specifications ...........................................................................................................................

Safety Information ....................................................................................................................

Carton Contents ....................................................................................................................

Assembly Instructions ............................................................................................................

Operating Instructions ........................................................................................................

Maintenance ........................................................................................................

End of Use and Storage Instructions ....................................................................................

Trouble Shooting Guide .......................................................................................................

Accessories ...................................................................................................................

Repairs ..............................................................................................................................

Warranty ..........................................................................................................................

2

5

16

16

17

25

30

33

36

36

37

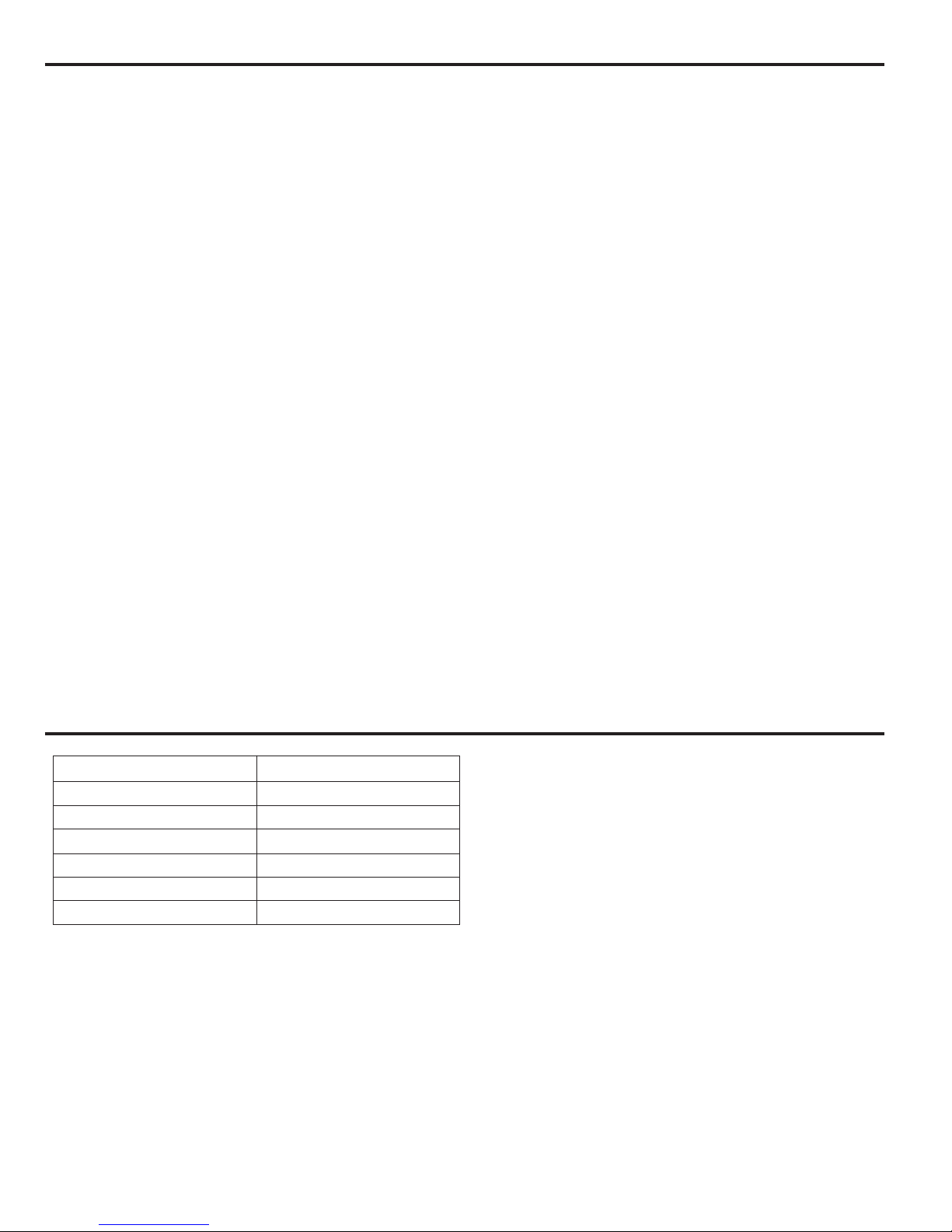

Max. pressure *

Water flow rate *

Engine

Pump

High pressure hose

Pressure of inlet water

Inlet water

2500 PSI

2.0 GPM

173cc OHV

Axial cam

25 ft

20 - 100 PSI

Cold tap water

* Ratings determined in accordance with PWMA. Standard PW101.

Engine Specifications ............................................................................................................... 3

