TCF IM-5500 Instruction manual

Centrifugal Powered

Roof & Wall Exhausters

IM-5500

August 2023

Installation, Operation & Maintenance Manual

This manual has been prepared to guide the users of centrifugal powered roof and wall exhausters in the proper installation, operation

and maintenance procedures to ensure maximum equipment life with trouble-free operation. For safe installation, startup and

operational life of this equipment, it is important that all involved with the equipment be well versed in proper fan safety practices

and read this manual. It is the user’s responsibility to make sure that all requirements of good safety practices and any applicable

safety codes are strictly adhered to. Because of the wide variety of equipment covered in this manual, the instructions given here are

general in nature. Additional product and engineering information is available at www.tcf.com.

REVIEW AMCA BULLETIN 410 PRIOR TO INSTALLATION

Table of Contents

Exploded View..............................................................................2

Fan Overview

Impeller Rotation and Airflow ..........................................3

Fan Nameplate..................................................................3

Dimensional Data..............................................................3

Receiving, Inspection & Unpacking .............................................4

Safety & Hazard Warnings ...........................................................4

Handling .......................................................................................5

Unit Storage .................................................................................6

General Installation......................................................................7

Check, Test & Start Procedure .....................................................8

Motor Wiring & Installation.........................................................9

Electrical Information...................................................................9

EC Motor Information................................................................10

Fan Bearing Maintenance ..........................................................10

Safety & Bearing Lubrication Instructions .................................10

Speed Control Installation..........................................................11

V-Belts ........................................................................................12

Maintenance ..............................................................................13

Accessory Installation Instructions ...................................... 14-19

Troubleshooting Guidelines .......................................................20

Installation / Start-Up Checklist .................................................21

Fan Maintenance Log........................................................... 22-23

Refer to the Safety section(s) in this manual prior to installing or servicing the fan. The most current version of this installation and maintenance

manual can be found on our website at www.tcf.com/resources/im-manuals.

SAFETY NOTICE

Twin City Fan

IM-5500

Installation, Operation & Maintenance Manual

2

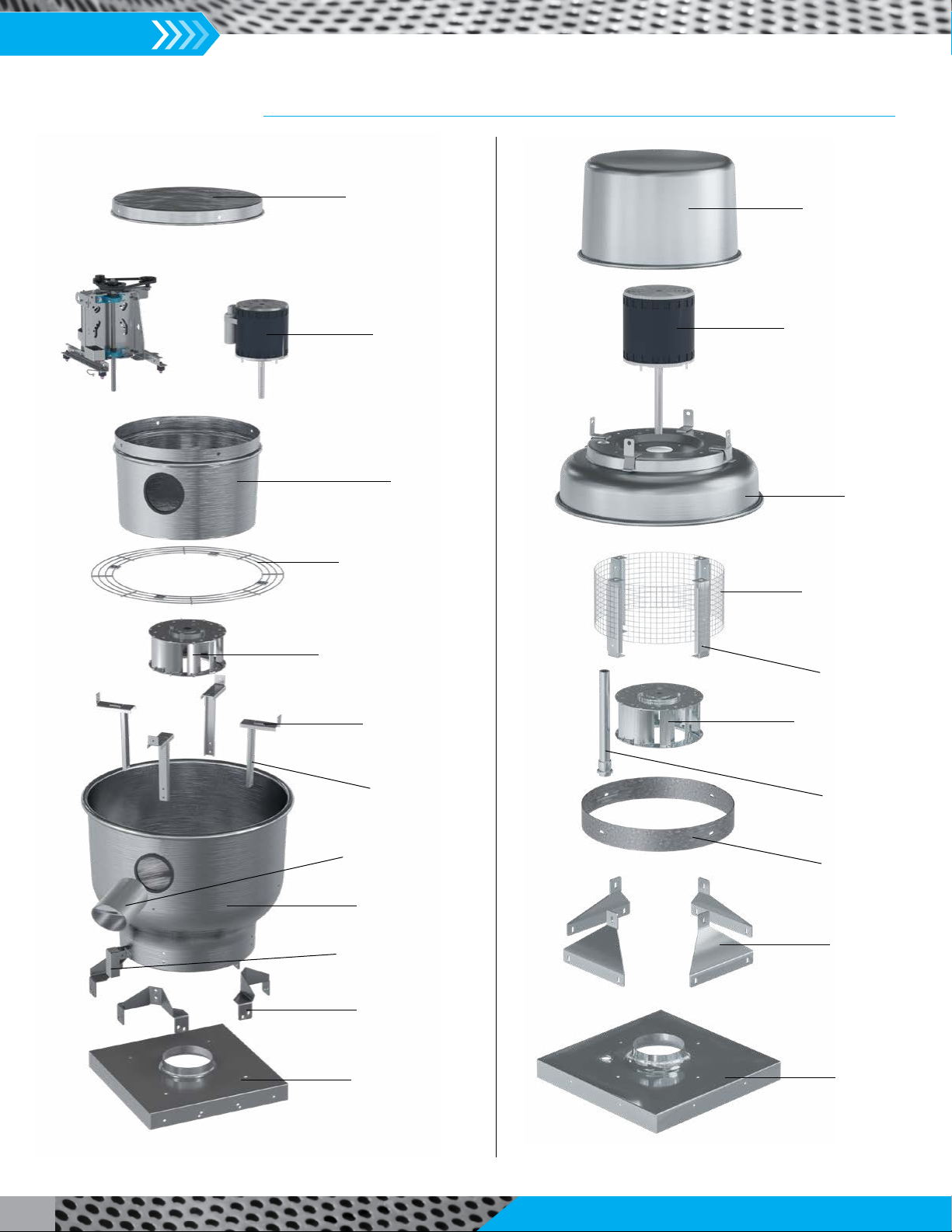

Exploded Views

Motor Cover

Motor

Motor

Housing

Bird Screen

Impeller

Shroud

Curb Cap

Vent Tube

Drain

Support

Brackets

Horizontal

Support

Post

Vertical

Support

Post

Upblast Exhaust Fan,

Models VCU & VCUB

Downblast Exhaust Fan,

Model VC

Motor Cover

Motor

Bird Screen

Impeller

Shroud

Curb Cap

Support

Brackets

Conduit

Vertical

Support

Post

Cutoff

Installation, Operation & Maintenance Manual

IM-5500

3

Blue Arrows = Impeller Rotation

Red Arrows = Airflow

Impeller Rotation and Airflow

Downblast Exhauster

Upblast Exhauster

SIZE CURB CAP DAMPER ROOF/WALL

OPENING

WALL OPENING

WITH MOUNTING

BRACKETS

WALL

MOUNTING

BRACKET SQUARE

APPROX. WEIGHT (lbs.) SHAFT

DIAMETER

(VCUB ONLY)

VCU VCUB

85 17.00 10.00 10.50 17.00 16.75 60 N/A N/A

89 – 112 20.00 14.00 14.50 20.00 19.75 65 N/A N/A

122 – 135 24.00 18.00 18.50 24.00 23.75 95 135 3/4

140 – 165 24.00 18.00 18.50 24.00 23.75 100 135 3/4

177 – 197 30.00 24.00 24.50 30.00 29.75 135 180 3/4

dimensional data – Models VCU, VCUB (Upblast)

SIZE CURB CAP DAMPER ROOF

OPENING

APPROX.

WEIGHT (lbs.)

