Technobake Roastrunner User manual

Unit 11 / 18 Hinkler Court, Brendale Qld 4500 Ph 061 7 3205 9066

Twin Oven Single oven

Installation manual Support Ph 0402 021 190

Your will need the correct PPE and White card to enter building sites.

• Safety glasses must be worn

• Sturdy footwear must be worn

• Gloves must be worn

• Hair must be contained

• No Rings and Jewelry

DO NOT use this machine unless you have been instructed in its safe

use and operation and have been given permission

NOTE; This manual is prepared for the use of trained Service Technicians.

This manual is intended as a guide. You will need to have the necessary tools/ instruments required.

Reproduction of this Manual, without the express written consent of Technobake Pty Ltd is prohibited.

ACN136 118 253, 11/18 Hinkler Court Brendale QLD 4500Australia Phone/Fax 61 07 3205 9066

General Technical Information

Always use never seize/copper slip on

all bolts and screws.

Warning: All electrical connections

must comply with local codes.

Water requirements: COLD WATER

ONLY

Warning: all plumbing connections

must comply with local sanitary, safety

and plumbing codes.

Unit 11 / 18 Hinkler Court, Brendale Qld 4500 Ph 061 7 3205 9066

Introduction to Roastrunner

• Twin chamber, sharing electronics, plumbing and fat separator. Operates like two separate ovens. If one

chamber has a fault the other chamber will still bake.

• ON/OFF switch in the middle, at the bottom of touch screen. Screen is split screen controlling either side

of the oven.

• When unit switched on, it carries out a system check, this can take a couple of minutes, checks proximity

switches, valves and rotation. Doors must be closed with gantries in the oven.

• Flooded floor generates steam for a gentle boil, fat etc. dripping from cooking, falls into water reducing

fire risk. Has as high-pressure spray of water which pushes all debris off the grate into the Catch Basket.

• Fluids on the floor of the oven is drained into the fat separator every 70 mins or so (configurable). Note:

there are two types of separator in the field. Old one works with probes that read the currents in water, air and fat

giving different probe readings and a float that activate a valve. New one works on specific gravity with no inter-

nal parts using weir system. Instructions on p.12

• Has a two hour wash which is very similar to a dishwasher. Wash is once only at end of day, the whole

oven – both chambers together. DOES REQUIRE STAFF to attend to cleaning tasks. Note: once wash cycle

has started you cannot cancel.

• Requires no toxic chemicals, uses off the shelf dishwasher tablets. Finish Brand tablets have been ap-

proved by Woolworths, the stores are to take them off the shelf and IDT them.

• Water Tank at rear ensures reliable water pressure.

• There are 2 racking styles, Chicken only – this is the wishbone style that holds thirty birds (30). And a tray

rack that holds 6 trays to cook all hot food products and has Add on Racks to cook 24 chickens (24). Ov-

ens are either; a double 30/30, double 24/30, 30 single or 24 single.

Tools required for installation

• Drill Impact drive screw driver • Adjustable spanner by 2 (150mm and 200mm)

• Crow bar, multi grips, vice grips • Anti-seize Lubricant, Allen keys full set, Knife.

Points to remember: -

Use tine holes for moving the oven.

You will need to ask for help you lift the oven with the forklift.

Ask manager where they would like steel frame disposed of.

Compact the cardboard after de-crating.

Use a container or small box to contain all nuts bolts and screws.

Unit 11 / 18 Hinkler Court, Brendale Qld 4500 Ph 061 7 3205 9066

Unpacking the unit

• Get the forklift in position for lifting (ask storeman or manager for assistance)

• Use tine holes in steel frame. There are two wooden or steel skids under the steel base either side of the

crate - remove those by removing screws, use a forklift to raise the oven so the timber/steel skids can be

removed. When moving the oven make sure forklift tines are all the way into the crate.

• Lower on to floor and remove forklift. Oven is now on its wheels.

• Remove cardboard from roof.

• Undo screws at bottom of cardboard and remove all cardboard – dispose. Might need to cut cardboard

down for compacting.

• Undo 19mm bolts into

caster.

• Undo 8mm tech screws

from frame support and remove.

• Undo all remaining 17mm nuts and bolts from base frame and dis-

mantle.

