-

,

. 4A

-

. 4B.

-

() .

4C.

-

4D ( )

() .

13 mm (1/2

) .

.

-

40°C (98°F).

10 bar (145 psi).

!

.

.

- "0".

- (Volt/Hz)

. 3B

- ,

.

-

IEC 364.

30 mA 30 ms

.

!

.

-

, 2-3

. ""

- .

-

5 , ,

.

- ,

.

5

- ,

.

TSS:

- TSS, ( 5C)

:

- ,

.

- ,

.

- TSS,

4-5

.

-

TSS,

15 .

-

( 0,5 ).

- "JET",

. 5D

-

.

-

,

. 5D.

( )

- ,

:

-

-

.

-

.

-

Ferm 91

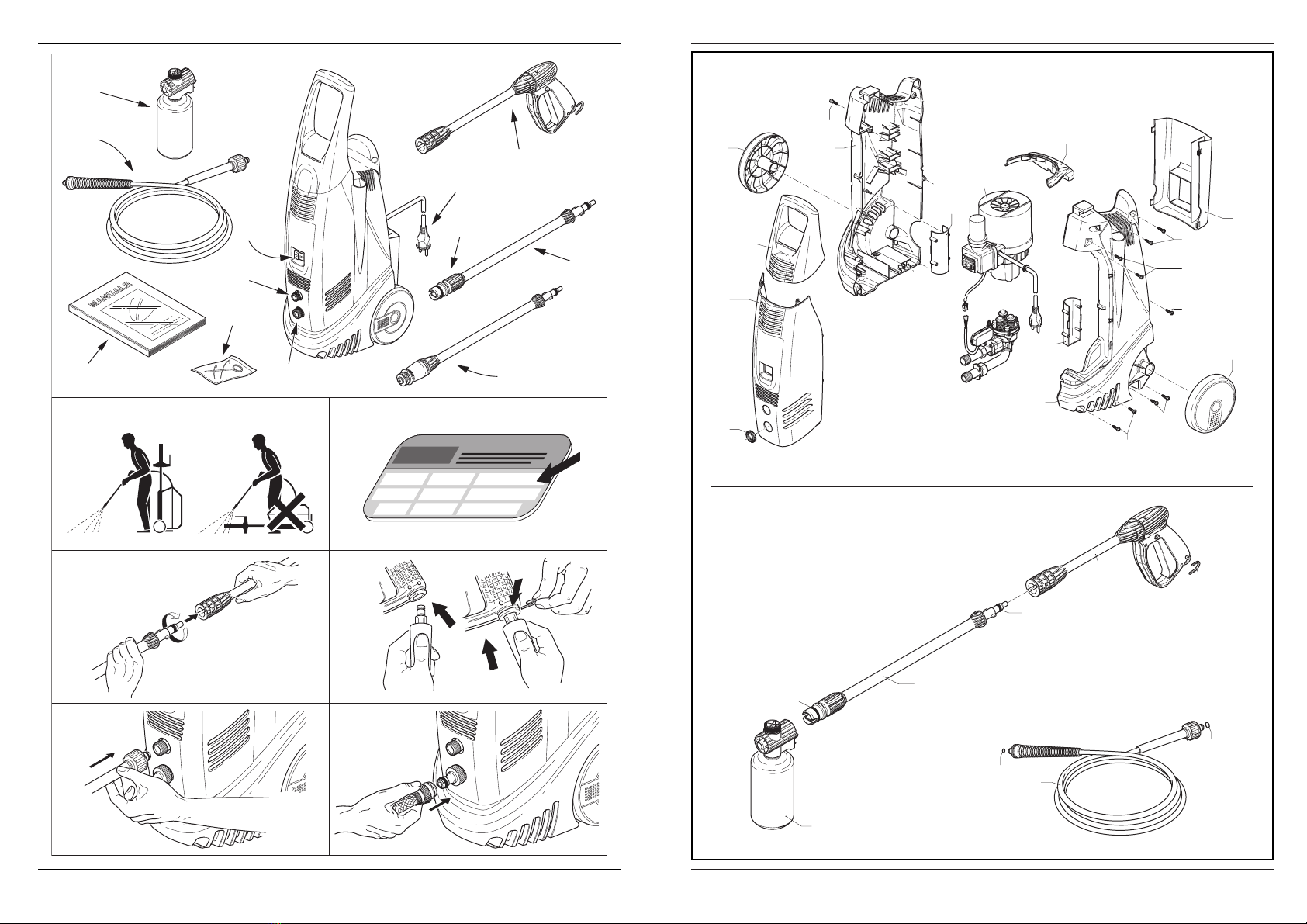

INSTALLATION

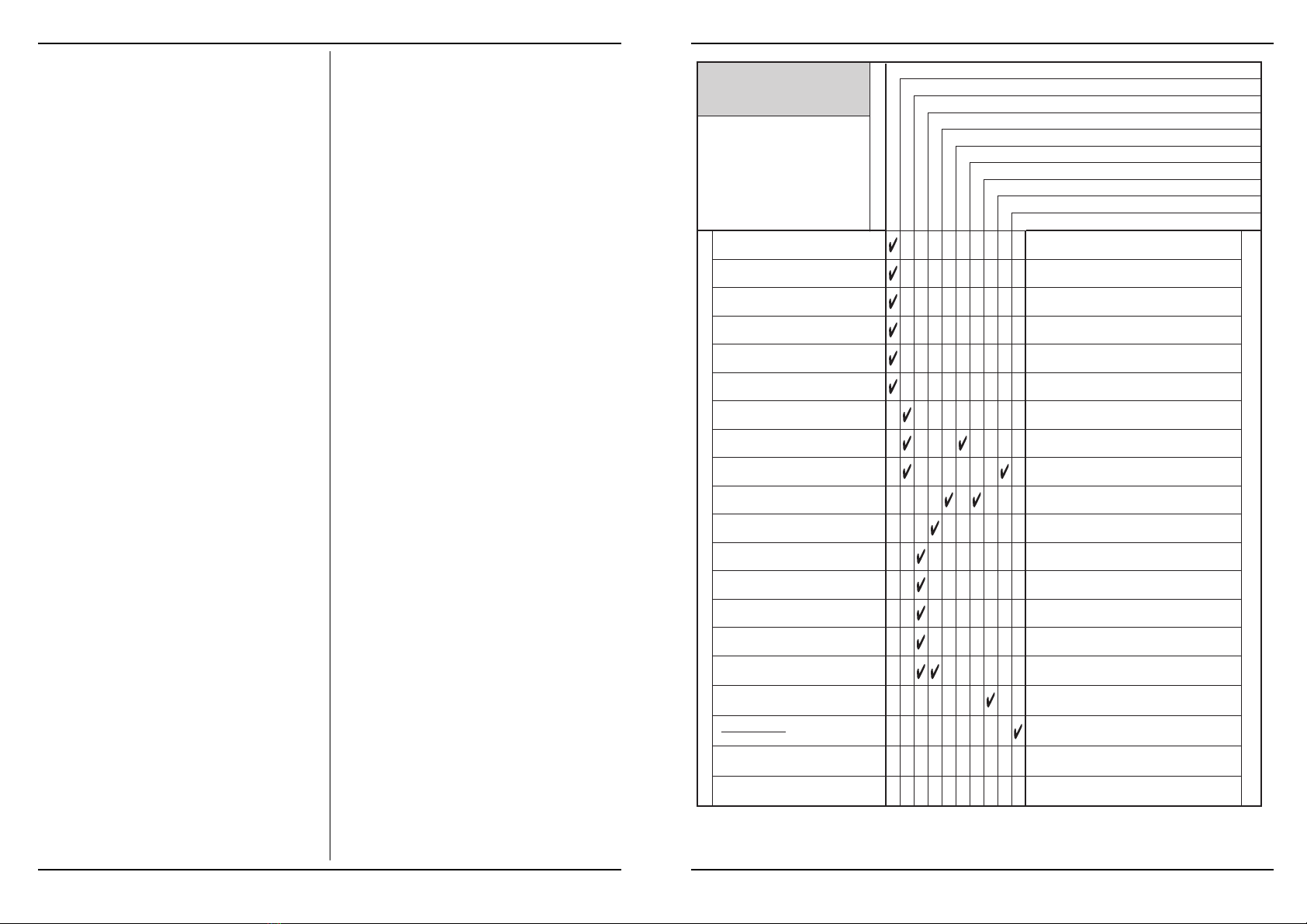

-Fitthe lanceinto thegun byrotating andpushing until

thetwo partsare completelylocked. FIG.4A

-Connectthe gunto thehigh pressurehose. FIG.4B.