77 17.00 10.00 10.50 40

83 17.00 10.00 10.50 36

85 17.00 10.00 10.50 36

89 17.00 10.00 10.50 41

98 17.00 10.00 10.50 41

112 17.00 10.00 10.50 43

120 17.00 10.00 10.50 43

dimensional data – Model VC (Downblast)

Fan Overview

Precisely designed for use in roof and wall exhaust applications, the fans covered in this manual offer a broad range of end-use

applications and should be carefully integrated to provide best use. Upblast direct drive fans are available with nominal impeller sizes

from 8.5” to 19.7” and belt driven with nominal impeller sizes 12.2” to 19.7”. Downblast direct drive fans are available in nominal

impeller sizes from 8.5” to 12.0”. Maximum continuous operating temperature for standard build fans is 122°F, with an option for

upblast units for a UL 762 restaurant-rated build for continuous airstream temperatures up to 300°F. Each fan bears an affixed

manufacturer nameplate with the model number and serial number. See below.

Nameplate

The serial number and fan type can be found on our permanent

nameplate of the fan.

Check to ensure the nameplated voltage matches the line

voltage being supplied to the unit.

Twin City Fan & Blower

Minneapolis, MN www.tcf.com

Twin City Fan

Parts & Service

888-444-4823 |fieldservice@tcf.com |parts@tcf.com

model

ser. #

voltshz

class

tag

hp phase

arr.

size

encl.

09-265399-1-1

VCUB

NOTES:

1. All dimensions are in inches unless otherwise noted.

2. Approximate weights shown above include only the bare fan and motor (heaviest at time of publication), not accessories.

IM-5500

Installation, Operation & Maintenance Manual

4

Safety & Hazard Warnings

For general safety practices for air moving equipment, see AMCA Bulletin 410. Twin City Fan & Blower offers many safety accessories.

These safety devices include (but are not limited to) Firestat, inlet and discharge screens. The use and suitability of safety devices is

the responsibility of the purchaser.

All fans should be powered through switches that are easily accessible to service personnel from the fan. Fan power must have the

ability to be “locked out” by service personnel trained in lockout/tagout procedures per OSHA requirements (29CFR1910.147). When

performing lockout, be aware of factors, such as building pressure and additional fans in the system that can influence unwanted fan

rotation (wind milling). If you have any doubt about your ability to perform a task, seek a person qualified to do that task. Before any

work is done on a fan, ensure that the fan is isolated from the electrical supply using a 'lockout/tagout system.'

Note: A stationary, non-rotating fan does not mean that the fan is isolated from the electrical supply. A non-rotating fan could be

subject to controls or other circuit protection devices that may start the fan without notice.

The following safety precautions should be followed, where applicable:

• Do not attempt to slow a rotating impeller even when it is isolated from the electrical supply. Fan impellers have a high inertia and

injury could result from an attempt to stop it. It is recommended that the impeller is isolated by closing off the inlet or outlet to

prevent wind-driven rotation. If an impeller is chocked to prevent rotation, ensure that the chocks are removed prior to start up.

• Wear appropriate personal protective equipment. This may include protective clothing, eye protection, ear protection, respiratory

equipment, hand and foot protection when installing or servicing the fan.

• Always use caution when entering a fan's air path. High velocity airflow can cause you to lose your balance.

• Motor, bearings and drives can be hot, and similarly if the fan is subject to processes that are hot, the fan housing could be hot.

• Sharp edges – wear protective gloves when handling, installing or servicing a fan.

• Fans can operate at high decibel sound levels. Wear proper ear protection to protect from excessive noise levels.

Throughout this manual, there are a number of HAZARD WARNINGS that must be read and adhered to in order to prevent possible

personal injury and/or damage to equipment. Two signal words "WARNING" and "CAUTION" are used to indicate the severity of a

hazard and are preceded by the safety alert symbol. It is the responsibility of all personnel involved in installation, operation and

maintenance to fully understand the warning and caution procedures by which hazards are to be avoided.

WARNING: Used when serious injury or death MAY result from misuse or failure to follow specific instructions.

CAUTION: Used when minor or moderate injury or product / equipment damage MAY result from misuse or failure to follow

specific instructions.

NOTICE: Indicates information considered important, but not hazard-related.

Receiving, Inspection & Unpacking

When the equipment is received all items should be carefully checked against the bill of lading to be sure all crates and cartons have

been received. Before accepting delivery, carefully inspect each carton or crate for visible shipping damage. If any damage is noticed,

the carrier should make the proper notation on the delivery receipt acknowledging the damage. Make notations of all damage on

all copies of the bill of lading and have all copies countersigned by the delivering carrier. The carrier should also fill out a Carrier

Inspection Report. The factory Traffic Department should then be contacted. File claim for damage with the carrier. Physical damage

to the unit after acceptance is not the responsibility of Twin City Fan Companies, Ltd.

Unpack each carton or crate and verify that all required parts and proper quantities of each item have been received. Refer to

drawings for part descriptions. Report shortages or missing items to your local representative to arrange for replacement parts. Due to

availability of carriers and truck space, it is not possible to guarantee that all items will be shipped together. Verification of shipments

must be limited to only those items on the bill of lading.

Installation, Operation & Maintenance Manual

IM-5500

5

Handling

Handling of all air moving equipment should be conducted by trained personnel and be consistent with safe handling practices. Verify

the lift capacity and operating condition of handling equipment. When using hoisting equipment, only qualified and trained personnel

should operate the equipment.

Units shipped completely assembled may be lifted with slings and spreader bars. (Use well-padded chains, cables or nylon straps,

rated to lift the required weight.) On most units, lifting lugs are designed to protect the fan and fan housing from damage. Never lift a

fan by the inlet or discharge flange, shafting or drives, impeller, motor or motor base, or in any other manner that may bend or distort

parts. Never lift with slings or timbers passed through the fan inlets.

Model VC fans: The fan may be lifted by the lip of the shroud. This can either be done manually

(total fan weight is between 50 – 70 lbs.) or with a minimum four-point hook system. Take

precautions to not cause any damage to the shroud.

Model VCU fans:

All Sizes: Fans may be lifted using hooks around the four (4) horizontal support posts with a

minimum of four lifting straps with spreader bars to ensure that no contact is made with the

motor housing.

Sizes 122 and greater: An alternative method for direct drive units between Sizes 122 and 197 is

to utilize the lifting holes located on the motor support plate within the housing. To lift the unit,

four straps and hooks should be used to lift by all four points.

Model VCUB fans: Two lifting lugs located on the bearing support plate provide easy access lifting

points. There are also four holes located on the drive frame bars from which the fan can be lifted.

Wall Mount Fan: Use two lifting straps around the shroud of the fan. One should be located

around the neck of the shroud and the other near to the shroud lip.

Model VCU

(Motor support plate

features four lifting points)

1. Maintain handling equipment to avoid serious personal injury and do not stand under

the load.

2. If supplied, only use the provided lifting lugs to lift the equipment.

3. Ensure that the lifting equipment is rated for the capacity to be lifted.

CAUTION

Model VC with lifting points

Model VCU

(all sizes method)

Model VCUB

(Bearing support plate features

two points for lifting)

IM-5500

Installation, Operation & Maintenance Manual

6

Unit Storage

If fan installation is to be delayed, store the unit in an environmentally stable and protected area. During storage, the fan should

not be subjected to vibration from external sources or bearing damage may occur. The unit should be reasonably protected from

any accidental impacts. Cover the fan to protect coatings and to prevent any foreign material or moisture from entering the inlet or

discharge. Take care to protect the motor, drives and bearings.