• Check equipment and parts for damage. Report any damage immediately to builder or store manager

and distributor. Note: take photos of any damage and send them with a report on the condition of the

• Remove all packing, cable ties and packing materials, including Fan Packer inside chamber. NOTE: If the

gantry does not move freely there could be cable tie holding it in place (one on the inside of the charmer

up top and one outside by the catch tray).

• Remove any parts and put them in a safe and easy to access place - they will be needed to complete in-

stall. Note: once all packing is removed parts can be stored in the chamber until needed.

• Once oven is ready to move check the path to the deli is clear and free of any obstructions.

• When moving the oven DO NOT PUSH USE THE GLASS. You can use the gantry handles, door handles or

the body of the oven to maneuver. Move the oven slowly be aware the plumbing at the rear and the

glass doors for clearance.

• Position oven in its allocated place in deli.

• Always leave your area clean and tidy take all rubbish and dispose of properly.

• Dispose of create in Woolworths bins or contraction site bins.

Unit 11 / 18 Hinkler Court, Brendale Qld 4500 Ph 061 7 3205 9066

Installing the unit

• When the oven has been positioned do a final check and make sure doors when opened clear any sur-

faces bench, wall or any other obstruction.

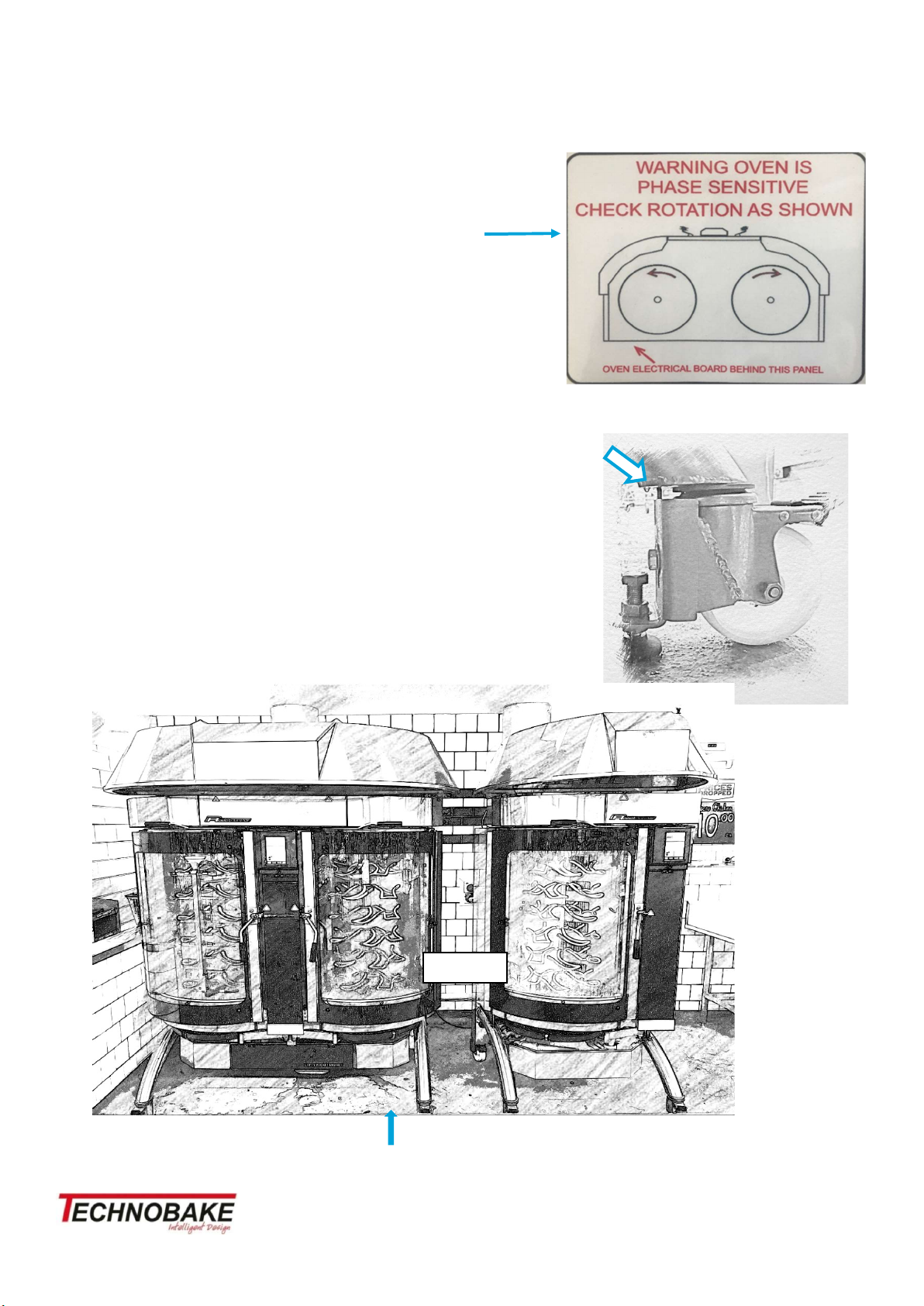

• Roastrunner oven is to be connected to a AC3 Phase + Earth power supply. Oven supplied with 2M lead

and a 5 pin plug. Double oven 50A IP56 - Single 32A. Where more than one outlet is available for the

oven, always check rotation is unchanged should socket be changed.

• An all-pole electrical isolation switch should be mounted on the wall and be fully accessible to the opera-

tor. It should be mounted 1.5m above the floor as a recommended height.

• Oven to drain to a Tundish in floor. Connect drainage piping - must have fall so the water runs downhill

to the drain. If plumbing does not have fall the fat separator cannot function properly. Contact Tech-

nobake if no Tundish.

• Connect water to the oven. Cold water only and tap fully open to allow maximum water flow. Tie or coil

all water hoses ensuring they are off the ground using cable ties.

Unit 11 / 18 Hinkler Court, Brendale Qld 4500 Ph 061 7 3205 9066

• Fit Foot Jack locate lock pin and level oven. Make sure water is level in each chamber with 10mm of wa-

ter in the oven floor. Note: the water level is very important as it effect the oven fat separation and

drainage. See below Levelling (if the floor is uneven we can use packers to level the oven)

