Techspan TE1600 User manual

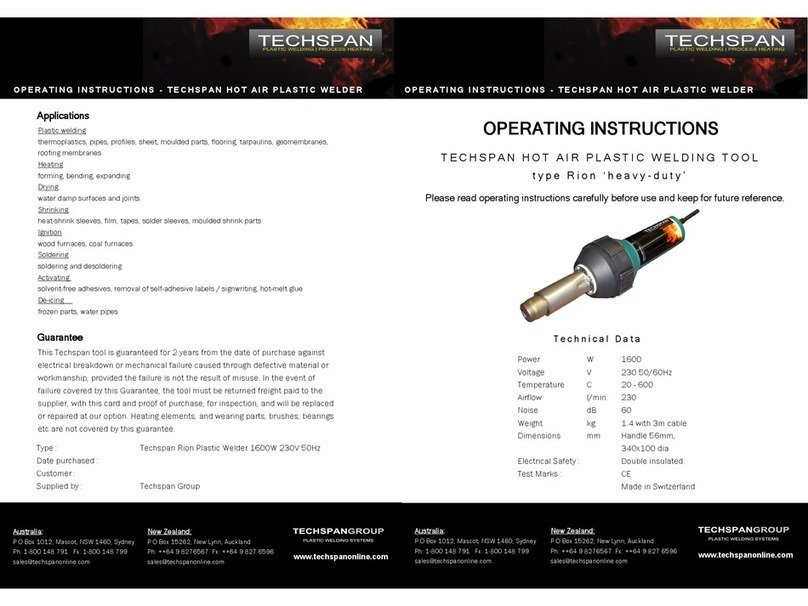

T E C H S P A N H O T A I R P L A S T I C W E L D I N G T O O L

t y p e T E 1 6 0 0

OPERATING INSTRUCTIONS

Please read operating instructions carefully before use and keep for future reference.

Power W 1600

Voltage V 230 50/60Hz

Temperature C 20 - 600

Airflow l/min. 230

Noise dB 60

Weight kg 1.4 with 3m cable

Dimensions mm Handle 55mm,

345x100 dia

Electrical Safety : Double insulated

Test Marks : CE European Conformity

Designed & Developed in Switzerland

Made in PRC

T e c h n i c a l D a t a

Applications

Plastic welding

thermoplastics, pipes, profiles, sheet, moulded parts, flooring, tarpaulins, geomembranes,

roofing membranes

Heating

forming, bending, expanding

Drying

water damp surfaces and joints

Shrinking

heat-shrink sleeves, film, tapes, solder sleeves, moulded shrink parts

Ignition

wood furnaces, coal furnaces

Soldering

soldering and desoldering

Activating

solvent-free adhesives, removal of self-adhesive labels / signwriting, hot-melt glue

De-icing

frozen parts, water pipes

O P E R A T I N G I N S T R U C T I O N S - T E C H S P A N T E 1 6 0 0 P L A S T I C W E L D E RO P E R A T I N G I N S T R U C T I O N S - T E C H S P A N T E 1 6 0 0 P L A S T I C W E L D E R

New Zealand:

P O Box 15262, New Lynn, Auckland

Ph: ++64 9 8276567 Fx: ++64 9 827 6596

info@plasticweldingtools.co.nz

Australia:

P O Box 5287, Brisbane, QLD 4069,

Ph: 1-800 148 791 Fx: 1-800 148 799

info@plasticweldingtools.com.au

This Techspan TE1600 tool is guaranteed for 1 year from the date of purchase

against electrical breakdown or mechanical failure caused through defective

material or workmanship, provided the failure is not the result of misuse. In the

event of failure covered by this Guarantee, the tool must be returned freight paid

to the supplier, with this card and proof of purchase, for inspection, and will be

replaced or repaired at our option. Heating elements, and wearing parts, brushes,

bearings etc are not covered by this guarantee.

