Powercraft 3

7. Use right tool

Don’t force small tools or attachments to do the job

of heavy duty tool. Don’t use tools for purposes not

intended.

8. Dress properly

Do not wear loose clothing or jewelry. They can be

caught in moving parts. Rubber gloves and nonskid

footwear are recommended when working out-

doors. Wear protective hair covering to contain long

hair.

9. Use safety glasses

Also use face or dust mask if cutting operation is

dusty.

10.Don’t abuse cord

Never carry tool by cord or yank it to disconnect it

from receptacle. Keep cord from heat, oil and sharp

edges.

11.Secure work

Use clamps or a vise to hold work. It’s safer than using

your hand and it frees both hands to operate tool.

12.Don’t overreach

Keep proper footing and balance at all times.

13.Maintain tools with care

Keep tools sharp and clean for better and safer per-

formance. Follow instructions for lubricating and

changing accessories. Inspect tool cords periodically

and, if damaged, have repaired by authorized service

facility. Inspect extension cords periodically and

replace if damaged. Keep handles dry, clean and free

from oil and grease.

14.Disconnect tools

When not in use, before servicing, and when chan-

ging accessories such as blades, bits and cutters.

15.Remove adjusting keys and wrenches

Form the habit of checking to see that keys and adjus-

ting wrenches are removed from tool before turning

it on.

16.Avoid unintentional starting

Don’t carry plugged-in tools with finger on switch. Be

sure switch is off when plugging in.

17.Outdoor use extension cords

When tool is used outdoors, use only extension

cords intended for use outdoors and so marked.

18.Stay alert

Watch what you are doing. Use common sense. Do

not operate tool when you are tired.

19.Check damaged parts

Before further use of the tool, a guard or other part

that is damaged should be carefully checked to deter-

mine that it will operate properly and perform its

intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect its

operation. A guard or other part that is damaged

should be properly repaired or replaced by an autho-

rized service center unless otherwise indicated

elsewhere in this instructions manual. Have defective

switches replaced by an authorized center. Do not

use tool if switch does not turn it on and off.

20.Warning

The use of any other accessory or attachment other

than recommended in this operation instructions or

the catalog may present a risk of personal injury.

21.Have your tool repaired by an expert

This electric appliance is in accordance with the rele-

vant safety rules repairing of electric apliances may be

carried out only by experts otherwise it may cause

considerable danger for the user.

22.Connect the dust extraction device

Whenever there are facilities for fitting a dust extrac-

tion system, make sure it is connected and used.

BEFORE EACH USE

1. Check the cutting-off machine. If any part of the cut-

ting-off machine is missing, bent or unusable in anot-

her way, or if electrical faults occur, switch off the

machine and remove the plug from the socket.

Replace all missing, damaged or faulty parts, before

using the machine again.

2. Make sure that hands, eyes, face and ears are well

protected.

•Use of safety goggles without the CE quality mark can

lead to serious injury if the glass breaks.

•In order to prevent the saw blade from becoming

jammed in the saw cut and workpieces being flung

away, the instructions below must be followed:

•Choose a suitable saw blade for the work.

Only use the cutting-off machine to saw wood

and derived products, or light metals such as alu-

minium. Other materials can be flung away, get

caught in the saw blade or cause other dangers.

•The arrow on the saw blade, which indicates the

direction of rotation, must point in the same

direction as the arrow placed on the machine.

The saw blade teeth must point downwards on

the front of the saw.

•Check whether the saw blade is sharp, undama-

ged and well aligned. Press the saw head down-

wards after removing the plug.

Turn the saw blade by hand and see whether it

turns freely. Put the machine in the 45° position

and repeat the test. If the saw blade touches any-

where, it must be adjusted again.

•Keep the saw blade and the tensioning surfaces of

the clamps clean.

•The saw blade flange must always be mounted

with the tightened recess towards the saw blade.

•The flange screw must be tightened with a 13 mm

open-end wrench.

•Check whether all the tensioning devices and

interlocks are secure and that no single part

shows too great a clearance.

•Never use just your hands for sawing.

•Always secure the workpiece against the check,

so that it cannot topple or turn during sawing. No

impurities may be allowed to gather under the

workpiece.