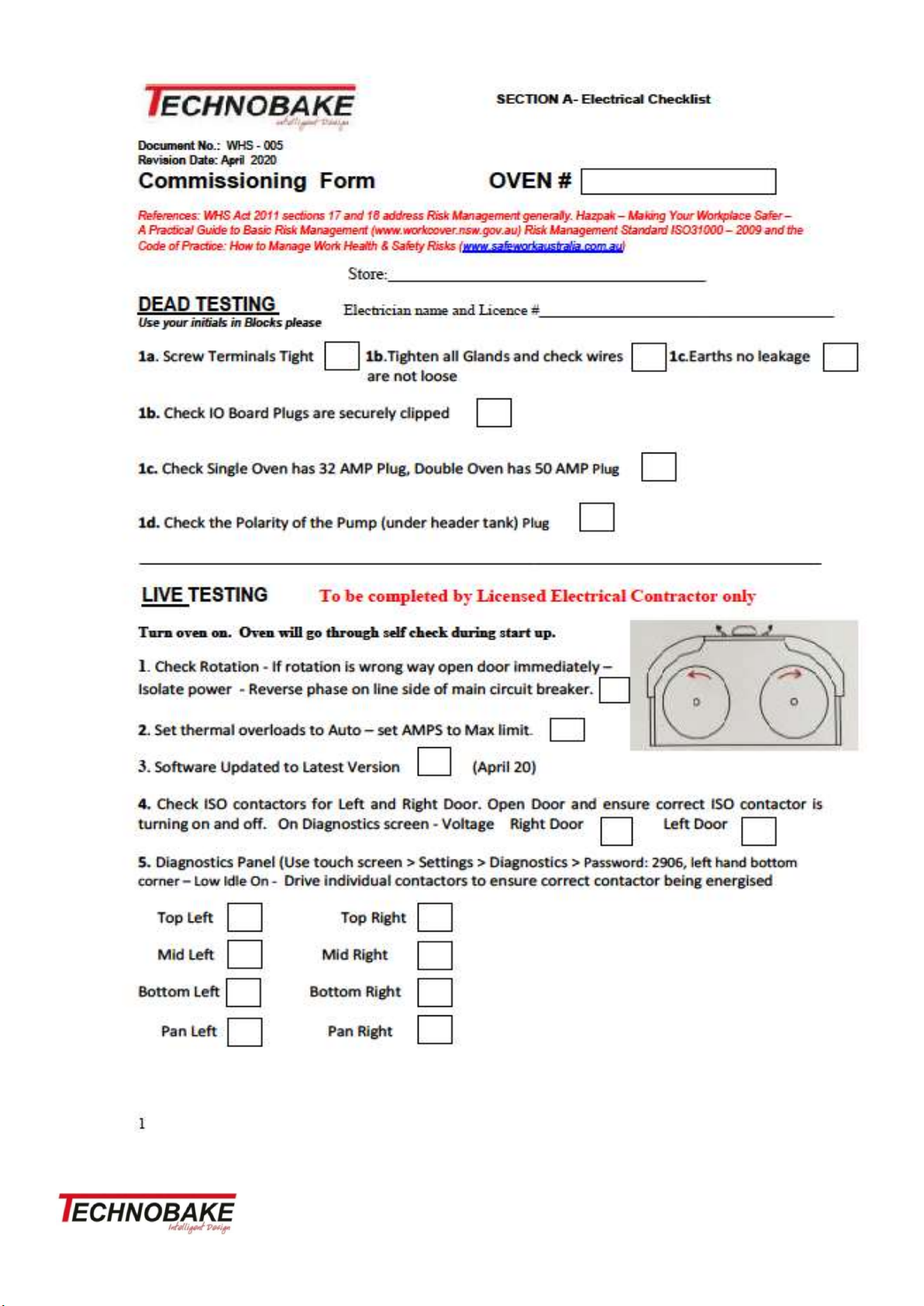

• Complete check lists as attached. Turn oven on at mains

Touchscreen will illuminate after 10 seconds. Ensure the motor

turns in the correct direction. Single oven rotates clockwise.

• Check termination at oven power box for correct voltage on all

phases.

How to level the oven

• Levelling can be difficult depending on the fall of the floor, if the

floor is uneven we can use packers that are in the install kit.

• Firstly use the foot lock/level in position ensuring the Pin is in position

and bracket is hard against the leg.

• Once both locks are in place the oven can be checked for level,

with 10mm of water in both chambers water in the chamber

floor should be pretty even.