3

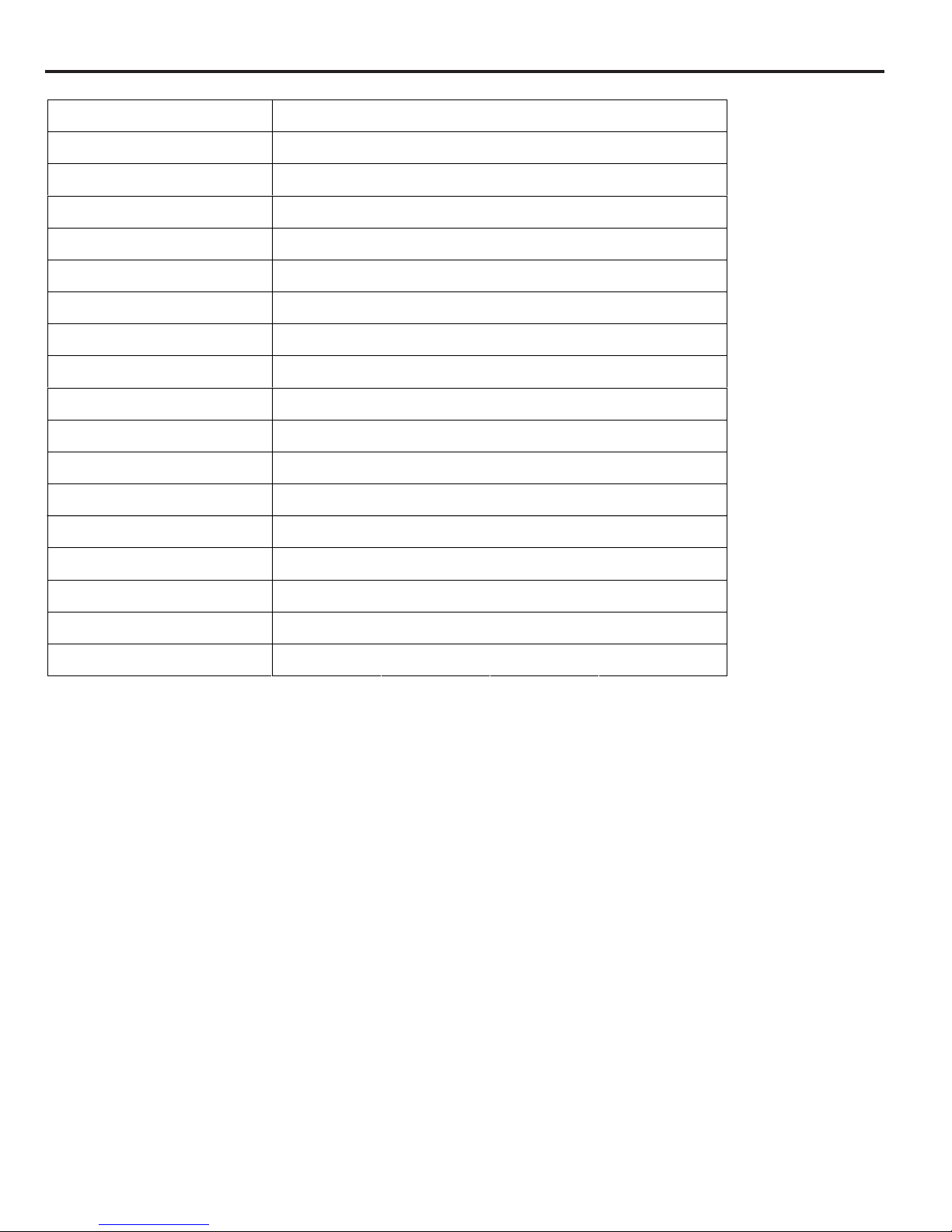

ENGINE SPECIFICATIONS

F07P1ledoM

VHO,gnilooCriAdecroF,ekortS-4,rednilycelgniSepyT

Max. power(kW/3600rpm) 4.0

Max. torque (N·m/rpm) 9.8/2500

Fuel consumption (g/kW·h) ≤395

Idle speed 1800 ±150 rpm

Bore X Stroke(mm) 70x45

Displacement(cc) 173

1:8

oitaRnoisserpmoC

hsalpSedomgnitacirbuL

tratslioceRedoMgnitratS

)edis.O.T.Pmorf(esiwkcolc-itnAnoitatoR

Valve Clearance Input valve :0.10 ±0.02mm, output valve :0.15 ±0.02mm

”130.0–820.0ROmm8.0~7.0ecnaraelcgulpkrapS

noitingIotengamdezirotsisnarTedoMgnitingI

retlifmaoF,htabliO,yrd-imeSrenaelcriA

Dimension(L×W×H)(mm) 470*390*380

Net weight (kg) 13.7

4

ENGINE SPECIFICATIONS

Serial Number Location

Record the engine serial number in the space below. You will need this serial number when

ordering parts, and when making technical or warranty inquires.

Engine serial number:

Maintenance

Follow the maintenance schedule. Remember that this schedule is based on the assumption that

your machine will be used for its designed purpose. Sustained high-load or high-temperature

operation, or use in unusually wet or dusty conditions, will require more frequent service.

Engine Tune-up

Quick Reference Information

ITEM SPECIFICATION

Spark plug gap 0.028-0.031 in

(0.70-0.80 mm)

Valve clearance IN: 0.10 ±0.02 mm (cold)

EX: 0.15 ±0.02 mm (cold)

Other specications No other adjustments needed

Type SAE 10W-30,API SE or SF, for general use

Engine Oil Capacity 1P61FA, 1P65FA : 0.55L (0.146 US Gal, 0.119 Imp Gal)

1P68FA, 1P70F, 1P70FA : 0.6L (0.16US Gal, 0.13mp Gal)

Type F7RTC or other equivalents.

Spark Plug Gap 0.028 -0.031 in (0.70 -0.80 mm)

Carburetor Idle speed 1800 ±150 rpm

Each use Check engine oil. Check air lter.

First 5 hours Change engine oil.

Maintenance

Subsequent Refer to the maintenance

ENGINE TYPE

SERIAL NUMBER

SAFETY INFORMATION

5

Please read and understand this entire manual before attempting to assemble, operate or install

the product. If you have any questions regarding the product, please contact our customer service

department at 1-866-393-3968.

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that is important for you to know and under -

stand. This information relates to protecting YOUR SAFETY and PREVENTING

EQUIPMENT PROBLEMS . To help you recognize this information, we use the

symbols below. Please read the manual and pay attention to these symbols.

Indicates an immi-

nently hazardous situ-

ation which, if not avoided, will result

in death or serious injury.

Indicates a potentially

hazardous situation

which, if not avoided, may result in

minor or moderate injury.

Indicates a potentially

hazardous situation

which, if not avoided, could result in

death or serious injury.

Used without the

safety alert symbol

indicates a potentially hazardous situ -

ation which, if not avoided, may result

in property damage.

CONSUMER SAFETYINFORMATION

This product may not be equipped with a spark arrest-

ing muffler. If the product is not equipped and will be used

around flammable materials, or on land covered with materials such as

agricultural crops, forest, brush, grass, or other similar items, then an

approved spark arrester must be installed and is legally required in the state

of California. It is a violation of California statutes section 130050 and/or

sections 4442 and 4443 of the California Public Resources Code, unless the

engine is equipped with a spark arrester, as defined in section 4442, and

maintained in effective working order. Spark arresters are also required on

some U.S. Forest Service land and may also be legally required under other

statutes and ordinances.

This product contains chemicals, known to the State of

California to cause cancer, and birth defects or other repro -

ductive harm. Wash hands after handling.

IMPORTANT SAFETYINSTRUCTIONS

Do not operate this unit until you have read and understand

this Operators Manual and the Engine Owners Manual for

Safety, Operation, and Maintenance Instructions.

READ AND SAVE THESE INSTRUCTIONS

RISK OF EXPLOSION OR FIRE

WHAT CAN HAPPEN HOW TO PREVENT IT

• Spilled gasoline and it's vapors

can become ignited from ciga -

rette sparks, electrical arcing,

exhaust gases and hot engine

components such as the muf -

fler.

• Shut off engine and allow it to cool

before adding fuel to the tank.

• Use care in filling tank to avoid spilling

fuel. Move pressure washer away from

fueling area before starting engine.

SAFETY INFORMATION

Please read and understand this entire manual before attempting to assemble, operate or install

the product. If you have any questions regarding the product, please contact our customer service

department at 1-866-393-3968.

RISK TO BREATHING (Asphyxiation)

WHAT CAN HAPPEN HOW TO PREVENT IT

Heat will expand fuel in the

tank which could result in spill-

age and possible fire explosion.

