TASKalfa 3500i User manual

2012.3. 8 Revised

3.16Revised

3.19Revised

3.21Revised

4. 6 Revised

8.30 Revised

2013.11.18 3rd Edition

3500i/4500i/5500i/6500i/8000i

Troubleshooting Guide

1

Content

2

Item Phenomeno

3500i/4500i/5500i 6500i/8000i Pages

Image Toner Color Dot / Color Mark ○ ○ 4-5

Void Line / White Band ○ ○ 6-9

Void Line / Black Band(Vertical Black Stripes)○ ○ 10

Image Smudges ○ ○ 11-23

Light Image ○ ○ 24

Edge Part Background ○ ○ 25

Measure for Condensation ○ ○ 26

DP-770 Tip50mm・End37mm Character Blurring ○27-28

Conveying

J0501~7 / J0523~7○ ○ 29-30

J051X ○ ○ 31

J05X8/J44XX ○ ○ 32

J0545 (PF-770) ○ ○ 33

PF-770 Repair for the procedures slope confirmation of TRAY PAPER ○ ○ 34

J1313 / J1314 ○ ○ 35

J150X/J1904 ○ ○ 36

J1512 ○ ○ 37

J341X(PF) ○ ○ 38

J4103/ J4104 ○ ○ 39

Abnormal Sound/J42XX/J40XX(Add Intermediate Motor Cover)○40

J42XX/Fixing Separation Claw Tip Missing or Damaged ○41

J421X/ J460X/ J470X ○○(J460Xのみ) 42-43

Torn Paper、J430X/431X/440X/471X, 60mm from bottom edge ○44

○ ○ 45

J49XX/ J50XX/ J51XX/ J600X ○ ○ 46-54

J610X/ J611X(DF) ○ ○ 55-60

J631X/ J641X/ J650X(DF) ○ ○ 61-63

J6510 (DF-790 Caution of Manual Staple) ○ ○ 64

J6600 (DF) ○ ○ 65

J6710 / J7710 (BF) ○ ○ 66

J9020/J9030 ○ ○ 67

J9010 / J9011 / J9110 / J9300 / J9310 / J9400 / /J9600 / J961 ○ ○ 68

Dog Ears ○ ○ 69-74

Paper Wrinkles ○ ○ 75-76

BF-730/720/710 Paper Wrinkle Correspondence of 1 Sheetsof Paper

When Folded in the Middle

○ ○ 77

Content

3

Item Phenomeno

3500i/4500i/5500i 6500i/8000i Pages

C-CALL C0640

○ ○

78

C2101

○ ○

79

C2201

○ ○

80

C510X

○ ○

81

C6000/C6030/C6050/C6200/C6230/C6250

○

82

C6020/C6220

○

83

C6020/C6030/Fixing Roller Fusing, Poor Fixing

○

84

C6030/C6050

○

85

C6600/C6720/Fixing Belt Damage

○

86-90

C6620

○

91

C6730

○ ○

92

C6770

○

93

C6910

○ ○

94

C7101

○ ○

95

C9500/C9510/C9520/C0630/C0640/CF245 SATA Cable Failture

○ ○

96

CF000/“Welcome” Screen Lock

○ ○

97

CF040

○ ○

98

CF182/186

○ ○

99

Abnormal Sound From Developing Unit

○ ○

100

Abnormal Sound From Fixing Drive Unit

○

101-105

DP Motor Driven Sound

○ ○

106

Others DP Size Detection Error

○ ○

107

Disporsal Toner Bottle

○

108

Time for maintenance.(T)

○ ○

109

Damage of Cassette Rail

○ ○

110-111

Abnormal

Sound

4

Black Dot / Black Marks

Image sample 1

1.126mm interval Black Dots (drum)

If one of several 126mm interval black dots appears randomly at sub scanning

direction, take the following measure.

(Image sample 1)

(*there is the case that the black dots appearance becomes vertical line.)

a.Replace the DRUM ASSY (DK-6305/6705).

126mm

Black Dot / Black Mark

2. 45mm interval Black dots

If 45mm interval paper appears at image in the sub

scanning direction, take the following measure.

a. Check whether the foreign substance are attached

on the developing roller surface.

b. If the foreign substance attached, wipe off by the

clean cloth.

c. If no foreign substance attached or it will not be

disappeared after wiping off, replace the developing

unit.

Image φ0.1~0.3mm

45mm

Above is to check the

black dots on the paper

by the Magnifying glass.

