Tecnibel CA250R5TA Series User manual

R 407 C

37.4163.194.0

INSTALLATION MANUAL

MANUALE D’INSTALLAZIONE

MANUEL D’INSTALLATION

MAGGIO 2001

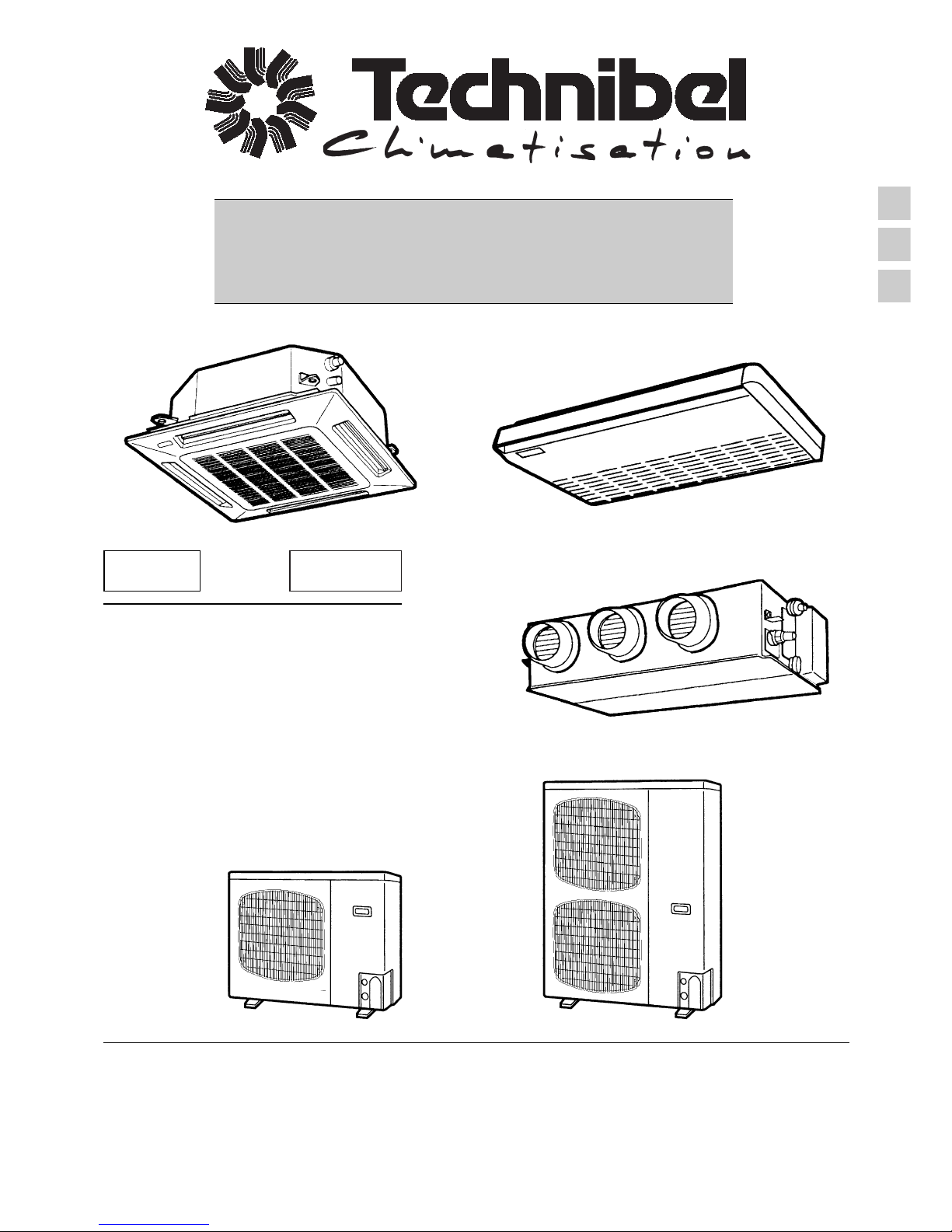

Split system air conditioner

Condizionatore d'aria split system

Climatiseurs split system

EG

I

F

CA250R5TA*

CA360R5TA*

CA480R5TA*

SPA250R5TA*

SPA360R5TA*

SPA480R5TA*

DSAV250R5TA*

DSAV360R5TA*

DSAV480R5TA*

CAV250R5TA*

CAV360R5TA*

CAV480R5TA*

SPAV250R5TA*

SPAV360R5TA*

SPAV480R5TA*

DSAV250R5TA*

DSAV360R5TA*

DSAV480R5TA*

R 22

Dear User

Thank you for selecting this product and we welcome you to the growing family of

satisfied products owners.

Like all products, it has been designed carefully and manufactured under strict quality

control.

We firmly believe that our products will give full satisfaction to users through proper

operation and maintenance.

Please read this manual, and be sure to keep it handy for your reference.

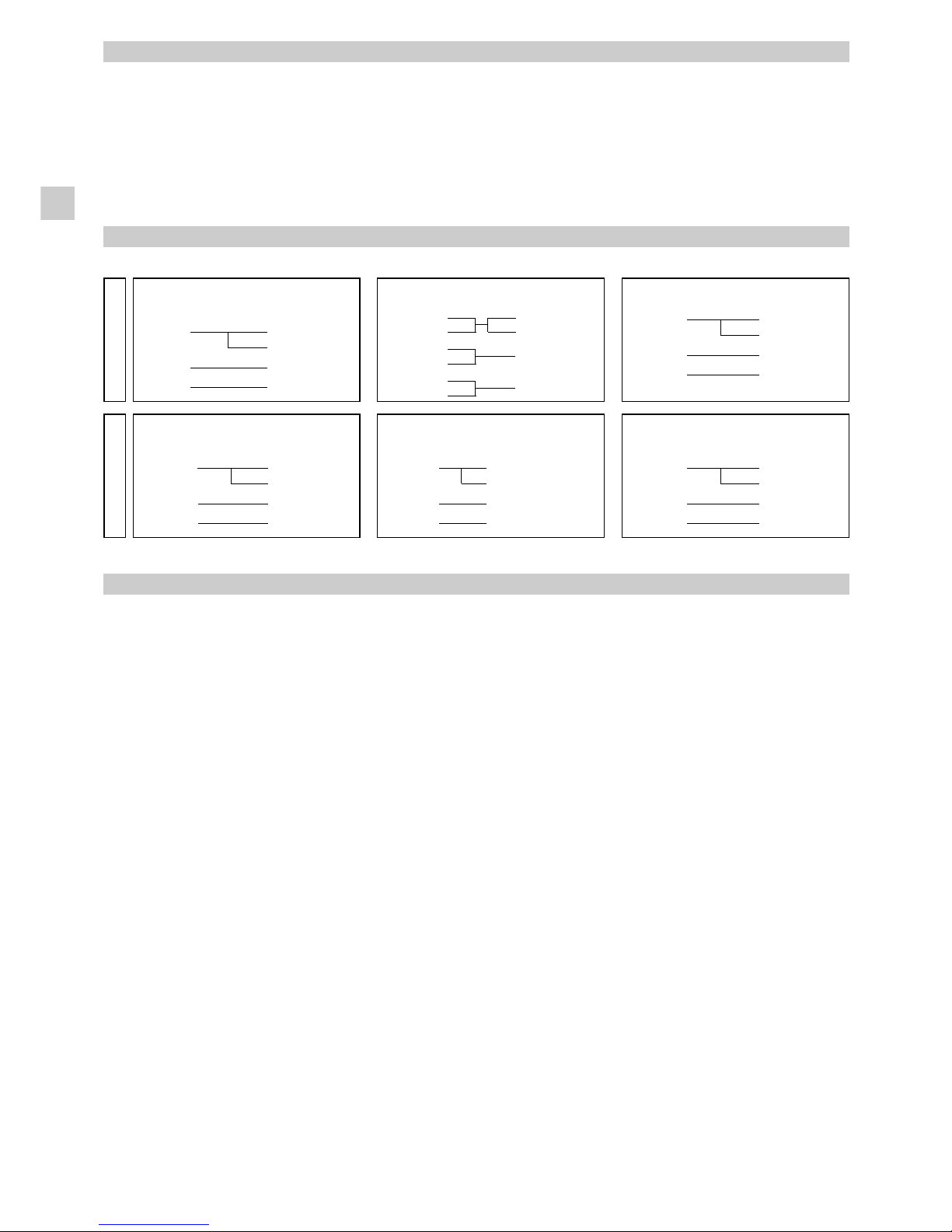

MODEL COMBINATIONS

CONTENTS

SEMI-CONCEALED MODEL

HEAT PUMP VERSION

INDOOR UNIT OUTDOOR UNIT

CA250R5 GR250R5

GR250R7

CA360R5 GR360R7

CA480R5 GR480R7

CEILING-MOUNTED MODEL

HEAT PUMP VERSION

INDOOR UNIT OUTDOOR UNIT

SPA250R5 GR250R5

SPAV250R5 GR250R7

SPA360R5 GR360R7

SPAV360R5

SPA480R5 GR480R7

SPAV480R5

CONCEALED DUCT MODEL

Combine indoor and outdoor units as listed above.

IMPORTANT: Please Read Before Starting

IMPORTANT: Precautions for new refrigerant R 407 C installation

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

1-1. Tools required for Installation (not supplied)

1-2. Accessories Supplied with Unit

1-3. Type of copper Tube and Insulation Material

1-4. Additional materials required for Installation

1-5. Tubing Lenght

1-6. Operating Limits

2. INSTALLATION SITE SELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

Indoor Unit

Outdoor Unit

2-1. Air discharge chamber for top discharge

2-2. Installing the unit in heavy snow areas

2-3. Precautions for installation in heavy snow areas

2-4. Dimensions of snow/wind-proof ducting

2-5. Wind shield

3. HOW TO INSTALL THE INDOOR UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

■4-WAY AIR DISCHARGE SEMI-CONCEALED TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

3-1. Suspending the Indoor Unit

3-2. Preparation for Suspending

3-3. Burying Inside the Ceiling

3-4. Installing the Drain Piping

3-5. Checking the Drainage

■CEILING-MOUNTED TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

3-6. Suspending the Indoor Unit

3-7. Duct for fresh air

3-8. Installing the drain piping

■CONCEALED-DUCT TYPE (DSAV Type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