-Connectthe highpressure hoseto thewater

(OUTLET)on thecleaner. FIG.4C.

-Connectthe watersupply hoseFIG.4D (not

supplied)to thewater (INLET)of thecleaner. The

supplyhose musthave aninternal diameterof atleast

13mm (1/2in.) andmust bereinforced. Thewater

supplymust beat leastequal tothe cleanerdelivery

capacity.

-Theintake watertemperature mustNOT exceed

40°C(98°F). Thewater supplypressure mustNOT

exceed10 bar(145 psi).

CAUTION!The cleanermust onlybe usedwith

cleanwater; useof unfilteredwater orcorrosive

chemicalswill damagethe cleaner.

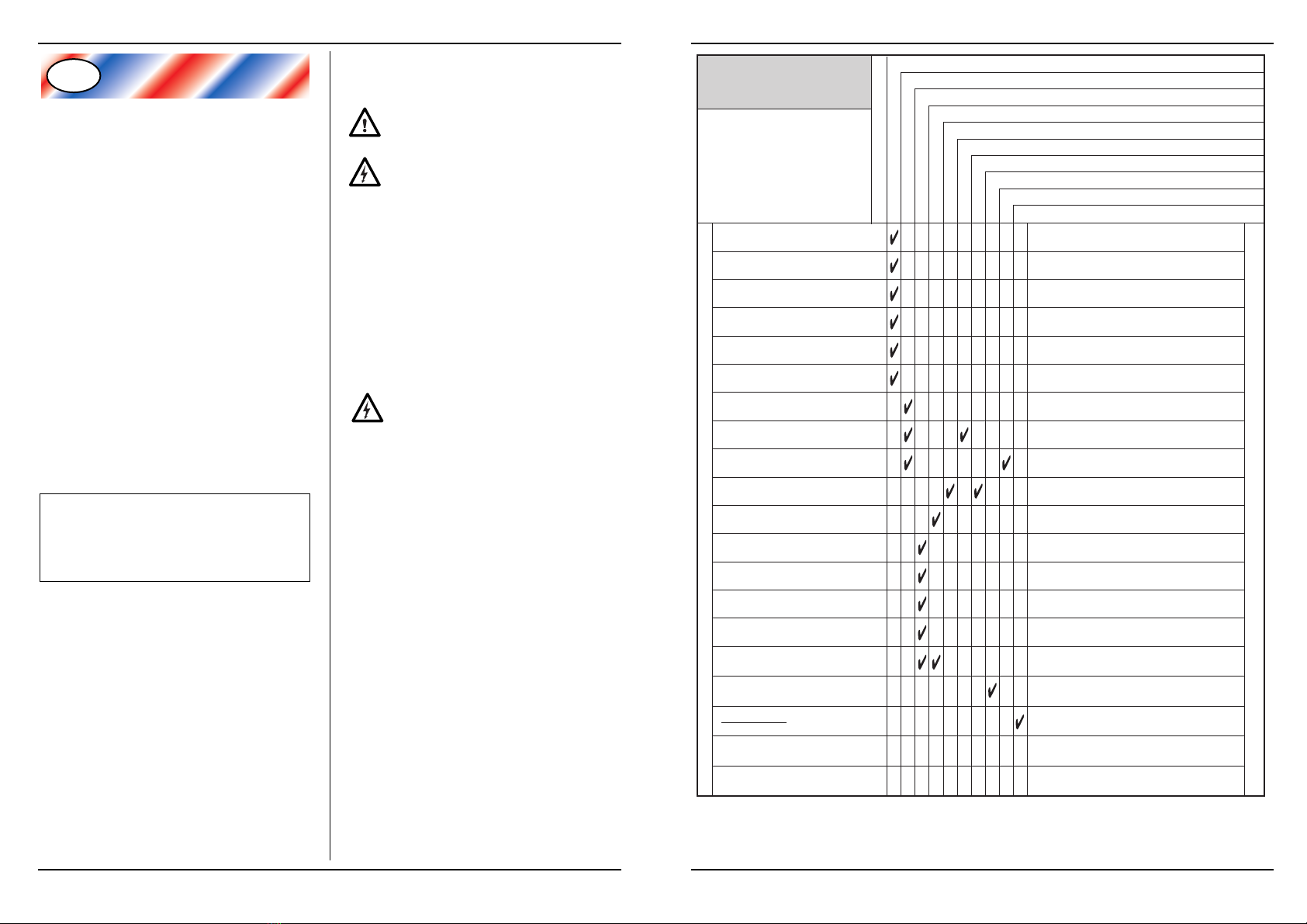

-Turnthe motorswitch tothe "0"position.

-Checkthat theelectrical supplyvoltage and

frequency(Volts/Hz) correspondto thosespecified

onthe cleanerdata plate.Fig. 3B

-Ifthe powersupply iscorrect, youmay nowplug in

thecleaner.

-Theelectric supplyconnection shallbe madeby a

qualifiedelectrician andcomply withIEC 364.It is

recommendedthat theelectric supplyto this

applianceshould includeeither aresidual current

devicethat willinterrupt thesupply ifthe leakage

currentto earthexceeds 30mA for30 msor adevice

whichwill provethe earthcircuit.

CAUTION!The machinemay causeelectrical

disturbanceswhen starting.

