TCW IBBS-12v-2ah User manual

REV 2.3 © 2012 TCW Technologies, LLC.

1

Integrated Back-up Battery System

Model: IBBS-12v-2ah

The Integrated Back-up Battery System, is an electronic system that combines a

Ni mh battery pack, a charger and switching logic in one convenient package. The

back up battery system has been engineered for use as a source of back up power

for single instrument applications. This unit may also be used to provide back up

power for electronic ignition systems utilized on 4 cylinder and smaller applications.

Integral to the IBBS is a nickel metal hydride battery pack and a matched charging

system to ensure the battery is properly charged and maintained. The system also

includes switching circuitry to provide a stable source of output power during normal

and emergency operations. The IBBS system also provides an output signal to

communicate the operating state of the back up bus as well as the state of the

battery.

The IBBS system connects to the standard aircraft power bus and provides an

output directly to the avionics requiring back up power. The IBBS has a pass through

power feature allowing it to provide normal as well as back up power to connected

equipment. Additionally, the IBBS system provides surge and sag protection for

connected equipment, allowing operation of critical equipment during engine starting.

No other uses of the IBBS system are permitted except for those identified in this

installation manual.

IBBS must be installed using the current aircraft standards and practices as shown

in AC 43.13 2A/1B. The installer/builder is solely responsible for determining the

suitability of the installation and use of this product.

REV 2.3 © 2012 TCW Technologies, LLC.

2

Installation Instructions:

1. IMPORTANT NOTE:

Consult the attached wiring diagrams to identify wiring connections for your

particular installation. The IBBS system may be fed from a bus that remains active

during engine starting, such as the master bus or it may be fed from an avionics

bus that is switched off during engine starting. If you want your avionics to be up

and running during engine cranking, ensure input power is derived from the master

bus.

2. The IBBS 12v 2ah was designed to drive one piece of equipment, such as an EFIS,

Autopilot or an electronics ignition module. The output current limit for this model is

3 amps maximum continuous current. If more load current is required use model

IBBS 12v 4ah. Consult the install manual for detailed specifications.

3. Mount the IBBS in a suitable location in the aircraft. Ensure the mounting points and

fasteners are suitable for the weight of the product, consult the specifications for

details. The IBBS must be mounted inside the aircraft, do not mount the IBBS in the

firewall forward area. Avoid mounting the IBBS unit up under the instrument panel

where significant heat may be trapped. Select an area that is accessible to allow for

future battery servicing. The operating temperature range of the system is 10 C° to

60 C° and the effective charging temperature range is 0 C° to 40 C°. Select an

installation location that will comply with these requirements.

4. Connect the aircraft wiring according to one of the wiring diagrams shown.

The IBBS must be powered through a properly sized circuit breaker or fuse.

ENSURE the proper size wire is utilized for the input feed, output supply and ground

connection. The IBBS has two power inputs, pin1 provides main recharge current

and main bus sensing, pin 6 provides pass through power from the main bus to the

connected load during normal operation. Connect the two input wires together at the

fuse or circuit breaker as shown in the diagrams. The IBBS 12v 2ah has three

output pins, pin 7,8,9, that provide power to the connected load. These three wires

may be paralleled together for added redundancy. The output wires of the IBBS

system are internally protected with a single 8 amp, 5 x 20 mm fuse. No additional

external fusing is required; however, use at least 20 awg wire for the output wires.

5. The Back up Power Master switch must be utilized to turn the back up battery

system off when not in use, except for installations utilizing ASF EFIS systems and

following the specific wiring diagram for this application. This switch gives the pilot

the ability to turn the back up battery system off. In some installations this may be

the only means to shut down the connected equipment.

6. Complete the installation of the wiring harness and connector prior to attaching the

connector to the IBBS product. This is essential to ensure the wires do not

inadvertently short together during installation. Remember, the IBBS pack is a

REV 2.3 © 2012 TCW Technologies, LLC.

3

back up source of power and is ready to deliver output power even when the aircraft

electrical system is in the off state.

7. When using the IBBS product to provide back up power to an electronic ignition

system it MUST be used to back up one and only one electronic ignition module. Do

not use one IBBS to back up both electronic ignition modules in a dual electronic

ignition system. Follow the wiring diagram for installation with electronic ignition

module; Note, the system connections directly to aircraft battery must be utilized as

shown.

8. When using the IBBS product to provide back up power to an electronic ignition

system (CDI), pullable circuit breakers must be used for over current protection as

shown on page 17.

9. When using the IBBS product to provide back up power to an electronic ignition

system, connect one and only one CDI module to an IBBS unit. DO NOT

CONNECT any other loads to the IBBS. It must only be used to back up the CDI

unit. Follow the wiring diagram on page 17 exactly.

10. The trickle charge wire must be connected as shown in the wiring diagram. This

connection keeps the battery topped off when the aircraft remains unused for

extended periods of time.

REV 2.3 © 2012 TCW Technologies, LLC.

4

Product Details and General Information:

Back-up Po er Master S itch:

The IBBS has one input switch connection as identified in the wiring diagrams: Back up

Power Master. This switch enables back up power from the IBBS system to be

available on the output wires when power on the normal aircraft bus falls into the range

of 10 11 volts.

If the back up power master switch is “ON” and normal aircraft power falls into the

range of 10 11 volts, then the internal back up battery will be connected to the output

and be utilized to supply back up power to the connected load.

If the normal aircraft power bus is above 11 volts, then the outputs are energized with

normal aircraft power and the back up battery remains off line. This pass through

power operation occurs regardless of the state of the Back up Power Master switch.

Having the Back up Master Switch ON allows for automatic transfer of power during the

transition between normal operation and back up operation.

The “Info ire”:

The IBBS includes an “info” wire as shown in the wiring diagram. The “info” wire may

be used in conjunction with other equipment such as EFIS systems or engine monitors

to provide information regarding the state of the back up battery system. When the

IBBS is off line and normal aircraft power is available on the input of the IBBS, the “info”

line may be read to determine the internal battery voltage. A nominal battery with a full

charge will read between 12 and 15 volts. When the IBBS is on line providing back up

power, the “info” line is pulled to a logic low level to signal connected equipment that the

system is currently running on back up power.