3-9. Required Minimun Space for Installation and Service

3-10. Suspending the Indoor Unit

3-11. Installing the Drain Piping

3-12. Increasing the Fan Speed

3-13. Checking the Drainage

4. HOW TO INSTALL THE OUTDOOR UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 17

4-1. Removing the Protective Spacer for Transportation

4-2. Installing the Outdoor Unit

4-3. Tubing Direction

EG

R

2

2

HEAT PUMP / COOLING ONLY VERSION

INDOOR UNIT OUTDOOR UNIT

CAV250R5 GRV250L5/R5

GRV250L7/R7

CAV360R5 GRV360L7/R7

CAV480R5 GRV480L7/R7

R

4

0

7

C

HEAT PUMP / COOLING ONLY VERSION

INDOOR UNIT OUTDOOR UNIT

SPAV250R5 GRV250L5/R5

GRV250L7/R7

SPAV360R5 GRV360L7/R7

SPAV480R5 GRV480L7/R7

HEAT PUMP / COOLING ONLY VERSION

INDOOR UNIT OUTDOOR UNIT

DSAV250R5 GR250R5

GR250R7

DSAV360R5 GR360R7

DSAV480R5 GR480R7

1

HEAT PUMP VERSION

INDOOR UNIT OUTDOOR UNIT

DSAV250R5 GR250R5

GR250R7

DSAV360R5 GR360R7

DSAV480R5 GR480R7

2

EG

5. ELECTRICAL WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

5-1. General Precautions on Wiring

5-2. Recommended Wire Lenght and Wire Diameter for Power Supply System

5-3. Wiring System Diagrams

6. HOW TO INSTALL THE REMOTE CONTROLLER (OPTIONAL PART) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

6-1. When Using a Wall Box for Flush Mounting

6-2. Basic Wiring Diagram

6-3. Wiring System Diagram for Group Control

6-4. Wiring System Digram for Multi-Remote Control

6-5. Meaning for Alarm Message

7. HOW TO INSTALL THE WIRELESS REMOTE CONTROLL UNIT (OPTIONAL PART) . . . . . . . . . . . . . . . . . . . . page 25

■4-WAY AIR DISCHARGE SEMI-CONCEALED TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 25

7-1. Indicator Section Installation

7-2. Operating Controler Installation

■CEILING-MOUNTED TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 26

7-3. Indicator Section Installation

7-4. Operating Controller Installation

7-5. Electrical Wiring

7-6. Room temperature Sensor Setting

7-7. Address Switches

7-8. Setting the Model Code (only for Heat Pump models)

7-9. Test Run switch

7-10. Misoperation Alarm Indicators (only for Heat Pump models)

7-11. Wireless Remote controller Installation

7-12. How to install batteries (only for Heat Pump models)

8. HOW TO INSTALL THE WEEKLY TIMER (OPTIONAL CONTROLLER) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 30

8-1. When Using a Wall Box for Flush Mounting

8-2. Wiring Diagram

8-3. Test Run Setting

8-4. Memory Back Up Function for Power Failure Compensation

8-5. State at Time of Power ON

9. HOW TO PROCESS TUBING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 32

9-1. Connecting Tubing Side

9-2. Connecting Tubing between Indoor and Outdoor Unit

9-3. Insulation of refrigerant Tubing

9-4. Taping the Tubes

9-5. Finishing the Installation

10. AIR PURGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 34

11. HOW TO INSTALL THE CEILING PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 36

■4-WAY AIR DISCHARGE SEMI-CONCEALED TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 36

11-1. Before Installing the Ceiling Panel

11-2. Installing the Ceiling Panel

11-3. When Removing the Ceiling Panel for Servicing

11-4. Adjusting the Motor Flap

12. TEST RUN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 38

12-1. Preparing for Test Run

12-2. PCB Setting

12-3. R.C. Address Setting Method

12-4. Automatic Address Setting Method

12-5. Test Run Procedure

12-6. Items to Check Prior to Test Run

12-7. The Main Alarms of Mis-wiring & Mis-setting

12-8. The Main Alarms of Unit Troubles

12-9. The Main Alarms of Power Supply Troubles

13. PUMP DOWN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 42

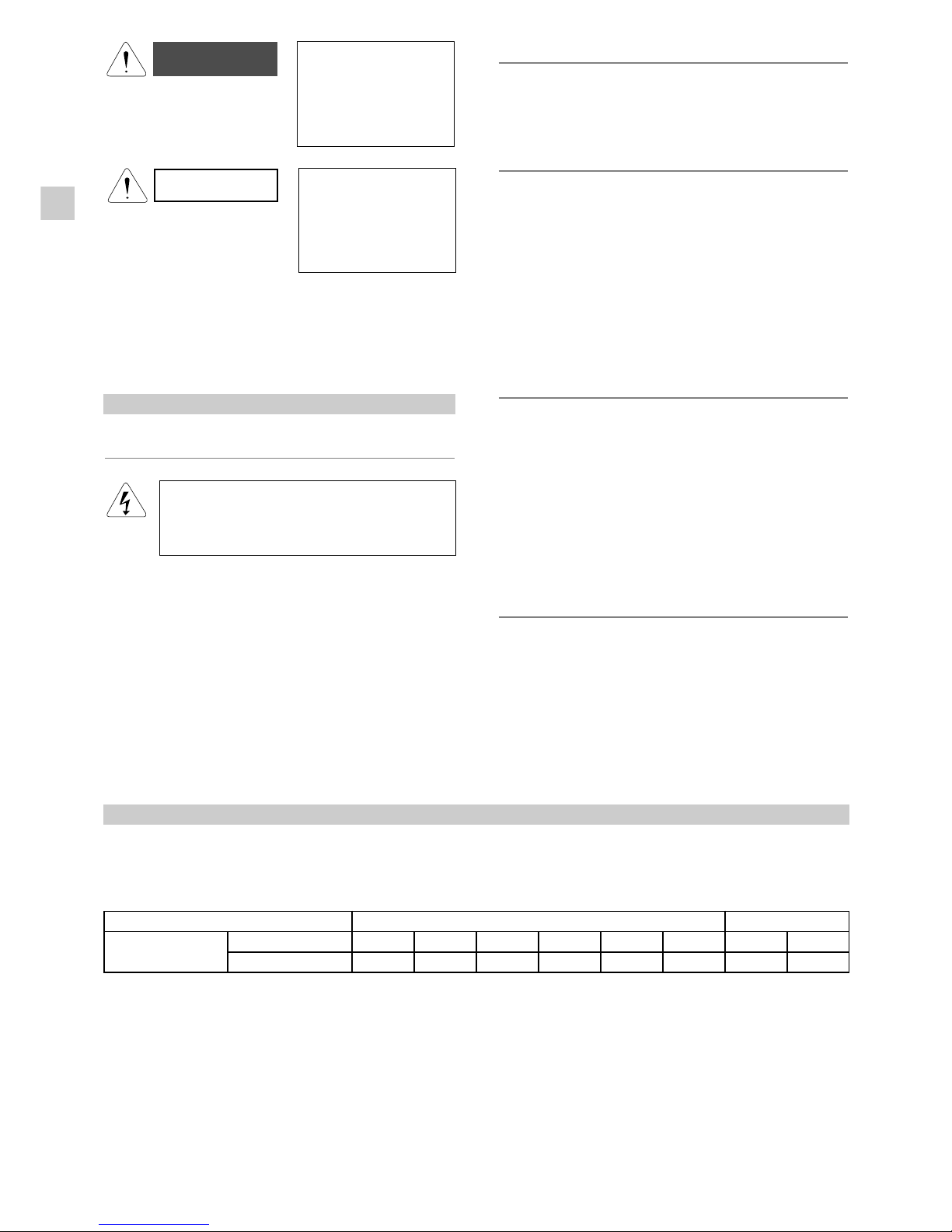

IMPORTANT PLEASE READ BEFORE STARTING

This air conditioning system meets strict safety and operating standards. As the installer or service person, it is an important part

of your job to install or service the system so it operates safely and efficienly.

For safe installation and trouble-free operation, you must:

• Carefully read this instruction booklet before beginning.

• Follow each installation or repair step exactly as shown.

• Observe all local, state, and national electrical codes.

• Pay close attention to all warning and caution notices given in this manual.

Outer diameter ø 6.35 ø 9.52 ø 12.7 ø 15.88 ø 19.05 ø 22.2 ø 25.4 ø 28.58

Wall thickness 0.8 0.8 0.8 1.0 1.0 1.2 1.0 1.0

3

EG

WARNING • This symbol refers to

a hazard or unsafe

practice which can

resuklt in severe

personal injury or

death.

IN CASE OF IMPROPER INSTALLATION

The manufacturer shall in no way be responsible for improper

installation or maintenance service, including failure to follow

the instruction in this document.

When Transporting

Be careful when pocking up and moving the indoor and outdoor

units. Get a partner to help, and bend your knees when lifting

to reduce strain on your back. Sharp edges or thin aluminum

fins on the air conditioner can cut your fingers.

When Installing

…In a Room

Properly insulate any tubing run inside a room to prevent

“sweating” that can cause driping and water damage to walls

and floors.

…In Moist or Uneven Locations

Use a raised concrete pad or concrete blocks to provide a

solid, level foundation for the outdoor unit. This prevents water

damage and abnormal vibration.

…In an area with High Winds

Securely anchor the aoutdoor unit down with bolts and a metal

frame. Provide a suitable air baffle.

When Connecting Refrigerant Tubing

• Executive enough ventilation in case refrigerant gases leak

during operations. Be careful that the contact of the

refrigerant gases with the flare will cause the generation of

poisonous gases.

• Keep all tubing runs as short as possible.

• Use the flare method for connecting tubing.

• Apply refrigerant lubricant to the matching surfaces of the

flare and union tubes before connecting them, then tighten

the nut with a torque wrench for a leak-free connection.

• Check carefully for leaks before starting the test run.

When Servicing

• Turn the power OFF at the main power box (mains) before

opening the unit to check or repair electrical parts and wiring.

• Keep your fingers and clothing away from any moving parts.

• Clean up the site after you finish, remembering to check

that no metal scraps or bits of wiring have been left inside

the unit being serviced.

CAUTION • This symbol refers to

a hazard or unsafe

practice which can

resuklt in personal

injury or product or

property damage.

SPECIAL PRECAUTION

• ELECTRICAL SHOCK CAN CAUSE SEVERE

PERSONAL INJURY OR DEATH. ONLY A

QUALIFIED, EXPERIENCED ELECTRICIAN

SHOULD ATTEMPT TO WIRE THIS SYSTEM.

When Wiring

• Do not supply power to the unit until all wiring and tubing are

completed or reconnected and checked.

• Highly dangerous electrical voltage are used in this system.

Carefully refer to the wiring diagram and these instruction

when wiring. Improper connections and inadequate

grounding can cause accidentaly injury or death.

•Ground the unit following local electrical codes.

• Connect all witing tightly. Loose wiring may cause

overheating at connection points and a possible fire hazard.

PRECAUTIONS FOR NEW REFRIGERANT R 407 C INSTALLATION

1. Care regarding piping

1-1. There is no need to change piping and tube wall thickness. Use refrigerant pipes of the same wall thickness as R22.