Fill tank to 1/2” (12.7mm) below bottom

of filler neck to provide space for fuel

expansion.

Operating the pressure washer

in an explosive environment

could result in a fire.

Materials placed against or

near the pressure washer can

interfere with its proper ventila-

tion features causing overheat-

ing and possible ignition of the

materials.

Muffler exhaust heat can dam-

age painted surfaces, melt any

material sensitive to heat (such

as siding, plastic, rubber, vinyl,

or the pressure hose itself), and

damage live plants

Improperly stored fuel could

lead to accidental ignition. Fuel

improperly secured could get

into the hands of children or

other unqualified persons.

Use of acids, toxic or corrosive

chemicals, poisons, insecticides,

or any kind of flammable solvent

with this product could result in

serious injury or death.

Operate and fuel equipment in well-

ventilated areas free from obstructions.

Equip areas with fire extinguishers suit-

able for gasoline fires.

Never operate pressure washer in an

area containing dry brush or weeds.

Always keep pressure washer a mini-

mum of 4’ (1.2m) away from surfaces

(such as houses, automobiles, or live

plants) that could be damaged from

muffler exhaust heat.

Store fuel in an OSHA-approved

container, in a secure location away

from the work area.

Do not spray flammable liquids.

Breathing exhaust fumes will

cause serious injury or death!

Engine exhaust contains car-

bon monoxide, an odorless and

deadly gas.

Some cleaning fluids contain

substances which could cause

injury to skin, eyes, or lungs.

Operate Pressure washer in a well-

ventilated area. Avoid enclosed areas

such as garages, basements, etc.

Never operate unit in a location occu-

pied by humans or animals.

Use only cleaning fluids specifically

recommended for high-pressure wash-

ers. Follow manunfacturers

recommendations. Do not use chlorine

bleach or any other corrosive compound.

6

RISK OF FLUID INJECTION AND LACERATION

WHAT CAN HAPPEN HOW TO PREVENT IT

RISK OF INJURY FROM SPRAY

WHAT CAN HAPPEN HOW TO PREVENT IT

SAFETY INFORMATION

Please read and understand this entire manual before attempting to assemble, operate or install

the product. If you have any questions regarding the product, please contact our customer service

department at 1-866-393-3968.

Your pressure washer operates

at fluid pressures and veloci-

ties high enough to penetrate

human and animal flesh, which

could result in amputation or

other serious injury. Leaks

caused by loose fittings or

worn or damaged hoses can

fesult in injection injuries. DO

NOT TREAT FLUID INJECTION

AS A SIMPLE CUT! See a phy-

sician immediately!

Inspect the high-pressure hose regular-

ly. Replace the hose immediately if it is

damaged, worn, has melted from con-

tacting the engine, or shows signs of

cracks, bubbles, pinholes, or other

leakage. Never grasp a high-pressure

hose that is leaking or damaged.

Never touch, grasp, or attempt to cover

a pinhole or similar water leak on the

high pressure hose. The stream of

water IS under high pressure and WILL

penetrate skin.

Never place hands in front of nozzle.

Direct spray away from self and others.

Make sure hose and fittings are tight-

ened and in good condition. Never

hold onto the hose or fittings during

operation.

Do not allow the hose to contact muffler.

Never attach or remove wand or hose

fittings while system is pressurized.

Injuries can result if system

pressure is not reduced before

attempting maintenance or

disassembly.

To relieve system pressure, shut off

engine, turn off water supply and pull

gun trigger until water stops flowing.

Use only hoses and accessories rated

for pressure higher than your pressure

washer’s psi.

High-velocity fuild spray can

cause objects to break, propel-

ling particles at high speed.

Light or unsecured objects can

become hazardous projectiles.

Always wear ANSI-approved Z87.1

safety glasses. Wear protective clothing

to protect against accidental spraying.

Never point wand at or spray people or

animals.

Always secure trigger lock when wand

is not in service to prevent accidental

operation.

Never permanently secure trigger in

pull-back (open) position.

7

SAFETY INFORMATION

Please read and understand this entire manual before attempting to assemble, operate or install

the product. If you have any questions regarding the product, please contact our customer service

department at 1-866-393-3968.

RISK OF UNSAFE OPERATION

WHAT CAN HAPPEN HOW TO PREVENT IT

Unsafe operation of your press-

ure washer could lead to seri-

ous injury or death to you or

others.

Do not use chlorine bleach or any other

corrosive compound.

Become familiar with the operation and

controls of the pressure washer.

Keep operating area clear of all

persons, pets, and obstacles.

Do not operate the product when

fatigued or under the influence of alco-

hol or drugs. Stay alert at all times.

Never defeat the safety features of this

product.

Do not operate machine with missing,

broken, or unauthorized parts.

Never leave the wand unattended

while the unit is running.

If proper starting procedure is

not followed, engine can kick-

back causing serious hand and

arm injury.

The spraygun/wand is a power-

ful cleaning tool that could look

like a toy to a child.

Reactive force of spray will

cause gun/wand to kick-back,

and could cause the operator to

slip or fall, or misdirect the

spray. Improper control of gun/

wand can result in injuries to

self and others.

If engine does not start after two pulls,

squeeze trigger of gun to relieve pump

pressure. Pull started cord slowly until

resistance is felt. Then pull cord rapidly

to avoid kick-back and prevent hand or

arm injury.

Keep children away from the pressure

washer at all times.

Do not overreach or stand on an

unstable support.

Do not use pressure washer while

standing on a ladder.

Grip gun/wand firmly with both hands.

Expect the gun to kick-back when

triggered.

8

SAFETY INFORMATION

Please read and understand this entire manual before attempting to assemble, operate or install

the product. If you have any questions regarding the product, please contact our customer service

department at 1-866-393-3968.

RISK OF INJURY OR PROPERTY DAMAGE WHEN

TRANSPORTING OR STORING

WHAT CAN HAPPEN HOW TO PREVENT IT

RISK OF BURSTING

WHAT CAN HAPPEN HOW TO PREVENT IT

RISK OF HOT SURFACES

WHAT CAN HAPPEN HOW TO PREVENT IT

Fuel or oil can leak or spill and

could result in fire or breathing

hazard. Serious injury or death

can result. Fuel or oil leaks will

damage carpet, paint, or other

surfaces in vehicles or trailers.

If pressure washer is equipped with

a fuel shut-off valve, turn the valve to

the OFF position before transporting to

avoid fuel leaks. If pressure washer

is not equipped with a fuel shut-off

valve, drain the fuel from tank before

transporting. Only transport fuel in an

OSHA-approved container. Always

place pressure washer on a protective

mat when transporting to protect

against damage to vehicle from leaks.

