TATRA TPI 05 D.V User manual

COMBI STEAM OVENS

BAKERY OVENS

Instruction Manual

Bedienungsanleitung

50LIB001

E n g l i s h | 1

INDEX: page

INSTRUCTIONS FOR THE INSTALLER

I. WARNING 2

II. PRELIMINARY OPERATIONS 2

III. INSTALLATION AREA 2

IV. PREPARING FOR INSTALLATION 3

V. ELECTRICAL CONNECTION 3

VI. WATER CONNECTION 6

VII. FUMES DISCHARGE 7

VIII. STACKING OVENS 7

IX. SPECIFICATIONS 7

INSTRUCTIONS FOR THE USER

I. WARNING 8

II. TESTING 9

III. ORDINARY MAINTENANCE 9

IV. EXTRAORDINARY MAINTENANCE 11

V. MAINTENANCE IN CASE OF BREAKAGE 11

VI. ADVICE DURING COOKING 12

VII. MECHANICAL OVEN CONTROL PANEL 13

VIII. MULTIFUNCTION OVEN CONTROL PANEL 14

IX. DIGITAL OVEN CONTROL PANEL 15

INTRODUCTION

Dear client, thank you and congratulations for buying this appliance; we are confident

that this is the beginning of a positive and long-lasting collaboration.

This manual has all the necessary information for the correct use, maintenance and

installation of this appliance. The objective of this manual is to enable the technician and

user to take all measures and precautions necessary for the safe, efficient, long-term

use of the appliance.

Keep this booklet in a safe place, over the entire life cycle of the product for subsequent

reference by the operators designated to use and specialized technicians.

Where documents are lost or damaged the replacement documentation must be

requested directly from the manufacturer or retailer.

The manufacturer is not held liable for any damage caused by people or things or for

inappropriate use of the appliance, modifications or repairs carried out by unauthorized

personnel or used with spare parts not recommended by the manufacturer and not

intended for use with this model.

This appliance complies with the EEC directives in force.

E n g l i s h | 2

INSTRUCTIONS FOR THE INSTALLER

I. WARNING

Read this instructions booklet carefully before starting the installation and start-up operations.

All installation, assembly, assistance and extraordinary maintenance shall be carried out

by qualified personnel and supplied with necessary professional (authorizations by the

manufacturer or retailer), in accordance with local laws in effect where installation takes

place regarding product and workplace safety.

Incorrect installation, assistance, maintenance, cleaning, tampering or modifications can cause

malfunction, damage and breakage.

The appliance must only be used for cooking or heating of foods in industrial kitchens. Any

other use is inappropriate and dangerous.

II. PRELIMINARY OPERATIONS

On receipt of the product, make sure it has not been damaged during transport and that the

packaging has not been tampered with. In the case of damage or missing parts inform the

carrier and retailer/manufacturer immediately, indicating the code (Art.) and serial number

(Ser N°) and attach a photo.

Check that the installation area is kept clear so that doors, corridors and passageways are

accessible.

WARNING: the appliance may fall over during transport leading to breakage and damage to

things and people. Use suitable transport capable of taking the weight of the appliance. Do not

drag or lean the device for any reason. Lift it up straight from the ground and place horizontally.

III. INSTALLATION AREA

The appliance shall be installed in enclosed and well ventilated areas (not outdoors).

The ambient temperature of the place of installation of the oven must be higher than +4° C.

Before positioning the appliance, check the overall dimensions and the exact position of the

electrical, water and fumes exhaust connections, fumes exhaust.

It is advised to place the oven under an extractor hood or in such a way that hot fumes and

odours exit the oven via adequate ventilation to the outside.

The oven must be placed on a flat surface so that it does not slip or turn over.

The installation area must be able to support the weight of the appliance filled to the maximum.

See the information level on the back of the oven for the gross weight.

Make sure that it is placed so that the door may be fully opened.

Position it so that the back of the oven is easily accessible for maintenance, connection to the

mains sockets, and water.

The appliance is not meant to be fitted and a 5 cm space must be left all round it.

Do not position other heat sources like, fryers or hotplates, near the oven. If this is not possible

at least respect the following distances from machinery: 50 cm from the sides and above the

appliance and 70 cm from behind.

Do not place the device near materials or containers of inflammable liquids (such as walls,

furniture, screens, gas canisters) as it can be a fire hazard. If this is not possible, cover the

inflammable parts with fire and heatproof material and by checking fire hazard regulations.

