TCT WebSaw User manual

TCT WebSaw

Starting the Websaw

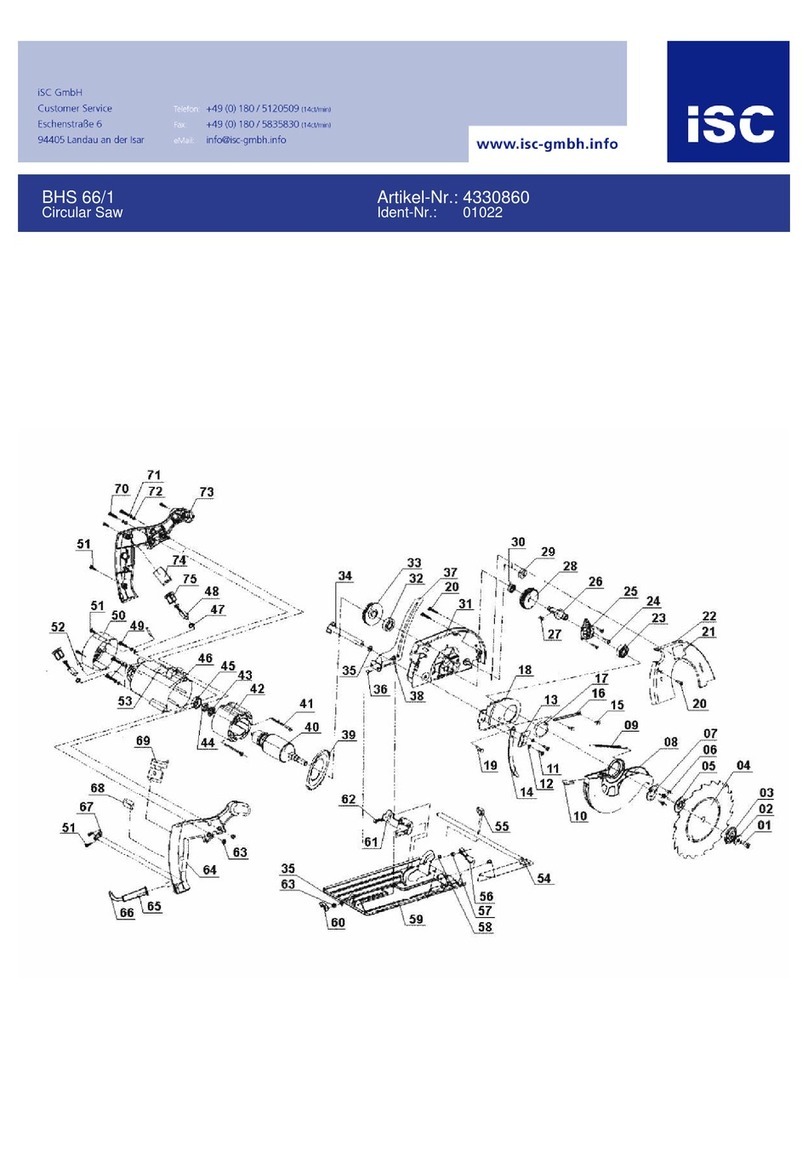

Bleed water from the regulator and check that the oil reservoir has oil.

Check that you have operational air pressure on your regulator. The normal operational range for the

saw is 60 to 80 PSI.

Check that the air filter is clean.

Switch on the main power disconnect (make sure both switches are turned on).

Wait for computer to boot up and open the Websaw software (located on desktop called “Websaw”).

Water

Bleed

Water

Bleed

Air PressureAir Pressure Air Pressure

Adjustment

Air Pressure

Adjustment

OilOil

PC Power

Disconnect

PC Power

Disconnect Websaw DisconectWebsaw Disconect

Check FilterCheck Filter

Page 1 Starting the Websaw

Operating the Websaw

Check that the “Emergency Stop”button is not engaged.

Turn the power on by pressing the green “Power” button.

Turn the “Conveyor” switch to “On”.

Home the saw blade using the “Home Blade” button.