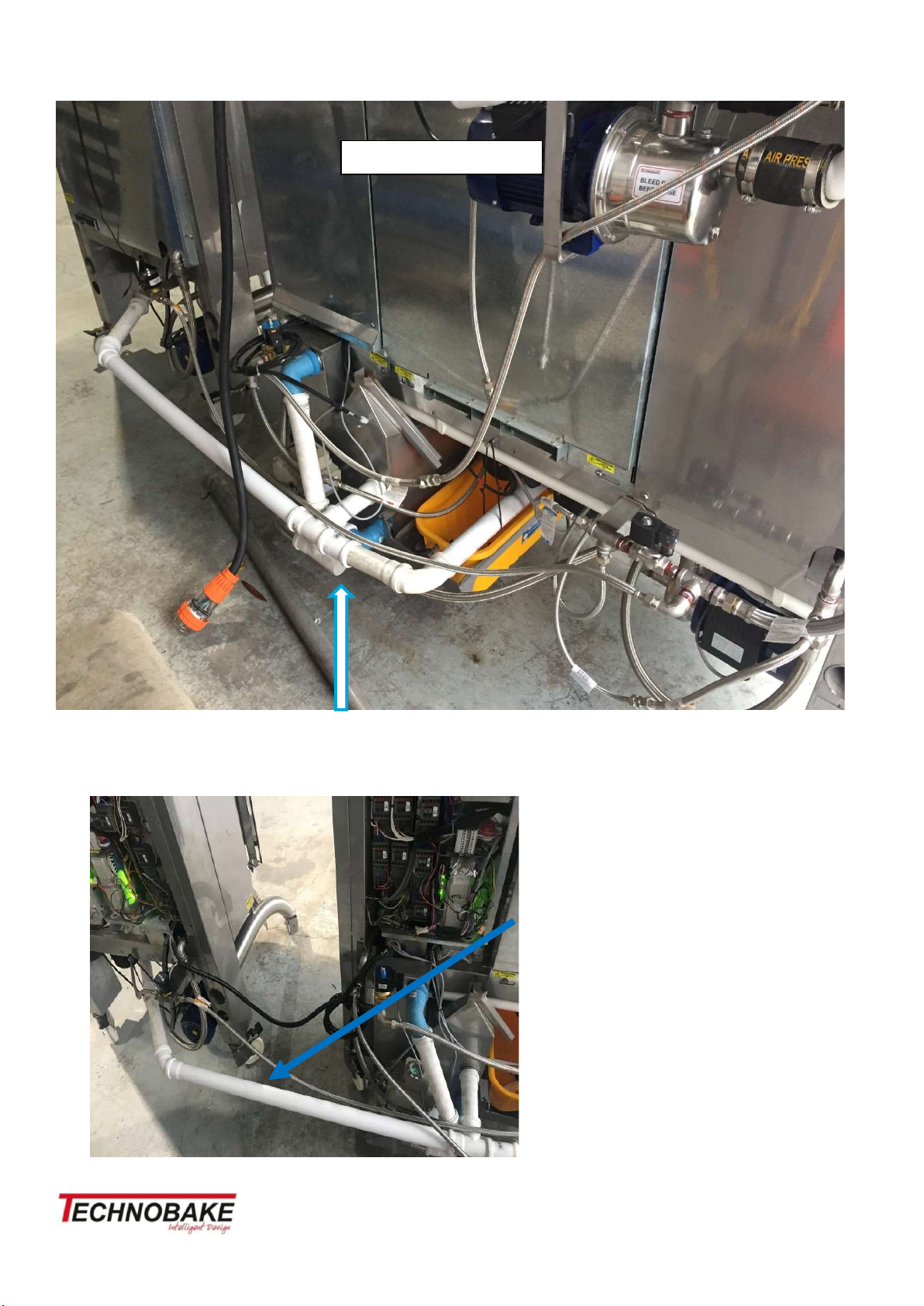

Double and Single Combined

The Double and Single oven combination share the one fat separator.

Plumping and wiring is connected.

Fat separato

Fixing

bolt

Packers

<

300

>

Locating

pin

Unit 11 / 18 Hinkler Court, Brendale Qld 4500 Ph 061 7 3205 9066

Connection wires Double and Single

To install a combination oven, follow the below format.

Two cables -1) 8 core cable (of that only 5 cables are used)

2) Solenoid cable

One end of all the needed core cables will be pre-connected to the single oven with

labels on them

Connect the other end to the double oven following the labels on to wago clips/

terminals And so on with the 5 cables

Connect the black and white wires of the Solenoid cable to the 6T3 and 14NO termi-

nals on the ‘HT pump Single’ Contactor.

Connect the green wire of the Solenoid cable to the earth terminal.

1

1

2

2

Unit 11 / 18 Hinkler Court, Brendale Qld 4500 Ph 061 7 3205 9066

Plumping connections

Connect to waste – Tundish

Maintain a 300mm gap between the two ovens and follow the plumbing above

Add the black heat shrink tube

over the extension pipe, use any

source of heat and make the tube

shrink to make the installation look

neat and tidy. Black pipe visually

disapears from front veiw.

Overflow

stops

here

–

Unit 11 / 18 Hinkler Court, Brendale Qld 4500 Ph 061 7 3205 9066

Fitting the separator valve and plumbing

Connect the 3 way valve

and its plumbing to the

fat separator by pre as-

sembling the valve and

its plumping as shown in

photo. Push the plastic

elbow on as far a it will

go.

Then fit the Tri Clover fit-

ting and its gasket (right).

If the waste tundish is too the right of the oven turn the stainless steel elbow 180 degree so

it faces the tundish.

Fit the drain from the

top weir to the plas-

tic T as shown left.

Slide the T onto the

stainless steel pipe as

far as it will go.

Unit 11 / 18 Hinkler Court, Brendale Qld 4500 Ph 061 7 3205 9066

Fit the Entry pipe to the

separator and slide on

as far as it will go.

Fit the feed pipe from the floor valve to the separator as shown below.

Note the feedpipe from the single chamber oven is fitted enters from the left as

shown - if not single oven fitted replace the T with a plastic elbow.