E n g l i s h | 3

IV. PREPARING FOR INSTALLATION

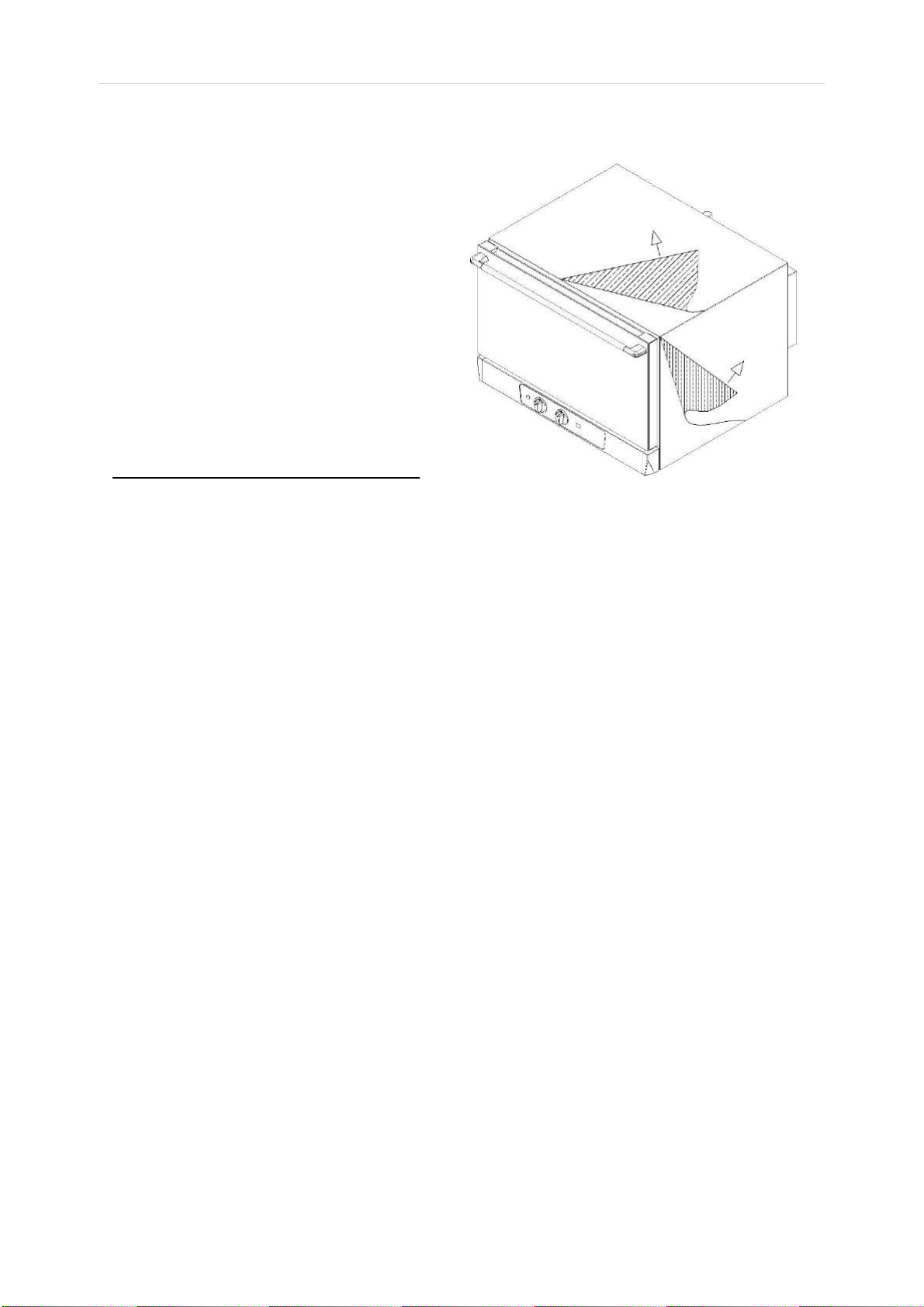

Remove the outer packaging (wooden or carton box) and dispose it in compliance with the laws

in force in the country of installation.

REMOVING PROTECTIVE FILM ETC.

Remove the protection film from the

external and internal walls. (See

image)

Remove all information covering

from the inside, and take off all

plastic packaging.

STAND ADJUSTMENT

Do not use the appliance without feet.

The adjustable feet are already screwed to the underside of the oven.

If they are not used, this prevents airflow from cooling the electric parts and outsides of the

oven which causes over-heating and damage to components.

The oven will function correctly if placed level on a flat surface by adjusting the feets accordingly

and using a spirit level. Screw or unscrew them as necessary to adjust.

V. ELECTRICAL CONNECTION

WARNING: Mains connection must be carried out by a qualified and authorized

technician according to national, international and local laws in the country where it is

installed. Before mains connection, ensure that the frequency (…..V) and voltage (….Hz)

meet the requirements indicated in the in the information tag on the back of the

appliance.The electric system, as prescribed and specified by the Standard in force, must be

equipped with an efficient ground. It is possible to guarantee the electric safety of the appliance

only in the presence of Standard electric system. For direct connection to the mains, it is

necessary tointerpose a device between the equipment and the same mains, sized for the load,

that ensure its disconnection. The contacts must have an opening distance enabling the full

disconnection, in conditions of over-voltage category III, per compliance with installation

regulations. This device also must be located in a place and in a manner to be easily accessible

at any moment by the operator.

OVENS WITH CABLE AND SINGLE PHASE PLUGS

For appliance with cable and plug (single phase 220-240V) the plug merely needs to go into

the appropriate socket (the socket must be adapted for the supplied plug and must withstand

the voltage required by the appliance indicated on the information plate). The product must be

positioned so that the plug is always accessible.

The appliance comes with certified cable and plug therefore they must not be tampered with or

modified. Only the cable can be substituted: this must be carried out by a qualified

authorized technician. The earth wire must always be yellow green.

E n g l i s h | 4

APPLIANCE NOT SUPPLIED WITH CABLE WITH

THREE PHASE TERMINALS

Articles supplied by us come with terminals such as in the image. To connect to the mains see

the label in the manual and stuck to the lower part of the back of the appliance near the

Information Plate .

The oven must be connected to the electricity with a rubber cable such as H07RN-F.

WARNING: the yellow/green voltage wires in the earth cable must be 3cm longer than the

others.

The oven must be connected directly to the mains and must have an easily accessible switch

from the start ,installed for the device according to the national, international and local laws in

the country where it is installed. This switch must separate polarization guaranteeing complete

disconnection in accordance with the overvoltage III category.

Correct earthing is obligatory and the earth wire must not be operated by the protection switch.

CABLE CONNECTION

Proceed as follows to connect the power supply wire to the terminal board:

•( A1 ) Loosen the tops of the cable gland and open the bottom part of the back of the

appliance by loosening the screws.

•( A2 ) Feed the new cable through the cable gland. Connect the cable voltage to the

terminal strips following the connection diagram on the label on the back of the appliance.

Only connect what is indicated inserting the copper bridge and the electricity cable

together under the screws, in the tightening direction, so the cable and the bridge are

tightly fixed by tightening the screw. The type of cable to be used (HO7RN-F) is indicated

on the label for each connection and the voltage sections in mm².

•( A4 ) Close the bottom part of the back of the appliance by tightening the screws and fit

the cable by tightening the cable gland top.

Erroneous connection could lead to overheating of the terminal board which could lead to

blowout and electric shock.

Check that all the connections are tight before connecting the oven to the mains.

PE = Yellow/Green: “EARTH” protection conductor.

N = Blue: neutral conductor.

L1, L2, L3 = Brown, Grey, Black: live conductors

E n g l i s h | 5

Check there is no static discharge between live and earth. Check the limit switch continuity

between the external casing and the earth wire of the mains. It is advised to use a multi tester

to carry out these operations.

E n g l i s h | 6

CABLE SUBSTITUTION

This must be carried out by a qualified authorised technician. The earth wire must always

be yellow green.

WARNING: the yellow/green voltage wires in the earth cable must be 3cm longer than

the others.

Proceed as follows to connect the power supply wire to the terminal board:

•( A1 ) Loosen the tops of the cable gland and open the bottom part of the back of the

appliance by loosening the screws.

•( A3 ) Loosen the terminal screws and feed the cable conductors through. Take out the

old cable from the cable gland.

•( A2 ) Feed the new cable through the cable gland. Connect the new cable’s conductors

to the terminal following the connection diagram on the label at the lower part of the back

of the appliance. Only connect what is indicated inserting the copper bridge and the

electricity cable together under the screws, in the tightening direction, so the cable and

the bridge are tightly fixed by tightening the screw. The type of cable to be used (HO7RN-

F) is indicated on the label for each connection and the voltage sections in mm².

•( A4 ) Close the bottom part of the back of the appliance by tightening the screws and fit

the cable by tightening the cable gland top.

Check that all the connections are tight before connecting the oven to the mains.

WARNING: Erroneous connection could lead to overheating of the terminal board which

could lead to blowout and electric shock.

Check there is no static discharge between live and earth. Check the limit switch continuity

between the external casing and the earth wire of the mains. It is advised to use a multi tester

to carry out these operations

The appliance must be connected to the mains using a H07RN-F cable.

EQUIPOTENTIAL CONNECTION

This connection shall becarried between the different appliances with

the terminal marked by the symbol: (see image).

This terminal enables the connection of Yellow/Green cable with a

section between 2.5 and 10mm² .

The appliance shall be included in an equipotential system whose

efficiency shall be duly verified according to the provisions of the laws

in force.

VI. WATER CONNECTION

Make sure the device is placed near a

water connection. Before connecting the

device, allow enough water through to

remove any remnants in the piping so that

they did not get into the magnetic valves.

On the back of the device, in the

areamarked with a label, the convection

oven has an input G 3/4'' with a filter.