Remove pressure washer from vehicle

immediately upon arrival at destination.

Over inflation of tires could

result in serious injury and

property damage.

Use a tire pressure gauge to check the

tire pressure before each use and while

inflating tires; see the tire sidewall for the

correct tire pressure.

NOTE: Air tanks, compressors, and

similar equipment used to inflate tires

can fill small tires similar to these very

rapidly. Adjust pressure regulator on air

supply to no more than the rating of the

tire pressure. Add air in small increments

and frequently use the tire gauge to

prevent over inflation.

High Velocity fuid spray directed

at pneumatic sidewalls

(such as found on automobiles,

trailers, and the like) could dam-

age the sidewall resulting in

serious injury.

On pressure washer rated above 1600

psi (110 Bar) use the widest fan spray

(40º nozzle) and keep the spray a mini-

mum of 8” (20cm) from the pneumatic

tire sidewall. Do not aim spray directly

at the joint between the tire and rim.

Contact with hot surfaces, such

as engine exhaust components,

could result in serious burn.

During operation, touch only the control

surfaces of the pressure washer.

Keep children away from the pressure

washer at all times. They may not be

able to recognize the hazards of this

product.

9

SAFETY INFORMATION

Please read and understand this entire manual before attempting to assemble, operate or install

the product. If you have any questions regarding the product, please contact our customer service

department at 1-866-393-3968.

RISK OF CHEMICAL BURN

WHAT CAN HAPPEN HOW TO PREVENT IT

• Use of acids, toxic or corrosive

chemicals, poisons, insecti-

cides, or any kind of flammable

solvent with this product could

result in serious injury or death.

• Do not use acids, gasoline, kerosene,

or any other flammable materials in this

product. Use only household deter-

gents, cleaners and degreasers recom-

mended for use in pressure washers.

• Wear protective clothing to protect

eyes and skin from contact with

sprayed materials.

RISK OF LACIRTCELE SHOCK

WHAT CAN HAPPEN HOW TO PREVENT IT

• Spray directed at electrical out-

lets or switches, or ob jects con-

nected to an electrical circuit,

could result in a fatal electrical

shock.

• Unplug any electrically operated prod-

uct before attempting to clean it. Direct

spray away from electric outlets and

switches.

RISK OF INJURY FROM LIFTING

WHAT CAN HAPPEN HOW TO PREVENT IT

• Serious injury can result from

attempting to lift too heavy an

object.

• The pressure washer is too heavy to be

lifted by one person. Obtain assistance

from others before lifting.

READ AND SAVE THESE INSTRUCTIONS

10

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other re

p

roductive harm.

The safety alert symbol ()is used to identify safety information about hazards that can

result in personal injury.

A signal word (WARNING,DANGER, or CAUTION) is used with the alert symbol to indicate the

likelihood and the potential severity of injury. In addition, a hazard symbol may be used to

represent the type of hazard.

WARNING indicates a hazard which, if not avoided, will result in death or serious

injury.

DANGER indicates a hazard which, if not avoided, could result in death or serious

injury.

CAUTION indicates a hazard which, if not avoided, might result in minor or moderate

injury.

When used without the alert symbol, indicates a situation that could result in damage to

the engine.

CAUTION:You should carefully read and understand the operating instructions for the

TF2500 Pressure Washer.

BEFORE OPERATING ENGINE

Read entire Operating &Maintenance Instructions AND the

instructions for the equipment this engine powers.

Failure to follow instructions could result in serious injury

or death.

THE OPERATING &MAINTENANCE INSTRUCTIONS CONTAIN

SAFETY INFORMATION TO

Make you aware of hazards associated with engines

Inform you of the risk of injury associated with those hazards,and

Tell

y

ou how to avoid or reduce the risk of in

j

ur

y

.