Unit 11 / 18 Hinkler Court, Brendale Qld 4500 Ph 061 7 3205 9066

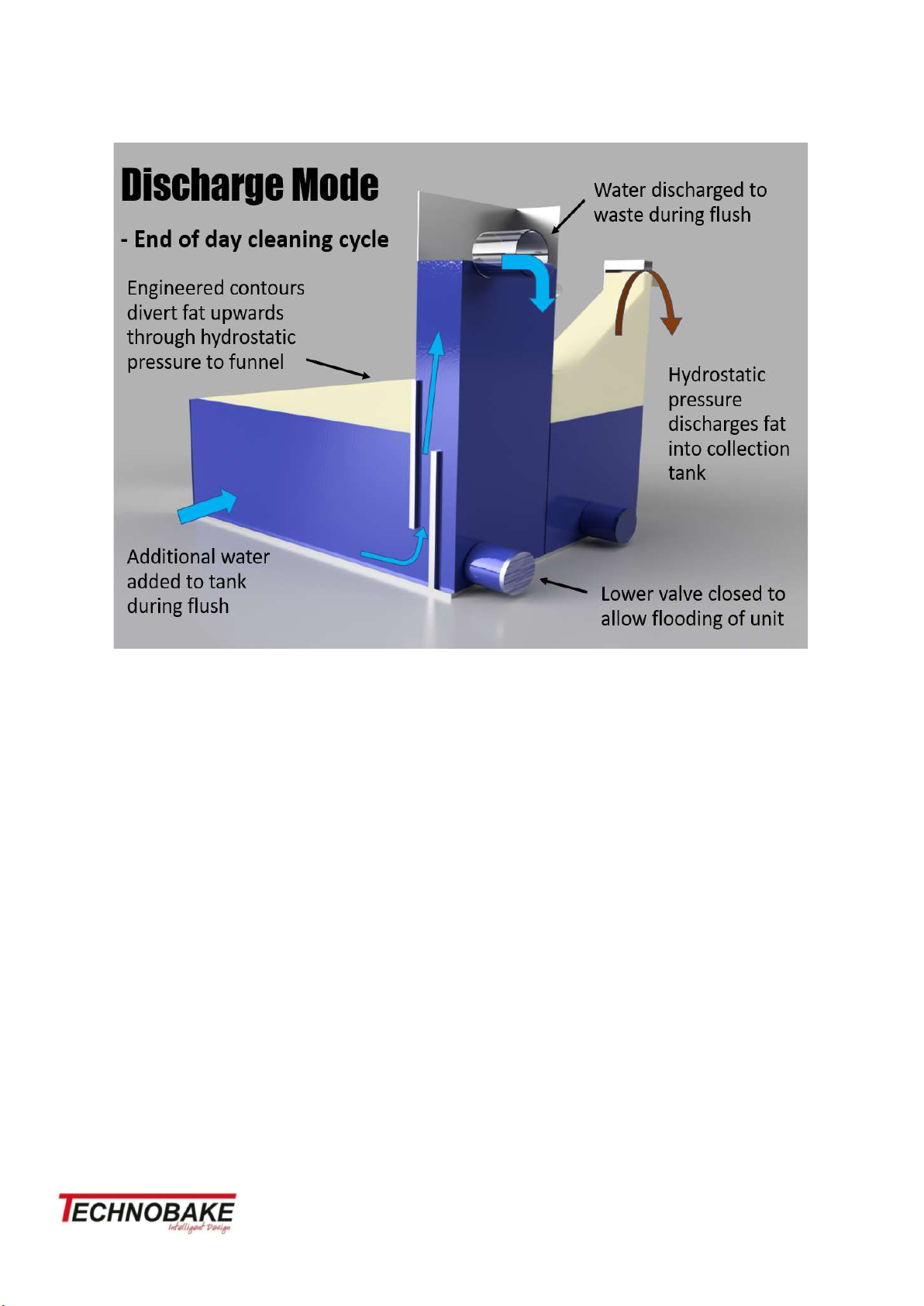

Fat separator operation

Method of operation

The 3 way valve can be driven by its motor to 3 positions. These are Separator Dump, Drain, and Closed.