E n g l i s h | 7

SUPPLY

FREQUENCY

WEIGHT

POWER

CONSUMPTION

INFORMATION

The inflowing water shall have a pressure value comprised between 150 (1,5 bar) and 200 kPa

(2bar) and a maximum temperature of 30°C. If the inflow pressure value exceeds 200kPa

(2bar), a pressure reducer will have to be installed, calibrated at 200kPa (2 bar).

DRAINAGE CONNECTION

Water flowing out from the oven drainage system may reach high temperatures (90°).

The pipes used for discharging the water must be capable of bearing such temperatures.

The discharge water pipe is located in the lower rear part of the back of the oven and it should

be connected using a rigid or flexible pipe and conveyed to an open or trapped drainage; its

diameter shall not be smaller than that of the drainage connection of the oven It is advisable to

insert a suitable syphon between the oven and the drain, so as to stop emission of unpleasant

odors and fumes from the oven and drains.

Avoid narrowing the flexible pipes and elbow joints on rigid pipes along the entire drainage

system meter.

The oven must have its own drainage connection.

If there are other appliance or tools connected to the one pipe, check that their size allows proper

drainage without blockage.

The local regulations and standards must be followed.

WATER TREATMENT

In order to ensure trouble-free operation of the device, the water should have a hardness of

maximum 5°f to prevent lime deposits. For higher values a water softening station should be

installed first.

VII. FUMES DISCHARGE

Hot fumes and odours are emitted from the cooking chamber during cooking. This is located at

the top part of the back of the oven. Do not place objects on the discharge so as not to hinder

the outflow of the fumes and hence avoid causing damage thereto. It is advisable to position the

oven under a suctioning or ensure adequate ventilation to outside for hot fumes and odours

through a pipe no smaller than the oven drainage. Avoid bends and blockages.

VIII. STACKING OVENS

Stacking several ovens requires the use of the special kit which keeps the correct distance

between the two ovens.

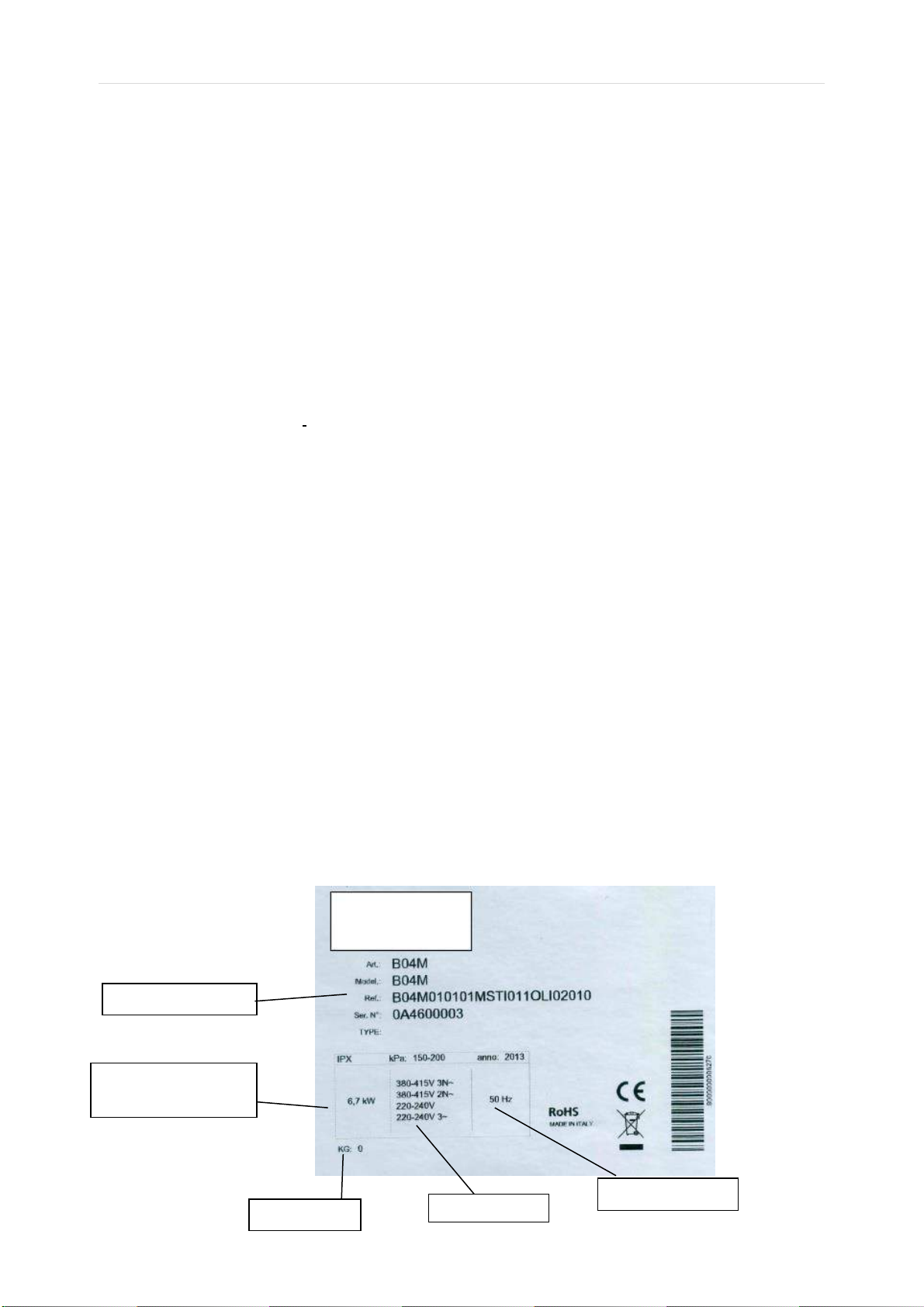

IX. SPECIFICATION INFORMATION PLATE

E n g l i s h | 8

Art./Model: model according to customer classification

Ref:model according to internal manufacturer’s classification

Ser. N°: identification number, different for each product

TYPE: product model according to its technical properties

Information: IPX4 protection level against water sprays / kPa….inflow water

pressure / production year.

Power consumption: appliance nominal power kW

Mains supply: TERMINAL CONNECTION TYPE: device tension in V, number of

phases and neutrals (3N = 3 phases more neutral).

Supply frequency: appliance frequency in Hz.

Weight: appliance weight

INSTRUCTIONS FOR THE USER

I. WARNING

The appliance has been designed to cook food in closed premises and must only be used for

this purpose:anyother usemust, therefore, beavoided as consideredimproper anddangerous.

The oven must only be used by staff adequately trained for its use.

To avoid the risk of accidents or damages to the appliance, it is also fundamental that staff

regularly receive precise instructions regarding safety.

The appliance is not suitable for use by people with low physical or mental abilities or lacking

experience, unless instructed regarding the operation of the oven by the personnel in charge of

safety their safety.

Do not leave the appliance unattended in presence of children and ensure that the latter do not

have access to the appliance.

Do not under any circumstance, leave flammable material near a appliance: it can be a fire

hazard.

Food container temperatures, accessories or other objects can be very hot; beware of burns

when moving them. Only touch them with relevant thermal protection

Careful while opening the oven door: danger of scalding due to high temperature emissions.

