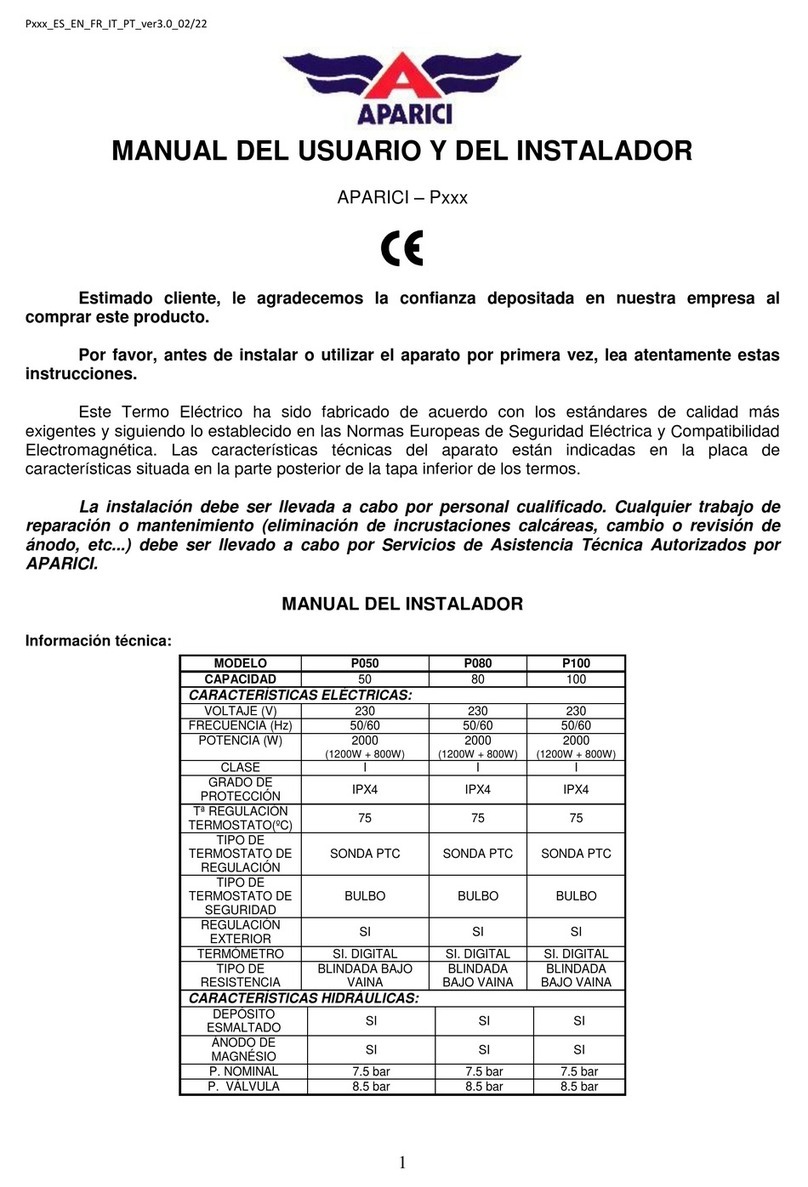

IV Installation/Piping

(cont’d)

A

BC

D

E

F

G

H

Legend

ABallValve—Typical

BDielectricUnion—Suggested

CTemperature&PressureReliefValve

DHeatTrapLoop—Suggested

EThermosta�cMixingValve–Suggested

FHighTemperatureOutlet

GMixedTemperatureOutlet

HExpansionTankinColdWaterSupply

Note: For drawing clarity, addiƟonal

isolaƟon valves and other accessories have

been omiƩed. Follow normal piping

pracƟces when installing tank.

Domes�cWater:

A.Installisola�onvalvebetweenthewatersupplyand

thecoldwaterinletofthetankforeaseofservice.

B.Installingaheattrapinthedomes�chotwateroutlet

pipingwillimproveenergyefficiencyandreducepip‐

ingheatloss.

C.AThermosta�cMixingValveisrecommendedand

mayberequiredbylocalcodes.Thevalvewillblend

thetankoutputwaterwithcoldwatertoachievea

moreconstantmixedtemperature.Theriskofscald‐

ingisnoteliminatedbyuseofamixingvalve.Refer

totheinstalla�oninstruc�onsprovidebythemixing

valvemanufacturerforproperinstalla�on.

D.ExpansionTank:Whenaback‐owdeviceor“no‐

return”valveisinstalledinthepipingsystemaTher‐

malExpansionTankdesignedforuseinadomes�c

hotwatersystemwillberequired.Installthetankin

thecoldwaterpipingclosetothetankbetweenthe

tankandtheback‐owdevice.(seepipingdiagram)

RefertoThermalExpansionTankmanufacturer’slit‐

eratureforsizingandinstalla�oninforma�on.