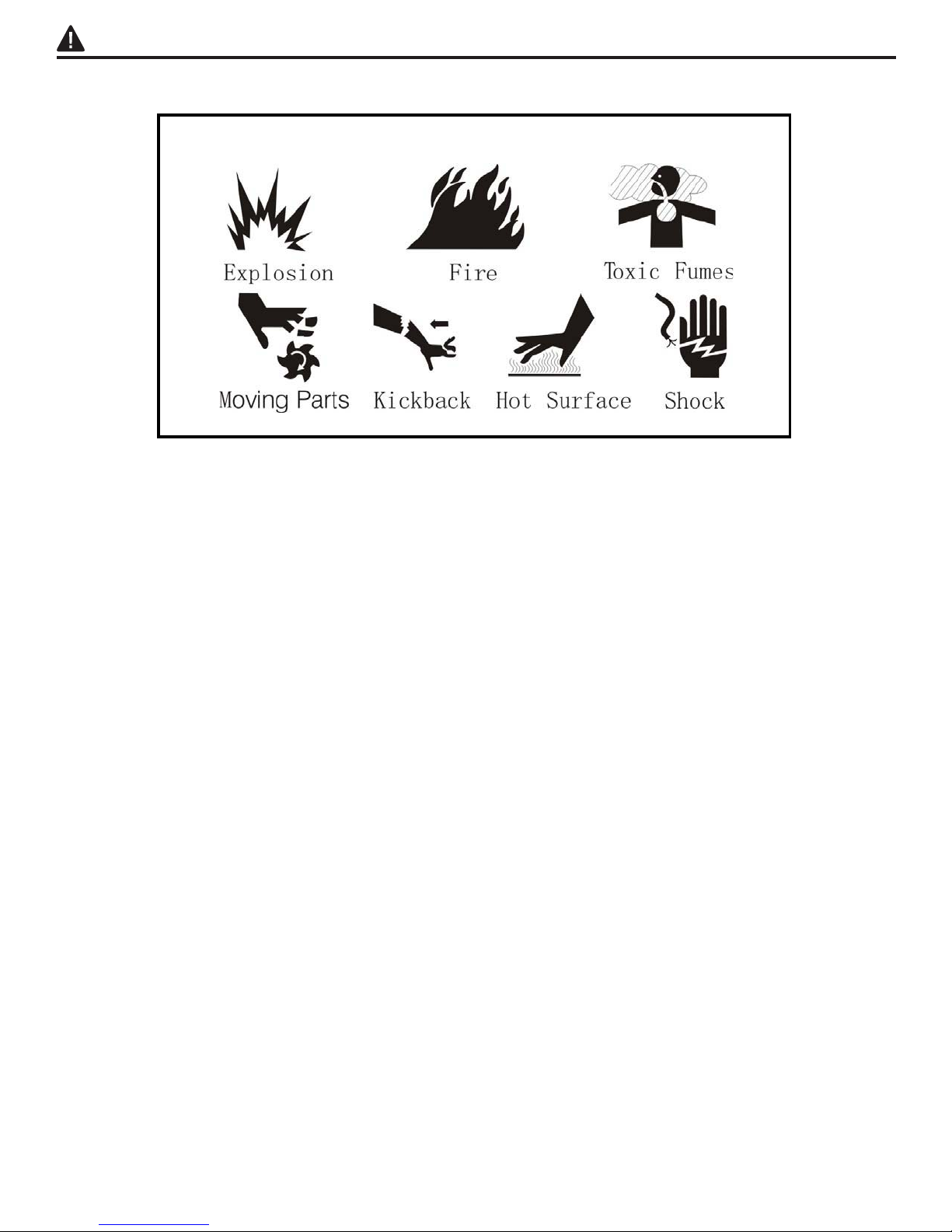

THE INTERNATIONAL SYMBOLS USED ON

THE ENGINE OR IN THIS MANUAL INCLUDE:

WARNING

SAFETY INFORMATION

11

SAFETY INFORMATION

12

HAZARD SYMBOLS AND MEANINGS

SAFETY INFORMATION

13

IMPORTANT SAFETY INFORMATION

Most accidents with engines can be prevented if you follow all instructions in this manual

and on the engine. Some of the most common hazards are discussed below, along with the

best way to protect yourself and others.

Owner Responsibilities

The engines are designed to give safe and dependable service if operated according to

instructions. Read and understand this owner’s manual before operating the engine. Failure

to do so could result in personal injury or equipment damage.

Know how to stop the engine quickly, and understand the operation of all controls. Never

permit anyone to operate the engine without proper instructions.

Do not allow children to operate the engine. Keep children and pets away from the area of

operation.

Gasoline and its vapors are extremely flammable and

explosive.

Fire or explosion can cause severe burns or death.

WHEN ADDING FUEL

Turn engine OFF and let engine cool at least 2 minutes before removing gas cap.

Fill fuel tank outdoors or in well-ventilated area.

Do not overll fuel tank. Fill tank to approximately 1-1/2 inches below top of neck to

allow for fuel expansion.

Keep gasoline away from sparks, open ames, pilot lights, heat, and other ignition

sources.

Check fuel lines, tank, cap, and ttings frequently for cracks or leaks. Replace if

necessary.

WHEN STARTING ENGINE

Make sure spark plug, muer, fuel cap and air cleaner are in place.

Do not crank engine with spark plug removed.

If fuel spills, wait until it evaporates before starting engine.

If engine oods, set choke to OPEN position, place ON/OFF switch in

ON position and crank until engine starts.

WHEN OPERATING EQUIPMENT

Do not tip engine or equipment at angle which causes gasoline to spill.

Do not choke carburetor to stop engine.

WHEN TRANSPORTING EQUIPMENT

Transport with fuel tank EMPTYor with fuel shut-o valve OFF.

WHEN STORING GASOLINE OR EQUIPMENT WITH FUEL IN TANK

Store away from furnaces, stoves, water heaters or other appliances that have pilot

light or other ignition source because they can ignite gasoline vapors.

WARNING

SAFETY INFORMATION

14

Starting engine creates sparking.

Sparking can ignite nearby flammable gases.

Explosion and fire could result.

If there is natural or gas leakage in area, do not start engine.

Do not use pressurized starting uids because vapors are ammable.

Rapid retraction of starter cord (kickback) will pull hand and

arm toward engine faster than you can let go.

Broken bones, fractures, bruises or sprains could result.

When starting engine, pull cord slowly until resistance is felt, then pull rapidly.

Remove all external equipment/engine loads before starting engine.

Direct coupled equipment components such as, but not limited to, blades, impellors,

pulleys, sprockets, etc., must be securely attached.

Engines give off carbon monoxide, an odorless, colorless,

poison gas.

Broken bones, fractures, bruises or sprains could result.

Start and run engine outdoors.

Do not start or run engine enclosed area, even if doors or windows are open.

Rotating parts can contact or entangle hands, feet, hair, clothing

,

or accessories.

Traumatic amputation or severe laceration can result.

Operate equipment with guards in place.

Keep hands and feet away from rotating parts.

Tie up long hair and remove jewelry.

Do not wear loose-tting clothing, dangling drawstrings or items that could become

caught.

WARNING

WARNING

WARNING

WARNING

SAFETY INFORMATION

15

Running engines produce heat. Engine parts,

especially muffler, become extremely hot.

Severe thermal burns can occur on contact.

Combustible debris, such as leaves, grass, brush,

etc. can catch fire.

Allow muer, engine cylinder and ns to cool before touching.

Remove accumulated combustibles from muer area and cylinder area.

Unintentional sparking can result in fire or electric

shock.

Unintentional start-up can result in entanglement,

traumatic amputation, or laceration.

BEFORE PERFORMING ADJUSTMENTS OR REPAIRS

Disconnect spark plug wire and keep it away from spark plug.

Disconnect battery at negative terminal (only engines with electric start).

WHEN TESTING FOR SPARK

Use approved spark plug tester.

Do not check for spark with spark plug removed.