The oven is provided with a safety system which automatically disables the operation of the

resistances, fans and vapour supply upon opening the door.

Do not put flammable or alcohol based foods in the oven as they can cause combustion and

explosions.

Avoid putting salt on food inside the cooking chamber of the oven. If this cannot be avoided,

ensure that it is cleaned as soon as possible as it can cause damage to the cooking chamber.

Use fingers to regulate the digital panel options; any other object may damage the oven hence

nullify the validity of the warranty

Installation, extraordinary maintenance and repair operations on the equipment must only be

carried out by professionally qualified staff.

Caution! The outside parts of the oven can exceed a

temperature of 60°C, therefore in order to avoid burning

it is advised not to touch the external parts marked by

the symbol shown here.

Damage or breakage of door glass components must be substituted immediately

(contact the Assistence Centre).

E n g l i s h | 9

When not in use for extended periods (for example 12 hours) it is advisable to leave the

door slightly open.

If it is not in use for long periods of time (many days) it is advisable to turn it off at the

mains and disconnect it from the water supply.

The producer shall not be deemed liable for any damage incurred by persons or

properties, caused by non compliance with the aforementioned instructions of deriving

from tampering with even a single part of the appliance and use of non-genuine spare

parts.

This appliance complies with the EU directives in force.

Ensure that the baking tray holders inside the cooking chamber are

well fitted to the walls. Otherwise the baking trays containing food

or hot liquids could fall resulting in scalding.

II. TESTING

The oven should be tested by carrying out a trial cooking session to check that the appliance is

working properly and that there are no problems or malfunctioning. Set the temperature

controller at 150° C and the timer to 10 minutes.

Check every item in the list below:

The coking chamber light is ON.

The oven stops (heating, humidification, motors/fans) when the door is opened and

resumes operating when the door is closed again. (This only for models with inverter gear)

On reaching the set temperature, the cooking temperature thermostat turns off the heating

elements.

The fans automatically invert the direction of rotation; the inversion occurs every 2 minutes.

Humidification turns off briefly for 20 seconds when the machine is stopped (This only for

models with inverter gear)

The cooking chamber fans spin in the same direction.

If the oven is equipped with a humidity controller, after using button to activate it, check

that water is being discharged to the fan from the humidity inlet duct in the oven chamber

CLEANING

FIRST CLEANING OF THE COOKING CHAMBER OF THE OVEN

Disconnect electrical power from the appliance and wait until the oven is cooled

completely before cleaning.

There should never be any residue of solvents or detergents. They should be removed by

rinsing thoroughly using a damp cloth. Appropriate eye, mouth and hand protection should be

used. Possible danger of corrosion.

Heat the oven empty up to 200° C (392° F) for about 30 minutes so as to eliminate thermal

insulation odors.

Clean the walls of the cooking chamber using hot water and soap, then rinse; never use

aggressive or acid products

E n g l i s h | 10

III. ORDINARY MAINTENANCE

The user is solely responsible for ordinary maintenance. The Assistence Centre must be

contacted for extraordinary maintenance which requires a specialized authorized technician.

Before cleaning, disconnect the device from the power supply and wait until it is fully

cold.

ATTENTION: never clean the device with water jet of pressurised vapour.

ORDINARY CLEANING OF COOKING CHAMBER

At the end of a working day, clean the equipment, both for hygienic reasons and to avoid

malfunctioning.

The oven must never be cleaned using direct or high pressure water jets. In the same manner,

to clean the appliance do not use pan-scrubbers, steel brushes or scrapers; it is possible to use

stainless steel wool, rubbing it in the direction of the sheets satin finish

For manual cleaning follow the procedure below:

•Turn on the appliance and set the temperature to 80°C.

•Leave it on for 10 minutes on steam

•Turn off the appliance and let it cool down

•Remove the side tray racks. Manually remove all removable residues placethe removable

parts inside dishwashers.

•To clean the cooking compartment use soapy warm water. Subsequently, all surfaces

must be thoroughly rinsed, being careful to ensure no detergent residues remain.

•To clean the oven external parts, use a damp cloth and a non-aggressive detergent.

•Clean with hot water and soap then rinse.

It is strictly forbidden to wash the cooking chamber in cooking temperatures higher than 70°C,

scalding danger.

Daily cleaning of the oven cooking chamber lining must be carried out with a non-abrasive

detergent to guarantee its full function.

Use plastic bristles or a sponge soave in vinegar and warm water in case of dirt crusts.

Warning: residue fats possibly present in the cooking chamber could catch fire when using the

oven, hence it is advisable to remove them quickly.

Only use products recommended by the manufacturer of the appliance.

EXTERNAL CLEANING

Only use a damp cloth with warm water or products suitable for cleaning stainless steel. Do not

use acidic products or ammonia.

WARNING: the appliance should never be cleaned with high pressure water sprays.