Place your floppy disk into the disk drive and press the “Copy To” button to load the job.

Click “Load AFile” and select the job that you want to cut (note you can only cut from a file

located on the local hard drive).

Start the blade by pressing the “Blade Start” button and wait for blade to fully spin up.

Go into cycle by pressing the “Cycle Start” button.

Once the “Ready” window appears feed wood into the machine.

Note never restart the saw motor until the motor has fully stopped.

PowerPower

Press Blade Start

and wait 20 seconds

for blade to spin up.

Press Blade Start

and wait 20 seconds

for blade to spin up.

Then press Cycle StartThen press Cycle Start

ConveyorConveyor

Emergency StopEmergency Stop Confirm that the power

light comes on in Websaw

Confirm that the power

light comes on in Websaw

Page 2 Operating the Websaw

Websaw Overview

Feed rollers

Infeed and outfeed rollers are used to move wood through the Websaw.

It is important they have firm tension on the wood and if needed tension pressure can be adjusted.

Proximity photo sensor (M120)

The proximity photo sensor (or eye) is used to detect a board entering the Websaw. Once it detects

the board the proximity sensor triggers the Websaw software to start “autocycle”. The photo sensor

sensitivity is fully adjustable with a small screwdriver.

Vertical limit sensors (Up M54 down M53)

The saw carriage has two proximity sensors for determining the location of the saw head.

If the saw carriage is up the top proximity sensor is tripped and the Websaw software will show this

on the front screen as “Saw Carriage Up”. Conversely if the saw carriage is down the proximity

switch will be trigged causing Websaw software to indicate “Saw Carriage Down”. The only other

position the Websaw software will read is “Saw Carriage Middle” when neither of the proximity

switches are triggered.

OutfeedOutfeed

InfeedInfeed

Top ProxTop Prox

Bottom

Prox

Bottom

Prox

Page 3 Websaw Overview

Pivot head angle and limit switches

Three pivot head switches control the pivot home position, and over rotation protection.

Homing proximity switch (M322)

When the saw head homes it looks for a known location by using the homing proximity switch. Note

that if this switch moves your 90 degree angles will be off according to the amount the proximity

switch moved. Make sure it stays tight!

Overtravel proximity switch (M321)

If the saw head starts to over rotate this switch will stop the software from going beyond the saws

operational range.

Mechanical overtravel switch (M12)

When all else fails this switch will stop the saw from over rotating by bypassing the software as a

last resort.

Motion Control

The TCT Websaw has two computers used for controlling the saw. One computer is a standard

PC running Microsoft Windows 98. In addition to this a second computer called a “PMAC”

controller is located inside the PC. PMAC is a 16bit computer running a real time OS for all

motion control.

Mechanical

Overtravel

Mechanical

Overtravel

Overtravel ProxOvertravel Prox

Homing ProxHoming Prox

Standard PCStandard PC

PMAC motion

control card

PMAC motion

control card

Page 4 Websaw Overview

Printer

The Websaw uses a Matthews Jet A Mark ©printer for printing on each board. The printer consists

of a three parts. The pump, control unit, and print head.

Note that the LCD readout must be set to “00”. If you press the “text” button and the LCD screen

reads anything other then “00” keep pressing the “text” button until the LCD is back on “00”.

Note the print head must be cleaned at least daily and if the printer is being shutdown for 2 or more

days the line must be bleed with cleaner fluid (see “Printer” page 13 for more details).

Air pumpAir pump

Power switchPower switch

Text ButtonText Button

Flush ButtonFlush Button

LCD ReadoutLCD Readout

Printer control unitPrinter control unit

Print HeadPrint Head

Ink supply

line

Ink supply

line

Bleed ValveBleed Valve

Page 5 Websaw Overview

Websaw Software

The Websaw software is a Windows application that provides an interface for the operator of the

Websaw. When upgrading the Websaw software both the PMAC microcode and Websaw software

must be kept up to latest versions (see software upgrade for additional details).

The above operator screen allows for quick and easy operation of the Websaw.

