Techno AT-480 User manual

10mm Air Belt Sander (Model AT-480)

INSTRUCTION MANUAL

Thanks for your purchasing our air tools

and please read this Instruction Manual carefully

and thoroughly before operating the tool to do your best jobs.

Revision: 01 (2004)

A. Features & Functions

* The smallest handy sanderwith 10mm widebelt. Lever throttlefor featuring control.

* Easy beltreplacement. Suitable for jobs in narrowspaces and recessed corners.

* Helps you to do fine sanding jobs like wood-working, furniture-polishing, plastic,

aluminum & metal-polishing and even small spot sanding jobs like trims, curves,

and other difficult-to-reach spots for common sanding machines.

* 3 different grit sanding belts (60, 80, 120 grit) included for different purpose and

function.

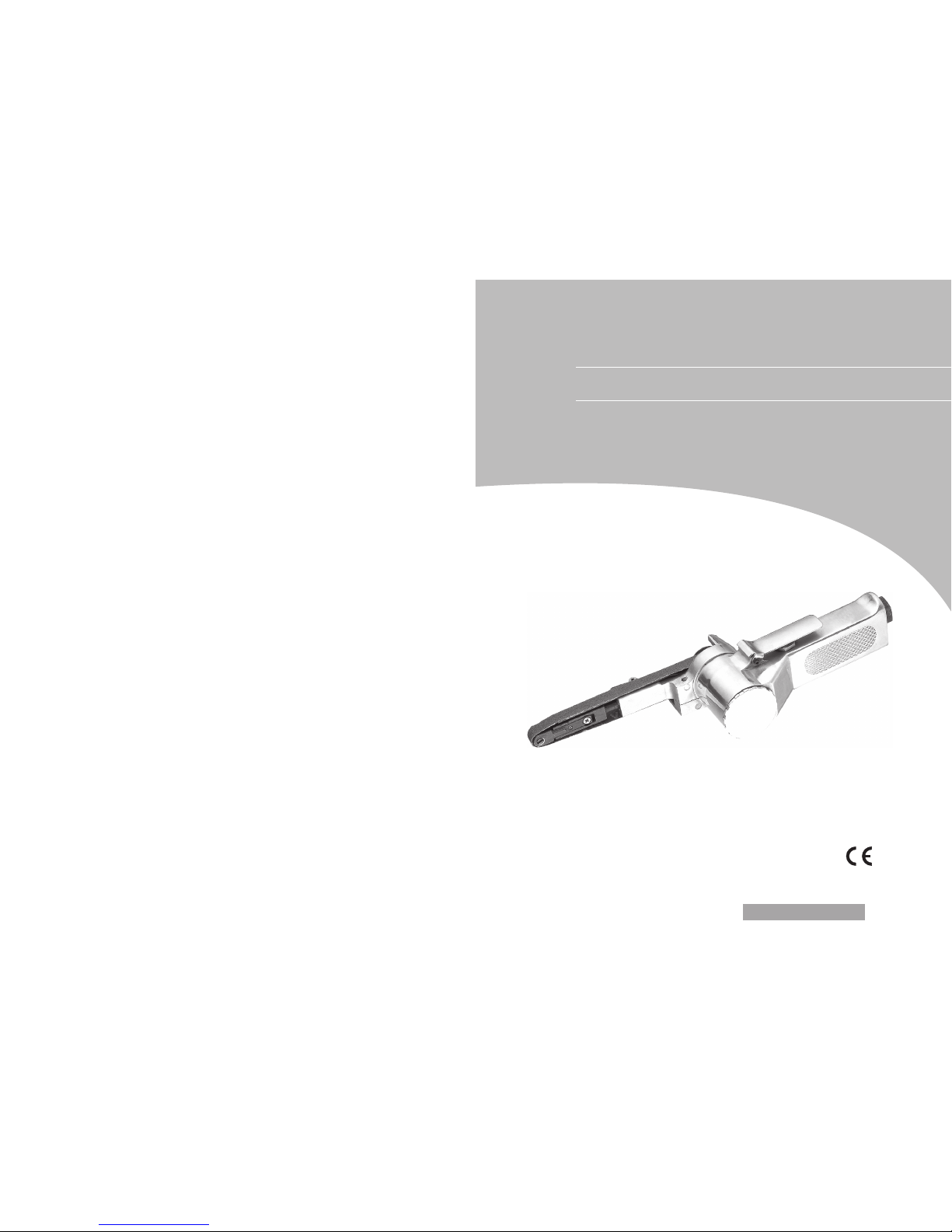

B. Air Supply (please referto the diagrambelow)

1. Make sure that the air compressor being used for the air tool operation supplies the

correct output (CFM).