-Ifthe motorstops andfails torestart, wait2-3

minutesbefore restarting.THERMAL CUTOUT

TRIPPED

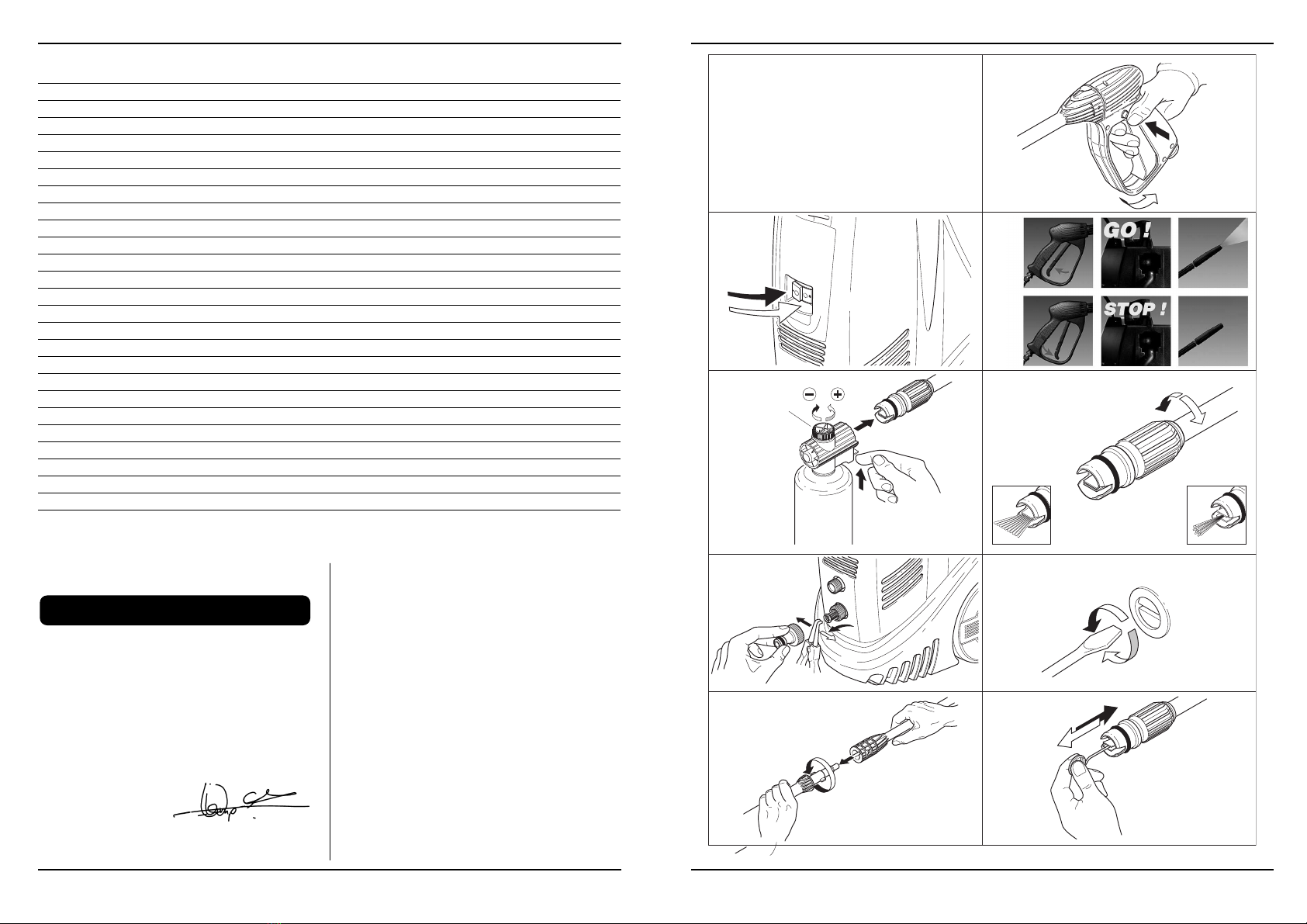

USE

-Turnon thewater supplytap FULLY.

-Releasethe safetycatch FIG.5A,then pressthe

triggerfor afew secondsto allowair toescape andto

dischargeresidual pressurein thepipes.

-Keepingthe triggerpressed, pushthe switchto start

themotor. FIG.5B

-Whenre-starting themotor, alwayskeep thetrigger

pressed.

TSSModels:

-InTSS models,(FIG. 5C)with automaticdelivery

flowcut-off:

-Whenthe triggeris released,the dynamicpressure

automaticallycuts outthe motor.

- Whenthe triggeris pressedthe pressuredrop

automaticallystarts themotor andthe pressureis

restoredwith avery slightdelay.

- Forcorrect operationof theTSS, oncethe trigger

hasbeen releasedit mustnot bepressed againfor at

least4-5 seconds.

-Forcorrect useof theTSS modelcleaner, donot

leavethe unitin automaticcut-off statusfor more

than15 min.

USINGDETERGENT

-Fillthe foamunit tankwith detergent(capacity about

0.5lt.).

-Setthe adjustablehead inthe “JET”position, thenfit

thefoam uniton headand fixit inposition. FIG.5D

CORRECTUSE OFSTANDARD

ACCESSORIES