Within the Websaw software under “Input / Output” you can view what PMAC PLCs that are

running and check the status of various sensors. This screen is primarily used to troubleshoot

problems. For an complete explanation of each option see “Websaw Software”.

Indicates if power

has been turned on

Indicates if power

has been turned on

Pieces per hour

baseline

Pieces per hour

baseline

Front and

backside offset

Front and

backside offset blade

width

blade

width Current

saw angle

Current

saw angle

Jog wood

control

Jog wood

control

Set lumber

length

Set lumber

length

Used daily to calibrate

web length

Used daily to calibrate

web length

Select scrap to cut

one web out of board

Select scrap to cut

one web out of board

Select number

of times to cut job

Select number

of times to cut job

Indicates

pieces cut

Indicates

pieces cut

Web lengthWeb length

Home blade

button

Home blade

button

Door unlockDoor unlock

Realtime

saw status

Realtime

saw status

Indicates

current job

Indicates

current job

Current line

selected

Current line

selected

Indicates last cut

web and truss name

Indicates last cut

web and truss name Loads a

file to cut

Loads a

file to cut Printer previewPrinter preview Exit Websaw

button

Exit Websaw

button Indicates if something has

caused E-Stop condition

Indicates if something has

caused E-Stop condition

Page 6 Websaw Overview

The “Motor Data” screen allows for quickly checking that each motor is responding and has not

jammed.

From within the “Cycle Status” screen all the software settings for the Websaw are easily calibrated.

See “Calibrating the Websaw” for additional details.

For additional details on the Websaw software see “Websaw software”.

Printer optionsPrinter options

Allows logging per

user or per day

Allows logging per

user or per day Adds small factor

to any length board

Adds small factor

to any length board Master scale to

set board length

Master scale to

set board length How much the board

is cleaned up on the

first cut

How much the board

is cleaned up on the

first cut

Angle adjustment for

angles + or - 90

Angle adjustment for

angles + or - 90

Rotates blade

for cleaning

Rotates blade

for cleaning

Set blade on 90Set blade on 90

Page 7 Websaw Overview

Websaw Maintenance

Feed Rollers

The Websaw feed rollers must be at least cleaned daily to allow for reliable traction on lumber. We

recommend using a steel brush with denatured alcohol for best results.

Print head cleaning

Remove the print head and using a small brush gently wipe away any ink and saw dust build up on

the print head. Dip your brush into the supplied Matthew’s thinner solution to help remove the gum

build up. Note if the printer is shutdown for two or more days it is necessary to bleed the line of ink.

See “Printer” page 13 for more details.

Air Pressure

Adjust air pressure to 80PSI. If “banging” occurs reduce air pressure. Air pressure operational range

is from 60 to 80 PSI and must not deviate more then 10 PSI while running. Note the minium

recommended air hose is 3/4 of an inch.

Keep dirt from building up

in the bottom of the valley

Keep dirt from building up

in the bottom of the valley

Clean with soft brush dailyClean with soft brush daily

Air PressureAir Pressure

Air Pressure

Adjustment

Air Pressure

Adjustment

Page 8 Maintenance

1-1/4”1-1/4”

Pneumatics

Keep oil reservoir supplied with approved pneumatic oil. Adjust pneumatic oil flow to last

between 2-3 weeks.

Roller Conveyor

Maintain 1-1/4 inch parallel adjustment between the feed rollers and the conveyor. This is an

average figure and may need to differ depending on your wood thickness. Adjust as necessary to

maintain positive traction at all times on lumber. Typically maintain slightly more traction on the

infeed side then the outfeed side.

Saw Motor

Grease approximately every 500 hours being carful not to over grease. The saw blade nut is right

hand thread. Make sure and only used approved wrench when tightening and apply a light amount of

oil to threads before tightening.

Oil Flow

Control

Oil Flow

Control

Grease NipplesGrease Nipples

OilOil

Adjust as

necessary

Adjust as

necessary

Page 9 Maintenance

Pivot Head

Check for oil leakage on worm gear. Check prox switches for tightness and maintain 1/16”

gap. Using a light silicon lube mechanical overtravel switch.