•Make sure that the workpiece cannot move after

being sawn through, for example, because it is not

supported by the full surface.

•For sawing workpieces which are not being sup-

ported by the full surface, use fillings or another

machine.

•Check whether the sawn off pieces can be removed

laterally from the saw blade. Otherwise they can be

caught by the saw blade and flung away.

•Never saw several workpieces at the same time.

10 Powercraft

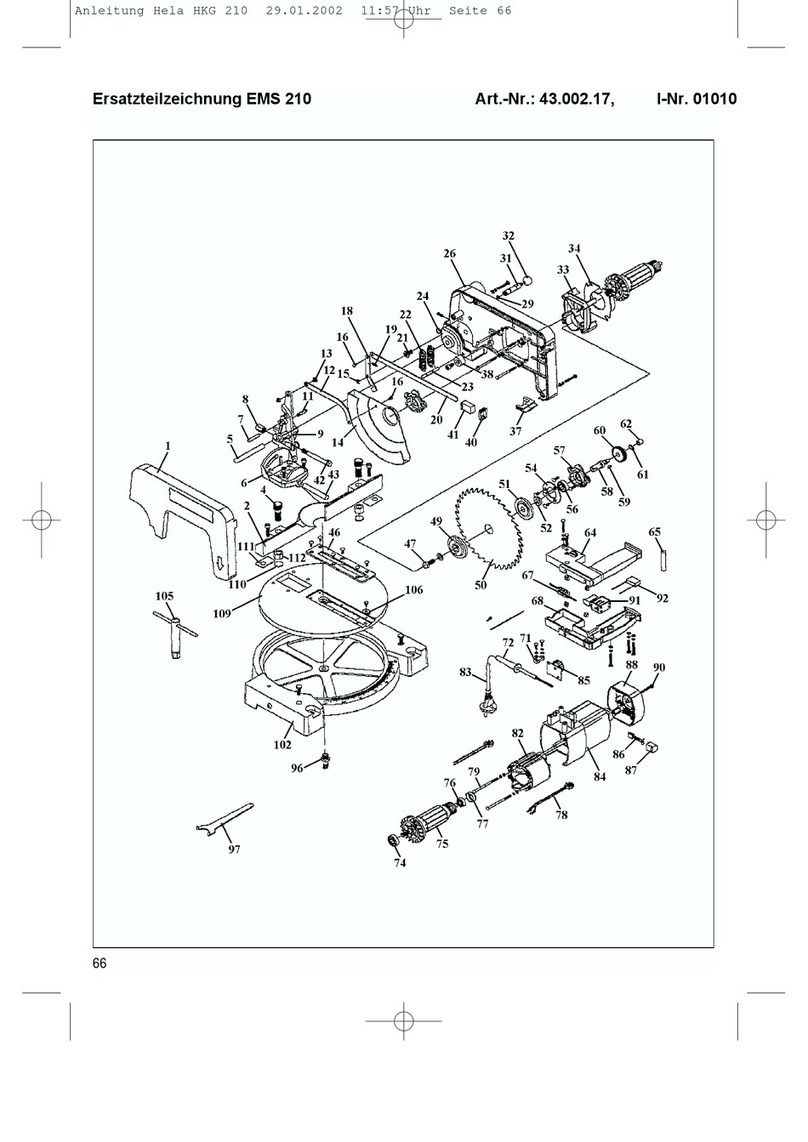

SPARE PARTS LIST PKZ-210

REF NR DESCRIPTION POWERCRAFT NR

3 SPRING 407573

53 GEAR WHEEL 407574

46 POSITIONING RING 407575

45 CLAMP RING 407576

65 ROTOR-ASSEMBLEY 407577

72 STATOR ASSEMBLY 407578

97 CARBON BRUSH 407579

104 BRUSH HOLDER 407581

89 CAPACITOR 407582

90 SWITCH 407583

SAW BLADE TCT/Z-24 210 X 18 MM.

EANNR. 87. 11425.70103.9 327208

SAW BLADE TCT/Z-40 210 X 18 MM.

EANNR. 87. 11425.70104.6 327209