Alternately, the “info” wire may be connected to a warning lamp to indicate that the main

aircraft bus is low and the back up bus should be switched on. See wiring diagrams for

LED warning lamp usage.

The Charging System:

The IBBS automatically maintains its internal battery pack. The internal charging circuit

monitors the state of the internal battery and recharges it as necessary when the aircraft

is operational. The maximum input current for battery recharging is 1.8 amps. When

the aircraft power bus is in the off state, a maintenance current of up to 4 milliamps may

be drawn from the aircraft battery to ensure the back up battery remains charged. The

maintenance charge current is drawn from the input wire marked: Aux Battery Trickle

Charge. If the internal battery is fully discharged for any reason it may require up to

two hours of recharge time with the normal aircraft bus on. NOTE: Do not attempt to

recharge the IBBS product by using an external battery charger directly connected to

the input of the IBBS. Battery chargers typically provide pulsating voltages that will

damage the IBBS product if the system is not connected to a typical primary aircraft

battery.

REV 2.3 © 2012 TCW Technologies, LLC.

5

Ground Based Recharging:

To accomplish ground based charging, connect an approved battery charger or power

source to the main aircraft battery and energize the main aircraft power bus by turning

on the master switch, leave all other aircraft loads in their off state. Note, the ground

base source of power must be able to supply the load current of all devices that can not

be turned off in this nominal state, plus the 1.8 amps of IBBS recharge current. Leave

the ground based charging system connected and powered until the IBBS system

completes its recharge cycle of its internal battery, for a fully discharged battery this

may take up to two hours.

Alternately, a ground based charger is available from TCW Technologies LLC, model #

IBBS 12v CHARGER. This charger may be used for recharging the IBBS unit as well

as keeping it topped off during long term product storage. (3 months or longer)

Battery Capacity:

The IBBS, model IBBS 12v 2ah provides an energy capacity of 2.0 amp hours at 12

volts when the system is fully charged and operated at 25 C°. Depending on various

conditions including operating and storage temperature and age of the battery pack, the

capacity of the system will vary. With a fully charged battery, the following average

performance can be expected in terms of operating duration. The operating duration is

for output voltage down to 9.5 volts.

Nominal Current Draw Duration

total connected load

1.5 amps 60 minutes

1.0 amps 100 minutes

0.75 amps 160 minutes

The Ni mh battery in the IBBS system is replaceable, however, the IBBS product must

be returned to TCW Technologies, LLC. for this service. Battery life depends strongly

on many factors including operating and storage temperature, number of discharge

cycles and depth of discharge. The battery capacity should be checked at least

annually for suitable back up power operation of the connected equipment. When the

battery capacity no longer meets the operating criteria of the aircraft it must be replaced.

Contact TCW Technologies, LLC. for battery replacement.

Storage beyond 3 months:

If the IBBS unit is to be stored without connection to the aircraft for a period greater than

3 months it must be connected to a source of DC power to maintain the battery’s

charge. Only connections to the ground terminal and the trickle charge terminal are

required. Connect Pin 2 (trickle charge) and Pin 3 (ground) of the IBBS to any source

of regulated DC power at 12 15 volts with a current capability of 0.1 amps to accomplish

trickle charging. The trickle charge connection may be left connected during the

entire storage period. Charger model IBBS 12v CHARGER is available from TCW

REV 2.3 © 2012 TCW Technologies, LLC.

6

Technologies, LLC. to simplify this requirement, it has the mating connector installed

and performs trickle charging as well as fast charging functions.

Upon completion of installation:

1) The builder/operator is responsible for determining the minimum operating duration

of the back up enabled equipment.

2) The required back up operating time for the connected equipment should be

recorded in the aircraft log book with follow up entries confirming the annual testing

results that indicate that the required operating time is satisfied.

Normal Product Operation:

For normal operation the following is the recommend operating procedure, it is strongly

recommended that this operating procedure be added to the aircraft operating check list

for standard procedures.

Start-up Procedure:

1) Prior to turning on the Aircraft Master Switch, turn ON the Back up Power master

switch.

2) Turn on any equipment that derives back up power from the IBBS product.

3) Ensure the connected equipment successfully boots up and is operating properly.

(During this period of time the equipment is running off of the back up battery in the

IBBS product. This test ensures the transfer circuit and back up battery are properly

working)

4) Turn on the Aircraft Master Switch, ensure the connected equipment remains

energized.

5) Start and operate the aircraft according to normal operating procedures.

Shut-do n Procedure:

1) Shut down aircraft engine using normal procedures.

2) Shut down the Aircraft Master Switch

3) Verify that equipment that derives back up power from the IBBS product remains ON

4) Turn off Back up Power Master switch, ensure that connected equipment powers

down.

(This procedure further ensures the operation of the transfer circuit in the IBBS

product.)

REV 2.3 © 2012 TCW Technologies, LLC.

7

Emergency Procedure for loss of main aircraft electrical po er:

1) Operate the Aircraft Master Power Switch per the Emergency Procedure checklist

already established for the aircraft.

2) Ensure the Back up Master Switch is in the ON position.

3) Land aircraft as soon as practical to resolve the loss of main electrical power.

Requirements for continued air orthiness:

On at least an annual basis the endurance capability of the IBBS system shall be confirmed and

compared against the back up endurance required for the connected equipment.

As an alternate to these tests, the IBBS unit may be returned to TCW Technologies for

a loaded endurance test, contact TCW Technologies for details.

Procedure for endurance testing (all applications except electronic ignition

systems):

1) Turn off the Aircraft Master Switch

2) Turn on the Back up Power Master Switch

3) Turn on all equipment connected to and supplied with back up power from the IBBS

product.

4) Measure and record at least the following information: The time until the first piece of

connected equipment no longer functions or the time until the output of back up

power supply voltage drops to 9.5 volts. AVOID allowing the back up battery voltage

to fall below 9 volts. Allowing the voltage to fall below 9 volts is detrimental to the life

and performance of the battery pack.