Extended storage requires monthly inspections. Check for corrosion or damage to the unit and for debris within the fan.

Bearings tend to take on moisture if the atmosphere in which they are stored is not at a constant temperature. To avoid corrosion, it is

necessary to keep the bearings full of grease and to rotate them periodically. Even when full of grease, bearings will take on moisture,

so it is necessary to purge the bearings with new grease to expel moisture every thirty days. It is recommended that the bearings be

purged with grease while being rotated by hand. Do not use high pressure greasers as they may ruin the bearing seals. Remove old/

excess grease and regrease the bearing in accordance with the bearing manufacturer's instructions.

The drives and belts should be removed if the fan is to be stored for a prolonged period. The drives should be labeled for service and

stored in a dry place. Belts should be removed, coiled without kinks, placed in a heavy carton and stored in a dry, well-ventilated place.

To prevent belt deterioration storage conditions should not exceed 85°F and 70% humidity. If belts show signs of deterioration, they

should be replaced prior to startup.

Motors should be stored in a clean, dry, vibration-free location. The packaging should be opened up enough to allow air circulation

around the motor. The winding temperature should be kept slightly above that of the surroundings to prevent condensation. This can

be accomplished by energizing the internal heaters, if the motor is so equipped, or by using space heaters. If it is impossible to heat the

windings, the motor should be wrapped tightly with a waterproof material that also encloses several bags of desiccant. Replace the

desiccant regularly to prevent moisture problems. The motor rotor should also be rotated regularly (monthly) to assure the bearing

parts are well greased. Shafts on motors equipped with shaft grounding rings must remain rust free. Failure to do so renders the

grounding feature inoperative. Consult the motor manufacturer for further detail on motor storage and start up after longer periods

of storage.

Twin City Fan

Installation, Operation & Maintenance Manual

IM-5500

7

Sheet metal parts, screws, clips and similar items inherently have sharp edges

and it is necessary that the installer and service personnel exercise caution.

CAUTION

General Installation

The installation of this equipment shall be in accordance with the regulations of authorities having jurisdiction and all applicable codes.

This equipment is to be installed by an experienced installation company and fully trained personnel.

The mechanical installation of the exhaust ventilator consists of making final connections between the unit and building services, duct

connections.

1. Install an appropriate roof curb for the fan size and use. Ensure proper caulking

and flashing are installed for a water-tight seal.

a. Sidewall Mounted Units: A wall mounting bracket is shipped for all fans

meant for sidewall installation. Bolt the wall mount bracket to the wall by

pre-drilling pilot holes and then using eight lag screws to secure the bracket.

2. Any backdraft damper, insect screen or performance baffle should be installed

now. Refer to the Performance Baffle Installation section for details.

3. Perform fan pre-check. See Check, Test & Start Procedure section for a full

checklist.

4. Perform installation of any externally mounted accessories that were shipped

loose with the fan.

5. Remove the fan motor housing cover by removing the four screws. See Motor

Housing Cover Removal images to the right for reference on screw location.

6.

a. Roof Mounted Units: Place the unit onto the roof curb. Secure the fan to the

curb with eight lag screws or other suitable fasteners. Verify that the fan is

oriented to facilitate installation of wiring.

b. Sidewall Mounted Units: Align and then affix the fan onto the wall mounting

bracket using the hardware provided. NOTE: The drain should always be

facing directly down and the vent tube to the lower right corner. See image

below for drain and vent tube location.

c. NOTE: If curb hinge, security latch or retaining chain accessories are selected,

please reference the Curb Hinge, Security Hasp and/or Retaining Chain

installation instructions towards the back of this manual.

7. Follow the Motor Wiring and Installation instructions section. Verify installation

of any accessories that were shipped loose with the unit.

8. Affix the motor housing cover back onto the unit.

Upblast

Motor housing cover removal

Downblast

Twin City Fan

Wall mounted unit with correct drain and vent

tube location

IM-5500

Installation, Operation & Maintenance Manual

8

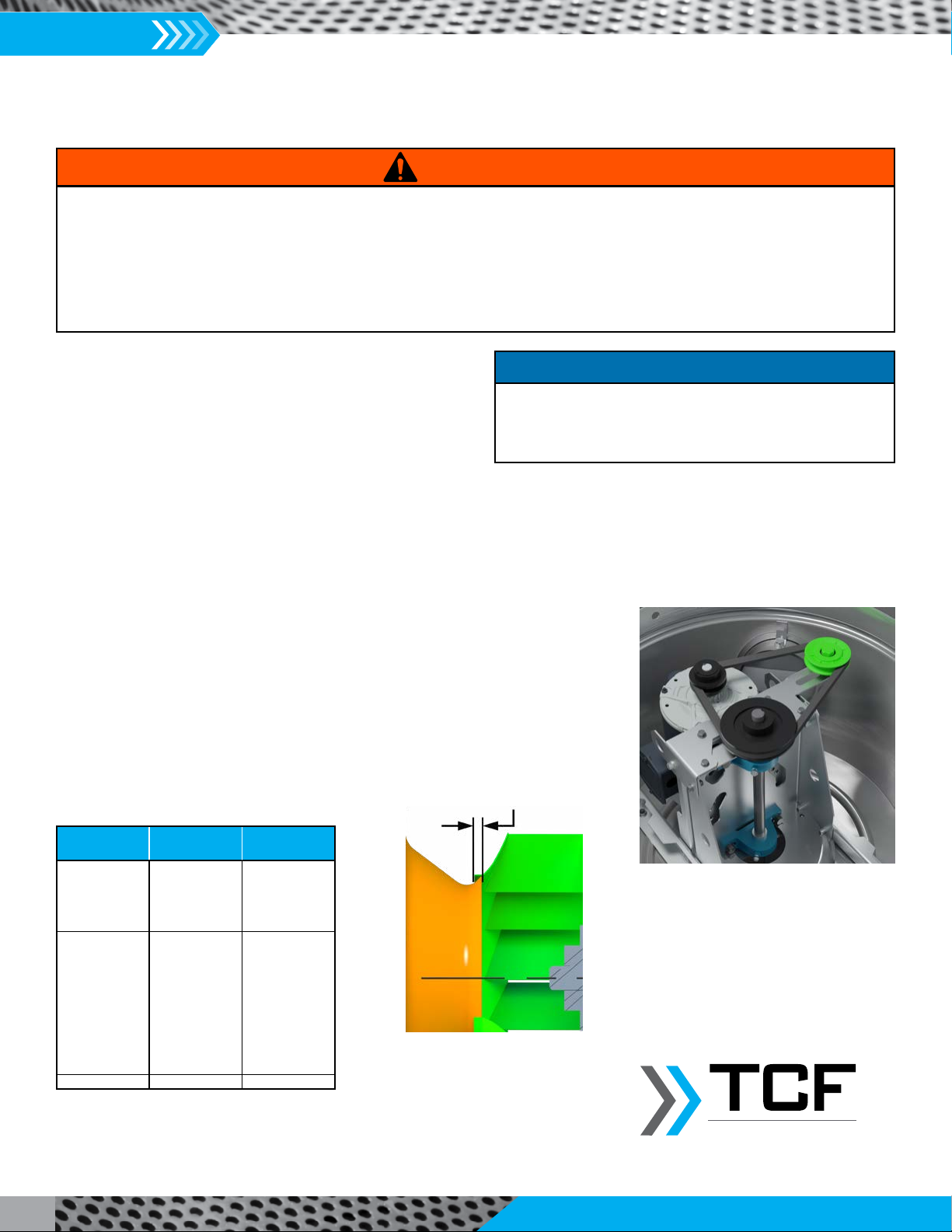

FAN

TYPE SIZES OVERLAP

(+/- 0.05")

VCU 085 0.20"

VCU 089 0.13"

VCU 098 0.13"

VCU 110 0.13"

VCU 112 0.20"

VCU & VCUB 122 0.20"

VCU & VCUB 124 0.13"

VCU & VCUB 135 0.20"

VCU & VCUB 140 0.13"

VCU & VCUB 150 0.20"

VCU & VCUB 157 0.13"

VCU & VCUB 165 0.20"

VCU & VCUB 177 0.20"

VCU & VCUB 182 0.20"

VCU & VCUB 197 0.20"

VC ALL SIZES 0.13"

Check, Test & Start Procedure

1. General unit check:

a. Check for any defects or damage. Contact your local

representative if any damage is present.

b. Verify that all accessories are installed and operational.

c. Validate all fasteners are secure and there are no loose parts.