Type 0 1/2 H, H

Copper tube

* C 1220 type with JIS H 3300 designation (Copper Pipe and Copper Alloy Seamless Pipe)

1-2. Prevent impurities including water, dust and oxide

from coming into the pipe. Impurities can cause R407C

refrigerant deterioration and compressor defects. Due

to the different features of the refrigerant and

refrigerating machine oil, the prevention of water and

other impurities becomes more important than ever.

2. Make sure to refill the refrigerant in liquid form

2-1. Since R 407 C is a non-azeotrope, refilling the

refrigerant in gas form can lower performance and

cause defects of the unit.

2-2. Since refrigerant composition changes and

performance decreases when gas leaks, collect the

remaining refrigerant and refill the required total amount

of new refrigerant after fixing the leak.

3. Different tools

3-1. Tools specs have been changed due to the features

of R 407 C. Some of the R 22 tools cannot be used.

Vacuum

pump

4

1. GENERAL

This booklet briefly outlines where and how to install the air

conditioning system. Please read over the entire set of

instructions for the indoor and outdoor units and make sure all

accessory parts listed are with the system before beginning.

1-1. Tools Required for Installation (not

supplied)

1. Standard screwdriver

2. Phillips head screwdriver

3. Knife or wire stripper

4. Tape measure

5. Level

6. Sabre saw or key hole saw

7. Hacksaw

8. Core bits

9. Hammer

10. Drill

11. Tube cutter

12. Tube flaring tool

13. Tourque wrench

14. Adjustable wrench

15. Reamer (for deburring)

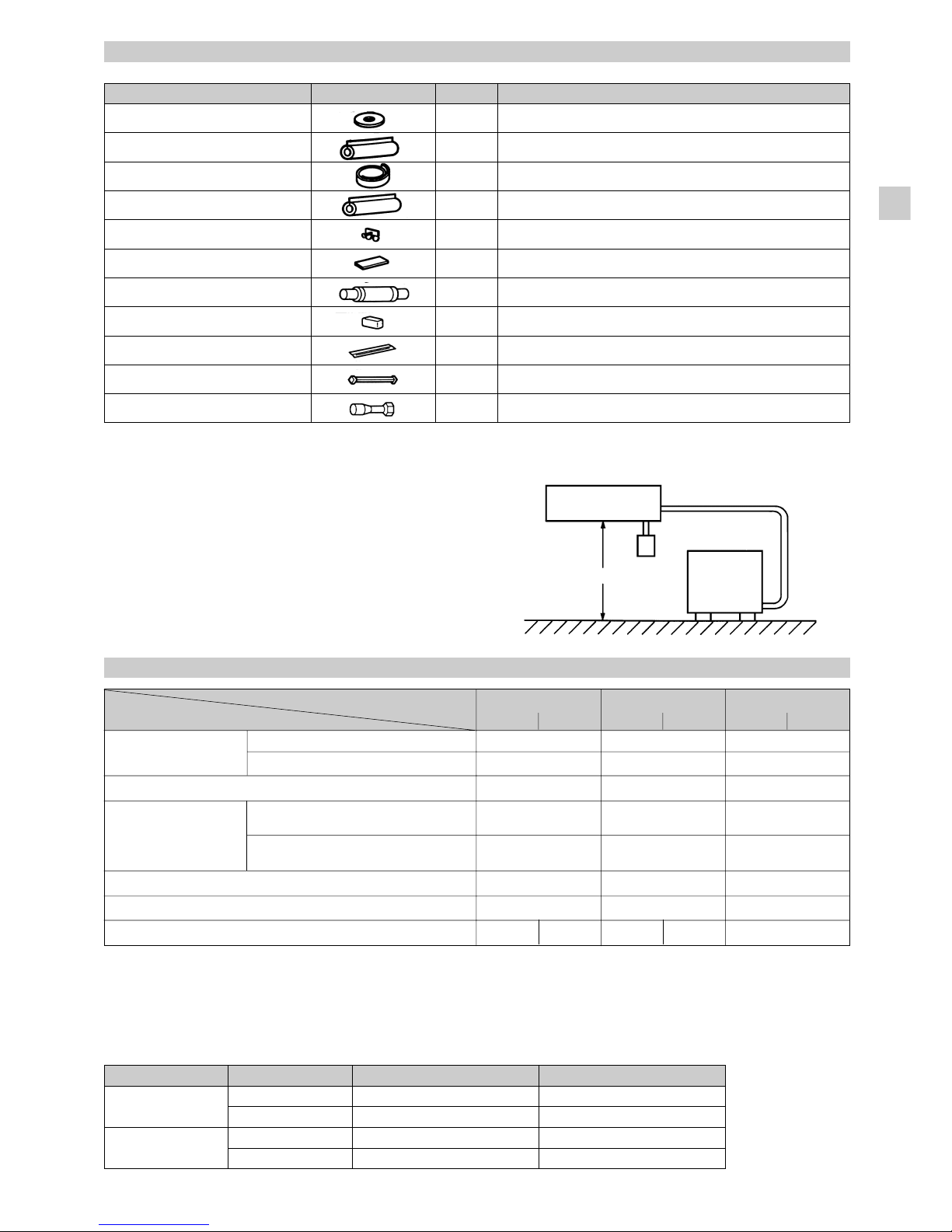

1-2. Accessories Suppled with Unit

See Table 1-1 to 1-3.

Table Type

1-1 4-Way AirDischarge Semi-Concealed

1-2 Ceiling-Mounted

1-3 Concealed-Duct

1-3. Type of Copper Tube and Insulation

Material

To purchase these material from a local source, you will need:

1. Deoxidized annealed copper tube for refrigerant tubing.

2. Foamed polyethylene insulation for 15.88 mm (5/8”) or

19.05 mm (3/4”) O.D. copper tubes as required to precise

length of tubing. Wall thickness of the insulation should

be not less than 8 mm.

3. Use insulated copper wire for field wiring. Wire size varies

with the total length of witing. Refer to Section 5. Electrical

Wiring for details.

EG

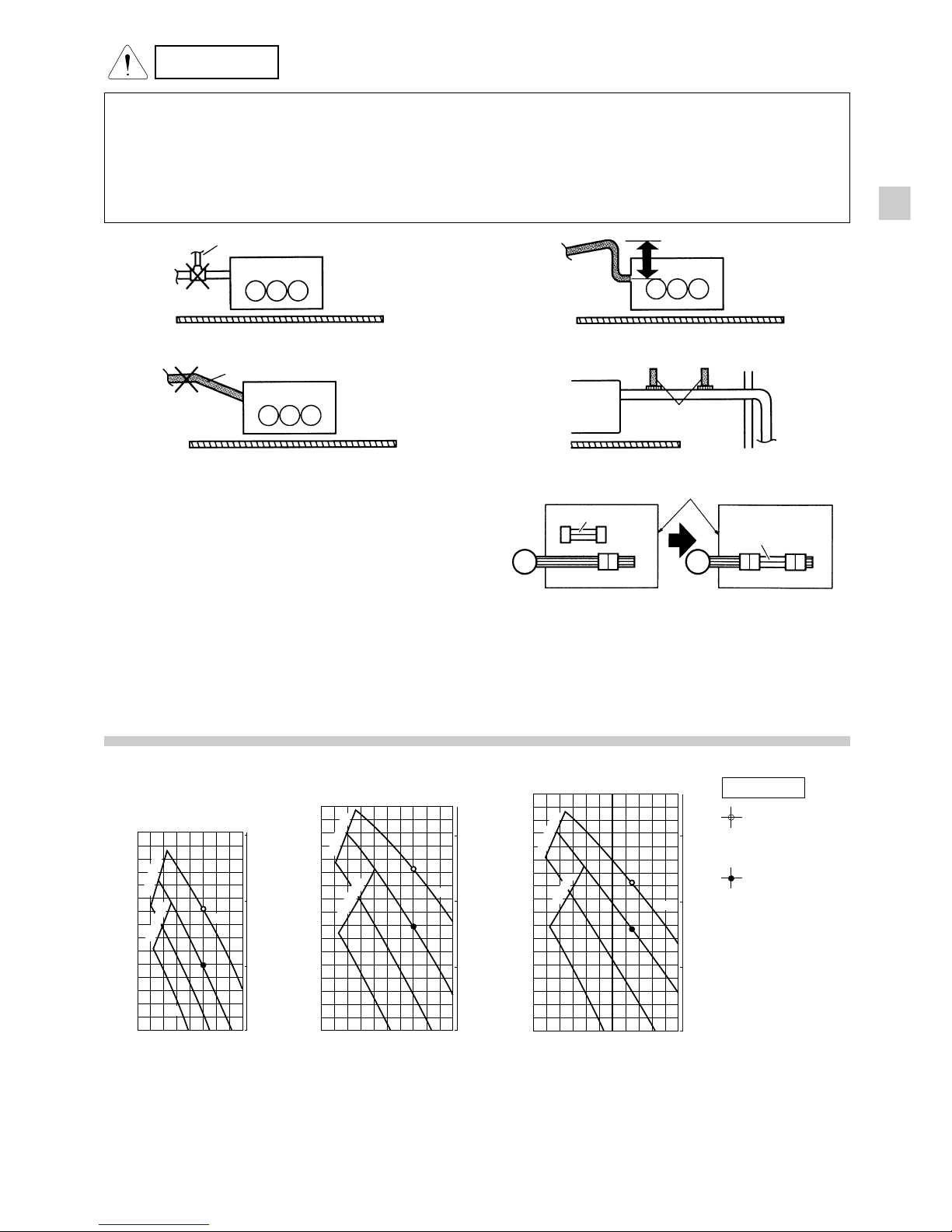

Gauge manifold

Vacuum pump

Outlet

Inlet

Liquid

Valve

Product name

Gauge

manifold

Charge

hose

Leak

detector

Flaring oil

New

tools

Yes

Yes

Yes

Yes

Yes

R22 tools

compatible

with R407C

No

No

Yes

No

No

Remarks

Types of refrigerant and refrigerating machine oil, and pressure

gauge are different.

To resist pressure and oil, material has been changed.

Use a conventional vacuum pump if it is equipped with a check

valve. If it has no check valve, purchase and attach a vacuum

pump adaptor.

Leak detector for CFC an HCFC which react to chlorine do not

function because R407C contains no chlorine. Leak detector for

R407C can be used for HFC134a.

Mineral oil (for example, suniso oil) can be used as R22 oil. Use

synthetic fluid (for example, ether oil) as R407C oil.

* Using both R22 tools and new tools together can cause defects.

3-2. Use a R407C exclusive cylinder only. Single-outlet valve

(with siphon tube).

Liquid refrigerant can be

refilled standing it up

straight.

New refrigerant R407C cannot be used for existing models.

1. Compressor specs are different.

When refilling the R22 compressor with R407C, durability will significantly decrease since some

of the materials used for compressor parts are different.

2. Existing piping cannot be used.

Completely cleaning out residual refrigerating machine oil is impossible, even by flushing.