Pillow Blocks

Once per month lightly grease each pillow block being carful not to over grease.

Bolts

Check for any lose bolds and tighten as necessary. Keep a close eye on the spider couplings and

pivot head prox switches.

Electrical

Check that all panel doors are tight and that ventilation fan and filter are clean and working. Check

all conduit for tightness and chaffing. Note any lose wire should be routed and tied back to minimize

damage.

Worm Gear

(check for oil leaks)

Worm Gear

(check for oil leaks)

Grease NipplesGrease Nipples

Overtravel

(check and lube)

Overtravel

(check and lube)

1/16”1/16”

Check tightnessCheck tightness

Check FilterCheck Filter

Page 10 Maintenance

Door Lock

Clean door lock daily by blowing off any saw dust buildup. Keep door lock clean and lubricate with

a light dry silicon.If the door lock sticks you can remove the side cover and lightly lubricate the

plunger and all moving parts.

Every 6 months or as required take apart the door lock as indicated below. Clean and lube as needed.

Keep CleanKeep Clean

Lightly lubricateLightly lubricate

Remove ScrewsRemove Screws

Gently pry apartGently pry apart

Clean and lighty lubricateClean and lighty lubricate

ReassembleReassemble

Key (used to open door with no power)Key (used to open door with no power)

Page 11 Maintenance

Proximity photo sensor

The proximity photo sensor (or eye) is affected by the ambient light and as such may need to be

adjusted. Most common cause of needing adjustment is when a board is placed into the websaw and

the websaw does not see the board or when the websaw keeps cutting air even when no wood is in

the saw. Note the eye will not see black and may have trouble seeing dark colors.

The focal distance determines how sensitive the eye is to seeing wood. The longer the focal distance

the more sensitive.

The “on” indicator light should come on at about 4 inches from the eye. However if you are finding

that the eye is to sensitive or not sensitive enough adjust as needed as your lighting conditions will

affect the actual focal distance.

Make very small adjustments at a time with the set screw and then test.

Remove bolts to access

photo sensor

Remove bolts to access

photo sensor

Move a white object towards the eye

until the “on” indicator light comes on

Move a white object towards the eye

until the “on” indicator light comes on

Carefully adjust the set screw

to adjust the focal distance.

Carefully adjust the set screw

to adjust the focal distance.

Page 12 Maintenance

Printer

The Websaw uses a Matthews Jet A Mark ©printer for printing on each board. The printer consists

of a three parts. The pump, control unit, and print head.

Note that the LCD readout must be set to “00”. If you press the “text” button and the LCD screen

reads anything other then “00” keep pressing the “text” button until the LCD is back on “00”.

Note the print head must be cleaned at least daily and if the printer is being shutdown for 2 or more

days the line must be bleed with cleaner fluid (see Printer for more details).

Air pumpAir pump

Power switchPower switch

Text ButtonText Button

Flush ButtonFlush Button

LCD ReadoutLCD Readout

Printer control unitPrinter control unit

Print HeadPrint Head

Adjustable

Bracket

Adjustable

Bracket

Ink supply

line

Ink supply

line Signal from

Control Unit

Signal from

Control Unit

Bleed ValveBleed Valve

Page 13 Printer

Configuring the Printer

1. Plug in the printer while holding down the “Text” button. Keep holding the text button down until

the LCD reads “88”. From this point on use the “Text button to change fields and the “Flush” button

to view the field. Confirm the following settings.

F7=B2

F8=D3

FA=01

FC=H1

Holding down the “Flush” button use the “Text” button to change the printer settings as needed.

2. From the computer desktop open “Printer1” icon. Note make sure Websaw is not running while

configuring the printer.

Confirm your Hyper Terminal settings as in photos above.

Text ButtonText Button

Flush ButtonFlush Button

PlugPlug

LCD ReadoutLCD Readout

Hyper Terminal SettingsHyper Terminal Settings

Page 14 Printer

3. Within the “Hyper Terminal” window make sure your caps lock is always turned on. Press the

“Escape” key and then one of the following values. Note never use number pad to type in numbers.