2. Impeller check:

a. Validate that the impeller is free and able to rotate.

b. Validate that the impeller to inlet venturi overlap is maintained. See Impeller to Inlet Venturi table below for the specified

overlap.

c. Apply power to the unit and check the rotation of the impeller. The label within the motor housing indicates the direction. See

images in the Impeller Rotation and Airflow section for visual aid.

d. Verify fan RPM using a tachometer. If a speed controller is used, check that the maximum and minimum RPM are as desired. If

the minimum RPM is not as desired, see Speed Control Installation section for instructions on how to adjust.

3. Drive and belt check (VCUB fans ONLY):

a. Verify that sheaves and idler pulley (auto-tensioner if accessory was selected) are

aligned parallel.

b. Verify that the belt is taut with minimal deflection. Adjustment can be made by

sliding the idler pulley along the groove to either tighten or loosen the belt. See

image to the right.

c. Verify the RPM of the impeller. Adjustment can be made via the variable speed

sheave attached to the motor to reach the desired RPM.

d. Bearings should be properly greased from the manufacturer.

e. See the V-Belts section for further information.

1. Electric shock hazard. Could cause severe injury or death. Failure to bond the frame of this equipment to the building electrical ground

by use of the grounding terminal provided or other acceptable means may result in electrical shock. Disconnect electric power before

servicing equipment. Service to be performed only by qualified personnel. Make sure power is turned off and locked in the OFF position.

2. Impeller rotation is critical. All units are designed to rotate in a CCW direction. If spun in the opposing direction, fan performance is heavily degraded

and the motor will overload and burn out prematurely.

3. Three-phase units are especially susceptible to incorrect rotation due to the ease of incorrectly connecting the wires. If the unit is checked on

temporary wiring, impeller rotation should be rechecked when permanently installed. Motor burn out or tripped overload protection devices

are key indications of a fan left to run in the wrong rotation.

WARNING

Impeller to Inlet Venturi

The impeller was balanced at the factory to be within stringent

vibration levels before shipment. However, there are several

things that may cause vibration, such as rough handling in

shipment and installation, weak foundations and alignments.

NOTICE

Model VCUB Idler Pulley

Impeller Overlap

Twin City Fan

Overlap

Installation, Operation & Maintenance Manual

IM-5500

9

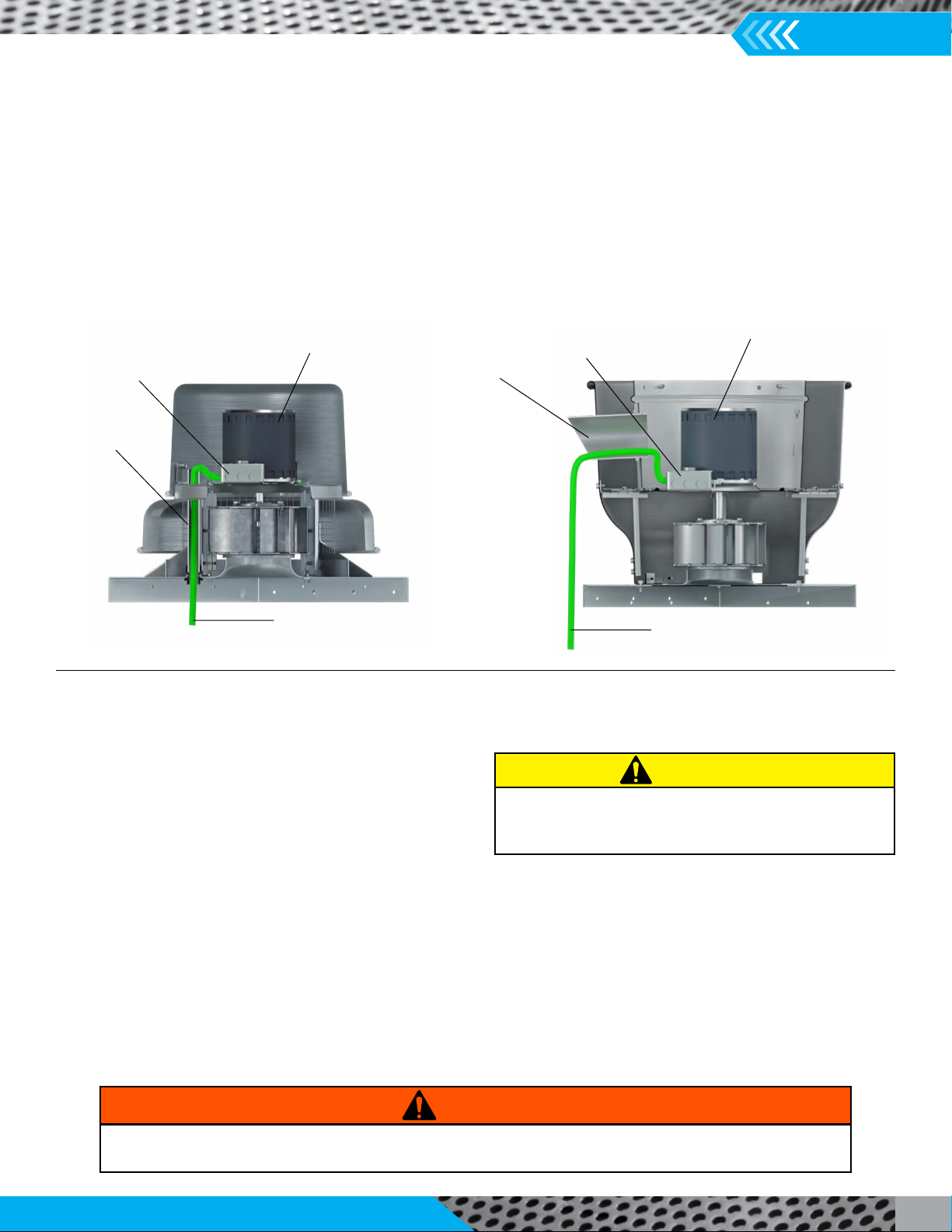

Motor Wiring & Installation

1. Proper Lockout/Tagout procedures should always be followed as discussed in the Safety & Hazard Warnings section. Verify that no

power is on the circuit to which the fan is being connected.

2. Run appropriately rated wiring for the installation method to the junction box located within the motor housing; only ½”

knockouts available.

Downblast Fans: The electrical supply is routed through conduit between the curb cap and motor compartment.

Upblast Fans: The electrical supply is routed through the vent tube.