5) After completing the endurance test, recharge the IBBS product by operating the

system with the Aircraft Master Switch in the ON position for up to two hours. This

may done by operating the aircraft in conditions known to not require back up power

or by powering the aircraft system on a suitable ground power source as described

in the section: Ground Base Recharging.

6) Record the results of the endurance testing in the aircraft log book.

7) If the IBBS no longer meets the endurance testing requirement, the back up battery

may need replacement.

REV 2.3 © 2012 TCW Technologies, LLC.

8

Requirements for continued air orthiness: Electronic Ignition System Back-up

On at least an annual basis the endurance capability of the IBBS system shall be confirmed and

compared against the back up endurance required for the connected equipment.

As an alternate to these tests the IBBS unit may be returned to TCW Technologies for a

loaded endurance test, contact TCW for details.

Procedure for endurance testing of system providing back-up po er

to electronic ignition systems:

COMPLETE THESE STEPS IN ORDER! Perform these tests with the aircraft properly

secured on the ground, these are not flight test procedures.

1) Start the aircraft using normal starting procedures, including turning ON the Back up

Master switch

2) Select engine operation based on the use of only the electronic ignition module

provided with back up battery power.

3) PULL the 5 amp breaker feeding the Back up Master Switch, confirm engine

continues to run.

4) PULL the 7.5 amp breaker feeding pin 6 of the IBBS, confirm the engine continues to

run.

5) Perform the following; test A or test B:

Test A: abbreviated battery test:

Monitor engine operation and voltmeter reading on any of Pin 7,8,9, back up output

wires. Confirm back up voltage begins above 12.0 volts and for a period of 15

minutes remains above 11.0 volts. If these requirements are met the battery pack is

satisfactory.

Test B: full endurance test:

Operate the engine on the electronic ignition system for the required minimum run

time requirement (typically 60 minutes ) monitor the back up battery voltage on the

voltmeter connected to pin 7, the battery voltage must remain above 10 volts for the

duration of the test. If this requirement is met the battery pack is satisfactory.

REV 2.3 © 2012 TCW Technologies, LLC.

9

6) Turn off the Back up Master Switch and confirm that the engine turns off.

7) IF all these tests pass, the IBBS system is functioning properly, record the results in

the aircraft log book.

8) IF any of these tests fail, the IBBS system is not functioning properly and corrective

action must take place. If the IBBS no longer meets the endurance testing

requirement, the back up battery may need replacement.

9) Return all pullable breakers to the normal ON position and ensure aircraft engine is

properly returned to the off position by following normal run and shut down procedures.

10) After completing these tests, recharge the IBBS product by operating the system

normally for up to two hours. This may be done by operating the aircraft in conditions

known to not require back up power or by powering the aircraft system on a suitable

ground power source as described in the section: Ground Base Recharging.

For service or if you have questions, please contact us.

610 928 3420

www.tcwtech.com

email: suppo[email protected]

TCW Technologies, LLC.

2955 Main Road East

Emmaus, PA 18049

REV 2.3 © 2012 TCW Technologies, LLC.

10

SPECIFICATIONS:

Input Voltage: 10-15 volts DC

Input Current 4.8 amps max continuous

Output Voltage: 10-12 volts DC during back-up operation

Output Current: 3 amps continuous

Battery:

Internal sealed Ni-MH

Charger: Integral high performance fast charger

Surge Protection: 16 volt active clamp, 1500 10/1000uS aveform

Wiring: CPC connector ith Mil-spec machined contacts

Field replaceable inline fuse: AGC-7.5

Enclosure: Cast aluminum

5.8” x 3.7” x 1.3” (including mounting flange)

Weight: 1.5 lbs

Temperature range: Operating -10 C° to 60 C°

Charging 0 C° to 40 C°

Connectors:

AMP type CPC # 206486-2 on product iring harness.

AMP type CPC # 206485-1 is utilized on the aircraft iring

harness.

REV 2.3 © 2012 TCW Technologies, LLC.

11

Wiring harness connector

Amp 206486-2 receptacle on IBBS product

mating CPC connector AMP part # 206485 1 on aircraft harness

PIN

# Description Wire Color (optional harness)

1 Main Aircraft Bus (charge power) Red

2 Aux Battery trickle charge, Always ON Purple/yellow

3 Aircraft ground Black

4 Back up power master switch White/black

5 Info Green/red

6 Main Aircraft Bus (pass thru power) Red

7 Back up battery output White

8 Back up battery output White

9 Back up battery output White

REV 2.3 © 2012 TCW Technologies, LLC.