1. 38mm interval black dots, black marks (Charger roller)

Take the following measure if the 38mm interval black dots or marks appear

at the image In the sub scanning direction.

a. Check the 38mm interval to print out the test sample by U089 Mono4.

b. Replace the MC-6705 after confirming the dots appears 38mm interval.

c. Execute U930 charger roller counter reset after replacing MC-6705.

38mm

5

a. If the void image appear at solid part of prints out on U089 Color

Belt, refer to below “b” * If the vertical streak image appears at the

halftone, replace the developing unit.

b. Execute U140 AC CalibHigh Altitude

c. Select “Altitude” and find the setting which the leak image does not

appear. * Avoid the setting far from the actual altitude.

d. If the image will not be recovered, replace the developing unit.

Image sample 1

◇Leak at the solid part

Void image appear at the solid part.

U89 Sample set

Void image at

Solid part

Image sample 2

◇Leak at the halftone part

Horizontal streaks appear at Halftone image.

U89 Sample set

Horizontal streaks

at halftone image

Void Line / White Band (Horizontal White Streaks)

1. Leak Image 1 (3500i、4500i)

Execute AC Calib Operation Automatically Select AC Calib High Altitude Setting

7550ci/6550ci O

5550ci/4550ci O

3550ci/3050ci O

8000i/6500i O

5500i O

4500i/3500i O

6

a. If the void image appear at solid part of prints out on U089 Color

Belt, refer to below “b” * If the vertical streak image appears at the

halftone, replace the developing unit.

b. Check the value of U140 Sleeve AC (1)

c. U140 Execute AC Calib(2)Set “K” Off to

On(3)Execute(4)Start

d. Check whether the value of U140 SleeveAC (3) becomes lower

and the image is recovered.

e. If the image will not be recovered, replace the developing unit.

(3)

(4)

(1)

(2)

Image sample 1

◇Leak at the solid part

Void image appear at the solid part.

U89 Sample set

Void image at

Solid part

Image sample 2

◇Leak at the halftone part

Horizontal streaks appear at Halftone image.

U89 Sample set

Horizontal streaks

at halftone image

Void Line / White Band (Horizontal White Streaks)

1. Leak Image 2 (5500i、6500i、8000i)

Execute AC Calib Operation Automatically Select AC Calib High Altitude Setting

7550ci/6550ci O

5550ci/4550ci O

3550ci/3050ci O

8000i/6500i O

5500i O

4500i/3500i O

7

Void Line / White Band

2. Horizontal white streaks (Image sample 1)

If 1.2mm interval horizontal streaks occur at

the gray image in the main scanning

direction, take the following measure. *In

case of this appearance at the machine’s

rear side is more noticeable than at front.

a. Replace the LSU.

Image sample 1

About

1.2mm

Machine

Front

Machine

Rear

8

Void Line / White Band

3.Vertical White streaks (Image sample 1)

If vertical white streaks appears continuously and

linearly in the sub scanning direction, take the

following measure.

a. Clean the cover glass on the LSU.

Image sample 1

Vertical white streaks

Image sample 2

4. Vertical White lines (void image) (Image sample 2)

If the void image appears by wide width in the sub scanning direction, take

the following measure.

a. Replace the LSU. (In case of the machine is produced before 2011 Oct.)

9

1. Vertical Black streaks (Image sample 1)

It occurs continuously and linearly toward the paper feeding direction.

Please remove the transfer belt unit and check whether the transfer belt is cracked.

1. When the transfer belt is torn or cracked, please replace the drum unit and the transfer belt unit.

2.Check the firmware version (U019) and upgrade it higher than Upgrade Pack Ver. V4.00

Image sample 1

Void Line / Black Band

Vertical Black Streak

Condition of tear or crack on the transfer belt

10

Image Smudges (1/13)

Image sample 2

View from

bottom part of

ejected paper

2.Image Smudges (Image sample 2)

The smudges appears at the leading edge of ejected

paper.

Clean the duct at inside if machine and the

developing unit.

Refer to “3.Cleaning Procedure” for cleaning.

1.Image Smudges (Image sample 1)

There is no periodicity and it occurs intermittently

in the paper conveyance direction.

a. Clean the conveying guide.

b. Clean the paper dust cleaner at the regist roller

section.

(-->)

Image sample 1

Cleaner

11

(Stains on the conveying guide)

The stains occur at the outside of paper path.

3. Cleaning Procedure Image Smudges (2/13)

a. Preparation before cleaning

Remove the lower rear cover and toner box

(Fig.1)

Remove the developing unit and drum unit

after detaching the inner unit .

Remove the toner box.

2 screws

Fig.1

b. Clean the conveying guide .