See images below for electrical routing.

a. Refer to the accessory installation portion towards the end of this manual for additional wiring instructions for various wired

accessories.

3. Leave enough slack in the wiring for maintenance accessibility.

Electrical Information

1. Check the wiring diagrams on the motor for connections.

2. The motor is factory set at the voltage marked on the fan

nameplate. Check the line voltage with the nameplate voltage

and wiring diagrams.

3. The main power wiring should be sized for the ampacity shown

on the dataplate. Size wires in accordance with the ampacity

tables in Article 310 of the National Electrical Code. If long wires

are required, it may be necessary to increase wire size to prevent excessive voltage drop. Wires should be sized for a maximum of

3% voltage drop.

4. Disconnect switches are not fused. The power leads must be protected at the point of distribution in accordance with the fan

dataplate.

5. On fans without a thermal protector integral to the motor (refer to unit or motor dataplate to determine if protector is present) a

separate overload device is required. Refer to Sections 430-32 of the N.E.C. for sizing.

6. All units must be electrically grounded in accordance with local codes or, in the absence of local codes, with the latest edition of the

National Electrical Code (ANSI/NFPA 70). A ground lug is provided as standard in the unit terminal box. Size grounding conductor

in accordance with Table 250-95 of the National Electrical Code. DO NOT use the ground lug for connecting a neutral conductor.

7. Supply voltage to the power ventilator should not vary by more than 10% of the value indicated on the unit dataplate. Phase

unbalance must not exceed 2%.

Failure of motor due to operation on improper line voltage or with excessive phase unbalance constitutes product abuse and

may cause severe damage to the unit’s electrical components.

WARNING

1. Use copper conductors only.

2. Protect wiring from sharp edges. Leave some slack in the line

to prevent damage.

CAUTION

Motor

Junction

Box

Conduit

Field

Wiring

Motor

Junction

Box

Field

Wiring

Vent

Tube

IM-5500

Installation, Operation & Maintenance Manual

10

*Suggested lubrication interval under continuous operation in adverse loading or with

elevated temperatures. For operation less than 24 hours per day or under ideal conditions,

lubrication frequency may be reduced. Relubricate while running, if safety permits, until

some purging occurs at seals. Adjust lubrication frequency depending on condition of

purged grease. Hours of operation, temperature and surrounding conditions will affect the

relubrication frequency required.

1. Lubricate with a high quality NLGI No. 2 lithium-base grease having rust inhibitors and

antioxidant additives, and a minimum oil viscosity of 500 SUS at 100°F (38°C). Some

greases having these properties are:

Shell - Gadus S2 V100 2 Mobil - Ronex MP

Mobil - Mobilith SHC100 Mobil - Mobilith SHC220

2. Lubricate bearings prior to extended shutdown or storage and rotate shaft monthly to aid

corrosion protection.

Fans with Ball Bearings

Relubrication Schedule (Weeks)*

Ball Bearing Pillow Blocks

Shaft DIA Speed (RPM)

500 1000 1500 2000 2500 3000 3500 4000 4500

3⁄4" (19 mm) 665332221

1. This equipment must not be operated without proper guarding

of all moving parts. While performing maintenance be sure

remote power switches are locked off. See installation manual

for recommended safety practices.

2. Before starting: Check all set screws for tightness and rotate

impeller by hand to make sure it has not moved in transit.

WARNING

Safety & Bearing Lubrication Instructions

Twin City Fan

Fan Bearing Maintenance (refer to safety section)

Proper lubrication of the fan drive bearings helps assure maximum bearing life. All fans are equipped with decals indicating the

recommended relubrication intervals for normal operating conditions.

The standard pillow block bearings on belt driven ventilators are factory lubricated and are provided with external grease fittings.

Annual lubrication is recommended, or more frequently if needed (see Greasing Intervals table). It is recommended to add fresh grease

at start-up, but do not over-grease. Use only 1 or 2 shots of a recommended lubricant with a hand gun in most cases. Maximum hand

gun rating 40 P.S.I. Rotate bearings during lubrication where good safety practice permits. The most frequent causes of bearing failure

are not greasing often enough, using an excessive quantity of grease or using incompatible greases. Excessive vibration, especially if

the bearing is not rotating, will also cause bearings to fail. Bearings must also be protected from water and moisture to avoid internal

corrosion.

During the rst few months of operaon it is recommended that the bearing set screws be checked periodically to ensure that they are

ght. The rotang impeller requires parcular aenon since materials in the air being handled can build up on the blades to cause

destrucve vibraon or weaken the structure of the impeller by corroding and/or eroding the blade metal. Regular inspecon and

correcve acon at intervals determined by the severity of each applicaon are essenal to good service life and safety.

Suggested Fan Bearing Greasing Intervals

INTERVAL

(MONTHS) TYPE OF SERVICE

12 to 18 Infrequent operaon or light duty in clean atmosphere

6 to 12 8 to 16 hrs./day in clean, relavely dry atmosphere

3 to 6 12 to 24 hrs./day, heavy-duty or if moisture is present

1 to 3 Heavy-duty in dirty, dusty locaons; high ambient

temperatures; moisture-laden atmosphere; vibraon

Greases of different soap bases (lithium, sodium, etc.) may

not be compatible when mixed. Prevent such intermixing

by completely purging the bearing of old greases.

CAUTION

EC Motor Information

See IM-4055 for EC motor details.

Installation, Operation & Maintenance Manual

IM-5500

11

Low End Setpoint Adjustment

NOTE: 5 amp model shown.

On 10 and 15 amp models,

adjustment is made through

clearance hole in heat sink. The

faceplate must be removed on

the 5 amp model to access this

screw.

SETPOINT

ADJUSTMENT

SCREW

Speed Controller Size

Speed Controller RPM Range

NOTES:

1. Speed control available only with 115/60/1 open motors (thermally protected).

2. Three-speed motor (multiple tap winding).

3. Speed control should not be connected to low speed tap on motor because of

starting characteristics.

4. Speed control connected to high speed tap on motor.

5. Speed control connected to medium speed tap on motor.

MOTOR SPEED CONTROLLER (FLA)