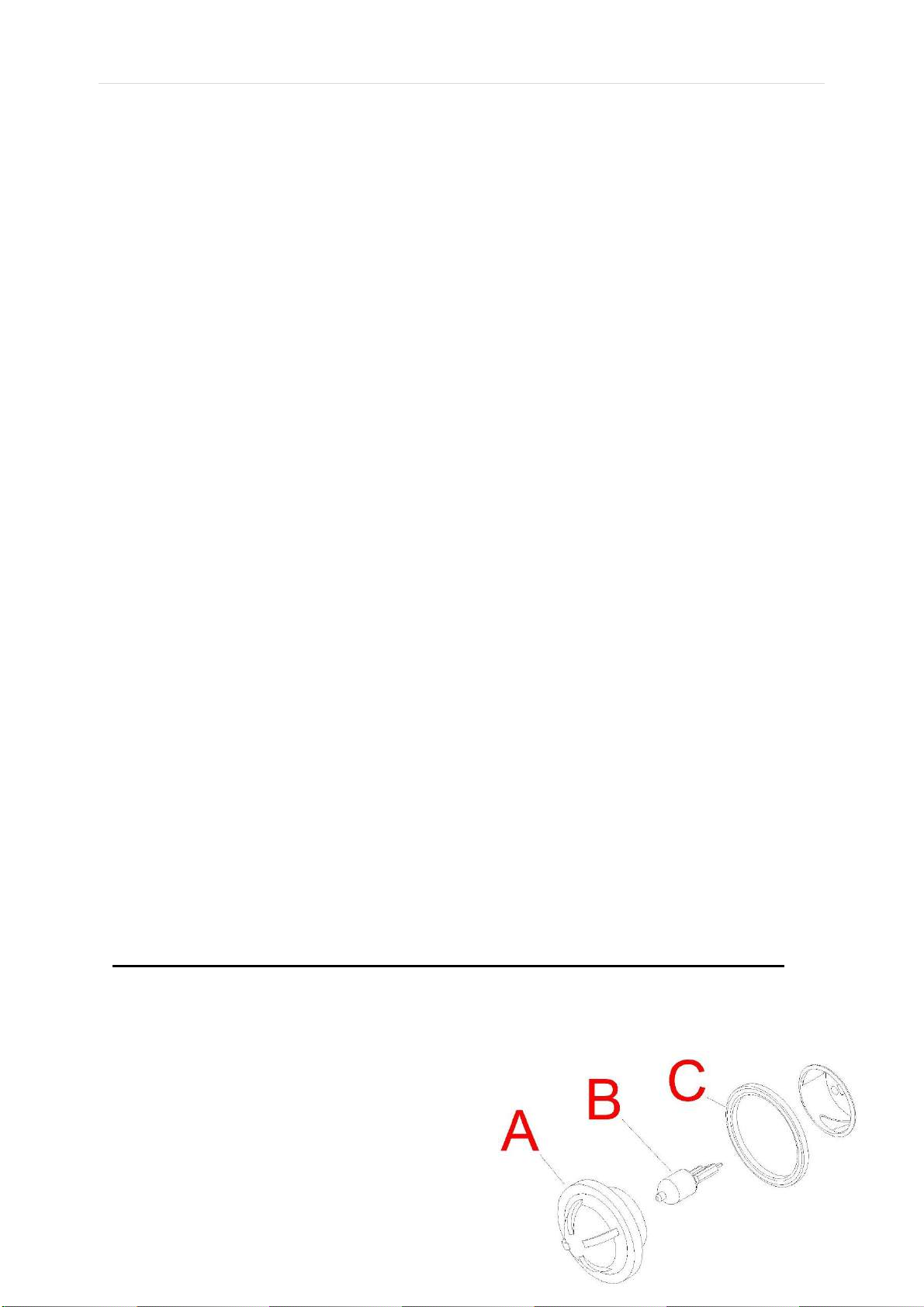

REPLACING LIGHT LAMPS

WARNING: Strictly adhere tothefollowing procedure in order toavoid electrocution or damage

to people:

•Disconnect the electrical

connection of the oven and leave it

to cool.

•take off the side grids that hold the

baking trays.

•Unscrew the glass cover “A” while

observing “C”. Replace the lamp

E n g l i s h | 11

•“B” with one having the same

characteristics.

•Screw back on glass cover “A”

while observing washer “C”.

•Put the side grids back on ensuring

they are well fitted.

Should the glass lid be broken or damaged, do not use the oven until the lid is replaced

(Contact the Assistence Centre).

IV. EXTRAORDINARY MAINTENANCE

It is advisable to have the appliance subjected to periodical checks (at least once per year) by

a specialized authorized technician.

Any maintenance, installation or repair work must be carried out by qualified authorized

personnel by contacting the Assistance Centre. Before carrying out any operation the appliance

must be plugged out at the mains, turn off the water mains taps and wait for it to cool down.

Before moving the appliance from position, check that the electricity and water connections

(electric cables water pipe and drainage) are correctly plugged out.

If the appliance is on wheels check that electric cables, pipes or anything else are not damaged

while moving it. Ensure the break is on. Avoid placing the device near heat (such as fryers etc.).

After carrying out the task and replacing the appliance in its initial position, check that the

electric and water are connected correctly.

V. MAINTENANCE IN CASE OF BREAKAGE

If the appliance breaks, disconnect it from the mains and turn off water.

Before ringing Customer Service, check the chart below.

FAILURE

CAUSE

SOLUTION

The oven doesn't start (This only for

models with inverter gear)

The door is not closed but open

Check that the door is closed

Door Micro switch doesn’t work

properly (for oven with inverter

system)

Contact specialised technician for repair

(Assistance Service ).

The fan stops while the oven is on

(This only for models with inverter

gear)

Safety thermostat measure motor

Turn off the oven and wait for the motor’s

thermal protection to reset itself. If the

problem persists call a specialised repair

technician (Assistance Service).

Motor capacitor break

Contact specialised technician for repair

(Assistance Service ).

Internal light does not work

Loose lamp

Correctly fit the lamp into the lamp holder

Blown lamp

Replace the lamp (see ordinary

maintenance )

There is no water inflow from the

humidifier pipes

Water inlet closed

Open water inlet

Incorrect connection to the water

supply system

Check connection to the water supply

system

The water filters are blocked by

impurities at the top

Clean the filters

Non-uniform cooking

The fans no long invert the

direction of rotation (only model

with inverter system)

Contact specialised technician for repair

(Assistance Service ).

One of the fans not operating

Contact specialised technician for repair

(Assistance Service ).

E n g l i s h | 12

Failure of one of the resistances

Contact specialised technician for repair

(Assistance Service ).

The oven is completely OFF

Supply voltage failure

Restore power supply voltage

Incorrect connection to the power

supply network

Check connection to the power supply

network

Safety thermostat measure

Contact specialised technician for repair

(Assistance Service ).

Water leaking from the gaskets with

the door open

Dirty lining

Clean the lining with a damp cloth

Damaged gasket

Contact specialised technician for repair

(Assistance Service ).

Problem regarding the closure of

the door

Contact specialised technician for repair

(Assistance Service ).

If the problem persists we advise you to consult a retailer or manufacturer asking for Assistance

Service specifying the problem and supplying the code (Art.) and appliance Ser N°.This

information is provided on the INFORMATION PLATE on the back of the machine.

SPARE PARTS

Use only authorized parts for product repair. All interventions shall be carried out by authorized

and specialized technical personnel. Contact the Assistance Centre to request spare parts.

VI. ADVICE DURING COOKING

Where the grill is used to cook fatty food such as roasts or poultry it is advisable to insert a

container on the bottom of the cooking chamber to collect the fat during cooking.

While cooking food with full containers or filled with liquids, ensure

they do not spill, both during and after cooking on taking them out

of the oven. Scalding danger!

When ovens are placed on leavening cabinets, stainless steel

tables or other ovens, it is not advisable to use shelves so high that

the inside of the oven is not at eye level. Scalding danger!

Always clean accessories before their usage.

To cook food perfectly and uniformly it is not advised to use deep baking trays because they

would prevent the correct air circulation. There must be a space of at least 2cm between the

top tray and food.

To cook uniformly do not overload the oven and make sure baked goods or bread face the right

direction toward airflow in the cooking chamber.

To counteract the loss of heat through opening the door to put food in the oven, it is advised to

preheat to at least 30 °C higher than the desired cooking temperature.

In case of interventions on the food, leave the door open for the least time possible, so as to

prevent the temperature within the oven from dropping to a point of jeopardizing successful

cooking.

WARNING: it is advisable to open the door twice: keep the door ajar (3-4 cm) for 4-5’’,

then open completely. This is to prevent heat and steam causing annoyance or burns.

DEFROST

The oven can be used for accelerating the defrosting process for foods to be cooked, by using

forced air at ambient temperature or at lower temperature (depending on the size of the product

to be defrosted). This guarantees quick thawing of frozen products without altering their taste

and aspect.

E n g l i s h | 13

STEAM

The humidification system is recommended for more delicate coking of all types of foods.

Furthermore, it is recommended quick defrosting, warming food products without dehydrating

or hardening them and for naturally desalting foods preserved by salting. The combination of

the steaming function with the conventional ones allows flexibility of use and saving energy and

time, simultaneously maintaining the nutritious and taste qualities of thefood unaltered. an ideal

cooking system for all types of food.