12

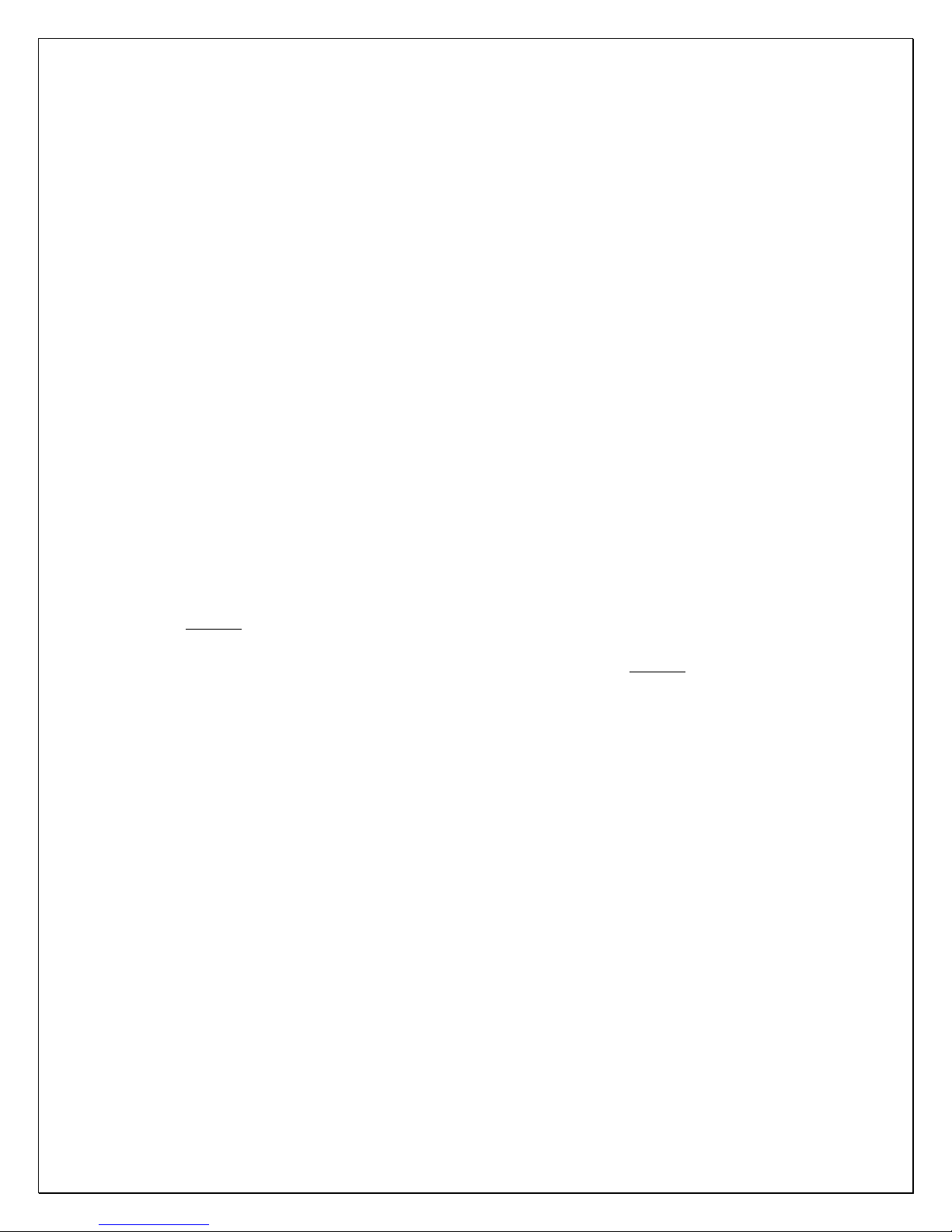

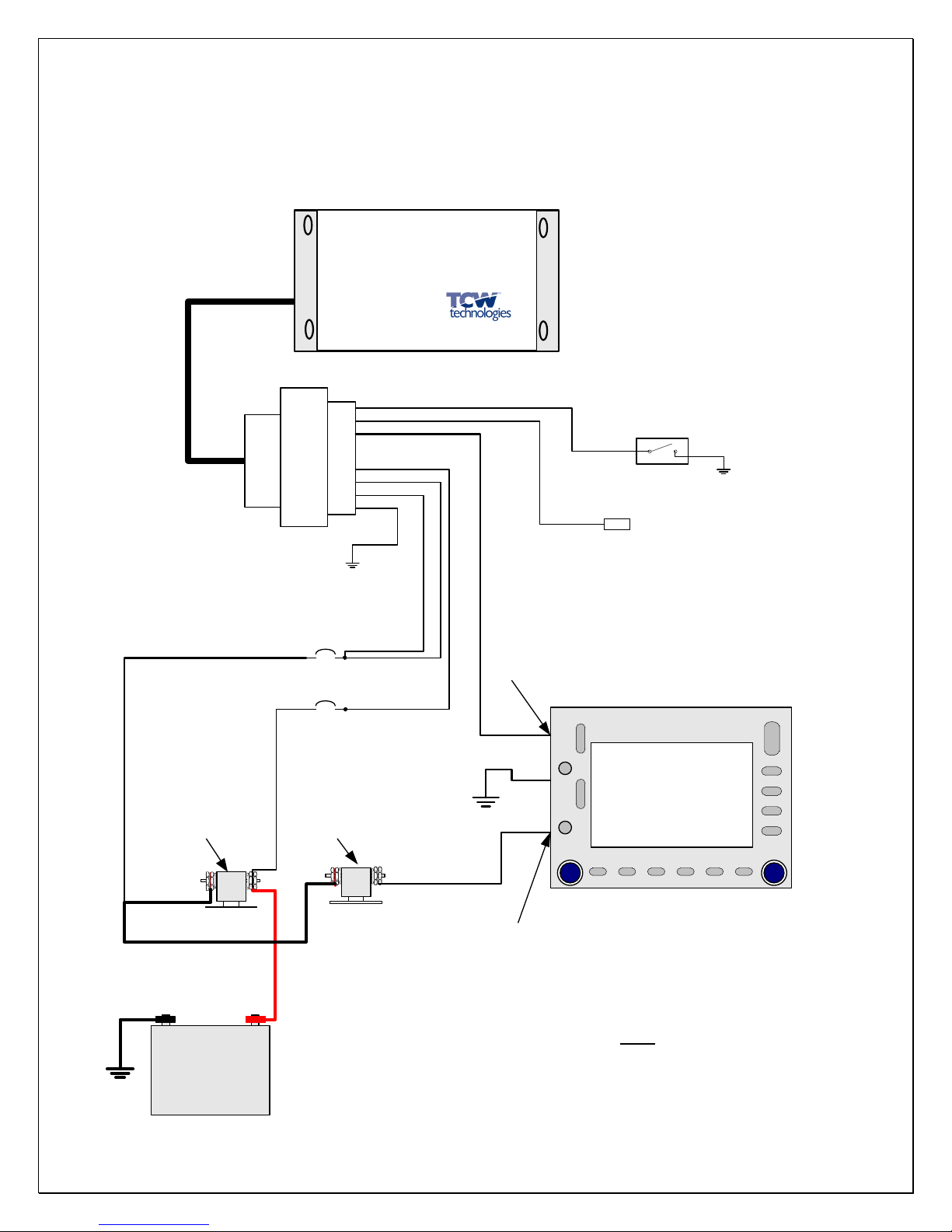

General Wiring Diagram

2 amps

10 amp

Main Aircraft Bus

Aux Battery

trickle charge

Back-up Power Master

cpc connector

Back-up power output

Total combined load on all three output = 3 amps

INFO

Low = active signal

igh =battery voltage

Back-up power output

Back-up power output

20 awg

22 awg

22 awg

20 awg

20 awg

22 awg

20 awg

20 awg

20 awg

www.tcwtech.com

mmaus, PA USA

MODEL: IBBS-12V-2AH

Input: 10-15 volts DC

Output: 12 volts, 3 amps

Capacity:2 amp-hours

INT GRAT D

Back-up Battery

SYST M

Pin #1 Main Aircraft Bus

Pin #2 Aux Battery trickle charge, Always-ON

Pin #3 Aircraft ground

Pin #4 Back-up power master switch

Pin #5 Info

Note: If the main aircraft bus power supply (pins 1,6) is provided through a

single wire to the cpc connector then 18 awg wire must be used.

