3

Table of contents

Scope of delivery............................................................................................................ 4

Introduction.................................................................................................................... 4

Notes on this product information.................................................................................................................................4

Used symbols and warning notices ..............................................................................................................................4

Further used symbols and designations.......................................................................................................................4

Safety instructions......................................................................................................... 5

General safety regulations............................................................................................................................................5

Requirements to protect against lightning ....................................................................................................................5

Product description ....................................................................................................... 5

Intended use .................................................................................................................................................................5

Short description...........................................................................................................................................................6

Display and control elements........................................................................................................................................6

Device overview............................................................................................................................................................7

Tecnical data.................................................................................................................................................................8

Mounting and installation .............................................................................................. 8

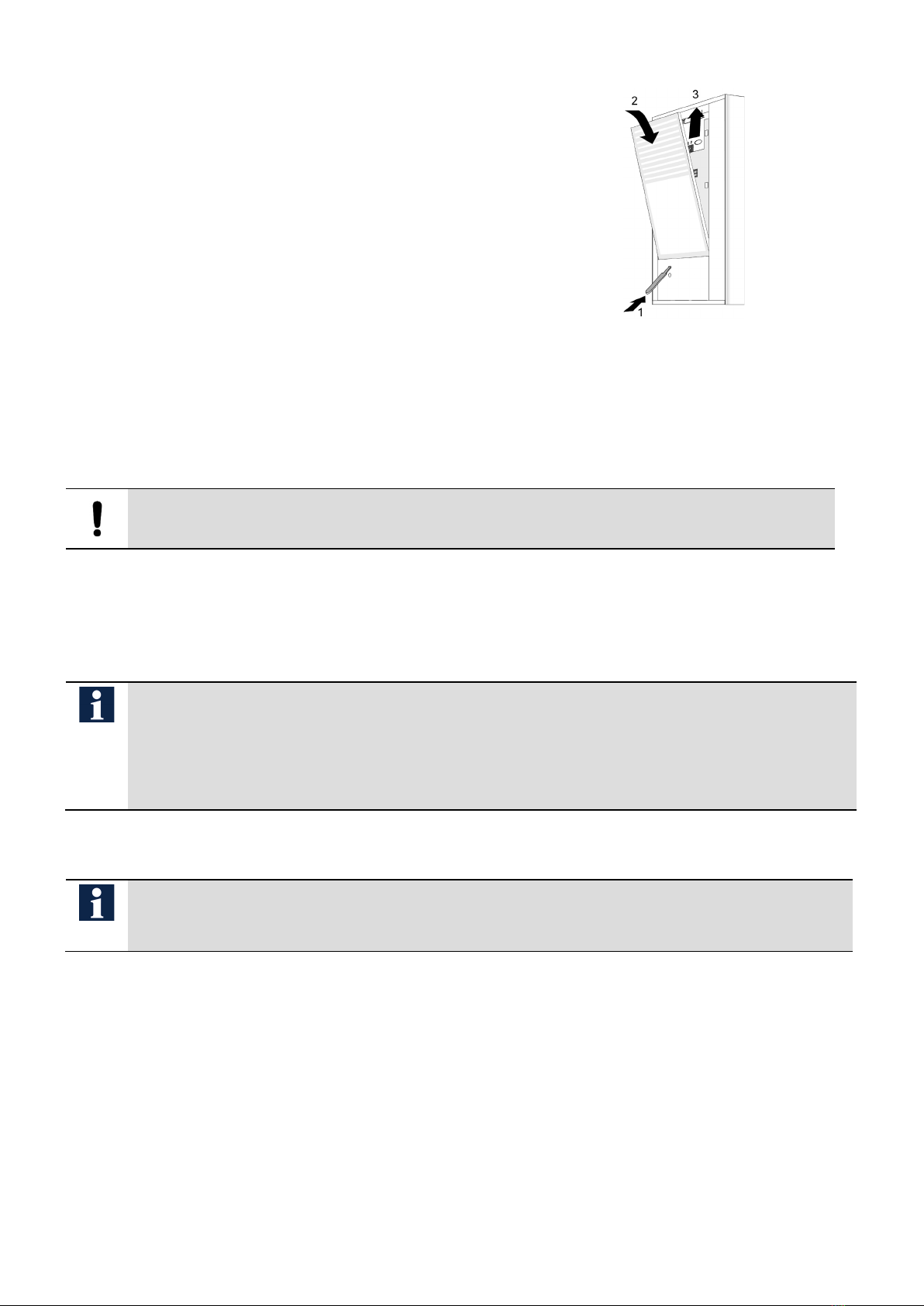

win:clipTM-System..........................................................................................................................................................8

Install the front door station ..........................................................................................................................................9

Connecting the lines .....................................................................................................................................................9

Example circuit 1: TCS:BUS with VBVS05.................................................................................................................10

Example circuit 2: installation with multiple transponder readers..............................................................................10

Example circuit 3: TCS:BUS with BVS20-SG.............................................................................................................11

Door opener in mixed installation ...............................................................................................................................11

Adapting the device ..................................................................................................... 11

Adapting the device ....................................................................................................................................................11

Activate infrared remote control..................................................................................................................................12

Initial operation............................................................................................................ 12

Error detection and indication .....................................................................................................................................12

Settings .......................................................................................................................................................................12

Configuration................................................................................................................ 13

Possible configurations...............................................................................................................................................13

Initial commissioning...................................................................................................................................................14

Legend ........................................................................................................................................................................14

Notices ........................................................................................................................................................................15

Programming with infrared remote control .................................................................................................................15

Programming with master transponder ......................................................................................................................23

Label info sign.............................................................................................................. 26

Operation...................................................................................................................... 26

Infrared remote control change batteries................................................................... 27

Cleaning........................................................................................................................ 27

Conformity .................................................................................................................... 27

Information on disposal ............................................................................................... 27

Warranty ....................................................................................................................... 28

Spare parts, accessory ................................................................................................ 28

Service.......................................................................................................................... 28