2. Turnthe throttle in the off position when connectingthe tool to the air supply.

3. Use normal90psi (or rangingfrom 6.0 to 8.0kg.) air pressurewhile running the tool.

High pressure and unclean air will shorten the tool’s life due to faster wear and also

may create ahazardous situation.

4. Drain the air tank daily. Water in the air line may enter the tool and damage the tool

mechanism at theoperation.

5. Clean theair inlet filtercartridge weekly. The recommended hook-up procedure can

be viewed inthe diagram below.

6. Line pressure should be increased accordingly to make up for extra long air hoses

(usually over 8 meters). The minimum hose diameter should be 1/4 I.D. and the

fittings should have the same inside dimensions. But usually a 3/8 I.D. air hose is

recommended for airsupply to get the best functionof air tool operation.

7. Use properhoses and fittings.We do not suggestconnecting quick change couplings

directly to the tool since they may cause failure due to vibration. Instead, add a

leader hose andconnect coupling between air supply andhose whip.

8. Keep hoses away from the heat, oil and sharp edges. Check hoses for wear before

individual use. Makecertain that all connections are insecurity.

C. Safety Instructions

1. Approved eye protector must be worn at all times. Be sure to use a dust mask since

the tool operation may creates dust which is harmful to health. If necessary, ear

protector and glovesshould be used.

2. Always keep good balance of body and footing. Secure work with clamps or vice so

both hands canbe free to operate the tool.

3. Be sure all clothing is tight to prevent entanglement with running tools. Remove

your jewelry andwatch for safety purpose.

4. Be sure that working area is clear of foreign objects and that no people are within

immediate access of tool operation scope. The working place shall be well

ventilated.

5. Disconnect theair hose before changing or adjustingany inserted tools/accessories.

6. Be surethe tool is in off position before connectingit to the air hose.

7. Disconnect the tool when itis not inuse. Release the on-off device in case of energy

supply failure.

8. Never carrytool by hose.

D. Maintenance And Lubrication

1. If you are not using an air line oiler, lubricate the air motor by using an oil pot or an

oil injector through the air inlet and then run the tool. Several drops of SAE #10

lubricant or sewing machine lubricant is acceptable for this purpose. Do not use

detergent oil.

2. Before connectingthe hose foroperation, apply 4 or 5 drops of #10 spindleoil at the

air inlet.Avoid the misuse ofthicker oil whichmay lead to the reduced performance

or malfunction.

3. Oiling isnecessary within 3 or 4 hoursof operation.

4. Afteroperation, take off the air hose and pour4 or 5drops of #60 spindle oil into the

air inlet, then connect the hose again to run the tool for a few seconds, which can

prolong the toollife.

5. Clean airinlet filter cartridge on the airline weekly.

E. Warnings

1. Never usethe tool in potentially explosive atmospheres.

2. Keep your body in well balanced position and always wear glovesto reduce therisk

of crushing causedby torque between a reaction barand work-piece.

6. Shut Off Valve

7. Whip Hose

8. Coupler Body And Connector

9. Drain Daily

10. 1/2” Or Larger Pipe And Fitting

1. Air Tool

2. Air Hose 3/8”(I.D.)

3. Oiler

4. Pressure Regulator

5. Filter

11. Air Dryer

12. 1” Or Larger Pipe And Fitting

13. Air Compressor

14. Auto Drain

15. Drain Daily

AIR SYSTEM LAYOUT

6

9

14

8

7

1

12

10

5

4

3

2

11

13

15

3. Unexpected tool movement due to reaction forces or breakage of inserted tool or

reaction bar maycause injuries.