3. Refrigerating machine oil differs.

Since R22 refrigerating machine oil is mineral oil, it does not dissolve in R407C. Therefore,

refrigerating machine oil discharged from the compressor can cause compressor damage.

R22 refrigerating machine oil Mineral oil (suniso oil)

R407C refrigerating machine oil Synthetic fluid (ether oil)

R 407 C

5

1-4. Additional Materials Required for

Installation

1. Refrigeration (armored) tape

2. Insulated staples or clamps for connecting wire

(See your local codes.)

3. Putty

4. Refrigeration tubing lubricant

5. Clamps or saddles to secure refrigerant tubing

CAUTION • Check local electrical

codes and regulations

before obtainig wire.

Also, check any

specified instructions

or limitations.

Part Name Figure Q’ty Remarks

Full-scale installation diagram 1 For determinig suspension bolt pitch

Flare insulator 2 For wide and narrow tubes

Installation gauge 1 For adjusting the unit position

Insulating tape 1 For wide tube flare nuts

Hose band 2 For Securing drain hose

Packing 1 For drain joint

Dran insulator 1 For drain joint

Drain hose 1 For drain hose joint

Sealing putty 1 For sealing recessed portion of power supply

Tube connector 1

For sizing up of narrow tube from 6.35 to 9.52 (only for 25 type)

Table 1-1. 4-Way Air Discharge Semi-Concealed

Table 1-2. Ceiling-Mounted

(White-for

insulating)

Part Name Figure Q’ty Remarks

Special washer 4 For suspending indoor unit from ceiling

Drain insulator 1 For drain hose joint

Flare insulator 1 Set For drain narrow tube joints

Drain hose clamp 4 For drain hose joint

2 For rubber cap (in case of using left side drain pipe)

Insulating tape 2 For wide flare joint

Vinyl clamp 8 For ends of flare insulator

Sealing insulator

1 For sealing top face

1 For sealing rear face

Grommet 1 For power supply inlet

Full-scale installation diagram 1 For determining suspension bolt pitch

Sealing putty 1 For sealing recessed portion of power supply

Owner’s manual 1 –

Drain hose 1 For drain hose joint

Tube connector 1

For sizing up of narrow tube from 6.35 to 9.52 (only for 25 type)

White

(heat-resisting)

T10

T3T5

EG

Special washer 8 For suspending indoor unit from ceiling

Flare Insulator 2 For wide and narrow tubes

Insulating Tape 1 For wide and narrow tubes flare nuts

Drain Insulator 1 For drain hose joint

Hose band 2 For securing drain hose

Packing 1 For drain joint

Drain hose 1

Sealing putty 1 For sealing recessed portion of power supply

Vinyl clamp 8 For flare insulator

Booster cable* 1 For increasing the fan speed

Tube connector 1

For sizing up of narrow tube from 6.35 to 9.52 (Only for 25 type)

6

Booster cable is housed inside the electrical component box.

1-5. Tubing Length

• Refrigerant tubing between the indoor and outdoor

units shall be kept as short as possible

• The length of the refrigerant tubes between the

indoor and outdoor units are limited by the elevation

difference between the two units. During tubing

work, try to make both the tubing length (L) and

the difference in elevation (H) as short as possible.

Refer to Table 1-4 for the details.

Installation Example 1

INDOOR

UNIT

Tubing length (L)

OUTDOOR

UNIT

Elevation difference (H)

Table 1-3. Concealed-Duct

Table 1-4.

6.35 (1/4)

15.88 (5/8)

50

50

30

30

a) 45

3.0 3.2

Tubing size Narrow tube mm(in.)

outer diameter Wide tube mm (in.)

Limit of tubing length (m)

Outdoor unit is placed upper (m)

Limit of elevation

difference between

the two units Outdoor unit is placed lower (m)

Max. allowable tubing length at shipment (m)

Required additional refrigerant*

1

(g/m)

Refrigerant charged at shipment (kg)

9.52 (3/8)

19.05 (3/4)

50

50

30

30

b) 50

3.5 4.0

9.52 (3/8)

19.05 (3/4)

50

50

30

30

b) 50

4,5

Models

Tubing Data

No additional charge of compressor oil is necessary.

*1 If total tubing length becomes 30 to 50 , charge additional refrigerant by a) 45 or b) 50 g/m.

EG

425 type

R22 R407C

436 type

R22 R407C

448 type

R22 R407C

1-6. Operating limits

Temperature Indoor air intake temp. Outdoor air intake temp.

Maximum 35°C DB / 25°C WB 43°C DB

Cooling Minimum 18°C DB / 14°C WB – 5°C DB (–15°C DB*)

Maximum 27°C DB 21°C DB / 15.5°C WB

Heating Minimum 15°C DB – 15°C WB

* R407C models only

Part Name Figure Q.ty Remarks

Ceiling-Mounted Type

DO:

• select an appropiate position from which every corner of the

room can be uniformly cooled.

• select a location where the ceiling is strong enough to support

the weight of the unit.

• select a location where tubing and drain pipe have the

shortest run to the outside.

• allow room for operation and maintenance as well as

unrestricted ai flow around the unit.

• install the unit within the maximum elevation difference (H)

above or below the outdoor unit and within a total tubing

length (L) from the outdoor unit as detailed in table 1-4.

• allow room for mounting the remote controller about 1 moff

the floor, in an area that is not in direct sunlight nor in the flow

of cool air from the indoor unit.

7

NOTE

Air delivery will be degraded if the distance from the floor to

the ceiling is greater than 3 m.

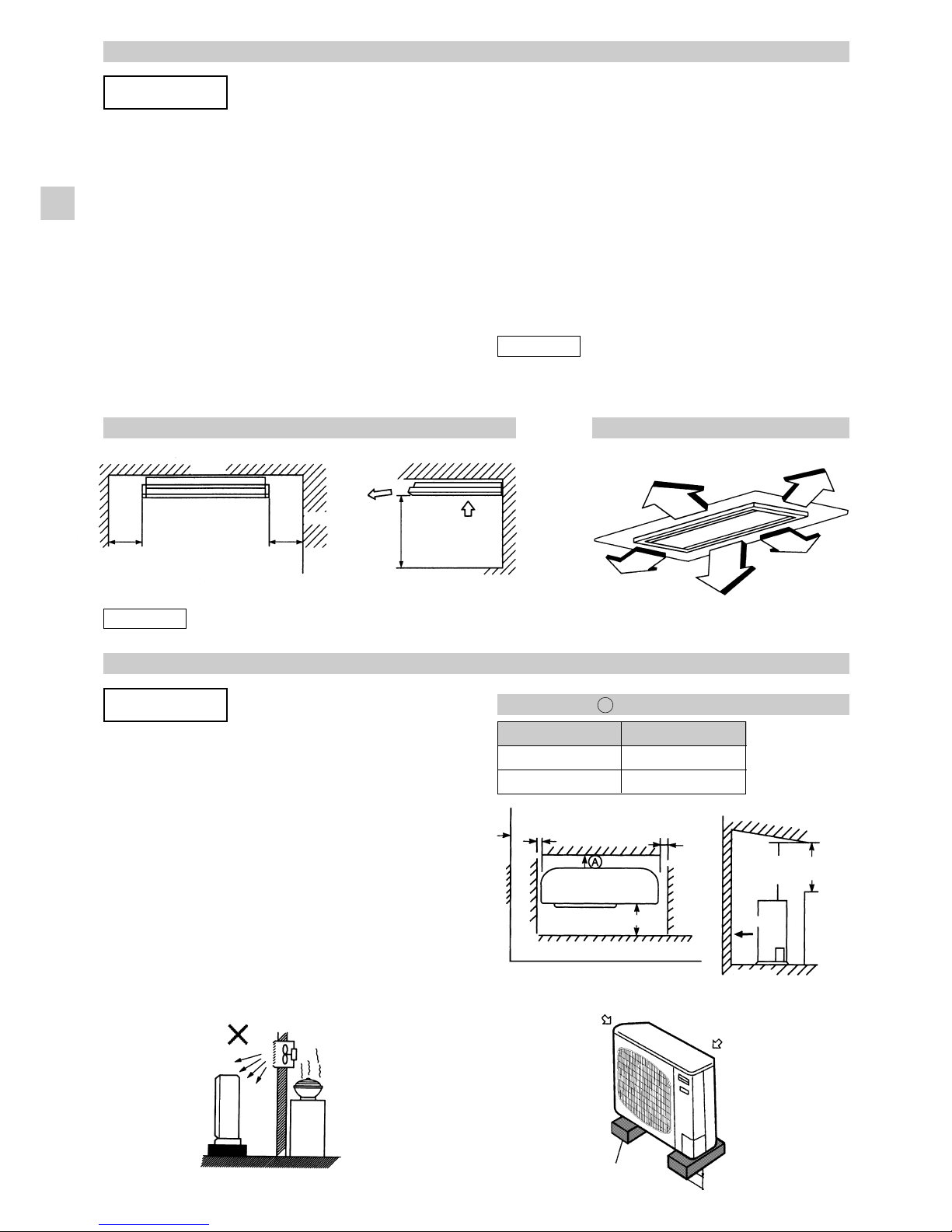

4-Way Semi-Concealed Type

Ceiling

Wall

25 cm min.

Air

discharge

Side view

Air intake

30 cm

min.

25 cm min.

NOTE The rear of the indoor unit can be installed

flush against the wall.

Front view

1 m

1 m

1 m

1 m

1 m

AVOID:

• heat source, exhaust fans, etc. (Fig. 2-1).

• damp, humid or uneven locations.

DO:

• choose a place as cool as possible.

• choose a place that well ventilated and autside air

temperature does not exceed maximum 45 °c constantly.

• allow enough room around the unit for air intake/exhaust

and possible maintenance. (Fig. 2-2).

• provide a solid base; about 15 cm above ground level to

reduce humidity and possible water damage in unit and

drecrease service life. (Fig. 2-3).

• use lug bolts or equal to bolt down unit, reducing vibration

and noise.

OUTDOOR UNIT

Air in Air in

Min. 15 cm

Air

discharge

Anchor bolts

(4 pieces)

Model Min. (cm)

425 type 10

436, 448 type 20

Fig. 2-3

Hot air

Out-

door

unit

Exhaust fan

Heat

source

Fig. 2-1

Fig. 2-2

Min.

1 cm Min.

1 cm

Min.

2 m

Ground

Min.

2 m

Obstacle

Air

dis-

charge

Min. 50 cm

Obstacle above

Table 2-1 Dimension

A

➩

2. INSTALLATION SITE SELECTION

AVOID:

• areas where leakage of flammable gas may be expected.

• places where large amounts of oil mist exist.

• direct sunlight.

• location where nearby heat sources may affect performance

of the unit.