HP RPM 5 AMP 10 AMP 15 AMP

1/30 ALL X

1/15 ALL X

1/8 ALL X

1/6 ALL X

1/4 ALL X

1/3 <= 1500 X

1/3 > 1500 X

1/2 ALL X

HP RPM MAX. RPM MIN. RPM

1/30 1650/1500/13502,3 1650413004

1/8 150059505

1/15

860 860 500

1/8

1/6

1/4

1/2

1/8

1140 1140 900

1/6

1/4

1/2

1/3 1725 1725 1200

1/2

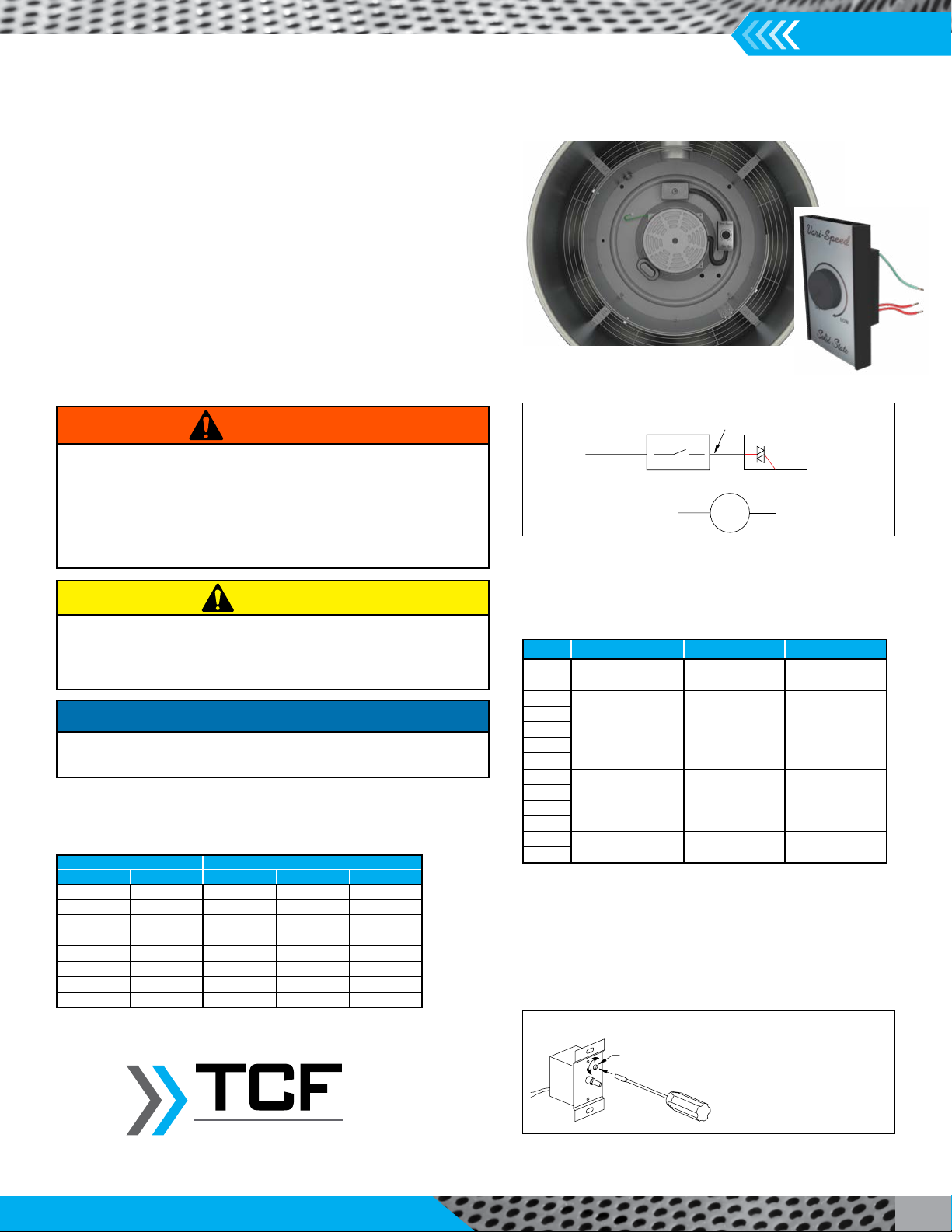

Speed Control Installation

When the controller is shipped loose, it can be installed externally, or

alternatively it can be installed inside of the fan 90 degrees from the

disconnect switch. On Model VCU it can be installed between the rib

and the raised motor mounting section of the housing compartment.

Speed control is available using 115/60/1 open type PSC motors.

Connect control in series with motor and line voltage (115V only).

Never connect across line. See Connection Diagrams.

Minimum Speed Setpoint

All controls are factory set to 65V±3V output as standard with an

input voltage of 120V. If different minimum speed is desired, the

control may be adjusted by turning minimum speed pot clockwise

to decrease minimum speed and counterclockwise to increase

minimum speed. Refer to Low End Setpoint Adjustment figure. Connection Diagrams, Speed Control

SPEED CONTROLLER WITH A NEMA 1 POWER SWITCH

Incoming Power Leads

NEMA 1 Switch

Motor Power Leads

Motor

Motor Control Leads

TRI-AC

Wire Harness

1. If minimum speed is readjusted, verify unit ampere draw does not

exceed motor nameplate amps. Do not operate unit in range where

amp draw exceeds motor nameplate.

2. Certain failure modes of solid-state controls such as half-waving can

cause high levels of DC, motor overheating and motor burn-out.

Therefore, a thermal overload protection (integral with motor) is

required to limit the maximum motor temperature under such a failure.

WARNING

These motors operate more efficiently in the ranges set from the

factory. Operating motor outside these ranges (see Speed Controller

RPM Range table) may cause the motor to run hotter and substantially

shorten motor life.

CAUTION

1. Lowering the minimum speed setpoint may adversely affect motor

start-up characteristics.

NOTICE

One red wire will be connected to the AC line voltage. The second red wire

will be connected to the input power lead for the motor. The green wire

is the ground wire.