4. Prevent long hair or loose clothing from drawing in while operating the tool. You

may get the risk of being injured if the handkerchief, necktie etc. are not kept away

from the runningtool.

5. The noise emission (sound pressure level) at the workplace may exceed the normal

standard ---usually 85dB(A).In this case, a quality earprotector should beused.

6. Unexpected directionof inserted tool movement could casea hazardous situation.

7. Slip / Trip / Fall is a major cause of serious injury or even death. Beaware of excess

hose left on your walking way or on the working surface and be aware of the

whipping air hosetoo.

8. Excessive high air pressure and too much freerotation may speedup the wearof the

tool and maycause dangerous situation.

9. Continuous operation and bad working condition will injure hands. Once hand

numbs or aches , operator shall stop the tool for a while for relaxing and re-start the

work after recovery. Operator shall immediately see a doctor if such a serious

symptom occurs.

10. Never change the inner construction and design, which may cause a danger in

operation.

F. General Trouble Shooting

* Troubles:

- Tool does not runat a normal speed or ata variable speed

- The motor blocks

- Automotive start whenconnected to compressed air

- Torque reduces

- Abnormal vibrating -Easy hot rising atthe housing

* Causes:

- Air supply isnot enough (air pressure not ina required standard)

- Speed controller/switch breaksdown

- Rotor blades breakor wear out

- Dust gets intothe motor

- Throttle lever orstarting trigger malfunctions

- Air leakage atthe inlet or somewhere else

- Bearing(s) damages

- Correspondent O-ring(s) wearsout or out of position

- Lack of lubricating

* TroublesShooting:

- Check the airhose to see whether it isblocked or twistedfor less airsupply.

- Check the aircompressor to gain the correct airpressure required.

- Replace rotor blades

- Disassemble the tooland clean the inner structure underproper instructions

- Check and fixthe throttle lever or starting triggerfor accurate operation

- Check the airleakage and fix it under properinstruction

- Replace new bearing(s)

- Replace the damagedO-ring(s) or put it back incorrect position

- Oil / Lubricatethe tool consistently until it gainsthe right speedand torque

* Note:

For any otherspecial troubles which cannot be settleddown by theoperator, please

contact the sellingagent from whom you purchase thetool.

G. Storage

Avoid to store the tool ina location subject to high humidity, which mayresult in rusty

mechanism inside thetool. Before storing, oil the toolat the airinlet with proper

spindle oil andrun it for a few seconds.

H. Disposal

When the toolis seriously damaged or out oflife, leave itin a resourcerecycling can.

Never drop itinto fire.

I. Ordering Spare Parts

1. Contact thesale agent fromwhom you purchase the tool for spare parts orderingfor

any necessary replacementfor continuous use of tool andextending the toollife.

2. In ordering spare parts and components, give each spare part number and order

quantity.

Thank you.

TECHNICAL DATA:

* Free Speed: 16,000 RPM * Sanding Belt: 2/5" x13" (10 x 330 mm) * Air Inlet (PT): 1/4"

* Air Hose(ID): 3/8" * Avg.Air Consumption: 6 SCFM * Working Pressure: 90 PSI (6.3 BAR)