Pin #7 Back-up battery output

Pin #8 Back-up battery output

Pin #9 Back-up battery output

Pin #6 Main Aircraft Bus

+

-Low Voltage Warning L D

REV 2.3 © 2012 TCW Technologies, LLC.

13

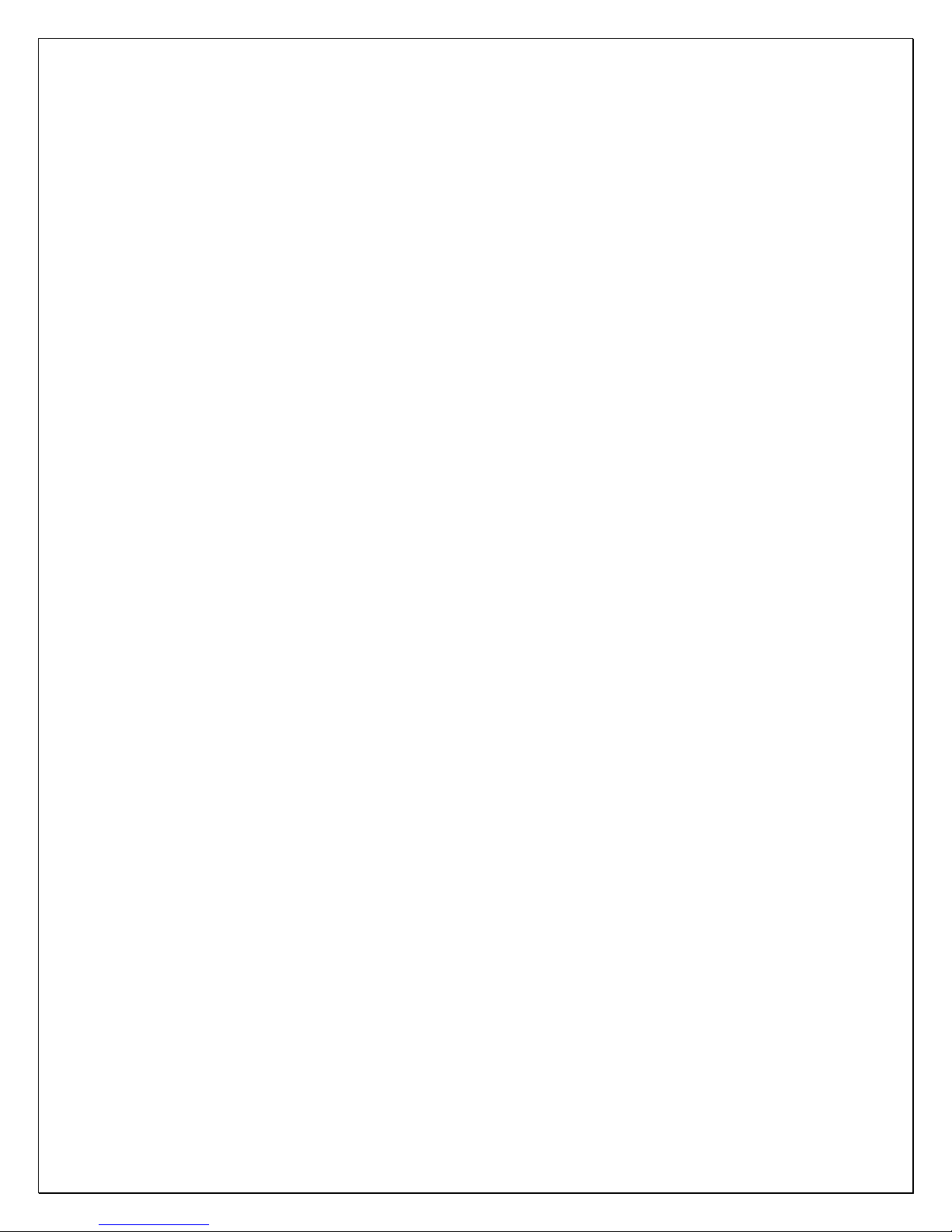

Battery

Master Solenoid

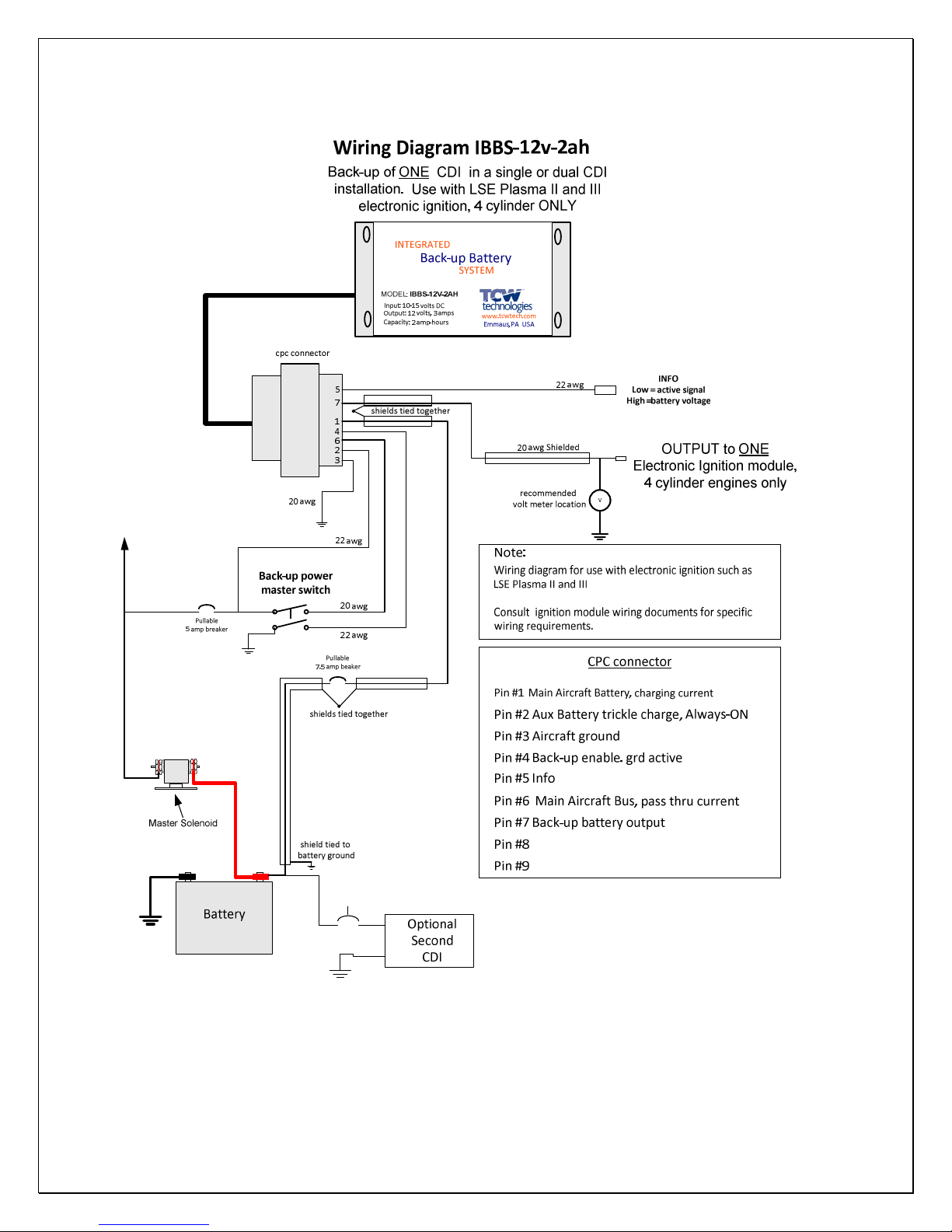

Wiring Diagram IBBS-12v-2ah

Equipment being

powered via IBBS

1) For Garmin 430/530, supply IBBS protected power only to gps/nav

power input, not com power input

Example wiring for systems ithout back up power inputs

quipment without Back-up Power Input

2 amps

10 amp

Main Aircraft Bus

Aux Battery

trickle charge

Back-up Power Master

cpc connector

INFO

Low = active signal

igh =battery voltage

Back-up power output

20 awg

22 awg

22 awg

20 awg

20 awg

22 awg

20 awg

www.tcwtech.com

mmaus, PA USA

MODEL: IBB-12V-2AH

Input: 10-15 volts DC

Output: 12 volts, 3 amps

Capacity: 2 amp-hours

INT GRAT D

Back-up Battery

SYST M

1

6

3

4

2

5

7

main power input

REV 2.3 © 2012 TCW Technologies, LLC.