Typical Speed Control Installation Location

Twin City Fan

IM-5500

Installation, Operation & Maintenance Manual

12

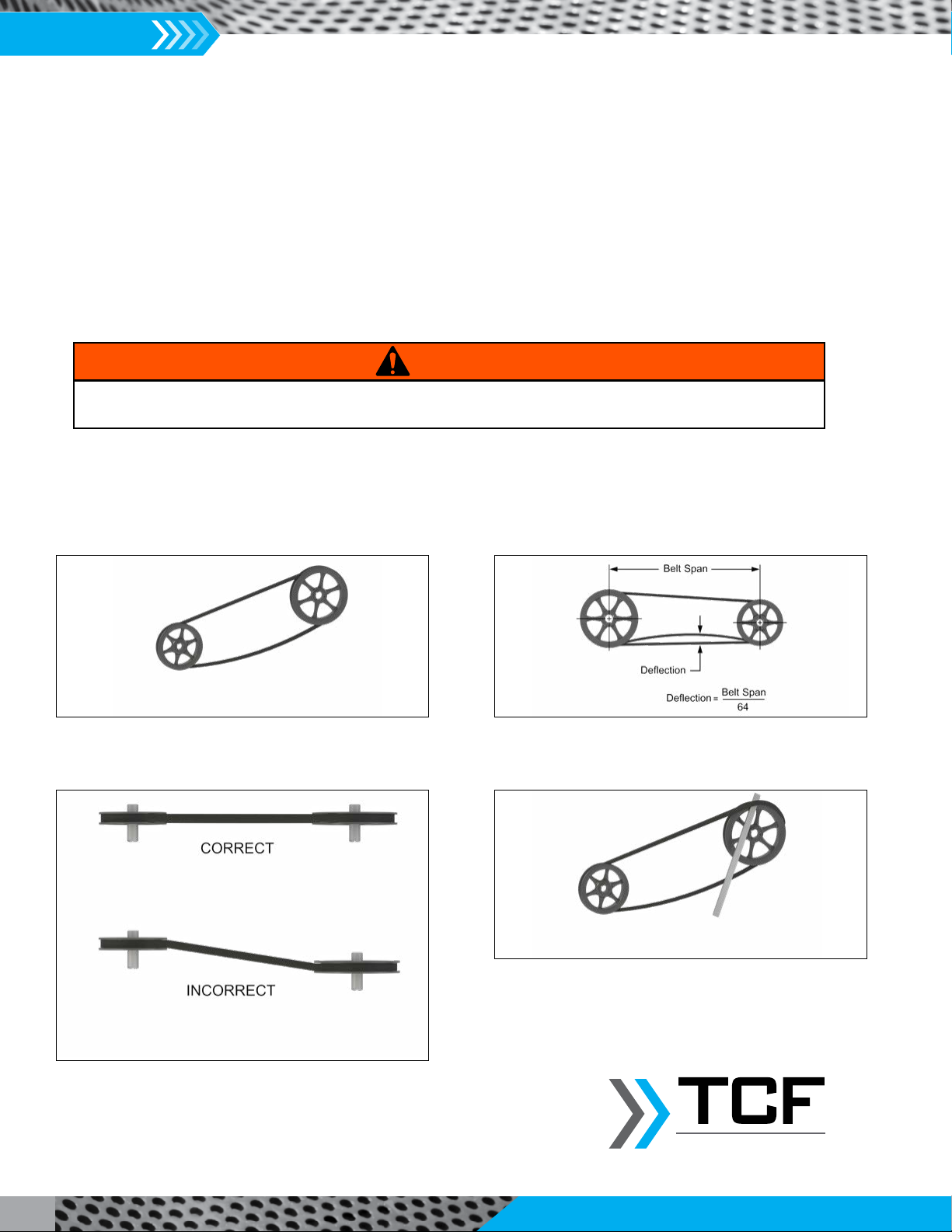

Figure 1. Eliminate Slack Figure 2. Belt Deflection

Figure 3. Alignment Figure 4. Belts

Slack belts wear excessively, cause slippage and deliver less power.

For longest belt life, always provide proper tension.

Mount belts straight. Shafts must be parallel and sheaves in

alignment to prevent unnecessary belt wear.

Do not force belt. Forcing the belt will break the cords and

cause belt failure.

V-Belts (refer to safety section)

V-belts on these belt driven fans are oil, heat and static resistant type and oversized for continuous-duty. With proper installation and

maintenance, years of operating efficiency can be added to the lifespan of the V-belt drive.

The condition of V-belts and the amount of belt tension should be checked prior to start-up (see Figure 1). When it becomes necessary

to adjust belt tension, do not over-tension as bearing damage will occur. Recommended belt tension should permit 1/64" deflection per

inch of span of the belt at the center of the belt span. To find this point, measure halfway between the pulley centerlines as shown in

Figure 2. Extreme care must be exercised when adjusting V-belts as not to misalign the pulleys. Any misalignment will cause a sharp

reduction in belt life and will also produce squeaky, annoying noises (see Figure 3).

1. Always loosen tension adjustment enough to place belts on sheaves without running belts over the edge of either sheave. A new

belt may be seriously damaged internally by careless handling (see Figure 4).

2. Fan speed can be increased by closing the adjustable motor pulley or decreased by opening it. Always check the load on the motor

when increasing the fan speed.

When removing or installing belts, never force belts over pulleys without loosening the idler pulley or auto belt tensioner first to

relieve belt tension.

WARNING

Twin City Fan

Installation, Operation & Maintenance Manual

IM-5500

13

Maintenance (refer to safety section)

Installation and maintenance are to be performed only by

qualified personnel who are familiar with local codes and

regulations and experienced with this type of equipment.

Preventive maintenance is the best way to avoid unnecessary

expense and inconvenience. Start-up and routine maintenance

should cover the following items:

a. Tighten all set screws, bolts and wire connections.

b. Cleaning of unit, impeller and damper (if present).

All motors containing ball bearings are permanently

lubricated from the factory. No additional maintenance is

required.

1. Before performing any maintenance on the fan, be sure power is turned off and locked in the OFF position at the service entrance.

2. Ventilators should be carefully checked at least once a year. For critical or rugged applications, a routine check every two or three

months is suggested.

3. All motors supplied with Twin City Fan & Blower ventilators carry a one-year limited warranty from date of shipment. For repairs

within the warranty period, the motor must be taken to the motor manufacturer’s authorized service dealer. Contact your

representative for additional warranty details.

4. A periodic motor check should consist of spinning the motor shaft with the power off to be sure the motor turns freely and the

bearings run smoothly.

5. The rotating impeller requires particular attention since materials in the air being handled can build up on the blades to cause

destructive vibration or weaken the structure of the impeller by corroding and/or eroding the blade metal. Regular inspection and

corrective action at intervals determined by the severity of each application are essential to good service life and safety.

Sharp edges and screws are a potential injury hazard. Avoid them.

CAUTION

Hazardous moving parts. Unit may contain protected fan motor

that may start automatically and cause injury. Allow time for

reset. Disconnect power before servicing.

WARNING

Twin City Fan

IM-5500

Installation, Operation & Maintenance Manual

14

Curb Hinge Installation

Parts Included

Curb Hinge

1/4-20 x 0.50" Lg Self-Tap Screw (Qty 8, 10 or 12)

Step 1: Align the holes on the curb hinge to the holes on the curb cap. This should be on the opposite side of the drain.

A. B.

Step 2: Insert provided screws to affix the hinge to the curb cap. Step 3: Place and install fan onto the roof curb.

Step 4: Properly align the fan with the roof curb. Pre-drill

holes for securing hardware.

Step 5: Fasten hinge to roof curb with customer provided

hardware.

Installation, Operation & Maintenance Manual

IM-5500

15

Security Hasp Installation

Parts Included

10-32 x 3/4", Bolt, Hex (4)

#10 , Star Washer (4)

#10 , Nut Hex (4)

Security Hasp, Hinged

Step 1: Drill (4) 0.19 holes on center curb cap from either

corner.

Step 2: Attach the hasp to the curb cap by using the included

#10 hardware.

Step 3: Drill (4) 0.19 holes on center of roof curb, 2" from

curb cap edge to top edge of staple. Step 4: Fasten staple with screws on roof curb.

Twin City Fan

Properly mated security hasp

IM-5500

Installation, Operation & Maintenance Manual

16

Retaining Chain Installation

Step 1: Drill two 1/4" diameter holes, one each corner of

curb base.

Step 2: Attach chain to outside of curb base with bolt head

on inside of curb base.

Step 3: Use one flat washer under bolt head and one on top

of chain.

Step 4: Use remaining fasteners to attach other end of chain

to anchor point.

Twin City Fan

Parts Included

Chain, 42" (2)

1/4-20 x 3/4" Bolt (4)

1/4-20 Nylon Hex Nut (4)

1/2" Washer (8)

Installation, Operation & Maintenance Manual

IM-5500

17

Firestat Installation

Step 1: Attach the bracket provided to the motor housing

support using the self-tapping screws that are fastened to the

support post.

Step 2: Drill holes and install firestat. Holes must be near a

support post. Note: The hole drilled in the motor housing must

be close to in line with the hole in the bracket provided.

Step 3: Cable tie sensing bulb to the nearest vertical support

post.

Step 4: Wire the firestat to the disconnect switch and motor.