Clean the paper feeding side of the

conveying guide (Fig.2)

At the next, remove the conveying guide

(one each at front and rear), clean the back

side of conveying guide (Fig.3)

* For cleaning, use the dry and soft cloth. (It

locates at the size indication plate slot on

1st cassette.) Clean the conveying guide

Screw

Fig.2

Fig.3

12

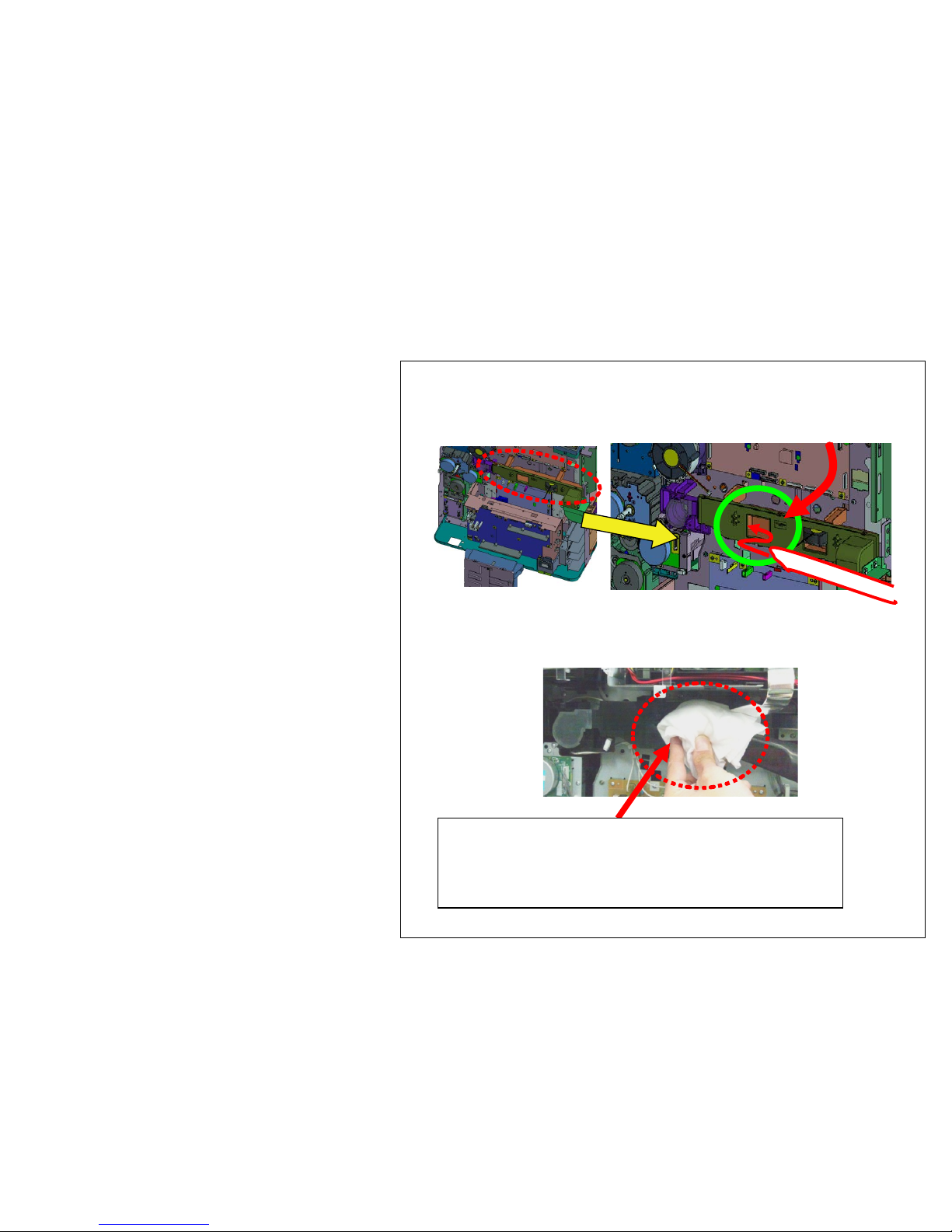

Image Smudges (3/13)

c. Clean the toner exhaust duct at inside of

machine

While the developing unit is taken out and the

conveying guide is removed, suction the toner

exhaust part at inside the machine where the

toner exhaust duct of the developing unit

connected with a cleaner. (Fig.4)

Note) Clean while paying attention not to scratch the gear and registration roller.

(Before

cleaning)

Tone is

accumulating.