E.VacuumBreaker:DHTrecommendsthatavacuum

breakerbeinstalledonthedomes�cpipingtothe

heater.Thevacuumbreakerprotectstheheaterin

theeventthatthetankpressurefallsbelowatmos‐

phericpressure.

F.Temperature&PressureReliefValve:(T&P)Installa

T&Preliefvalve(longelementtype)intotheseparate

tappingdesignatedfortheT&Pvalve.Installtemper‐

atureandpressureprotec�veequipmentrequiredby

localcodes,butnolessthanacombina�ontempera‐

tureandpressurereliefvalvecer�edasmee�ngthe

requirementsforreliefValveandAutoma�cShutoff

DevicesforHotWatersystems,ANSIZ21.22,bya

na�onallyrecognizedtes�nglaboratorythatmain‐

tainsperiodicinspec�onoflistedequipmentormate‐

rials.Thevalvemustbeoriented,providedwithtub‐

ingorotherwiseinstalledsothatdischargecanexit

onlywithinsix(6)inchesabove,oratanydistance

below,thestructuraloor,andcannotcontactany

electricalpart.Thevalvemustbepipedtoanarea

wheredischargewillnotcausepersonalinjuryor

damagethesurroundingarea.

WARNING

Install a T&P relief valve with a rated capacity equal

or greater that the output of the energy source.

Removal of the T&P Valve or failure to replace the

valve will release the manufacturer from any claim

which might result from excessive

temperatures and pressures

10

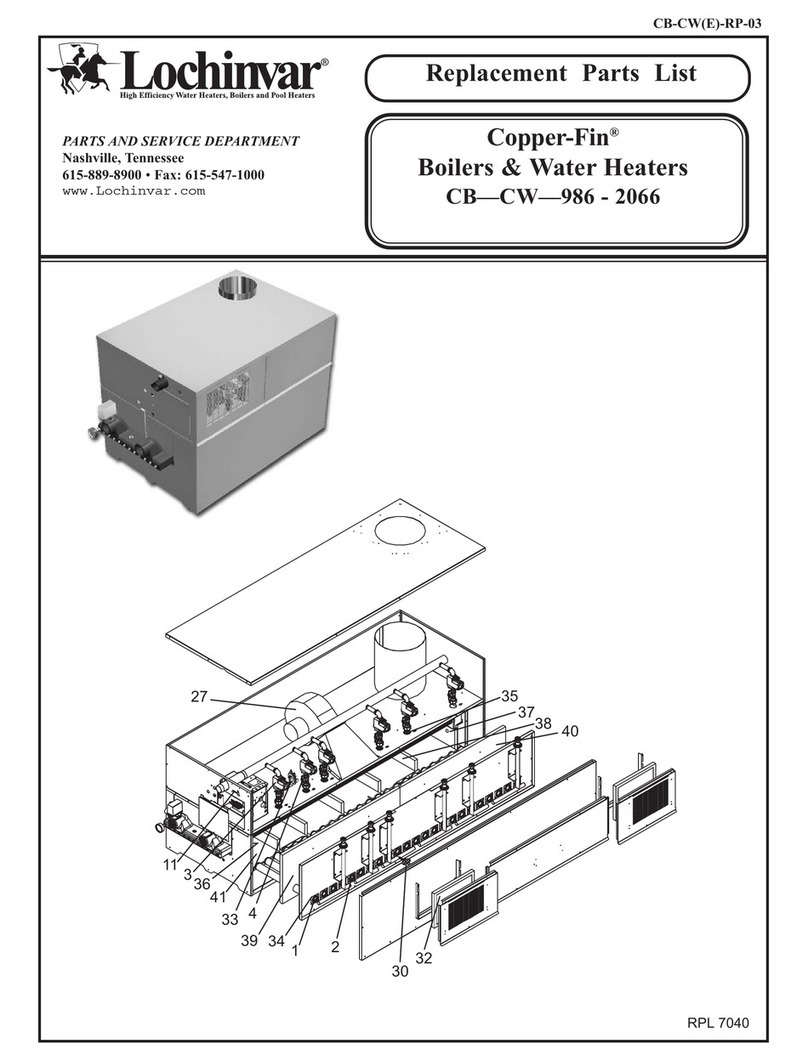

IV Installation/Piping

(cont’d)

A

BC

D

E

F

G

H

Legend

ABallValve—Typical

BDielectricUnion—Suggested

CTemperature&PressureReliefValve

DHeatTrapLoop—Suggested

EThermosta�cMixingValve–Suggested

FHighTemperatureOutlet

GMixedTemperatureOutlet

HExpansionTankinColdWaterSupply

Note: For drawing clarity, addiƟonal

isolaƟon valves and other accessories have

been omiƩed. Follow normal piping

pracƟces when installing tank.