Type : Techspan TE1600 Plastic Welder 1600W 230V 50Hz

Date purchased :

Customer :

Supplied by : TECHSPANGROUP (Plastic Welding Tools P/L)

Guarantee

Plastic Welding Tools

Australia

www.plasticweldingtools.com.au

New Zealand

www.plasticweldingtools.co.nz

New Zealand:

P O Box 15262, New Lynn, Auckland

Ph: ++64 9 8276567 Fx: ++64 9 827 6596

info@plasticweldingtools.co.nz

Australia:

P O Box 5287, Brisbane, QLD 4069,

Ph: 1-800 148 791 Fx: 1-800 148 799

info@plasticweldingtools.com.au

Plastic Welding Tools

Australia

www.plasticweldingtools.com.au

New Zealand

www.plasticweldingtools.co.nz

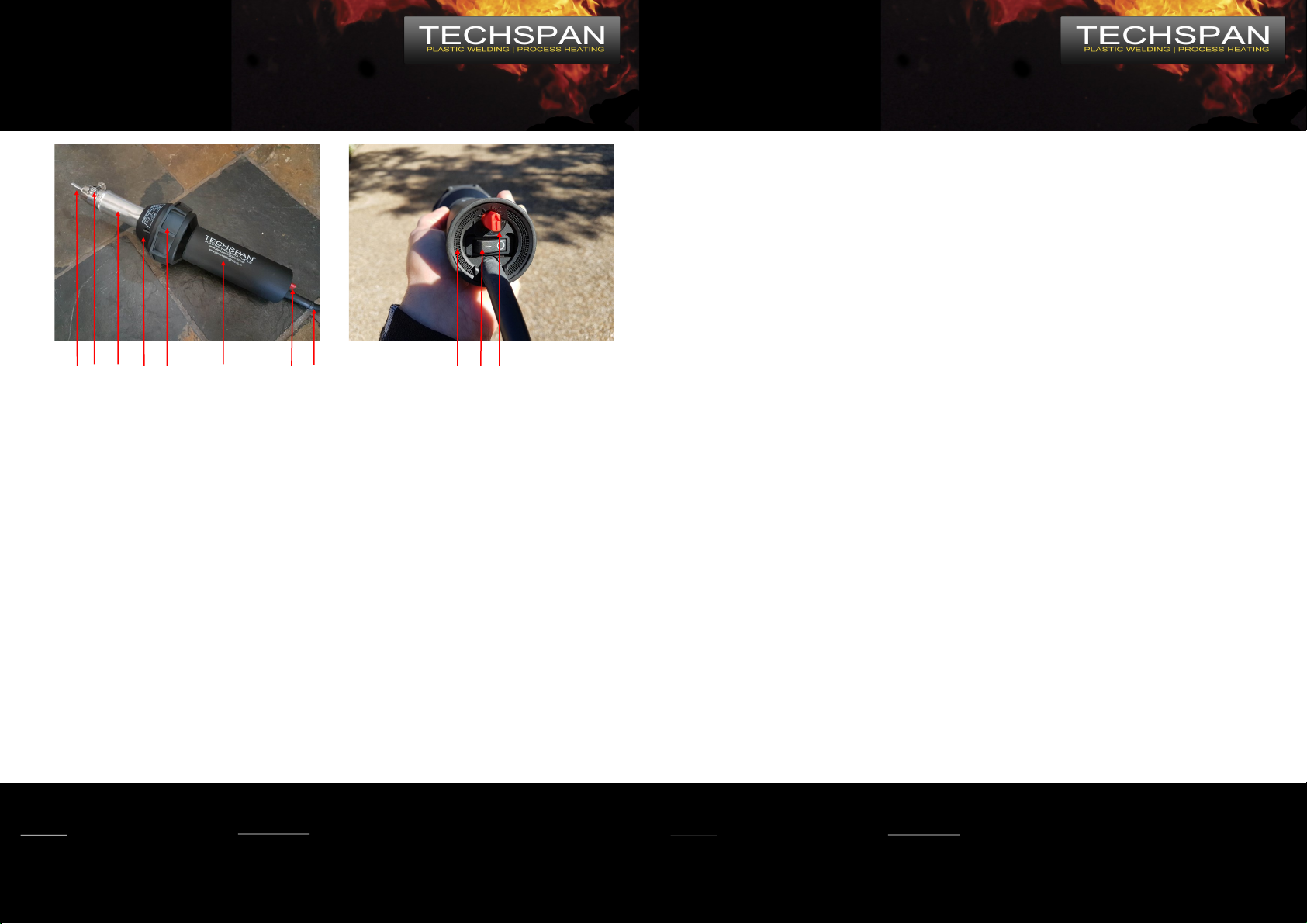

Description

1 Nozzle (LE100303 plastic welding nozzle shown)

2 Clamp screw for nozzle

3 Element housing / protective sleeve

4 Impellor housing

5 Rubber tool rest

6 Handle

7 Potentiometer for temperature adjustment

8 Mains cable

9 Air filter

10 On/Off Rocker Swith

11 Potentiometer for temperature adjustment

To operate the tool

1 Fit appropriate nozzle (1,2) as required.

2 Connect tool to the mains (single phase, 230 volt, 50 Hz, 10 amp

3 Adjust hot air temperature by turning the potentiometer (11)

4 Turn on switch (10) and allow tool to come up to temperature (approx. 2 mins)

5 After use always allow tool cool down. This will preserve the heating element

6 For plastic welding training contact Techspan or approved service centre.

1 2 3 4 5 6 7 8 9 10 11

O P E R A T I N G I N S T R U C T I O N S - T E C H S P A N T E 1 6 0 0 P L A S T I C W E L D E R

O P E R A T I N G I N S T R U C T I O N S - T E C H S P A N T E 1 6 0 0 P L A S T I C W E L D E R

1 The carbon brushes of the tool’s motor should be checked after about 1200 hours

running time by your service centre.

2 Repairs must be carried out by Techspan service centres. They guarantee a specialized and reliable

repair service.

3 The warranty will be void if repairs have not been carried out by a Techspan service centre using

Techspan spare parts.

1 Before changing nozzles, allow the tool to cool down, or use combination pliers

2 Do not touch hot nozzle (1,2) and only place the nozzle on a heat resistant surface

due to fire hazard.

3 The nozzles are easily pushed onto the element housing (3) and are then secured by tightening the

clamp screw (2) with a screwdriver.

4 Only Techspan nozzles and accessories should be used.

Maintenance

1 The welding tool’s air filter (9) must be cleaned with a brush if necessary.

2 A wire brush should be used for cleaning the welding nozzle (1)

3 Check power supply cable (8) along the full length, as well as the plug, for any possible electrical or