The water –injected on the fan –is atomized and passes through the resistance turning into

vapour.

WARNING: Satisfactory operation of the moisturizing function requires that the temperature of

the thermostat be set at least at 80--100°C. Steam is rarely produced at lower temperatures

and the majority of the water falls to the bottom of the oven.

Furthermore, good vapour cooking required preheating the oven to the desired temperature

before activating the vapour supply.

PREHEATING

To avoid the effects of heat loss when the oven door is opened to place food inside it is advised

to preheat to at least 30 °C higher than the desired cooking temperature.

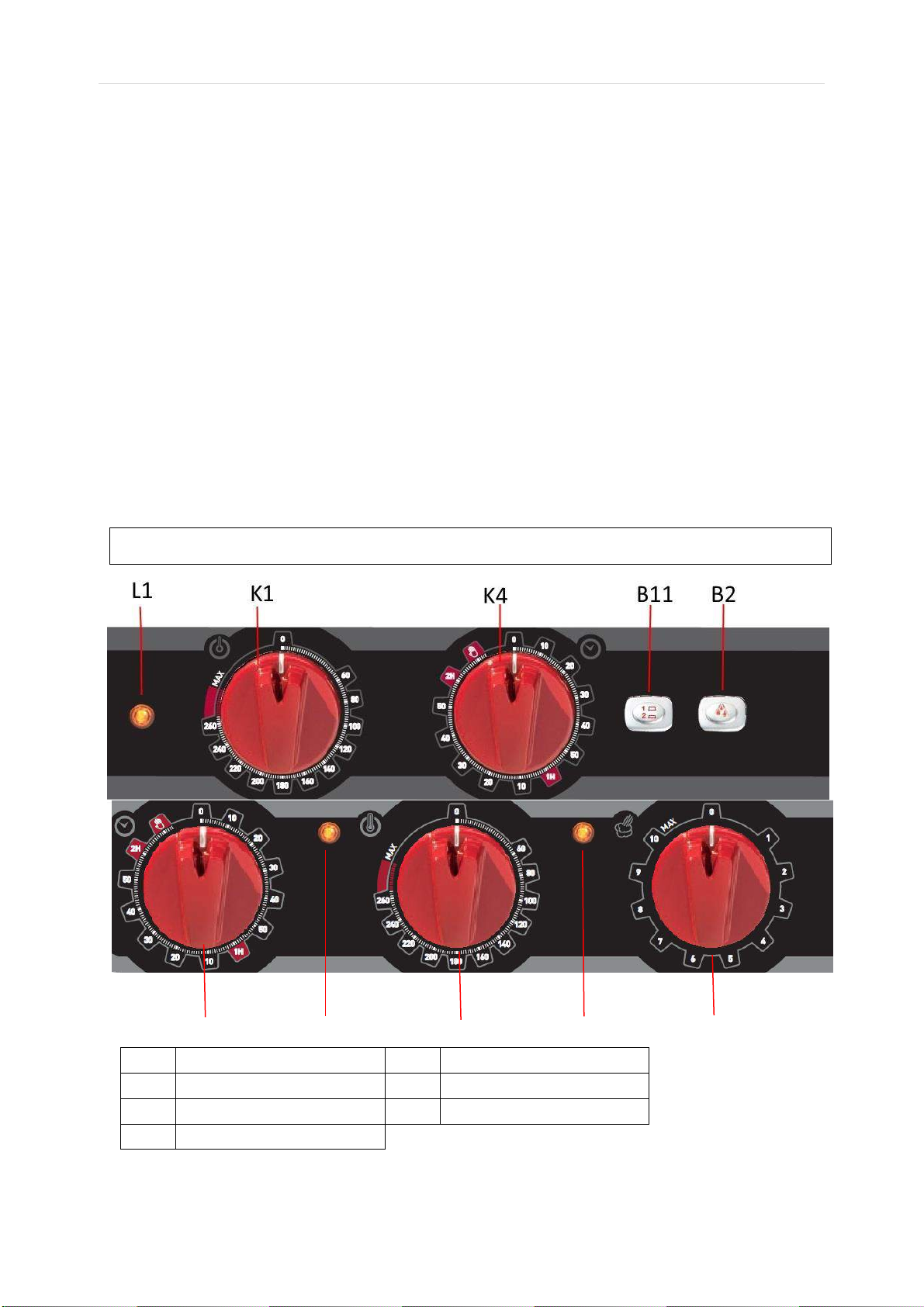

VII. MECHANICAL OVEN CONTROL PANEL

K4 L1 K1 L2 K2

K1

Thermostat knob

B11

Speed regulation

K4

Timer knob

K2

Steam knob

L1

Thermostat light

L2

Humidification light

B2

Steam selector

E n g l i s h | 14

TIMER SELECTOR

When manual is selected, the oven stays on until someone turns it off.When a certain value

is selected, the oven stays on for that time (120 minutes maximum).

THERMOSTAT SELECTOR

This knob allows selecting the desired cooking temperature.

THERMOSTAT LIGHT

This light is on when the oven heating elements are on therefore the temperature in the

cooking chamber is less than that set by the thermostat dial. When the light goes off it

means that the heat is off and that the cooking chamber has reached the set temperature.

STEAM SELECTOR

This button enables humidifying for the length of time it stays pressed.

STEAM KNOB

This knob allows activating the moisturizing function and it can be regulated from minimum

to maximum in the clockwise direction.

WARNING: Satisfactory operation of the moisturizing function requires that the

temperature of the thermostat be set at least at 80-100°C.

Steam is not produced at low temperatures in the oven and the majority of water in the

oven flows into the drain.

Furthermore, good vapor cooking required preheating the oven to the desired temperature

before activating the vapor supply.

SPEED ADJUSTMENT

The oven fan/motor has two speed levels. Press the button and enter the speed required:

1 means that the motor is at its maximum speed. Used for most cooking methods.

2 means that the motor is at its minimum speed. Used especially to cook delicate dishes,

such as pastries.

VIII. MULTIFUNCTION OVEN CONTROL PANEL

K1

Thermostat knob

B2

Steam selector

K3

Cooking selector knob

D1

Defrost

K4

Timer knob

D2

Convection

L1

Thermostat light

D3

Grill

L3

Thermostat light

D4

Grill + convection

E n g l i s h | 15

TIMER SELECTOR

When manual is selected, the oven stays on until someone turns it off. When a certain

value is selected, the oven stays on for that time (120 minutes maximum).

THERMOSTAT SELECTOR

This knob allows selecting the desired cooking temperature.

THERMOSTAT LIGHT

This light is on when the oven heating elements are on therefore the temperature in the

cooking chamber is less than that set by the thermostat dial. When the light goes off it

means that the heat is off and that the cooking chamber has reached the set

temperature.

STEAM SELECTOR

This button enables humidifying for the length of time it stays pressed.

COOKING SELECTOR

There are 5 positions: Off, Defrost, Convection, Grill, Grill + Convection.

1) When it is set to OFF, the oven is completely off.

2) When it is set to DEFROST the fan is working and heating system is off.

3) When it is set to CONVECTION, the FAN is running and heating system is on.