• locations where nearby external air may enter the room

directly. This may cause “sweating” in the air discharge ports,

causing them to spray or drip.

• location where the remote controller will be splashed with

water or affected by dampness or humidity.

• installing the remote controller behind curtains or furniture.

INDOOR UNIT

EG

8

Min. 1 m Min. 1 m Min. 1 m Min. 1 m

Min. 20 cm

Min. 35 cm

Min. 35 cm

Min. 30 cm

Min. 30 cm

Air

discharge

chamber

Min. 1.5 m

Min. 30 cm

Min. 35 m

Min. 20 cm

In case of multiple installations

■ Unit spacing if air discharge chamber is not used. ■ Unit spacing when air dscharge chamber is used.

* If you would like to make the separation smaller on the

air discharge side, use an air discharge chamber.

* Your can install any number of units side-by-side.

* Only up to 3 units can be install side-by-side under the

above conditions. the next group must be spaced at

least 30 cm away from the first group.

2-1. Air Discharge Chamber for Top

Discharge

Be sure to install the air discharge chamber in the field

when:

• it is difficult to keep a space of min. 50 cm between

the air discharge outlet and the obstacle.

• The air discharge outlet is facing to the sidewalk and

discharged hot air annoys the passers.

Refer to Fig. 2-4.

2-2. Installing the Unit in Heavy Snow

Areas

In positions with strong wind, snow-proof ducting

should likewise be fitted and direct exposure to the

wind should be avoided as much as possible.

Countermeasures against snow and wind in regions

with snow and strong wind, the following problems

may occur when the outdoor unit is not provided with

a platform and snow-proof ducting.

a) The outdoor fan may not run and damage of the

unit may be caused.

b) There may be no air flow.

c) The tubing may freeze and burst.

d) The condenser pressure may drop because of

strong wind, and the indoor unit may freeze.

2-3. Precautions for Installation in Heavy

Snow Areas

1) The platform should be higher than the max, snow

depth. (Fig. 2-5).

2) The two fixing feet of the outdoor unit should be

used for the platform, and the platform should be

installed beneath the air intake side of outdoor

unit.

3) The platform foundation must be firmer and the

unit must be secured with anchor bolts.

4) In case of installation on a roof subject to strong

wind, countermeasures must be taken to prevent

the unit from being blown over.

Air discharge

Fig. 2-4

In regions with snow fall, the outdoor unit should be provided

with a platform and snow-proof duct.

Without snow-

proof ducting

(Low platform)

With snow-proof

ducting

(High platform)

Fig. 2-5 Fig. 2-6

Air

Intake

Platform (foundation)

Higher than the

maximum

snow depth

Duct

About 1/2 of the

unit height

Air

Intake

Duct

Outdoor

Unit

Example of Installation

Duct

Duct

Outdoor Unit

Min. 100

300

Min. 100 300 Unit: mm

2-4. Dimensions of Snow/Wind-proof

Ducting and Refrigerant Tubing Space

for Installation

EG

9

■4-WAY AIR DISCHARGE SEMI-CONCEALED TYPE

EG

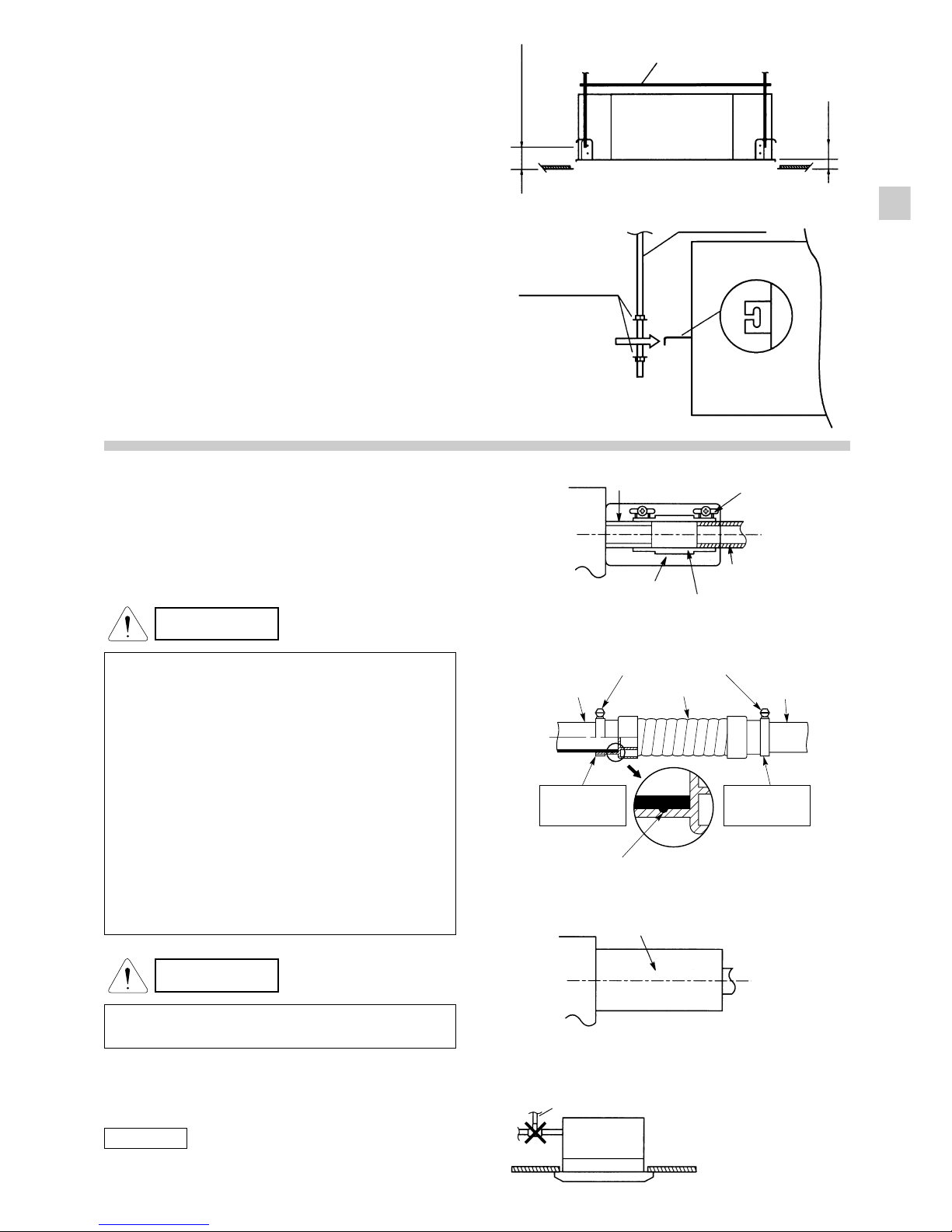

3-1. Suspending the Indoor Unit

This unit uses a drain pump. Use a carpenter’s level to check

that the unit is level.

3-2. Preparation for Suspending

(1) Fix the suspension bolts securely in the ceiling using

the method shown in the drawings (Figs. 3-1 / 3-2 /

3-3), by attaching them to the ceiling support structure,

or by any other method that insures that the unit will

be securely and safely suspended.

(2) Follow Fig. 3-2 and Table 3-1 to make the holes in the

ceiling.

Model A B

425 type 820 730

436, 448 type 1110 1020

3) Determine the pitch of the suspension bolts using the

provided full-scale installation diagram. The diagram

and table (Fig. 3-3 and Table 3-3) show the relationship

between the position of the suspension fitting, the unit,

and the panel.

Model ABCDE

425 type 150 200 255 298 125

436, 448 type 165 235 285 328 125

Hole-in-anchor

Hole-in-plug Concrete Insert

Suspension bolt (M10 or 3/8’’)

(field supply)

A (ceiling opening dimension)

B (suspension bolt itch)

Electrical component box

Refrigerant

tubing side

Drain hose

side

Refrigerant tubing joint (narrow tube side)

Refrigerant tubing joint (wide tube side)

Drain inspection port

Suspension lug

Power supply inlet

Unit: mm

820 (ceiling opening dimension)

590 (suspension bolt pitch)

Fig. 3-1

Fig. 3-3

Fig. 3-2

3. HOW TO INSTALL THE INDOOR UNIT

Table 3-1

Table 3-2

Unit: mm

Unit: mm

2-5. Wind Shield for “SHL”, “SCL” Model

It is recommended to install wind shields for cooling operation

in low outdoor temperature condition. (Fig. 2-8).

General

When the outdoor unit is installed in a position exposed to

strong wind (like seasonal winds with low air temperature in

winter), wind shield must be installed on the outdoor unit.

This unit is designed so that the fan of the outdoor unit runs at

low speed when the air conditioner is operated at low outdoor

air temperatures. When the outdoor unit is exposed to strong

wind, the system pressure drops because of the freeze protector.

For outer dimensions of wind shield, please see Fig. 2-9.

IMPORTANT

Fig. 2-8

Wind shield

(air discharge side)

Front

3 - ø60 hole

8 - ø6 hole

450 100250250

1116

132

567

131

300

592

3 - ø40 hole

6 - ø6 hole

25054924

132

57013

596

554

13125025027

554

For 436,448 type

For 425 type

Fig. 2-9

Recommended outer dimensions

of wind shield (field supply).

10

EG

3-3. Burying inside the Ceiling

(1) When placing the unit inside the ceiling, determine the

pitch of the suspension bolts using the provided full-

scale installation diagram. (Fig. 3-4).

Tubing and wiring must be laid inside the ceiling when

suspending the unit. If the ceiling is already constructed,

lay the tubing and wiring into positiion for connection

to the unit before placing the unit inside the ceiling.

(2) The length of suspension bolt must be so that the

distance between the bottom of the bolt and the bottom

of the ceiling is more than 60 mm as shown in Fig. 3-4.

(3) Thread the 2 hexagonal nuts and washers (field supply)

onto the 4 suspension bolts as shown in Fig. 3-5.

Use 2 sets of nuts and washers (upper and lower), so

that the unit with not fall off the suspension lugs.

(4) Remove the protective cardboard used to protect the

fan parts during transport.

(5) Adjust the distance between the unit and surface of

the ceiling (48 mm) using the supplied installation

gauge. (Fig. 3-4).

3-4. Installing the Drain Piping

(1) Prepare a standard hard (PVC) pipe (O.D. 32 mm) for

the drain and use the accessory drain hose and hose

band to prevent water leaks.

The PVC pipe must be purchase separately.

The transparent part allows you to check drainage.

(Fig. 3-6).

Full-scale installation drawiong

(provided)

Transparent part for

checking drainage Hose band (supplied)

Hard PVC pipe

pipe (not supplied)

Drain hose (supplied)

Packing (supplied)

Nuts and washers

(2 sets)

Suspension bolt

Suspension lug

Uppper

Lower

More than 60 mm

48 mm

Fig. 3-4

Fig. 3-5

CAUTION

• Tighten the hose band firmly after the supplied drain

hose has been inserted to touch the ends of both of the

connection pipes, as shown in Fig. 3-7.