WARNING

WARNING

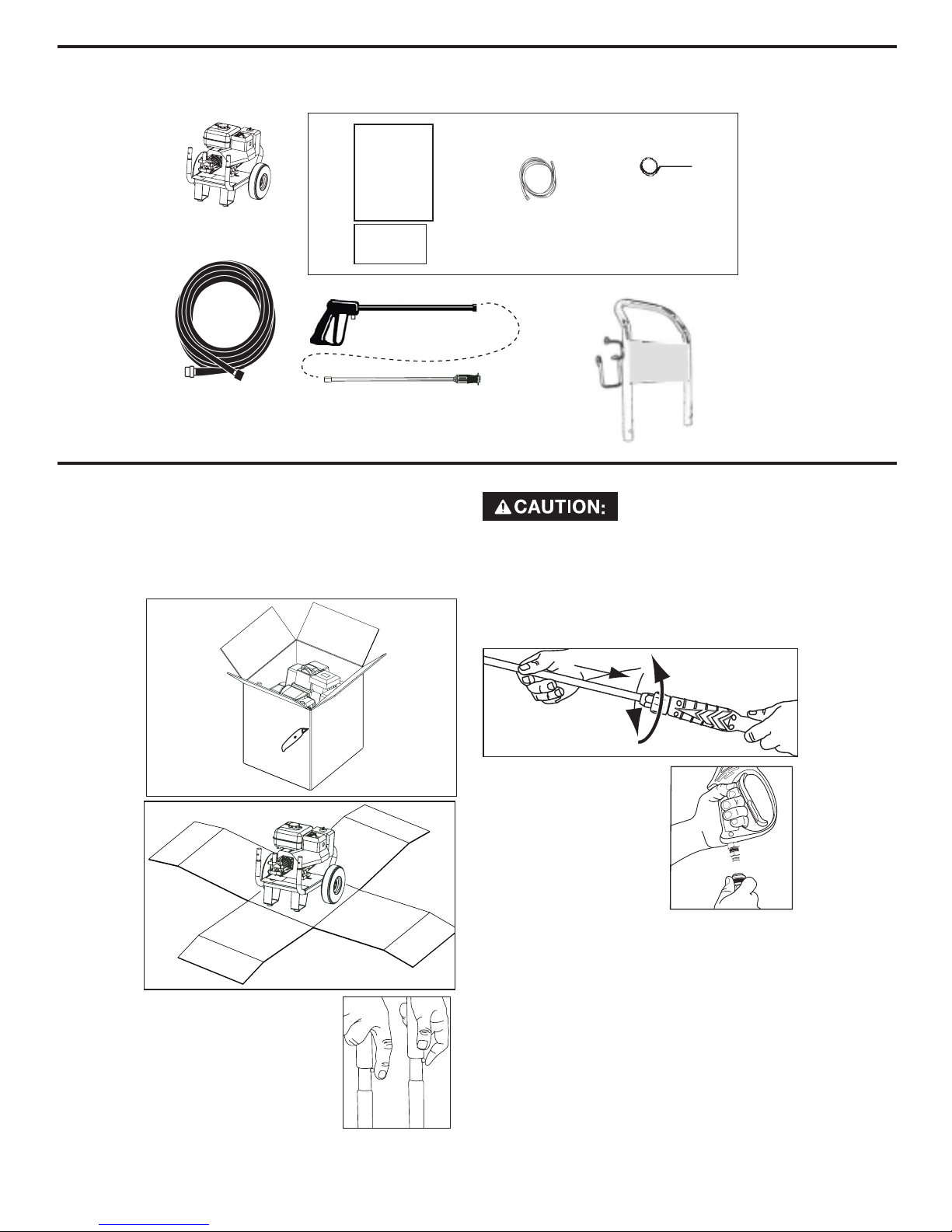

CARTON CONTENTS

1. Locate and remove all loose

parts from the carton.

2. Cut four cornersof the carton

from top to bottom and lay the

panels flat.

3. Place handle onto

frame , depress the

snap buttons, and

slide the handle

assembly onto the

frame until snap

buttons snap into

place.

Risk of personal

injury. Avoid plac-

ing hands between handle and

frame when assembling to prevent

pinching.

4. Connect wand to gun.Tighten

securely.

5. Attach high

pressure hose to

gun. Tighten

securely.

Engine Frame

and Wheel

Assembly

High Pressure

Hose

Spray Gun

Handle

Chemical

Hose

Bagged Parts

Nozzle

Cleaning

Tool

Engine

Manual

Operation

Manual

Multi-Adjustable

Spray Wand

ASSEMBLY INSTRUCTIONS

16

NOTE: Photographs and line drawings used in this manual are for reference only

and do not represent a specific model.

OPERATING INSTRUCTIONS

NOTE: The pump on this unit is

maintenance free and requires no oil.

If there is a problem with the pump

contact an Authorized Service Center.

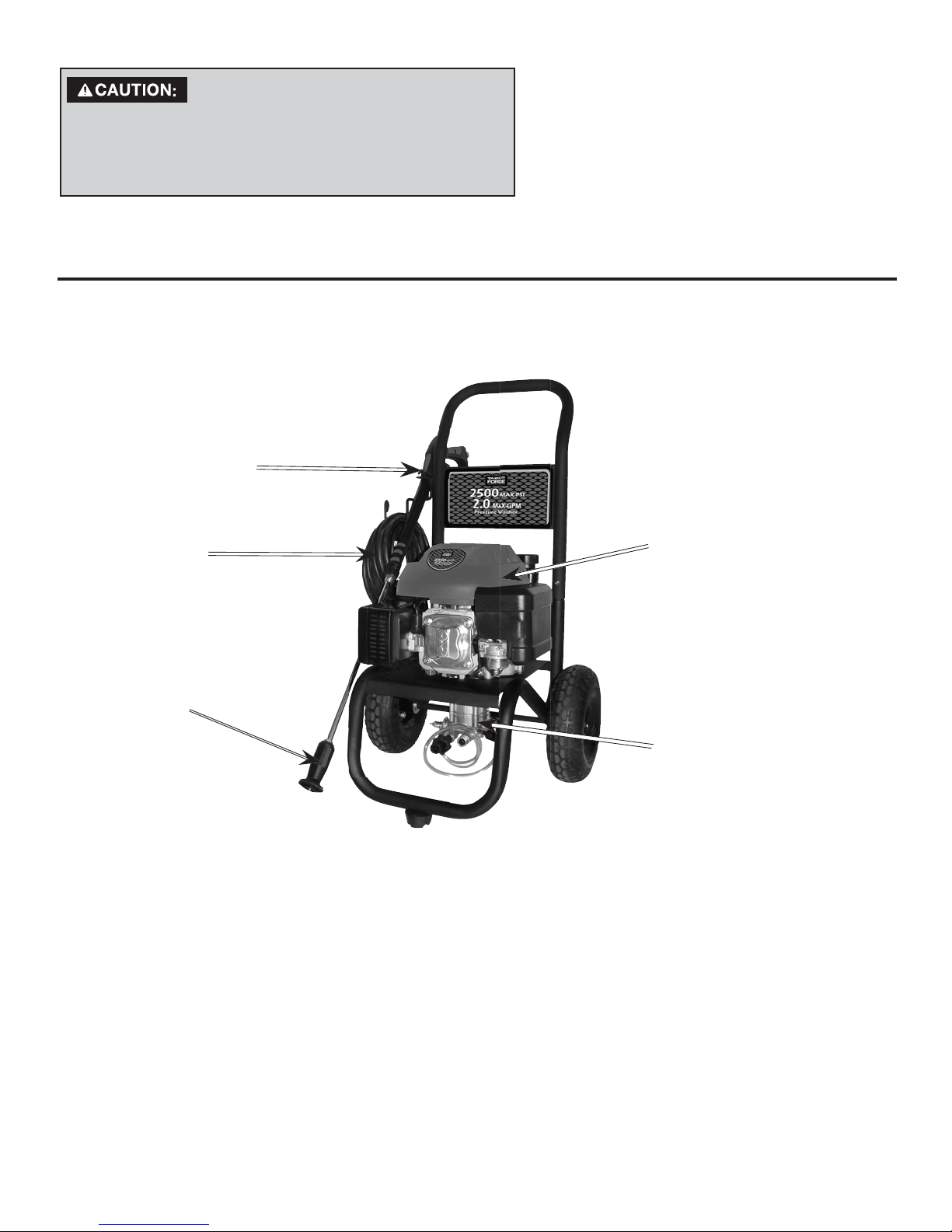

Compare the illustrations with your unit to familiarize yourself with the location of

various controls and adjustments. Save this manual for future reference.