‘Separator dump’ will permit the water In the separator tank to remain approximately 2/3 full. This is its

normal working position for collecting water throughout the day. Separator Valve will read ‘from weir’ in

this position.

‘Drain’ will drain the separator of water after the fat has been drained away each night.

‘Closed’ position will cause both the separator dump and drain outlets to be closed off, so water intro-

duced through the flood solenoid will cause the water level in the tank to reach the top weir The fat will

run out the fat outlet for a preset period ( typically 300 seconds) The fat will stop flowing once it has

drained from the tank, even though the water will continue flowing through the top weir. Once the fat

Transfer has completed the flood solenoid will be off, the 3 way valve will open to drain. This empties the

tank of water and allows it to drain until use the next day.

Unit 11 / 18 Hinkler Court, Brendale Qld 4500 Ph 061 7 3205 9066

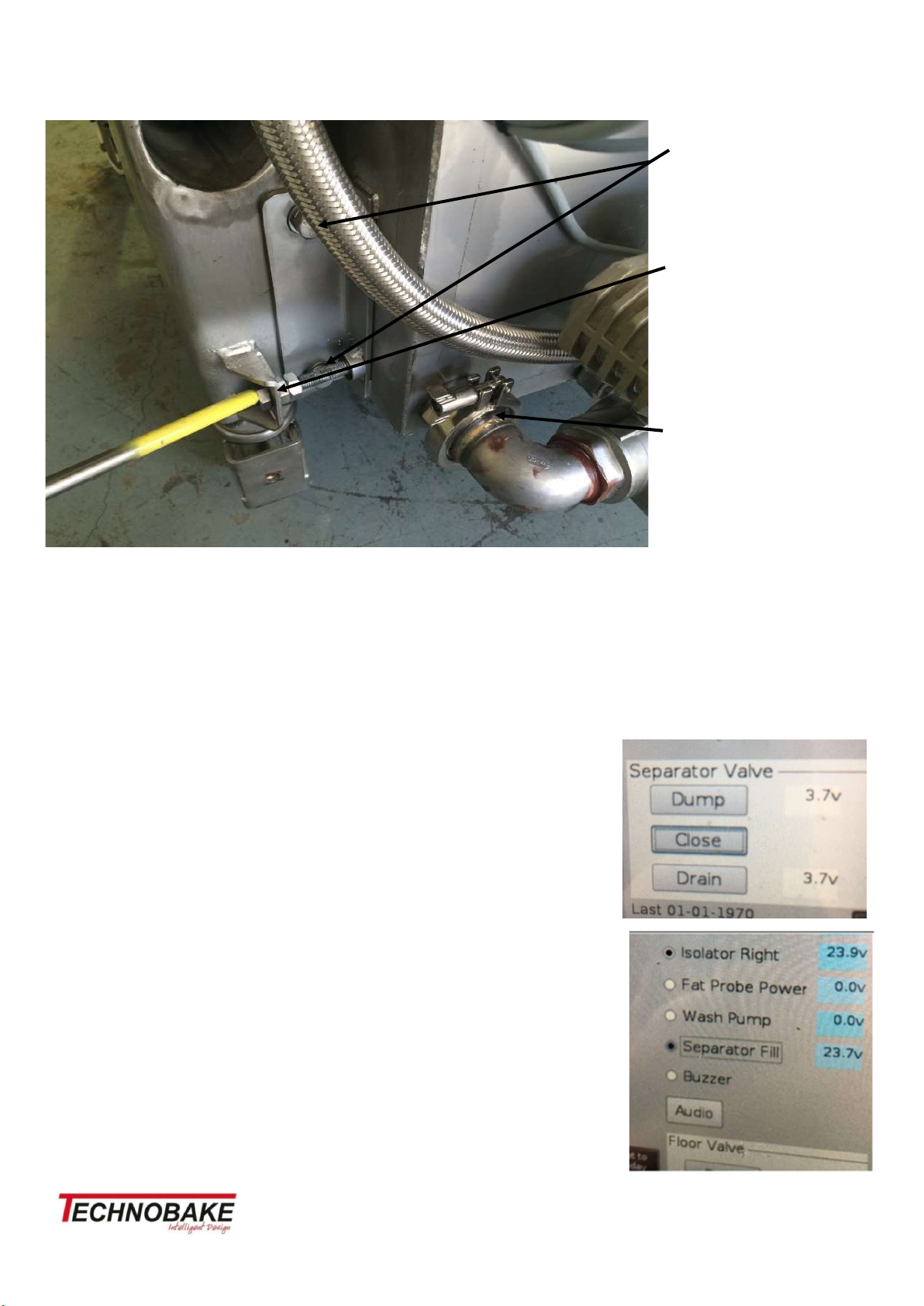

Levelling the Separator

The two mounting bolts on the oven leg, affix the separator tank to the leg, ensuring that the bolts can be