IM-5500

Installation, Operation & Maintenance Manual

18

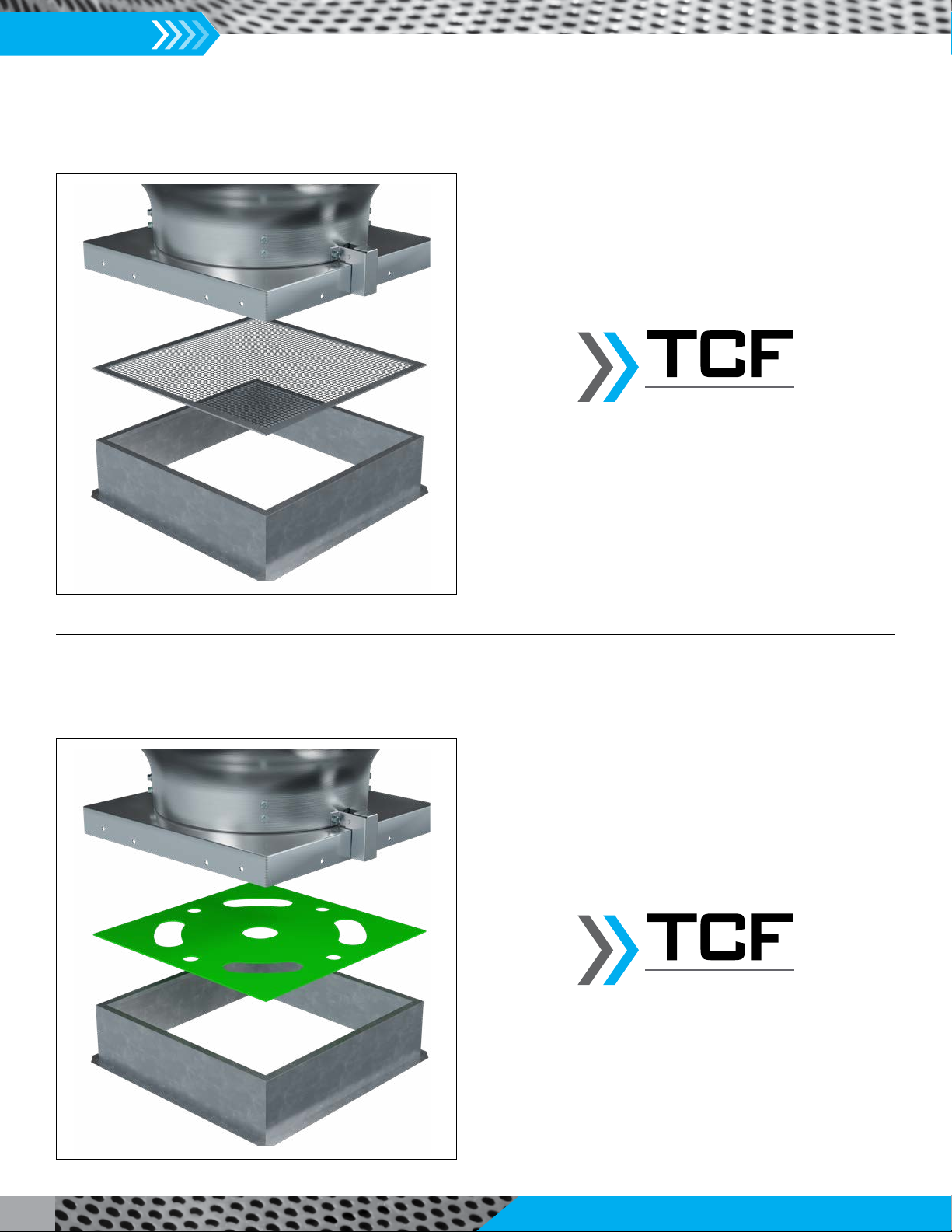

Insect Screen Installation

Step 1: Place the insect screen between the fan inlet and the roof or roof curb. Fasten with screws or nails, if desired.

Twin City Fan

Performance Baffle Installation

Step 1: Place the performance baffle between the fan inlet and the roof or roof curb. Fasten with screws or nails, if desired.

Twin City Fan

Installation, Operation & Maintenance Manual

IM-5500

19

Damper Installation

Step 1: Attach using sheet metal screws. (Roof curbs come with damper trays.)

Grease Box Installation

Step 1: Fasten the grease box to the curb cap under the drain, using supplied hardware.

Parts Included

Grease Box

Cover

Grease Pad

1/4-20 x 5/8" Lg Hex Bolt

1/4-20 Hex Nut

Washer, Flat, 1/4"

Twin City Fan

Twin City Fan

IM-5500

Installation, Operation & Maintenance Manual

20

Troubleshooting Guidelines

Use current safety practices when investigating fan or system

performance problems. General safe practices and performance

troubleshooting guidelines can be found in AMCA Publications

410 and 202, respectively. Fan application and field measurement

procedures can be found in AMCA Publications 201 and 203.

Below is a list of possible areas to check when air or sound values

do not match expectations. Most fan problems can be pinpointed

to one of these common causes.

Air Capacity Problems

1. Resistance of the system is not at design rating. If resistance is

lower than expected, both airflow and horsepower may be up.

If resistance is higher than anticipated, air volume will be down.

2. Fan speed is not at design speed.

3. Air density is not at the design value. Also check air performance

measurement techniques/procedures.

4. Devices for air modulation are closed or plugged. Also check

filters.

5. Impeller mounted improperly or is rotating in reverse.

6. Parts of the system or fan have been damaged or need cleaning.

Noise Problems

1. Air performance is incorrect and the fan is not at design point

of operation. Fan is being forced to operate in an unstable flow

region near peak or to the left of the peak of the curve.

2. Supply voltage high or inconsistent supply frequency. Adjustable

frequency controllers can generate motor noise.

3. Objects, including flow sensors, that are installed in a high

velocity airstream can generate noise.

4. Poor fan inlet conditions.

5. Acoustics or sound measurement procedure incorrect.

Vibration Problems

1. Poor foundation or mounting structure (resonances).

2. Foreign material attached to rotating components.

3. Damaged rotating components (bearings, shaft, fan, impeller,

sheaves).

4. Broken, loose or missing set screws.

5. Loose hardware.

6. Vibration transmitted by another source.

7. Fan is operating in stall or unstable flow region.

Motor Problems

1. Incorrect wiring.

2. Speed of fan too high.

3. Parts improperly installed; binding.

4. WR2capability of motor too low for application.

5. Protection devices may be improperly sized.

6. VFD compatible electrically? Effective shaft grounding?

7. Is cabling and grounding correct?

Vibration Guidelines

Condition

Fan

Applicaon

Category

Rigidly Mounted

mm/s (in./s)

Flexibly Mounted

mm/s (in./s)

Start-up

BV-3 6.4 (0.25) 8.8 (0.35)

BV-4 4.1 (0.16) 6.4 (0.25)

Alarm

BV-3 10.2 (0.40) 16.5 (0.65)

BV-4 6.4 (0.25) 10.2 (0.40)

Shutdown

BV-3 12.7 (0.50) 17.8 (0.70)

BV-4 10.2 (0.40) 15.2 (0.60)

Values shown are peak velocity, mm/s (inches/s), Filter out. Table taken from ANSI/AMCA

Standard 204-05, Table 6.3. AMCA defines BV-3 for applications up to 400 HP; BV-4 for

applications over 400 HP.

All fans manufactured by Twin City Fan & Blower are factory

balanced prior to shipment. Installation variables, handling and

movement of the fan during shipment may cause the rotating

assembly to shift. Balance should be checked once the fan is

installed. If a final trim balance is required, it is the end user's

responsibility to bring the fan back to factory specifications. Final

trim balancing is not the responsibility of Twin City Fan & Blower.

Refer to the Vibration Guidelines table below.

NOTICE

Twin City Fan

Table of contents

Popular Ventilation Hood manuals by other brands

Pkm

Pkm S7-60 ABTH instruction manual

NuTone

NuTone Elite EW4830SS Installation use and care manual

Hanseatic

Hanseatic SY-103A6-P1-C59-600 user manual

hestan

hestan KVI Installation use and care manual

KOBE

KOBE RA2230SQF Installation instructions and operation manual

ROBINHOOD

ROBINHOOD RHCV9G VETRO WALL installation instructions