-Thecleaner isequipped witha nozzlefor adjustment

ofthe jetfrom concentratedto fan.FIG. 5E

-Itis alsoequipped withthe foamunit fordetergent

distribution,with adjustmentof thequantity of

detergentusing theknob M.FIG. 5D

CORRECTUSE OFTHE ROTARYNOZZLE

(Wherefitted)

-Forincreased washingpower, usethe rotarynozzle

kitas follows:

-Turnoff thehigh pressurecleaner

-Unscrewthe adjustablehead andfit therotary

nozzleonto thelance.

-Turnthe highpressure cleanerback on.

RECOMMENDEDCLEANING PROCEDURE

-Dissolvedirt byapplying detergentwith thefan jetto

thedry surface.On verticalsurfaces, workfrom the

bottomupwards. Leavethe detergentto actfor 1to

2minutes, butdo notallow todry out.Apply thehigh

pressurejet, keepingthe nozzleat least30 cm(10 in.)

fromthe surface,working fromthe bottomupwards.

Avoidallowing therinsing waterto runon to

unwashedsurfaces.

STORAGE

-Switchoff thecleaner. Turnoff thewater supplytap.

-Dischargeresidual pressureby pressingthe trigger

untilno morewater comesout ofthe adjustable

nozzle.

-Engagethe gunsafety catch.

-Removethe plugfrom thesocket.

-Operatethe cleanerwith noncorrosive/non-toxic

antifreezebefore storingfor thewinter.

6Ferm