14

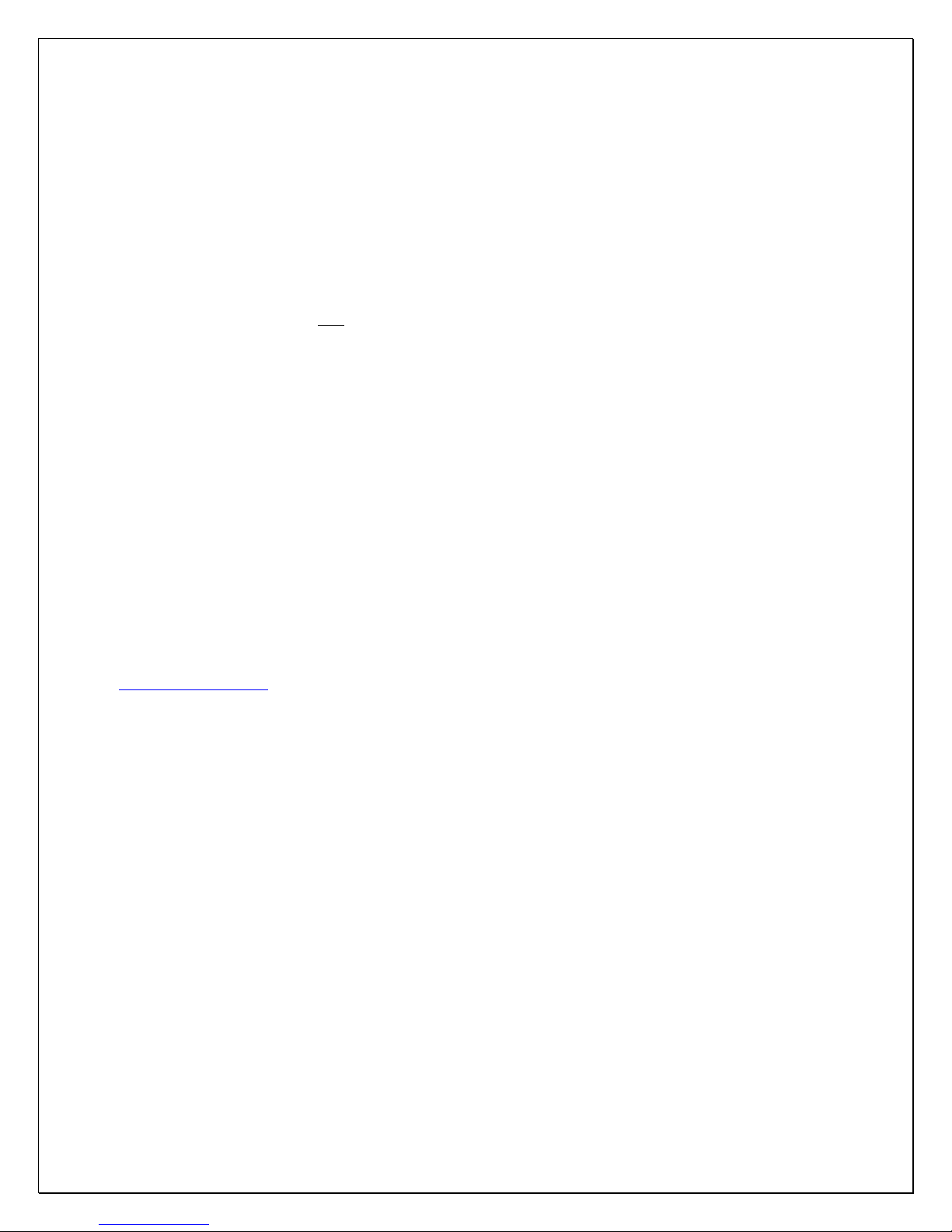

Battery

Master Solenoid

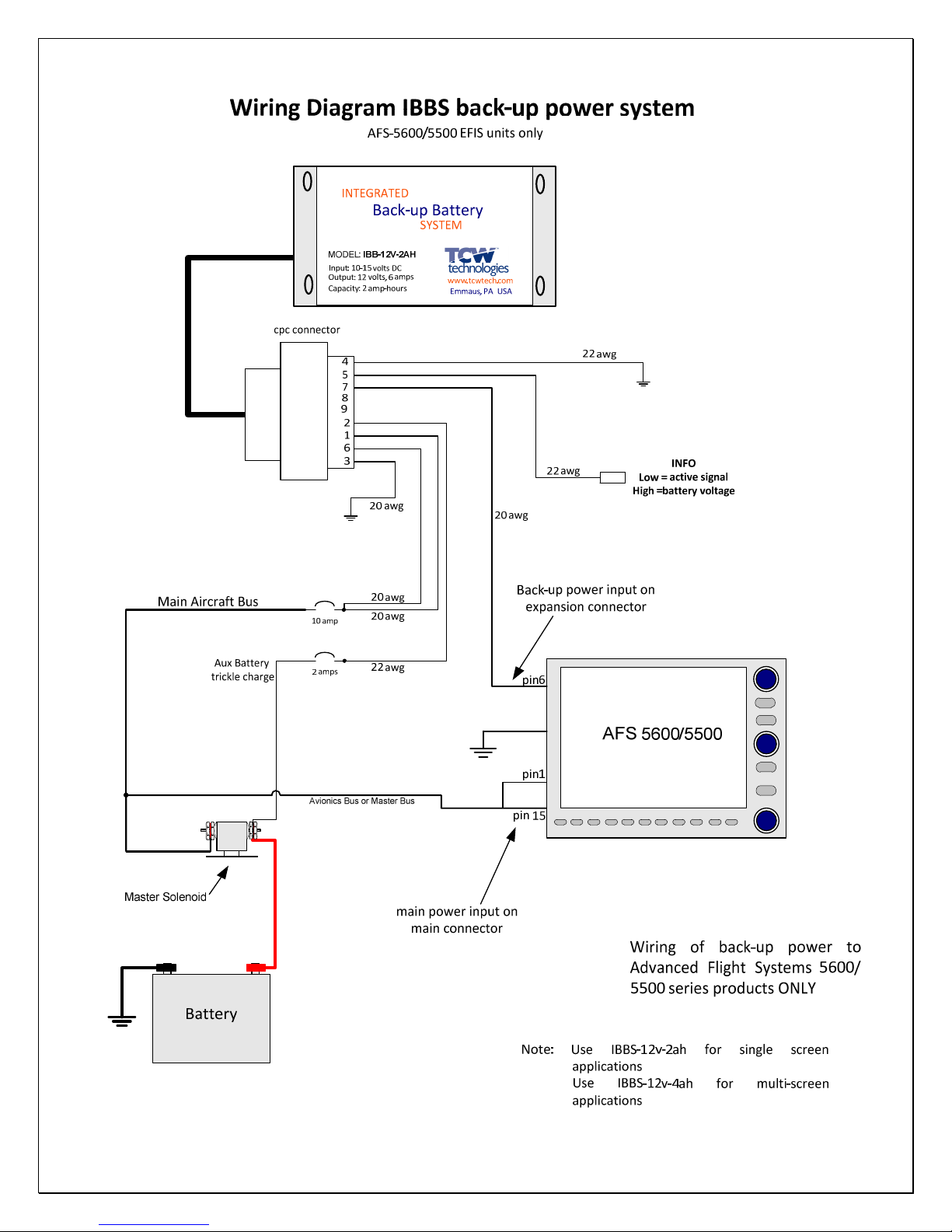

Wiring Diagram IBBS-12v-2ah

Equipment being

powered via IBBS

Example wiring for systems ith back up power inputs

quipment with Back-up Power Input

2 amps

10 amp

Main Aircraft Bus

Aux Battery

trickle charge

Back-up Power Master

cpc connector

INFO

Low = active signal

igh =battery voltage

Back-up power input

20 awg

22 awg

22 awg

20 awg

20 awg

22 awg

20 awg

www.tcwtech.com

mmaus, PA USA

MODEL: IBB-12V-2AH

Input: 10-15 volts DC

Output: 12 volts, 3 amps

Capacity: 2 amp-hours

INT GRAT D

Back-up Battery

SYST M

1

6

3

4

2

5

7

Avionics Bus Solenoid

main power input

Note: terminal 7, 8, 9 may be used for

back-up power outputs

Avionics Bus

REV 2.3 © 2012 TCW Technologies, LLC.