mechanical damage.

Accessories

1 The Techspan plastic welder is supplied without nozzles, which are sold separately.

2 Only Techspan nozzles and accessories should be used.

Service and repairs

Changing Nozzles

Guarantee and Liability

Guarantee and liability are in accordance with this guarantee certificate and the current terms and conditions

of sale. Techspan rejects any guarantee claims for tools which are not in original condition. The tool must

never be modified.

Caution - Risk of Serious Injury and property damage

Always lie the tool on a non-flammable surface & keep the hot air stream well away from combustible materials, includ-

ing combustible materials hidden behind ceilings, walls, cavities or floors. Do not point the hot air stream at the same

spot for extended periods. Incorrect use can cause fire. Do not touch the element housing or nozzle with any part of the

body during use as they get very hot and there is a danger of serious injury by burning. When working with plastics,

varnish or similar materials vapours/gases/smoke develop which can be harmful. Do not breathe in vapours/gasses/

smoke as they can be highly toxic. Always provide good ventilation of the working area with an extraction system and/or

wear a respirator. Keep the unit dry. Do not use in the rain or in damp conditions. Always store the unit in a dry place.

*Setting Deg. C

1 20

2 200

3 350

4 450

5 540

6 570

7 590

8 610

9 620

10 650

New Zealand:

P O Box 15262, New Lynn, Auckland

Ph: ++64 9 8276567 Fx: ++64 9 827 6596

info@plasticweldingtools.co.nz

Australia:

P O Box 5287, Brisbane, QLD 4069,

Ph: 1-800 148 791 Fx: 1-800 148 799

info@plasticweldingtools.com.au

Plastic Welding Tools

Australia

www.plasticweldingtools.com.au

New Zealand

www.plasticweldingtools.co.nz

New Zealand:

P O Box 15262, New Lynn, Auckland

Ph: ++64 9 8276567 Fx: ++64 9 827 6596

info@plasticweldingtools.co.nz

Australia:

P O Box 5287, Brisbane, QLD 4069,

Ph: 1-800 148 791 Fx: 1-800 148 799

info@plasticweldingtools.com.au

Plastic Welding Tools

Australia

www.plasticweldingtools.com.au

New Zealand

www.plasticweldingtools.co.nz

Other Techspan Welding System manuals

Popular Welding System manuals by other brands

ESAB

ESAB Aristo WeldCloud Mig U5000i instruction manual

Lincoln Electric

Lincoln Electric INNERSHIELD PRO K126-10 Operator's manual

Lincoln Electric

Lincoln Electric RED-D-ARC LN-25TM PRO EXTREME IM10078 Operator's manual

Amada

Amada PU-G Operation manual

Leister

Leister Uniplan E operating instructions

GYS

GYS HEAVYMIG 400-4 manual