4) When it is set GRILL, the oven heating system is on and controlled by thermostat knob.

Only the grill heating element is working, while the circulating resistance around the

fans is off.

5) When it is set to GRILL + CONVETION the oven heating system is on and controlled by

thermostat knob. The grill heating element is working and also the circulating resistance

around the fans is on

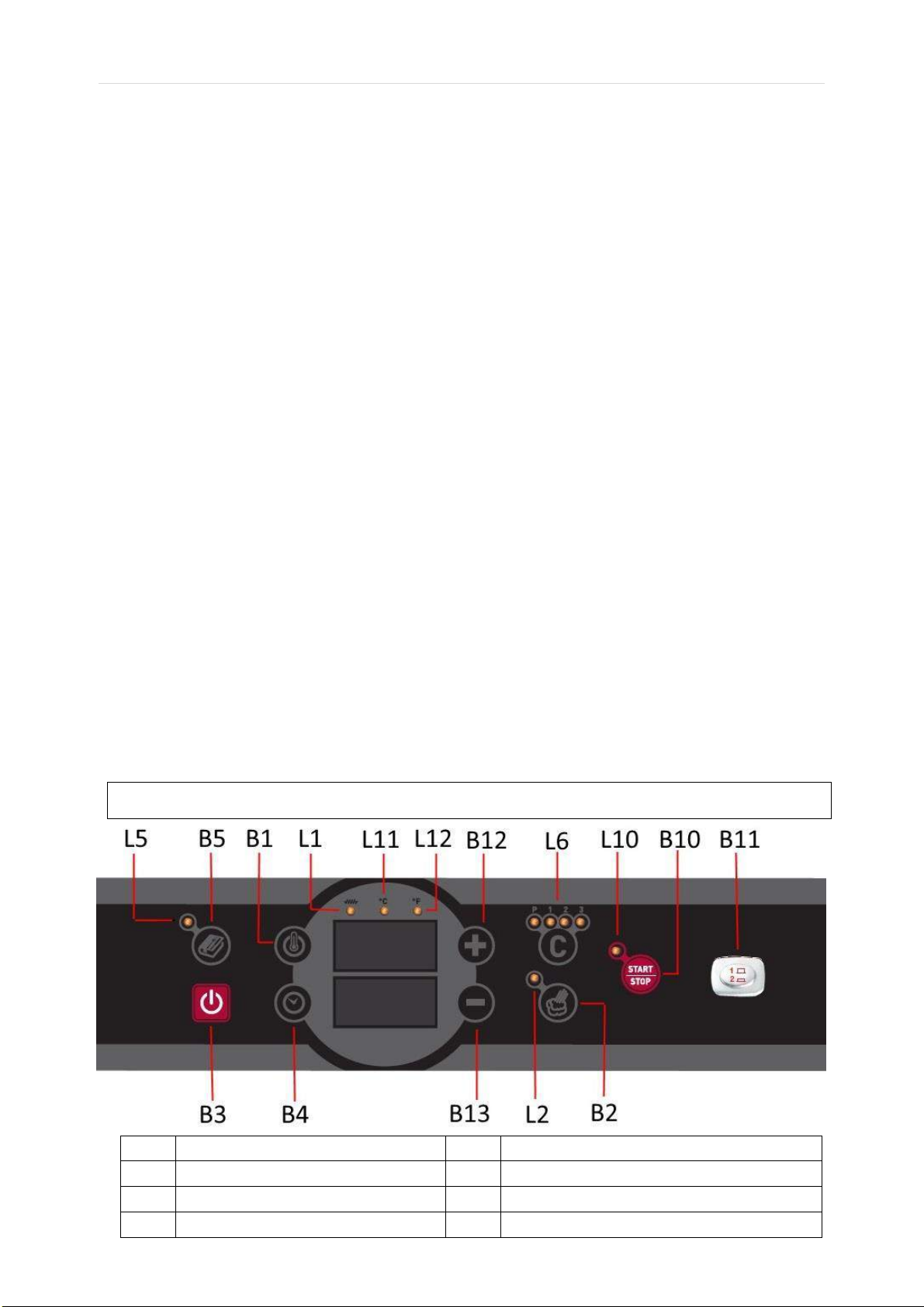

IX. DIGITAL OVEN CONTROL PANEL

L1

Thermostat light

B2

Steam selector

L2

Humidification Light

B3

ON /OFF button

L5

Cooking programs led

B4

Timer selection

L6

Cooking cycle led

B5

Cooking programs

E n g l i s h | 16

L10

START / STOP cooking light

B10

START / STOP cooking

L11

CELSIUS led

B11

Speed regulation

L12

FAHRENHEIT led

B12

Increase button

B1

Temperature selector

B13

Decrease button

ON/OFF

When power is supplied to the oven the control panel lights up and the operating display

indicates temperature in cooking chamber.The oven now is ready for operating.

START/STOP COOKING PROGRAM

This button starts/stops a previously set program or cooking cycle.

TEMPERATURE SELECTOR

When the oven is on “ON” the temperature display shows the temperature in the cooking

chamber.To set the desired cooking temperature press the temperature selector and

press (+) or (-) buttons for INCREASE or DECREASE. The temperaturedisplay will show

the set value. Press the temperature button for confirmation or wait 5 seconds and it will

automaticallybe confirmed. Valuesgofrom 30°C to 260°C.During cooking the CHAMBER

display shows actual internal chamber temperature and to see the set temperature you

must press “temperature button”. Heating element led is on red when the heat is on and

green when it is off.

TIMER

Press Timer button, to set the time value by acting on (+) or (-) for INCREASE or

DECREASE. The time which appears on the displaymust be confirmed pressing the timer

button or wait 5 seconds for automatic confirmation.

The programmable times range is 999 minutes.

Acting on the timer button if you go under value of “1” on display you will see “----“: means

“infinite time” the oven will continue to work with the set parameters until START/STOP

button is pressed. The time display will start count-up so you can see from how long the

oven is operating.

In case you set minutes on the time display will start countdown during cooking.

•STEAM

Enables humidifying in manual cooking or to program the various humidity settings during

process.

-Humidifying in manual cooking: during cooking, the STEAM button enables the release

of steam into the cooking chamber for as long as it is pressed. The STEAM led will be on.

If the motor turns the other way (only for models with inverter system), humidifying will

stop briefly.

-To program automatic humidifying during cooking: after pressing the STEAM button, it is

possible to increase or decrease the humidity by pressing + / -. It ranges from: OFF –

20% - 40% - 60% - 80% - 100%. During programming the values flash on the display and

pressing STEAM again will memorize them or wait 5 seconds for automatic confirmation.

-During cooking, the STEAM led goes on when steam is being released into the cooking

chamber and it stop briefly when the motor turns the other way (only models with inverter

system).

-Pressing the HUMIDIFICATION button whilst cooking generates vapour in the cooking

chamber for the entire time it is pressed.

The set of humidification is allowed only before running a cycle.

E n g l i s h | 17

•COOKING CYCLE

The oven is suitable for 3 different cooking phases for each cooking program

(1,2,3).

•COOKING CYCLE LED

The led that is on will show you in which cooking phase is operating (1,2,3).