High

Pressure

Hose

Spray

Gun

High Pressure Pump

Engine

Multi-Adjustable

Spray Wand

BASIC ELEMENTS OF A

PRESSURE WASHER

High Pressure Pump: Increases the

pressure of the water supply.

Engine: Drives the high pressure

pump.

High Pressure Hose: Carries the pres-

surized water from the pump to the

gun and spray wand.

Spray Gun:Connects with spray wand

to control water flow rate, direction,

and pressure.

Multi-Adjustable Spray Wand: Allows

the user to use high or low pressure and

adjusts from a pencil stream (0°) to a wide

angle fan spray (40°). See How To Use Wand

instructions in this section.

Chemical Hose (not shown): Feeds

cleaning agents into the pump to mix

with the water. See

How To Apply

Chemicals/Cleaning Solvents

instruc-

tions in this section.

17

Engine shipped without oil. Before starting engine,

fill with oil provided. If you start the engine

without oil, the engine will be damaged beyond

repair and will not be covered under warranty.

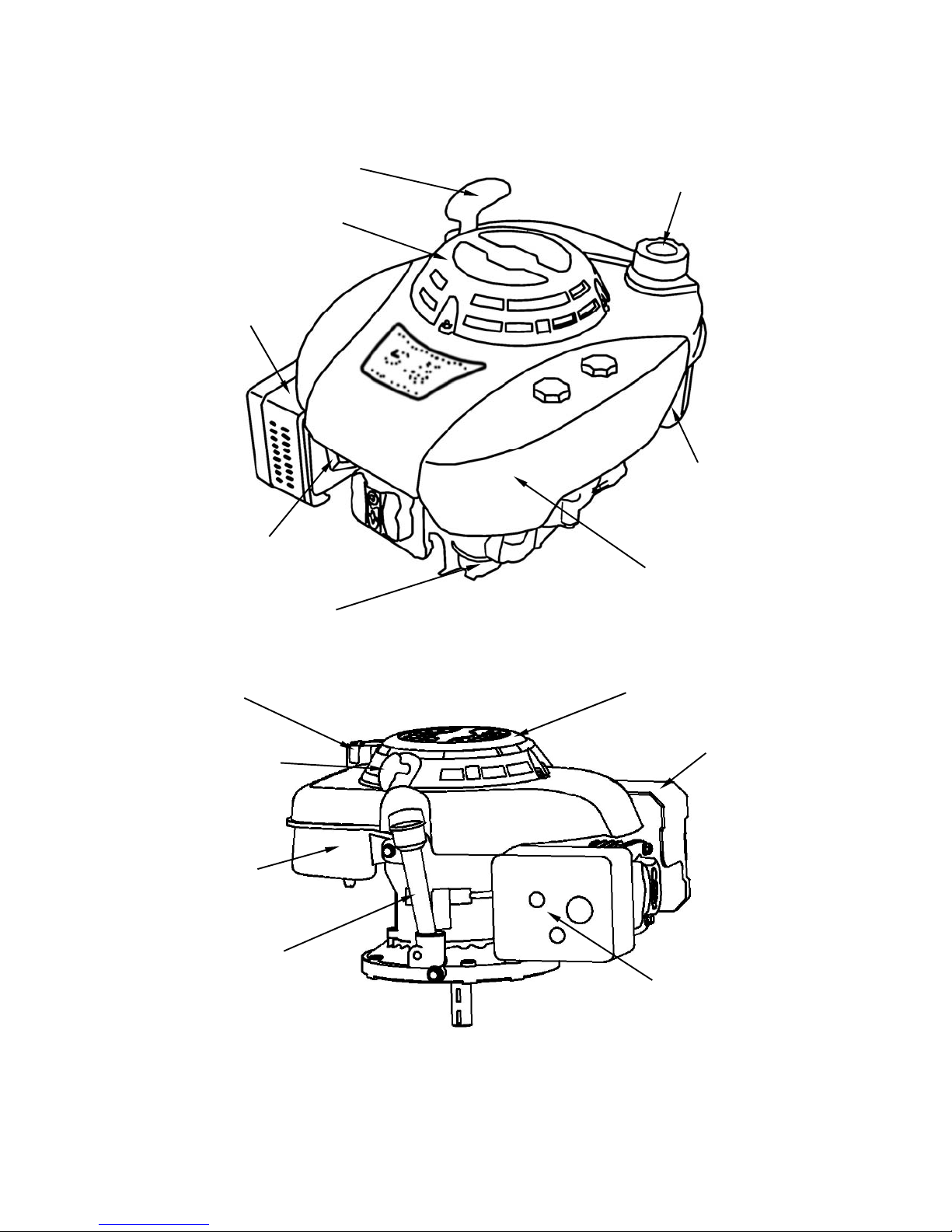

BASIC ELEMENTS OF AN

ENGINE

18

1P68FA, 1P70F, 1P70FA

1P61FA, 1P65FA

FUEL TANK

FUEL TANK CAP

STARTER GRIP

OIL FILLERCAP/

DISPTICK

A

IR CLEANER

MUFFLER

FINGER GUARD

CARBURETOR

FUEL TANK CAP

FUEL TANK

AIR CLEANER

SPARK PLUG

MUFFLER

FINGER GUARD

STARTER GRIP

PRESSURE WASHER OPERATING

FEATURES

Pressure Adjustments

The pressure setting is preset at the fac-

tory to achieve optimum pressure and

cleaning. If you need to lower the pres-

sure, it can be accomplished by these

methods.

1. Back away from the surface to

be cleaned. The further away you

are, the less the pressure will be on

the surface to be cleaned.

2. Rotate the nozzle at the end of

the multi-adjustable spray wand

to widen the fan spray.

The wider fan spray will minimize

the pressure on the surface to

be cleaned.

PRESSURE WASHER

TERMINOLOGY

psi: Pounds per Square Inch. The unit

of measure for water pressure. Also

used for air pressure, hydraulic pres-

sure, etc.