• Do not use an adhesive when connecting the supplied

hose.

Reasons:

1. It may cause water to leak from the connection. Sin-

ce the connection is slippery just after the adhesive has

been applied, the pipes easily slip off.

2. The pipes cannot be removed when maintenaces is

needed.

• Do not bend the supplied drain hose 90° or more. The

hose may slip off.

• Align the hose bands with the ends of the hoses. Ti-

ghten the hose bands firmly. PLease make sure that the

stopper is not covered by the hose band, as shown in

Fig. 3-7.

CAUTION

• Tighten the hose clamps so their locking nuts face

upward (Fig. 3-6).

(2) After checking the drainage, wrap the supplied packing

and drain pipe insulator around the pipe. (Fig. 3-8.)

NOTE

Make sure the drain pipe has a downward gradient (1/100 or

more) and that there are no water traps.

Fig. 3-6

Fig. 3-7

Drain insulator (supplied)

Air bleeder

Fig. 3-8

Fig. 3-9

Stopper

Hose band Supplied

drain hose

Drain pipe

(not supplied)

Connection

pipe

Hose band

Align the hose

band with the end

of the pipe

Align the hose

band with the end

of the pipe

11

EG

3-5. Checking the Drainage

After wiring and piping are completed, use the following procedure to check that the water will drain smoothly. For this, prepare a

bucket and wiping cloth to catch and wipe up spilled water.

(1) Connect power to the power terminal board (L, N terminal) inside the electrical component box.

(2) Remove the tube cover and through the opening, slowly pour about 1,200 cc of water into the drain pan to check drainage.

(3) Short the check pin (CN5 withe) on the indoor control main board and operate the drain pump. Check the water flow and see

if there is any leakage.

CAUTION •Be careful since the

fan will start when you

short the pin on the in-

door control board.

(4) When drain checking is finished, open the check pin

(CN5 white) and remount the tube cover.

CAUTION •To mount the tube co-

ver, use 4 x 8 tapping

screws. Do not use

long screws as they

may puncture the

drain pan and cause

water leakage.

4 x 8 mm

tapping screw

Tube cover

Front face

Rear

Full-scale diagram

Hole-in-anchor

Hole-in-plug Concrete Insert

Suspension bolt (M10 or 3/8’’)

(field supply)

Fig. 3-13

■CEILING-MOUNTED TYPE

3-6. Suspending the Indoor Unit

(1) Place the full-scale diagram (supplied) on the ceiling

at the spot where you want to install the indoor unit. Use

a pencil to mark the drill holes. (Fig. 3-14).

NOTE

Since the diagram is made of paper, it may shrink or stretch

slightly because of high temperature or humidity. For this

reason, before drilling the holes maintain the correct dimensions

between the markings.

(2) Drill holes at the 4 points indicated on the fullscale

diagram.

(3) Depending on the ceiling type:

a) Insert suspension bolts as shown in Fig. 3-15.

or

b) Use existing ceiling supports or construct a suitable

support as shown in Fig. 3-16.

Fig. 3-14

Fig. 3-15

CAUTION

•Do not install an air bleeder, as this may cause water

to spray from the drain tube outlet. (Fig. 3-9)

•If it is neccesary to increase the height of the drain

pipe somewhat, the portion directly after the connection

port can be raised a maximum of 25 cm. Do not raise

it any higher than 25 cm, as this could result in water

leaks. (Fig. 3-10)

•Do not install pipe with an upward gradient from the

connection port. It will cause the drain water to flow

backwards and leak when the unit is stopped.

(Fig. 3-11)

•Do not apply force to the piping on the unit side when

connecting the drain pipe. The pipe should not be

allowed to hang unsupported from its connection to the

unit. Fasten the pipe to a wall, frame, or other support

as close to the unit as possible. (Fig. 3-12)

•Be sure to provide insulation for any drain piping

installed indoors.

30 cm or less (as short as possible)

25 cm or less

Upward gradient

Support

pieces

Fig. 3-10

Fig. 3-11

Fig. 3-12

12

EG

Ceiling tiles

Ceiling support

A

A

unit

Fixture

Ceiling

surface

Within

50 mm

WARNING

•It is important that you use extreme care in supporting

the indoor unit from the ceiling. Ensure that the ceiling

is strong enough to support the weight of the unit.

Before hanging the ceiling unit, test the strength of

each attached suspension bolt.

(4) Screw in the suspensions bolts, allowing them to

protrude from the ceiling as shown in Fig. 3-16. The

distance od each exposed bolt must be of equal length

within 50 mm. (Fig. 3-17)

(5) Before suspending the indoor unit; remove the 2 or 3

screws on the latch of the air-intake grilles, open the

grilles, and remove them by pushing the claws of the

hinges as shown in Fig. 3-18. Then remove both side

panels sliding them along the unit toward the front after

removing the two screws which fix them. (Fig. 3-19).

(6) Preparation for suspending the indoor unit. The

suspension method varies depending on whether the

unit is next to the ceiling or not. (Fig. 3-20 and 3-21).

(7) Suspend the indoor unit as follows.

(a) mount a washer and two hexagonal nuts on each

suspension bolt as shown in Fig. 3-22.

Fig. 3-16

Fig. 3-17

Pul out the Air-

Intake grille

pushing claws

of the hinges Hinge

Screw

Latch

Air-intake grille

Suspension bolt

(field supply)

Ceiling surface

Washer (supplied)

Double nut

(field supply)

Fixture

unit

Slide toward

front side

Sode panel

Ceiling

surface

Nut

(field supply)

Suspension bolt

Washer

(supplied)

Approx.

25 mm

Slide

Fig. 3-18

Suspension bolt

(field supply)

Washer (supplied)

Washer (field supply)

Double nut

(field supply)

unit

Fig. 3-19

Fig. 3-20 Fig. 3-21 Fig. 3-22

Fig. 3-23

Fig. 3-24

(b) Lift the indoor unit, and place it on the washer

throught the notches, so as to fix it in place.(Fig. 3-23)

(c) Tighten the two hexagonal nuts on each suspension

bolt to suspend the indoor unit as shown in Fig. 3-24.

NOTE

A ceiling surface is not always level. Please confirm that the

indoor unit is evenly suspended. For the installation to be

correct, leave a clearance of about 10 mm between the ceiling

panel and the ceiling surface and fill the gap with an appropriate

insulation or filler material.

(8) If the tubing and wiring have to pass towards the rear

of the unit, make holes in the wall. (Fig. 3-25)

(9) Measure the thickness of the wall from the inside to

the outside and cut PVC pipe at a slight angle to fit.

Insert the PVC pipe in the wall. (Fig. 3-26)

NOTE

The hole should be made at a slight downxard slant to the

outside.

13

3-7. Duct for Fresh Air

There is a duct connection port (knock-out hole) at the right-

rear on the Panel Top of the indoor unit for drawing in fresh air.

If it is necessary to draw in fresh air, remove the cover by

knocking out and connect the duct to the idoor unit throught the

connection port. (Fig. 3-27)

If connection at the right-rear on the Panel Top is not

appropriate, another duct connection port can be made by

cutting an opening on the left side of the Rear Panel of the

indoor unit as shown in Fig. 3-28.

3-8. Installing the Drain Piping

•Prepare a standar PVC pipe for the drain and connect it to

the indoor unit drain pipe with the supplied hose clamps to

prevent water leaks.

CAUTION

•Tighten the drain pipe clamps so that the locking nuts

are facing upwards. (If tightened with the locking nuts

facing downwards, it may cause water leakage).

•Do not use an adhesive when connecting the drain

hose (supplied) to the drain connection (main unit,

PVC pipe).

•Connect the drain piping so that it slopes downward from

the unit to the outside. (Fig. 3-29)

•Never allow traps to occur in the course of the piping.

•Insulate any piping inside the room to prevent dripping.

•Use the supplied drain pipe to connect the drain pipe with the

drain outlet of the indoor unit.

•After connecting the drain pipe securely, wrap the supplied

drain pipe insulator around the pipe, seal the gap at the drain

socket with the supplied black insulation tape, then secure

it with clamps. (Fig. 3-30)

•After the drain piping, pour water into the drain pan to check

that the water drains smoothly.

CAUTION •Check local electrical

codes and regulations

before obtaining wire.

Also, check any spe-

cified instruction or li-

mitations.

Duct connection port

(Knock-out hole)

Panel Top

Right side

Right side Cut this portion

Fig. 3-27

Fig. 3-28

Fig. 3-29

Fig. 3-30

ABC

425 110 100 100

110 100 150

436 448

Min. 1/100

Good

Not good

Drain hose

(supplied)

Drain pipe camp

(supplied)

Hard PVC pipe

(not supplied)

Vinyl clamp

(supplied)

Packing

(supplied)

EG

Fig. 3-25 Fig. 3-26

Indoor side Outdoor side

PVC pipe (localy purchased) INSIDE OUTSIDE

PVC pipe

Slight

angle

Cut at slight angle

Wall

1,380 490

436, 448 1,442 1,480 1,560 335 310 1,460 1,495 130 240 16 18

(230x6) (245x2)

LM

No. of holes

ABCDEFGH I JK

Refrigerant tubing joint (narrow tube)

Refrigerant tubing joint (wide tube)

Upper drain port (O.D. 32 mm)

Bottom drain port (O.D. 26 mm)

Suspension lug

Power supply outlet (2-ø30)

Fresh air intake port (ø150)

Flange for the flexible air outlet duct (ø200)

Tube cover

Electrical component box

Flange for the air intake duct

(Option or field supply)

9

10

9

10

11

11

(Suspension bolt pitch)

(Suspension bolt pitch)

M-ø3.3

(Hole)

4-ø12

(Hole)

(Hole)

A (O.D.)

L-ø6

I

10 10

10

5555 200

10

IJJK

B

C

D (150)

40

EEEF75

65

285

70 130

25 210

310

25

175

35

90 3131

H (Duct suspension bolt pitch)

G (Ceiling opening dimension)

25

100

185

58025

115

190

85

25 70 30

160

630 25

10

88

275

(Ceiling opening dimension)

260

(O.D.)