•HEATING ELEMENTS LED

When heating elements are working the led is on.

CELSIUS / FAHRENHEIT LED

The led for Celsius or Fahrenheit will be on to indicate in which condition the oven is

operating.

•COOKING PROGRAMS

To program a cooking process press the button and acting on + / - you can select the

program number to set. After selected the program number confirm pressing on cooking

program button. Each program can be modified any time.

AUTOMATIC PREHEATING

This function is automatic for all cooking programs (manual or programmable).

This pre-heats the oven to 20% value higher than the set temperature. This function is

necessary to compensate for the loss of heat through opening the door to put food in.

When a program starts the oven first starts this preheat cycle (“PRE” on the display and

the first cooking cycle led “P” will light), it beeps at the end and only stops when the door

is opened. The previously selected program starts automatically when the door is closed.

The beeping can be stopped by pressing any button other than opening the door. During

pre-heating is not possible to use the humidity.

MANUAL COOKING

Press ON/OFF button to active the oven and after setting TEMPERATURE, TIME, STEAM (see

previous instruction) the cooking cycle begins by pressing START/STOP. The oven will start to

pre-heat and after “beep” will be ready to load the food. After introduced the food will start the

program settled. The cooking cycle may be stopped at any time by pressing START/STOP.

During the cooking process you can modify the Temperature and the Time, only the automatic

STEAM figure cannot be changed during operating, you need to stop the oven and modify

manually.

Manual STEAM can be introduced any time pressing the STEAM button.

During the cooking process the time display will show the count-down.

END flashes on the display at the end of a cooking cycle, fan, humidifying and heating stop and

it beeps for 40 seconds.

PROGRAMMED COOKING

The oven has 99 pre-programmed recipes, each one with 3 cooking phases (1,2,3,).

To create a new cooking program, with the oven in ON/STANDBY, press the RECIPE button

and on display will appear “P01”, acting on + / - button you go to the program number desired

+ press the RECIPE button for confirmation.

Now the oven will be in position of first cooking cycle (N. 1 led will be on) and you can select

the time, temperature and steam in the various phases as below:

-Select the temperature button and with +/- introduce the value desired + press the

temperature button for confirmation.

E n g l i s h | 18

-Select the time button and with +/- introduce the value desired + press the the time button

for confirmation.

-Select the Steam button and with +/- introduce the value desired + press the the Steam

button for confirmation.

-Select the cooking cycle button (C) to go at second phase (in case the cooking process as

different phases) and you will see the Cooking cycle led on under N. 2. Now you can settle

the time, temperature, steam as previously describe and go to “cooking cycle” N. 3. If you

have 3 phases you can save the program with the RECIPE button (press until the led

flashes). In case you have only 1 or 2 phases on the new phase leave “0” under time and

save the program.

-When program is saved you can press START/STOP to activate the cooking process.

-The oven will start to pre-heat and after “beep” will be ready to load the food. After introduced

the food will start the program settled, the PHASES led always shows the current program

phase.

-END flashes on the display at the end of a cooking cycle, fan, humidifying and heating stop

and it beeps for 40 seconds.

It is permitted to modify program data is loaded before baking and cooking in execution, to

adapt cooking product needs.

For manual cooking cycle, all changes made before or during cooking are impermanent, i.e.

are not persisted: If you bring the unit into Standby and then back in ON the manual cycle is

reset to default values.

Changes that were made during the cooking stage are valid only for cooking.

If you press C in a program cooking you can go to the next phases before the end of the time.

To delete the program, change the time of the first phase in infinity time and save the program.

RETURN TO MANUAL COOKING

To go back to MANUAL you have to follow the procedure below to exit programs:

Press ON-OFF until MANU (manual) will appear on the display.

TIME ON DISPLAY

When the oven started the cooking program the time display will show the countdown.

In case you use “INF” time the oven will show the count-up of cooking time.

POWER FAILURE

In case of power failure during the cooking cycle, the oven turns in OFF position.

SIGNALS AND ALARMS

All alarms are indicated by a buzzer. The buzzer can be silenced by pressing a key.

Err = CHAMBER PROBE ALARM:

This is triggered if the chamber probe fails.

D e u t s c h | 1

INHALTSVERZEICHNIS: Seite

ANLEITUNG FÜR DEN INSTALLATEUR

I. HINWEISE 2

II. VORBEREITUNGEN 2

III. INSTALLATIONSORT 3

IV. VORBEREITUNG ZUR INSTALLATION 3

V. ELEKTRISCHER ANSCHLUSS 4

VI. WASSERANSCHLUSS 7

VII. ANSCHLUSS DER ABLUFT 7

X. ÜBEREINANDERSTELLEN VON ÖFEN 7

XI. TECHNISCHE DATEN 8

ANLEITUNG FÜR DEN BENUTZER

I. HINWEISE 8

II. ERSTER GEBRAUCH 10

III. REGELMÄßIGE WARTUNG 10

IV. AUSSERORDENTLICHE WARTUNG 12

V. INSTANDSETZUNG BEI STÖRUNGEN 12

VI. EMPFEHLUNGEN ZUM GAREN 13

VII. MECHANISCHES BEDIENFELD 15

VIII. MULTIFUNKTIONS-BEDIENFELD 16

IX. DIGITALES BEDIENFELD 17

EINLEITUNG

Sehr geehrter Kunde, wir danken Ihnen und beglückwünschen Sie zum Kauf dieses Gerätes; wir

hoffen, dass dies der Anfang einer positiven und langen währenden Zusammenarbeit darstellt.

Diese Betriebsanleitung enthält alle erforderlichen Informationen für einen korrekten Betrieb, die

Wartung und Installation des Gerätes. Der Zweck dieses Handbuchs ist es, dem Installateur und

vor allem dem Verwender des Gerätes zu ermöglichen, alle Maßnahmen und Vorkehrungen zu

treffen, die für einen sicheren, dauerhaften und wirkungsvollen Betrieb notwendig sind.

Die Betriebsanleitung ist für den gesamten Lebenszyklus des Gerätes sorgfältig als

Nachschlagewerk für Bedienpersonal und Servicetechniker aufzubewahren. Im Falle von Verlust

oder Beschädigung der Dokumentation ist diese direkt beim Hersteller oder beim Verkäufer

anzufordern.

Der Hersteller lehnt jede Haftung für Schäden an Personen oder Sachen ab, die auf

unsachgemäßen Gebrauch, Veränderungen oder Reparaturen durch nicht autorisiertes Personal,

oder auf Verwendung von nicht modellspezifischen oder nicht originalen Ersatzteilen

zurückzuführen sind. Dieses Gerät entspricht den geltenden EU-Richtlinien.

This manual suits for next models

2

Table of contents

Languages:

Popular Oven manuals by other brands

Zanussi

Zanussi ZOP38903XD user manual

KitchenAid

KitchenAid IMPERIAL KEBI141YBL4 parts list

VERDER

VERDER CARBOLITE GERO LGP 2/2160 Installation, operation and maintenance instructions

Beko

Beko CSS 53010 G user manual

Wood Stone

Wood Stone WS-MS-4-W Installation and operation manual

Siemens

Siemens HB676GB 1Y Series instruction manual