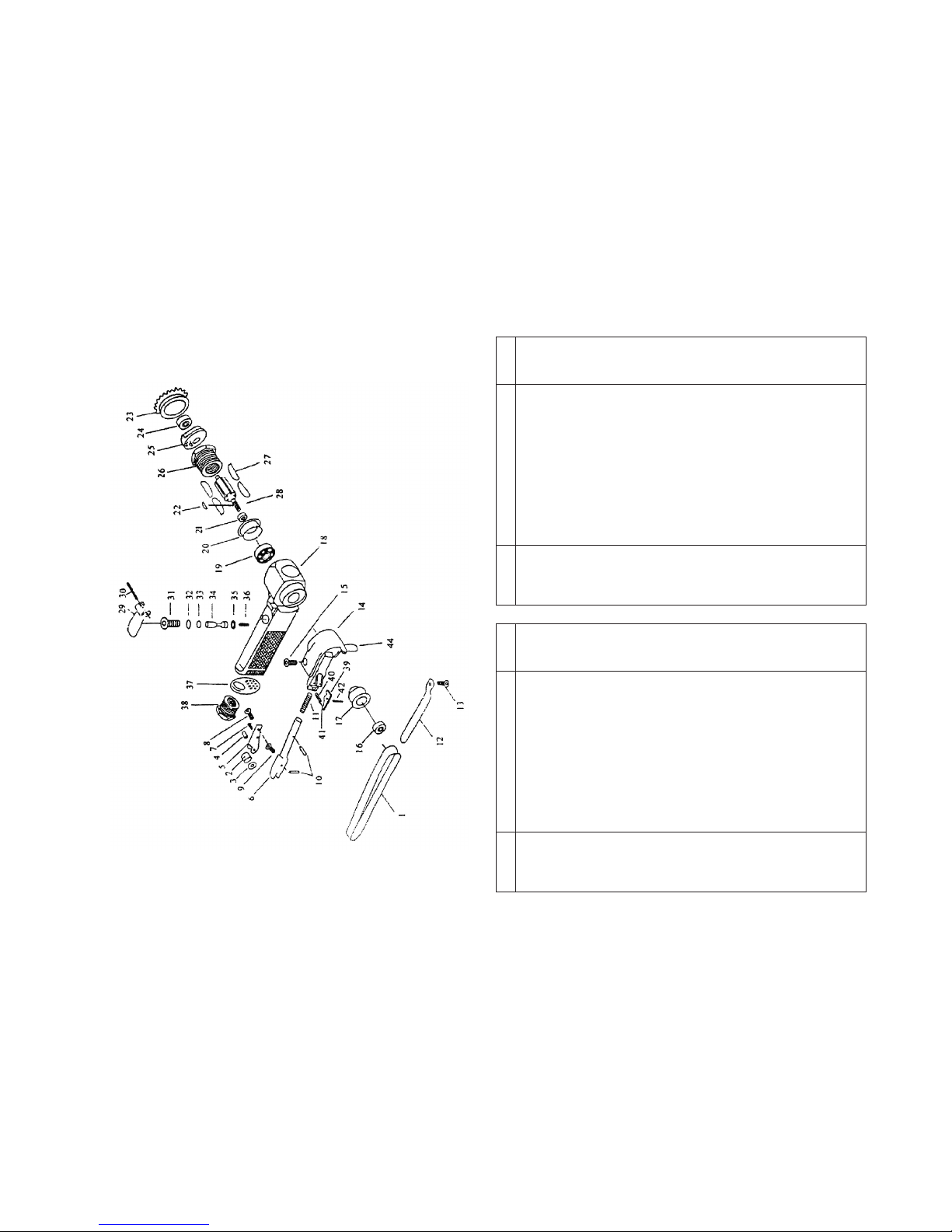

10mm Air Belt Sander (Model: AT-480)

SPARE PARTS LIST

Part No.

Description

Part No.

Description

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

Grinding Belt

Grinding Belt

Grinding Belt

Idle Pulley

Washer

Idle Pulley Screw

Bracket 10

Tension Bar 10

Hexagon Socket Headless

Set Screw 3x10

Cross-Recessed Flat Head

Mashine Screw 3x8

Spring 1.0x7.2x6.5

Spring Pin 3x10

Spring 1.07x4.0x35.5

Shoe 10

Cross-Recessed Flat Head

Mashine Screw 4x8

Guard Sud Assy A

Hexagon Socket Head

Bolt 5*15

Hexagon Pulley

Drive Pulley

Housing

Ball Bearing 628zz

End Plate B

Spacer 8x11x3

Sunk Key 3x3x1

Cap

Ball Bearing 607zz

End Plate A

Cylinder

Blade Assy (4pc/set)

Rotor

Throttle Lever

Lever Pin

Valve Body

O-ring (P9)

O-ring (P5)

Valve Stem

O-ring (3.6x2.4)

Valve Spring

Defrector

Air Inlet

Tension Bar

Spring

Lever Pin (m2x6)

Lever Pin (m2.5x10)

1

1A

1B

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Qty. Qty.

1

1set

1

1

2

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

5

1

1

1set

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1