GPM: Gallons Per Minute. The unit of

measure for the flow rate of water.

CU: Cleaning Units. GPM multiplied

by psi. GPM x psi = CU

Bypass Mode: Allows water to

re-circulate within pump when the gun

trigger is not pulled.

Allowing the unit to

run for more than

two minutes without the gun trigger

pulled could cause overheating and

damage to the pump.

Thermal Relief Valve (not shown)

When the temperature inside the

pump rises too high the valve will

open and release a gush of water in

an effort to lower the temperature

inside the pump. The valve will then

close.

Chemical Injection System: Mixes

cleaners or cleaning solvents with

the water to improve cleaning

effectiveness.

Water Supply: All pressure washers

must have a source of water. The min-

imum requirements for a water supply

are 20 psi and 5 gallons per minute.

19

Risk of fluid

injection. Do not

direct discharge stream toward

persons, unprotected skin, eyes or

any pets or animals. Serious injury

will occur.

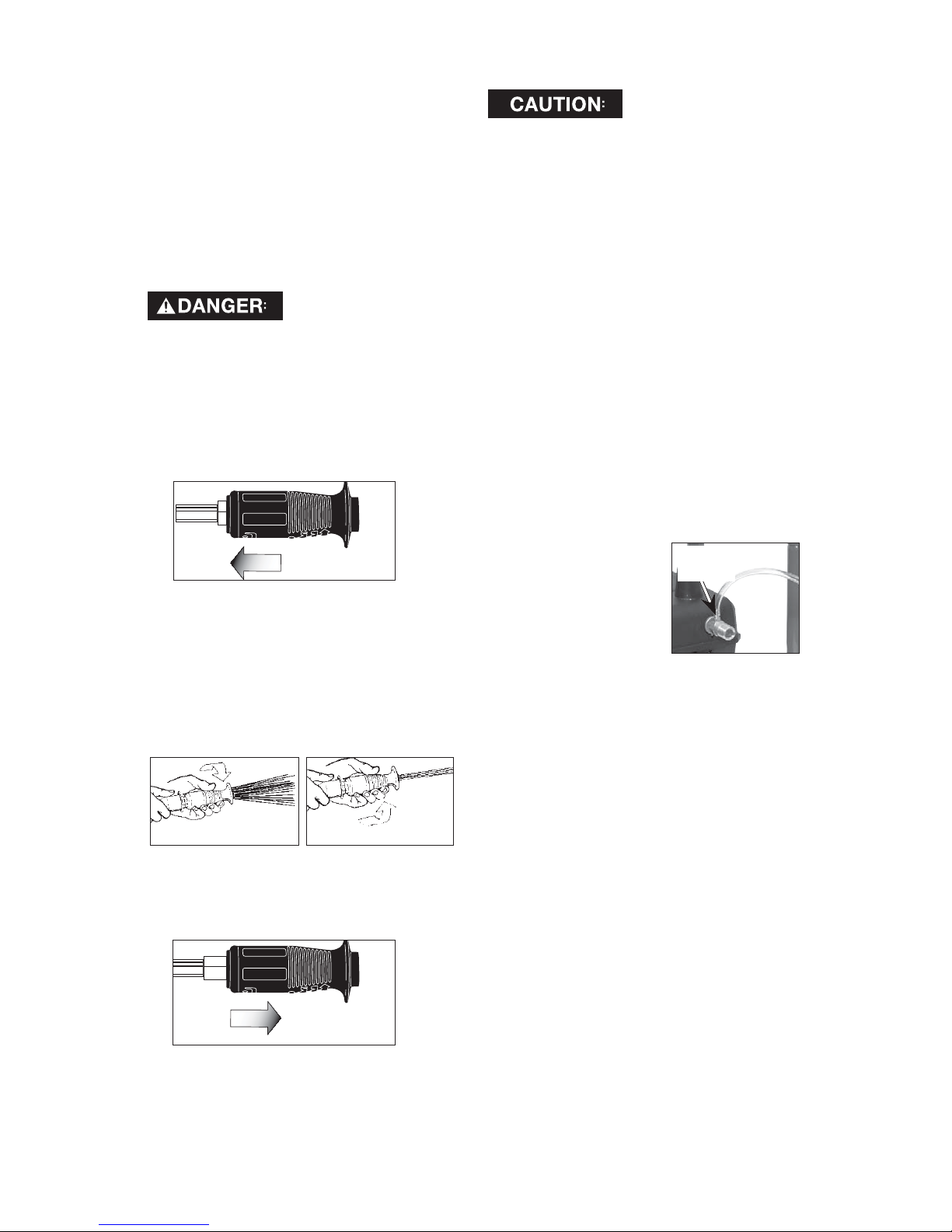

For high pressure operation, pull back

the nozzle of the multi-adjustable

spray wand as shown.

The nozzle at the end of the multi-

adjustable spray wand can be rotated

to change the high pressure spray

pattern from a 0º pencil stream to a

40º fan spray, as shown. Markings

have been placed on the nozzle to

help you select the spray pattern.

For low pressure operation, extend

the nozzle of the multi-adjustable

spray wand as shown.

The powerful

spray from your

pressure washer is capable of

causing damage to surfaces such

as wood, glass, automobile paint,

auto striping and trim, and delicate

objects such as flowers and shrubs.

Before spraying, check the item to

be cleaned to assure yourself that it

is strong enough to resist damage

from the force of the spray.

HOW TO USE SPRAY WAND

Your pressure washer is equipped

with a multi-adjustable spray wand

with both high and low pressure

settings. The high pressure setting

is for cleaning and rinsing, the low

pressure setting is for applying

chemicals or cleaning solutions to

surfaces.

How to Apply Chemicals/Cleaning

Solvents

Applying chemicals or cleaning sol-

vents is a low pressure operation.

NOTE: Use only soaps and chemicals

designed for pressure washer use. Do

not use bleach.

To Apply chemicals:

1. Press chemical Barbed

Fitting

hose onto

barbed fitting

located near high

pressure hose

connection of

pump as shown.

2. Place other end of chemical hose

with filter on it into container hold-

ing chemical/cleaning solution.

NOTE: For every 7 gallons of

water pumped 1 gallon of chemi-

cal/cleaning solution will be used.

20

3. Set multi-adjustable nozzle to

low pressure setting. See How

To Use Wand paragraph in this

section.

4. After use of chemicals,place

chemical hose into container of

clean water and draw clean water

through chemical injection

system to rinse system

thoroughly. If chemicals remain

in the pump it could be

damaged. Pumps damaged

due to chemicals will not be

covered under warranty.

Table of contents

Languages:

Other Task Force Pressure Washer manuals