Domes�cWater:

A.Installisola�onvalvebetweenthewatersupplyand

thecoldwaterinletofthetankforeaseofservice.

B.Installingaheattrapinthedomes�chotwateroutlet

pipingwillimproveenergyefficiencyandreducepip‐

ingheatloss.

C.AThermosta�cMixingValveisrecommendedand

mayberequiredbylocalcodes.Thevalvewillblend

thetankoutputwaterwithcoldwatertoachievea

moreconstantmixedtemperature.Theriskofscald‐

ingisnoteliminatedbyuseofamixingvalve.Refer

totheinstalla�oninstruc�onsprovidebythemixing

valvemanufacturerforproperinstalla�on.

D.ExpansionTank:Whenaback‐owdeviceor“no‐

return”valveisinstalledinthepipingsystemaTher‐

malExpansionTankdesignedforuseinadomes�c

hotwatersystemwillberequired.Installthetankin

thecoldwaterpipingclosetothetankbetweenthe

tankandtheback‐owdevice.(seepipingdiagram)

RefertoThermalExpansionTankmanufacturer’slit‐

eratureforsizingandinstalla�oninforma�on.

E.VacuumBreaker:DHTrecommendsthatavacuum

breakerbeinstalledonthedomes�cpipingtothe

heater.Thevacuumbreakerprotectstheheaterin

theeventthatthetankpressurefallsbelowatmos‐

phericpressure.

F.Temperature&PressureReliefValve:(T&P)Installa

T&Preliefvalve(longelementtype)intotheseparate

tappingdesignatedfortheT&Pvalve.Installtemper‐

atureandpressureprotec�veequipmentrequiredby

localcodes,butnolessthanacombina�ontempera‐

tureandpressurereliefvalvecer�edasmee�ngthe

requirementsforreliefValveandAutoma�cShutoff

DevicesforHotWatersystems,ANSIZ21.22,bya

na�onallyrecognizedtes�nglaboratorythatmain‐

tainsperiodicinspec�onoflistedequipmentormate‐

rials.Thevalvemustbeoriented,providedwithtub‐

ingorotherwiseinstalledsothatdischargecanexit

onlywithinsix(6)inchesabove,oratanydistance

below,thestructuraloor,andcannotcontactany

electricalpart.Thevalvemustbepipedtoanarea

wheredischargewillnotcausepersonalinjuryor

damagethesurroundingarea.

WARNING

Install a T&P relief valve with a rated capacity equal

or greater that the output of the energy source.