M1= (Print Direction)

PS=4000 to 4500 (Print Speed, higher number reduces letter spacing)

D1=30 to 40 (Print Delay, higher number reduces first letter crunching)

DS=600 to 900 (Dot Size, will vary depending on air pressure)

Then press the “Enter” key twice. The current value will appear on the screen.

To change a value press “Escape” key followed by value (DS) then “:” then what number you want

to change it to. Note you will not be able to see what you type so make sure and be carful not to make

any typing mistakes. Example “Esc key” DS:800 “Enter twice”. If you typed everything correctly the

screen will display DS=800.

Note make sure you close out of “Hyper Terminal” before you go back into Websaw.

4. From within Websaw chose the printing options that you would like to have printed on the board

by turning the desired switch.

Note from the main screen in Websaw you can preview what will be printed.

5.Adjust the print head location in or out from outfeed roller. The further the print head is away from

the outfeed roller the better it will print on longer boards. Likewise the closer it is to the outfeed

roller the better it will print on small boards. Adjust until a happy medium is found.

Printer PreviewPrinter Preview

Prints filename

on each board

Prints filename

on each board

Allows you to print

same thing on each board

Allows you to print

same thing on each board

Adjust as NecessaryAdjust as Necessary

Maintain ½ inch

clearance

Maintain ½ inch

clearance

Page 15 Printer

Printer Cleaning

The print head must be cleaned at least daily and the print hose and print head must be flushed

anytime the printer is shutdown for 2 or more days.

Cleaning the Print Head

Open the Websaw door and remove the print head. Using a soft brush dip the brush in the Matthews

cleaning solution and gently wipe away the built up grime. Keep washing away the dirt until the head

once again looks shiny.

Flushing the Print Head

Disconnect the ink and connect the cleaning fluid up to the printer. Bleed the ink line until cleaning

fluid comes out of the line.

Press the “Flush” button until cleaning fluid comes out of the print head jets.

With both the head clean and the line bleed with cleaning fluid it is now safe to leave your printer

unused over the weekend.

Note never blow compressed air into the print head as damage will occur (minium repair cost is

$500).

Flush ButtonFlush Button

Connect Cleaning SolutionConnect Cleaning Solution

Flush LineFlush Line Flush Print HeadFlush Print Head

Page 16 Printer

Websaw Software

Websaw software consists of two components. The Windows executable “websaw.exe” and the

PMAC microcode that runs on the PMAC motion controller.

Websaw

Websaw is a 32bit Windows application designed to give the Websaw operator an easy to use

intuitive interface.

Input / Output screen provides realtime sensor readings.

Indicates if power

has been turned on

Indicates if power

has been turned on

Pieces per hour

baseline

Pieces per hour

baseline

Front and

backside offset

Front and

backside offset

Realtime kurf

calculation

Realtime kurf

calculation

Reminder to home

blade when first started

Reminder to home

blade when first started

blade

width

blade

width Current

saw angle

Current

saw angle

Jog wood

control

Jog wood

control

Set lumber

length

Set lumber

length

Used daily to calibrate

web length

Used daily to calibrate

web length

Select scrap to cut

one web out of board

Select scrap to cut

one web out of board

Select number

of times to cut job

Select number

of times to cut job

Indicates

pieces cut

Indicates

pieces cut

Web lengthWeb length

Home blade

button

Home blade

button

Door unlockDoor unlock

Realtime

saw status

Realtime

saw status

Indicates

current job

Indicates

current job

Current line

selected

Current line

selected

Indicates last cut

web and truss name

Indicates last cut

web and truss name Loads a

file to cut

Loads a

file to cut Printer previewPrinter preview Exit Websaw

button

Exit Websaw

button Indicates if something has

caused E-Stop condition

Indicates if something has

caused E-Stop condition

Page 17 Websaw Software

Door lock open or closedDoor lock open or closed

Sends 24VDC to relay switcheSends 24VDC to relay switche

Sends 24VDC to pneumatic switch to drop bladeSends 24VDC to pneumatic switch to drop blade