15

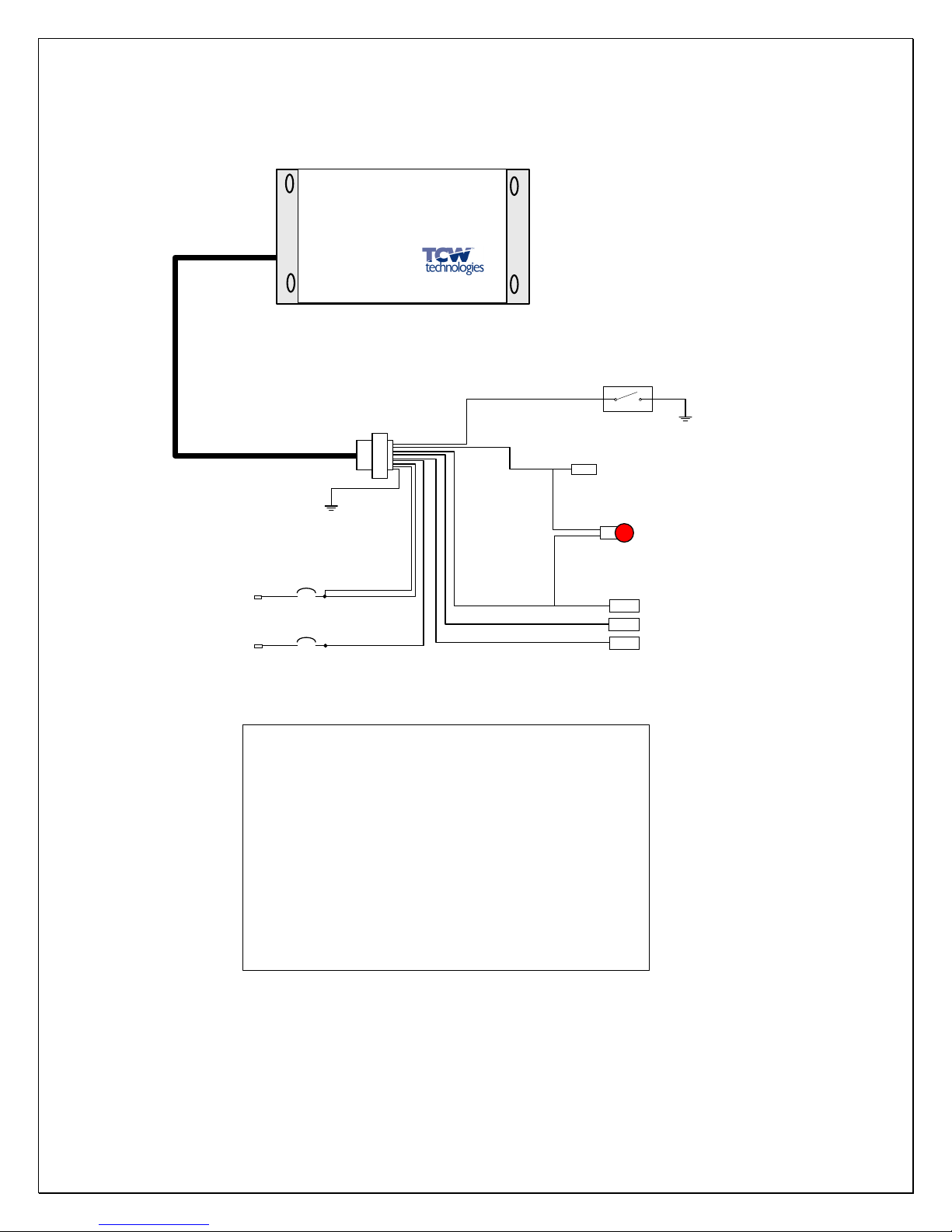

Main Aircraft Bus

20 awg Shielded

REV 2.3 © 2012 TCW Technologies, LLC.

16

REV 2.3 © 2012 TCW Technologies, LLC.

17

TCW Technologies, LLC.

During the first 12 months from the date of purchase and subject to the conditions hereinafter set forth, TCW

Technologies, LLC. (TCW) ill repair or replace to the original user or consumer any portion of your ne TCW product

hich proves defective due to defective materials or orkmanship of TCW. Contact TCW Technologies for arranty

service. TCW shall have and possess the sole right and option to determine hether to repair or replace defective

equipment, parts or components. Damage due to equipment, environment or conditions beyond the control of TCW

Technologies are NOT COVERED BY THIS WARRANTY.

LABOR, COSTS: TCW shall IN NO EVENT be responsible or liable for the cost of field labor or other charges incurred

by any customer in removing and/or reaffixing any TCW product, part or component thereof.

THIS WARRANTY WILL NOT APPLY: (a) to defects or malfunctions resulting from failure to properly install,

operate or maintain the unit in accordance ith printed instructions provided; (b) to failures resulting from abuse,

accident, or negligence; (c) to normal maintenance services and the parts used in connection ith such service; (d) to

units hich are not installed in accordance good trade practices; or (e) to unit used for purposes other than for hat it

as designed and manufactured.

RETURN OR REPLACED COMPONENTS: any item to be replaced under this Warranty must be returned to

TCW Technologies in Emmaus, PA, or such place as TCW may designate, freight prepaid.

PRODUCT IMPROVEMENTS: TCW reserves the right to change or improve its products or any portions

thereof without being obligated to provide such a change or improvement for units sold and /or shipped prior

to such change or improvement.

WARRANTY EXCLUSIONS: as to any specific TCW product, after the expiration of the time period of the

warranty applicable thereto as set forth above. THERE WILL BE NO WARRANTIES, INCLUDING ANY

IMPLIED WARRANTIES OR MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not

apply to you. No warranties or representations at any time made by any representative of TCW shall vary or

expand the provisions hereof.

LIABILITY LIMITATION: IN NO EVENT SHALL TCW OR ITS AFFILIATES BE LIABLE OR RESPONSIBLE

FOR CONSEQUENTIAL, INCIDENTAL OR SPECIAL DAMAGES RESULTING FROM OR RELATED IN ANY

MANNER TO ANY TCW PRODUCT OR PARTS THEREOF. THE SUITABILITY OF USE OF THE TCW

TECHNOLGIES, LLC. PRODUCT IS TO BE DETERMINED BY THE AIRCRAFT BUILDER.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

This Warranty gives you specific legal rights and you may also have other rights which vary from state to

state. In the absence of other suitable proof of this installation date, the effective date of this Warranty will be

based upon the date of manufacture plus one year. Direct All Notices To: Warranty and Product Service

Department, TCW Technologies, 2955 Main Road East, Emmaus, PA 18049

Table of contents