1919

Inspection access

(450 ×450)

(Field supply)

Inspection access panel

Ceiling

14

Fig. 3-31

Fig. 3-33

Fig. 3-32

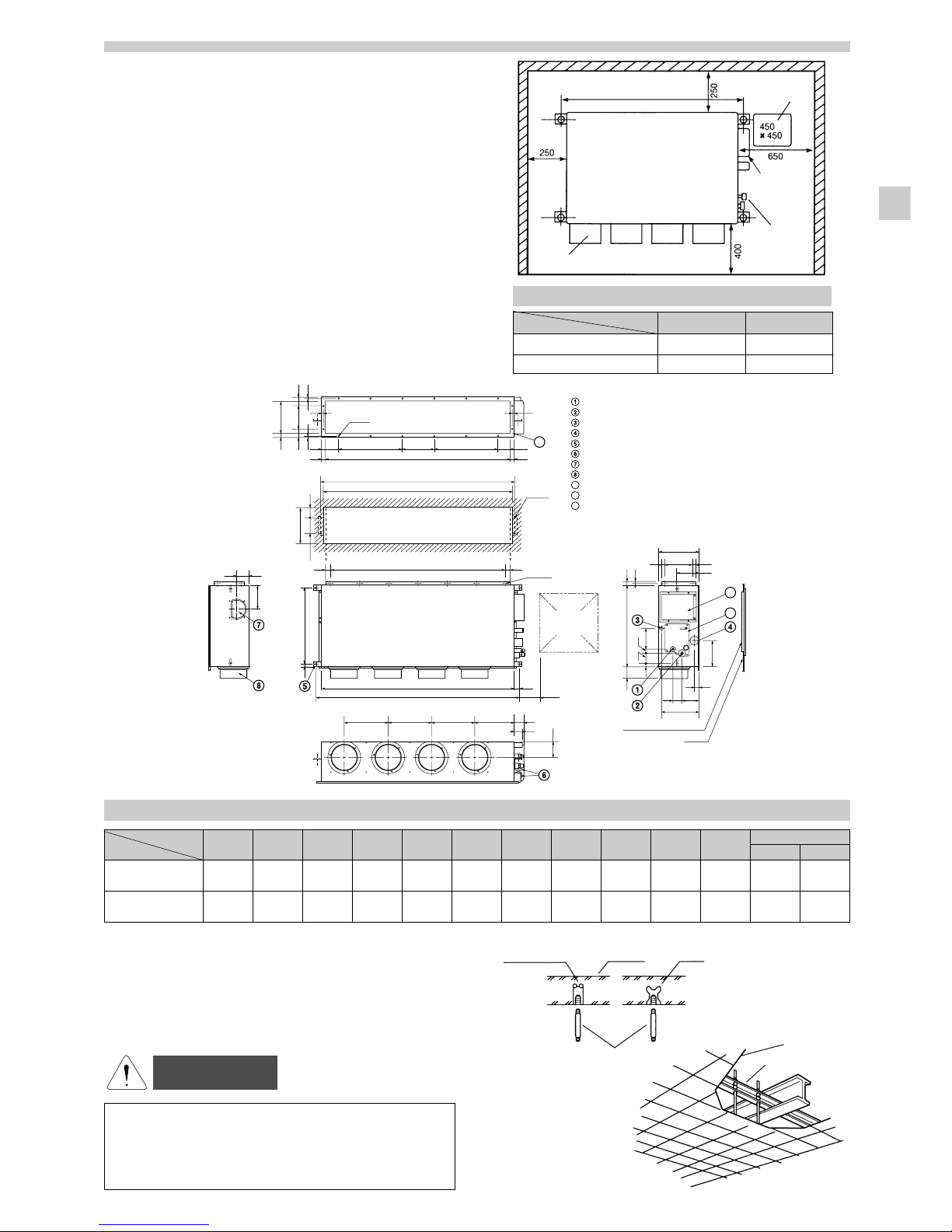

■CONCEALED DUCT TYPE (model ADR)

3-9. Required Minimum Space for Instal-

lation and Service

•This air conditioner is usually installed above the ceiling so

that the indoor unit and ducts are not visible. Only the air

intake and air outlet ports are visible from below.

•The minimum space for installation and service is shown in

Table 3-3.

•It is recommended to provide inspection access (450 x 450

mm) for checking and servicing the electrical system.

•Fig. 3-31 and Table 3-4 show the detailed dimensions of the

indoor unit.

3-10. Suspending the Indoor Unit

Depending on the ceiling type:

•Insert bolt anchors as shown in Fig. 3-32.

or

•Use existing ceiling support or construct a suitable support

as shown in Fig. 3-33.

A (Suspension blt pitch) Inspection

access

Electrical

component

box

Refrigerant

tubing

Air outlet duct flange

Indoor Unit

425 Type 436, 448 Type

A1080 1560

Number of duct flanges 34

Model

Model

Dimension

Dimension

WARNING

•It is important to use extreme care in supporting the

indoor unit inside the ceiling. Ensure that the ceiling

is sufficiently strong to accept the weight of the unit.

Before hanging the unit, test the strenght of each

attached suspension bolt.

Ceiling tiles

InsertConcrete

Hole-in-anchor

Hole-in-plug

Suspension bolt (M10 or 3/8’’)

(field supply) Ceiling Support

EG

Table 3-3

Table 3-4

900 245

425 962 1,000 1,080 290 272 980 1,015 130 250 12 16

(180x5) (245x1)

15

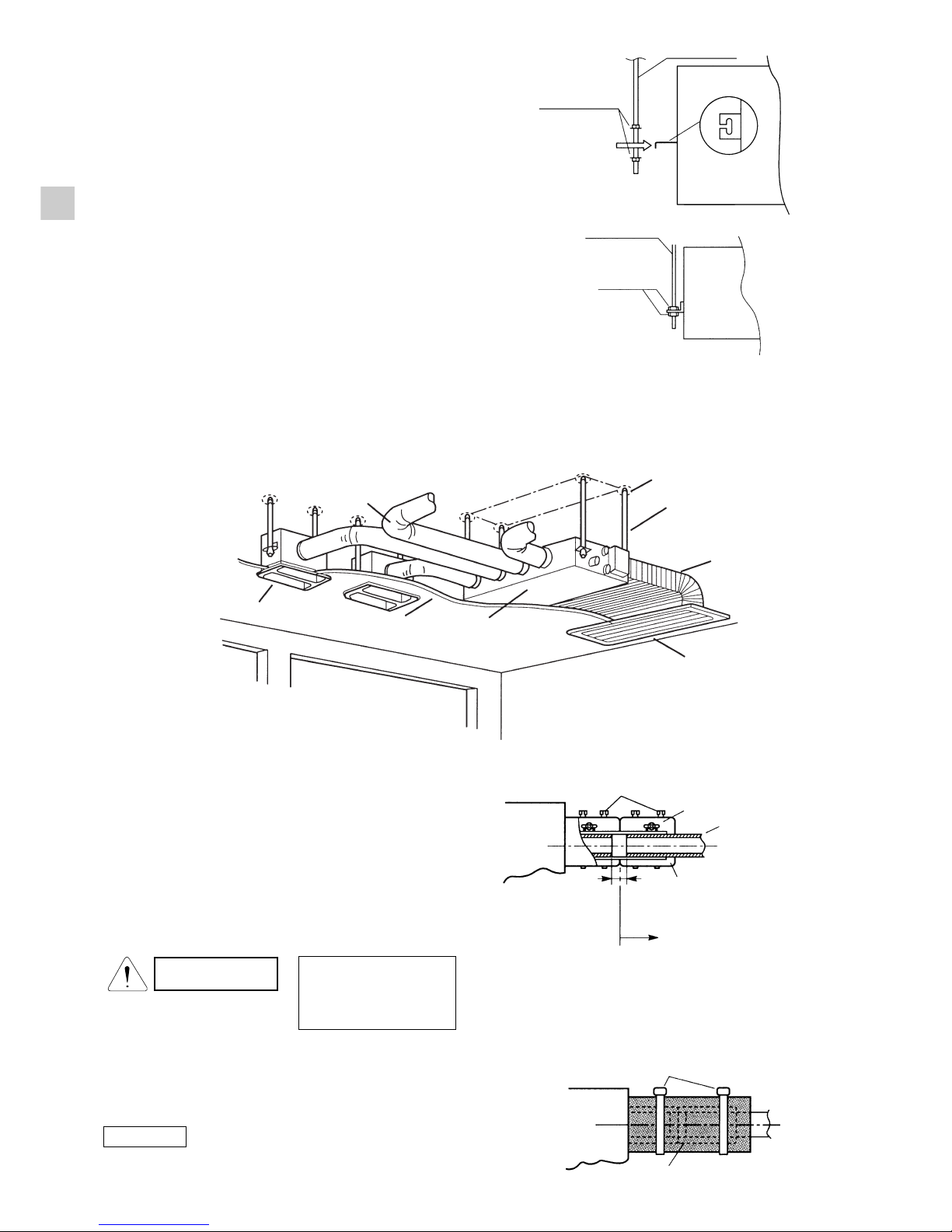

•Fig. 3-36 shows an example of installation.

Bolt anchor

Suspension bolt

Air intake duct

Air intake grille

Clamps (supplied) Hose band (supplied)

Hard PVC pipe

(not supplied)

Packing (supplied)

To be installed

at the site

Camps (supplied)

Drain insulator (supplied)

gap

Indoor unit

Ceiling material

Air outlet grille

Air outlet duct

Fig. 3-36

3-11. Installing the Drain Piping

(1) Prepare standard hard PVC pipe (O.D. 32 mm) for the

drain and use the accessory hose band to prevent

water leaks. The PVC pipe must be purchased

separately.

When doing this, leave a gap between the drain socket

of the unit and the PVC pipe to allow the drainage to

be checked (Fig. 3-88).

CAUTION •Tighten the hose clam-

ps so their locking

nuts face upward. (Fig.

3-88)

(2) After connecting the drain pipe securely, wrap the supplied

packing and drain pipe insulator around the pipe, then

secure it with the supplied clamps. (Fig. 3-38)

NOTE

Make sure the drain pipe has a downward gradient (1/100 or

more) and that there are no water traps.

Fig. 3-37

Fig. 3-38

EG

Fig. 3-35

Fig. 3-34

(1) When placing the unit inside the ceiling, determine the

pitch of the suspension bolts refering to the dimensional

data on the previous page. (Fig. 3-31).

Tubing must be laid and connected inside the ceiling

when suspending the unit. If the ceiling is already

constructed, lay the tubing into position for connection

to the unit before placing the unit inside the ceiling.

(2) Screw in the suspension bolts allowing them to protrude

from the ceiling as shown in Fig. 3-32 (Cut the ceiling

material, if necessary).

(3) Thread the 2 hexagonal nuts and washers (field supply)

onto the 4 suspension bolts as shown in Figs. 3-34

and 3-35. Use 2 sets of nuts and washer, so that the

unit will not fall off the suspension lugs.