Sends 24VDC to saw cabinet door lock to unlockSends 24VDC to saw cabinet door lock to unlock

Sends power to AC-Tech relaySends power to AC-Tech relay

Triggers AC-Tech saw motor relayTriggers AC-Tech saw motor relay

Sends 24VDC to outfeed pneumatic switch (clamp)Sends 24VDC to outfeed pneumatic switch (clamp)

Sends 24VDC to outfeed pneumatic switch (unclamp)Sends 24VDC to outfeed pneumatic switch (unclamp)

Sends 24VDC to infeed pneumatic switch (clamp)Sends 24VDC to infeed pneumatic switch (clamp)

Sends 24VDC to infeed pneumatic switch (unclamp)Sends 24VDC to infeed pneumatic switch (unclamp)

White I/O ModulesWhite I/O Modules

Red I/O ModulesRed I/O Modules

Signal to PMAC that “eye” sees a boardSignal to PMAC that “eye” sees a board

Not usedNot used

Not usedNot used

Sends signal from upper prox to PMACSends signal from upper prox to PMAC

Sends signal from lower prox to PMACSends signal from lower prox to PMAC

Signal to PMAC to start saw motorSignal to PMAC to start saw motor

MC relay has powerMC relay has power

Sends signal to PMAC to Start AutocycleSends signal to PMAC to Start Autocycle

Sends signal to PMAC to Stop CycleSends signal to PMAC to Stop Cycle

Indicates saw motor not turningIndicates saw motor not turning

AT relay has powerAT relay has power

ES relay has powerES relay has power

Saw head past 15/165 degreesSaw head past 15/165 degrees

Page 18 Websaw Software

PLCs are extremely fast running mini programs of code that run on the PMAC motion controller.

They control anything time critical and start and stop the servo motion on the Websaw. Most of the

time you won’t be able to see any PLCs running except 3, 5, 6, 7, 8, and 9. The other PLCs do turn

on and off as required however most of the time they run to fast to actually see.

Note if the above PLCs 3,5,6,7,8, and 9 are not running restart the machine. If they still do not

appear to run reload the PMAC configuration.

Motor data screen provides an easy to read screen for troubleshooting servo related issues and

general servo information.

Main PLC that calls other PLC and then shuts itself offMain PLC that calls other PLC and then shuts itself off

Jogs #1 and #2 motor outwardsJogs #1 and #2 motor outwards

Jogs #1 and #2 motor inwardsJogs #1 and #2 motor inwards

Not usedNot used

Not usedNot used

Not used...no longer calculated in PMACNot used...no longer calculated in PMAC

Causes #3 motor to home looking for “ homing prox” switch then returns to 90Causes #3 motor to home looking for “ homing prox” switch then returns to 90

Board present flagBoard present flag

Monitor wood presentMonitor wood present

Enable front panel “Blade Start” and “Cycle Start” for scrollingEnable front panel “Blade Start” and “Cycle Start” for scrolling

Monitors front panel “Cycle Start” and “Cycle Stop” buttons starting PLC1 or PLC2Monitors front panel “Cycle Start” and “Cycle Stop” buttons starting PLC1 or PLC2

Monitors front panel “Blade Start” and “Cycle Start” and scrolls screen as requestedMonitors front panel “Blade Start” and “Cycle Start” and scrolls screen as requested

Monitors blade moving and allows PLC4 to run if blade is stoppedMonitors blade moving and allows PLC4 to run if blade is stopped

Opens door and waits set time to lock againOpens door and waits set time to lock again

Monitors E-Stop relay and runs PLC2 if relay loses powerMonitors E-Stop relay and runs PLC2 if relay loses power

Kills infeed roller home sequence and calls motion controlKills infeed roller home sequence and calls motion control

Stops everything and unclampsStops everything and unclamps

Page 19 Websaw Software

Table of contents