Removal of the T&P Valve or failure to replace the

valve will release the manufacturer from any claim

which might result from excessive

temperatures and pressures

10

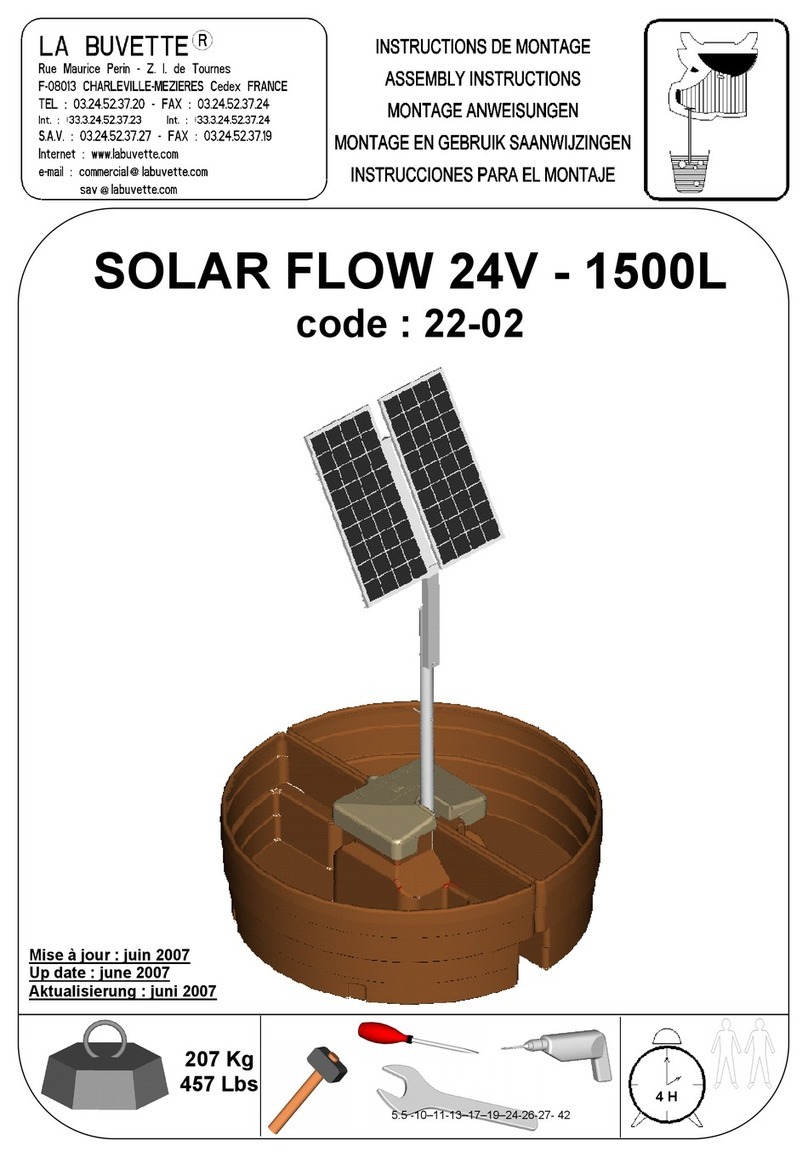

IV Installation/Piping

(cont’d)

A

BC

D

E

F

G

H

Legend

ABallValve—Typical

BDielectricUnion—Suggested

CTemperature&PressureReliefValve

DHeatTrapLoop—Suggested

EThermosta�cMixingValve–Suggested

FHighTemperatureOutlet

GMixedTemperatureOutlet

HExpansionTankinColdWaterSupply

Note: For drawing clarity, addiƟonal

isolaƟon valves and other accessories have

been omiƩed. Follow normal piping

pracƟces when installing tank.

Domes�cWater:

A.Installisola�onvalvebetweenthewatersupplyand

thecoldwaterinletofthetankforeaseofservice.

B.Installingaheattrapinthedomes�chotwateroutlet

pipingwillimproveenergyefficiencyandreducepip‐

ingheatloss.

C.AThermosta�cMixingValveisrecommendedand

mayberequiredbylocalcodes.Thevalvewillblend

thetankoutputwaterwithcoldwatertoachievea

moreconstantmixedtemperature.Theriskofscald‐

ingisnoteliminatedbyuseofamixingvalve.Refer

totheinstalla�oninstruc�onsprovidebythemixing

valvemanufacturerforproperinstalla�on.

D.ExpansionTank:Whenaback‐owdeviceor“no‐

return”valveisinstalledinthepipingsystemaTher‐

malExpansionTankdesignedforuseinadomes�c

hotwatersystemwillberequired.Installthetankin

thecoldwaterpipingclosetothetankbetweenthe

tankandtheback‐owdevice.(seepipingdiagram)

RefertoThermalExpansionTankmanufacturer’slit‐

eratureforsizingandinstalla�oninforma�on.

E.VacuumBreaker:DHTrecommendsthatavacuum

breakerbeinstalledonthedomes�cpipingtothe

heater.Thevacuumbreakerprotectstheheaterin

theeventthatthetankpressurefallsbelowatmos‐

phericpressure.

F.Temperature&PressureReliefValve:(T&P)Installa

T&Preliefvalve(longelementtype)intotheseparate

tappingdesignatedfortheT&Pvalve.Installtemper‐

atureandpressureprotec�veequipmentrequiredby

localcodes,butnolessthanacombina�ontempera‐

tureandpressurereliefvalvecer�edasmee�ngthe

requirementsforreliefValveandAutoma�cShutoff

DevicesforHotWatersystems,ANSIZ21.22,bya

na�onallyrecognizedtes�nglaboratorythatmain‐

tainsperiodicinspec�onoflistedequipmentormate‐

rials.Thevalvemustbeoriented,providedwithtub‐

ingorotherwiseinstalledsothatdischargecanexit

onlywithinsix(6)inchesabove,oratanydistance

below,thestructuraloor,andcannotcontactany

electricalpart.Thevalvemustbepipedtoanarea

wheredischargewillnotcausepersonalinjuryor

damagethesurroundingarea.

WARNING

Install a T&P relief valve with a rated capacity equal

or greater that the output of the energy source.

Removal of the T&P Valve or failure to replace the

valve will release the manufacturer from any claim

which might result from excessive

temperatures and pressures

10