(-->) Toner ExhaustAperture

Fig.4

d. Check the machine’s production month

Check the production month from the

machine’s serial number on the rating label and

clean it according to the production month.

・Before 2012/Feb. production machine.

Refer to the cleaning procedure “e”

”g”

・After 2012 / Mar. production model.

Refer to the cleaning procedure “f”

“g”

MACHINE No. N4P22*****

16 : 2011/6

17 : 2011/7

18 : 2011/8

19 : 2011/9

1X : 2011/10

1Y : 2011/11

1Z : 2011/12

21 : 2012/1

22 : 2012/2

23 : 2012/3

24 : 2012/4

25 : 2012/5

(Rating label) (Way of refer to the

production month)

N4P:Model

Number

It differs

according to

the model

22:Indicate

2012 Feb.

production

13

Image Smudges (4/13)

e. Clean the DUCT TONER UNIT

( In case of 2012 Feb. production machine)

Clean the DUCT TONER UNIT with the vacuum

cleaner.

Procedure 1) Clean and suction the outlet of duct with

cleaner for 1 min.

Acleaner tip is put in and attracted from this direction.

(If a opening is covered with a rag etc. so that the open

air may not be attracted from a cleaner tip, toner can

be attracted effectively.)

14

Image Smudges (5/13)

Procedure 2)

Remove the 302LF33012/DUCT FAN TONER

from the machine and clean, suction it with the

vacuum cleaner.

Reattaching the seal after cleaning and cut the

part of duct.

302LF33012/DUCT FAN TONER

Remove the duct

with 2 screws

Lift up this

part if it is

detached.

Clean the removed duct

Clean after removing the duct too.

(Before cleaning )

Toner is accumulating.

15

Re-attach with 302LF33201/SEALTONER

DUCTA (Change with 5mm thick sponge)

Cut the rib (claw) of the duct.

Procedure 3)

Peel off the FILM of 302LF33012/DUCT FAN

TONER and replace with 302LF94410/PARTS LID

TONER FAN ASSY(ZG) SP

302LF94410/PARTS LID TONER FAN ASSY(ZG) SP

FILM

302LF94410 is re-usable.

After this replacement, the level of unit is same

as 2012 Mar. and after production model.

Please replace with the parts as shown in fig when

302LF94410/PARTS LID TONER FAN ASSY(ZG)

SP.is available.

Image Smudges (6/13)

16

f. Clean the DUCT TONER UNIT

(In case of 2012 Mar and after production

machine)

Clean suction the DUCT TONER UNIT with

the vacuum cleaner.

Procedure 1) Clean suction the duct outlet for 1 min with

the vacuum cleaner.

Acleaner tip is put in and attracted from this direction.

(If a opening is covered with a rag etc. so that the open

air may not be attracted from a cleaner tip, toner can be

attracted effectively.)

Image Smudges (7/13)

17

Procedure 2)

Remove the 302LF33830/LID TONER FAN from

the machine and clean suction it with the vacuum

cleaner.

(Before cleaning )

Toner is accumulating.

LID TONER FAN

Remove it after releasing 3

pcs of snap-fit

Return the LID TONER FAN at original position after cleaning

Image Smudges (8/13)

18

(-->)

g. Replace the DISPOSAL TONER UNIT.

- Replace the following DISPOSAL TONER UNIT.

302LF94400 PARTS DISPOSAL UNIT(ZG) SP

- Clean suction the accumulatingtoner at the

DISPOSALTONER UNIT inside or the FILTER.

Refer to the right figure for the cleaning

procedure.

( FILTER )

302LC33240/FILTER OPTION A (New type)

302LF33820/FILTER TONER (Old type)

Remove the LID from the DISPOSAL TONER

Old type (2 piles

sheets) New type (2 layer

structure)

Clean the inner part of accumulating toner and filter after opening the DISPOSAL

TONER UNIT.

When cleaning the old type Filter, Be careful for FILTER of the thinner side not to

be inhaled by the cleaner due to two-sheet piles.

FILTER

FILTER

Remove 3 pcs of screws Release 8pcs of snap-fit

Install the thick density side of FILTER at Fan side

with (both sheets). There are not difference in

performance between old and new 2 type of filters.

Image Smudges (9/13)

19

FILTER 2

FILTER 2

6500i/8000i

3500i/4500i/5500i

At cleaning the FILTER, the FILTER can be detached after removing

the DF Rear Cover without releasing DF from the main body.

After removing, clean or replace it.

h. Clean the FILTER

( FILTER )

302LC33370/FILTER LEFT SIDE

Image Smudges (10/13)

20

This manual suits for next models

4

Table of contents