loosened to make the setup of water level adjustment possible.

Check that oven is in its intended working position on the floor, level oven, lock leg jacks in place.

Connect water hose 1/2 inch braided hose to the flood solenoid.

Remove top inspection cover over the top weir. Connect oven to power and turn oven on.

After 3 minutes, access the DIAGNOSTIC function on the touch screen. It

will ask for a Code 2906 then press enter

Initial set up/adjustment

• With water turned on, from the diagnostic screen press CLOSE on the

separator valve control buttons

• Press Separator Fill button on screen (it only runs for 60 seconds so will

need to repeat this 4 times)

• When water fills to the top weir and with water flowing into the top weir

from inlet has stopped, the water level in the fat outlet should be 4 to 5

mm below the knife edge of the fat outlet.

• If adjustment is needed use the level adjustment bolt wind in or out as

needed. Loosen the leg fixing bolts to allow the tank to move.

• When correct tighten the all bolts.

Fixing bolts

Fat separator

level adjustment

bolt

Tri Clover fittings

with Gasket

Unit 11 / 18 Hinkler Court, Brendale Qld 4500 Ph 061 7 3205 9066

Configuration

How to check and change configuration if needed. Current settings are factory settings

and should need no adjustments. Below is how to access if needed.

Press Settings

press

“Configuration”

Enter passcode

“4500”

Press enter

Password en-

tered correctly

you will see this

screen

Unit 11 / 18 Hinkler Court, Brendale Qld 4500 Ph 061 7 3205 9066

Diagnostic

How to use diagnostic screen. Warning; Fan motors may start without warning when oven is in diagnostic

mode. Isolate power to oven before accessing working parts.

• Press ‘settings’ Password “2906”

From here you can manually run functions of the oven, it will also help quickly diagnose faults. Example;

You can test a proximity switch by watching the voltage while using the function if it stays at 0-3.7v its not

reading.

All components are shown here and can turn them on individually, to turn on simply press the circle next

it. It's on when the circle turns black.

Temperature shown here

Voltage shown here – power to

contactor only.

Fan Motors on/off

Voltage shown here – coil volt-

age to contactor only.

Proximity switches shown here

Gantry reads is tray/wishbones

are in or out

2 Door switches at bottom of

door - top and bottom

Run oven functions here, floor

flush, wash pump, speaker, sep-

arator fill.

If old style separator fitted

probe -Power and readings here

Separator valve, voltage shows

valve position.

Drain chamber floor open/close

All of and close returns to home

screen.

Unit 11 / 18 Hinkler Court, Brendale Qld 4500 Ph 061 7 3205 9066

Clean up

• On completing the job the site has to be left in a clean and tidy with no trip hazards.

• All packing creating goes in a bin

• Polish all stainless steel removing all fingerprints

• Polish all glass removing any marks

• Once oven is clean check for cleaning instruction sticker, if one is not present put one where it is easily

visible and make staff aware

• Ensure unit has serial number

• Final check of the unit making sure no leaks or damage to report

If there is anything to report at time of install it must be reported so it can be rectified immediately and If

parts are required, we can get them away in a timely manner.

Please take Photograph of your installation - front and

back and send to service@technobake.com.au

(we attach to our data base for that oven)

Thank you.

Unit 11 / 18 Hinkler Court, Brendale Qld 4500 Ph 061 7 3205 9066

Unit 11 / 18 Hinkler Court, Brendale Qld 4500 Ph 061 7 3205 9066

Unit 11 / 18 Hinkler Court, Brendale Qld 4500 Ph 061 7 3205 9066

Other manuals for Roastrunner

1

Table of contents