Hex nut

Suspension bolt

Nuts and washers

(2 sets)

Suspension bolt

Suspension lug

Upper

Lower

20

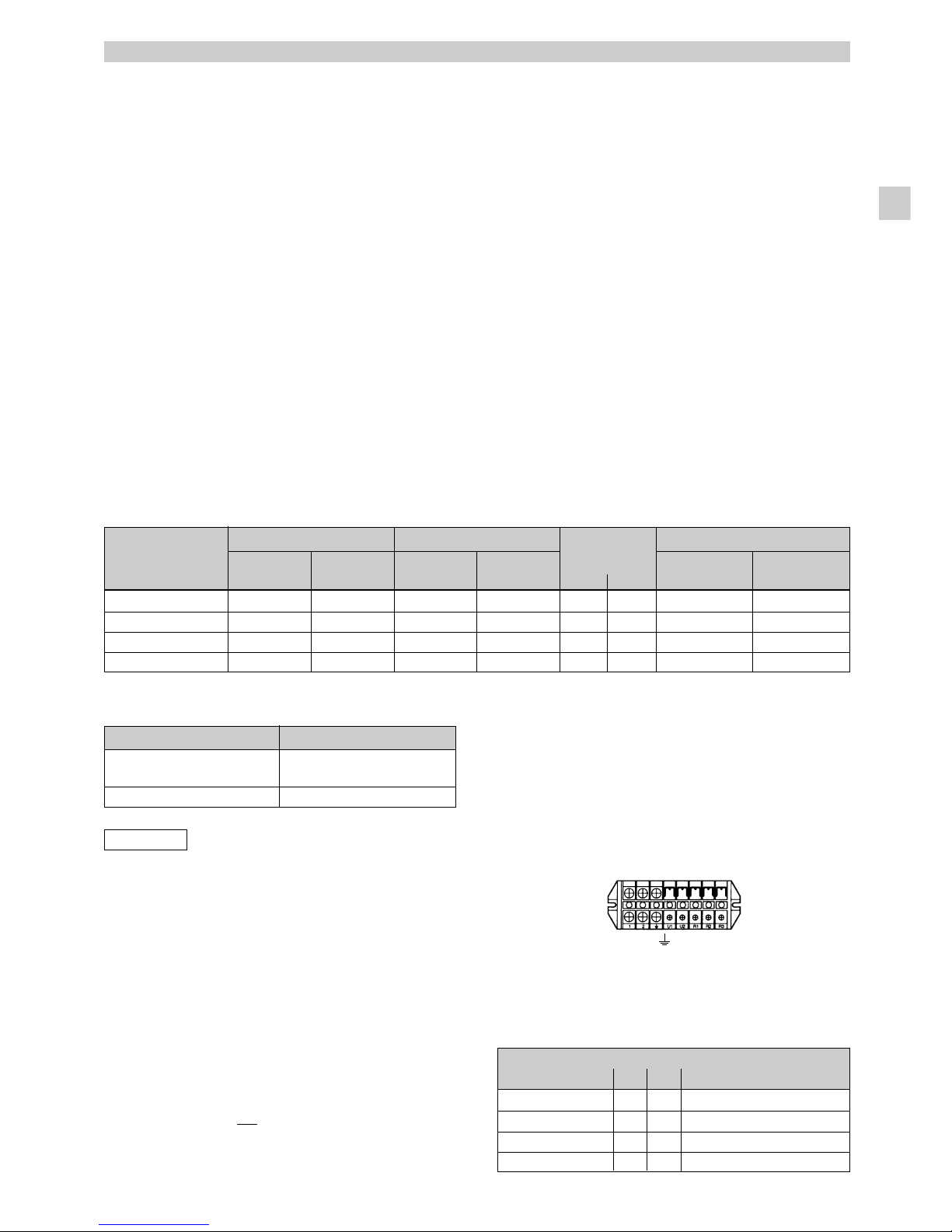

Air Flow (m

3

/minute)

External Static Pressure

0

50

0

5

10

15150

10

Limit line

Limit line

HT

H

L

100

M

(mmAq)

(Pa)

30 40

Air Flow (m

3

/minute)

External Static Pressure

0

50

0

5

10

15

150

20

Limit line

Limit line

L

100

M

H

(mmAq)

(Pa)

HT

30

Air Flow (m

3

/minute)

External Static Pressure

0

50

0

5

10

15

150

20

Limit line

HT

L

100

M

H

Limit line

(mmAq)

(Pa)

436 Type 448 Type

425 Type

16

Air bleeder 25 cm or less

Upward gradient

Support

pieces

CAUTION

•Do not install an air bleeder, as this may cause water to spray from the drain pipe outlet. (Fig. 3-39)

•If it is necessary to increase the height of the drain pipe, the section directly after the connection port can be raised

a maximum of 25 cm. Do not raise it any higher than 25 cm, as this could reasult in water leaks. (Fig. 3-40)

•Do not install the pipe with an upward gradient from the connection port. This will cause the drain water to flow

backward and leak when unit is not operating. (Fig. 3-41)

•Do not apply force to the piping on the unit side when connecting the drain pipe. The pipe should not be allowed to

hang unsupported from its connection to the unit.

Fasten the pipe to a wall, frame or other support as close to the unit as possible. (Fig. 3-42)

Fig. 3-39 Fig. 3-40

Fig. 3-41 Fig. 3-42

3-12. Increasing the Fan Speed

If external static pressure is too great (due to long extension

of ducts, for example), the air flow volume may drop too low

at each air outlet. This problem is solved by increasing the fan

speed using the following procedure:

(1) Remove 4 screws on the electrical component box

and remove the cover plate.

(2) Disconnect the fan motor sockets in the box.

(3) Take out the booster cable (with sockets at both ends)

clamped in the box.

(4) Securely connect the booster cable sockets between

the disconnected fan motor sockets in step 2 as shown

in the Fig. 3-43.

(5) Place the cable neatly in the box and reinstall the cover

plate.

Electrical component box

Booster cable

Booster cable

Fan

motor

(Booster cable installed)(At shipment)

Fan motor socket

Fig. 3-43

Fig. 3-44

NOTE

HT : Using the

booster

cable

H : At shipment

INDOOR FAN PERFORMANCE

EG

■HOW TO READ THE DIAGRAM

The vertical axis is the external static pressure (mmAq) while the horizontal axis represents the AIR FLOW (m3/min.). The

characteristic curves for “HT”, “H”, “Med”, and “Low”fan speed control are shown. The nameplate values shown are based on the

“H”air flow. In case of model 425 type, the air flow is 18 m3/min., while the external static pressure is 49 Pa at “H”position. If external

static pressure is too great (due to long extension of duct, for example), the air flow volume may drop too low at each air outlet.

This problem may be solved by increasing the fan speed as explained above.

17

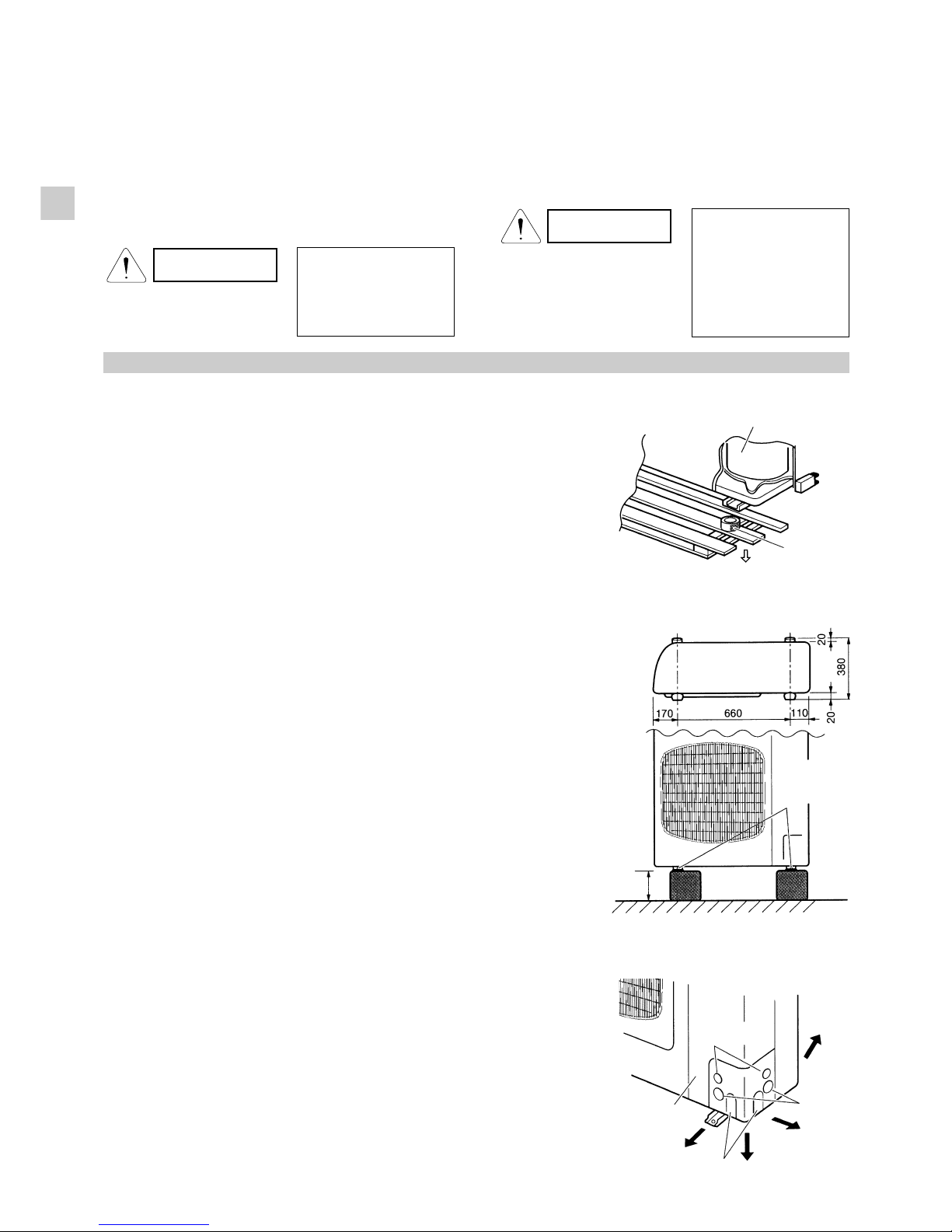

4-1. Removing the Protective Spacer for

Transportation

Remove the packing skid from the botton of unit and then

remove the plastic spacer used to secure the compressor

during transportation (Fig. 4-1).

* The plastic spacer is not provided with some models.

Place the unit on a level concrete pad, block or equal and

anchor.

Refer to Section 2. “Installation Site Selection”.

4-2. Installing the Outdoor Unit

(1) Install blocks or a solid platform under the outdoor unit

which provides a minimum height of 15 cm from ground

level. (Fig. 4-2)

(2) The outdoor unit must be bolted down tightly to the

blocks or platform with 4 anchor bolts.

4-3. Tubing Direction

•Tubing can be extended in 4 different directions as shown

in Fig. 4-3.

•Service valves are housed inside the unit. To access them,

remove the access panel by removing the 2 attaching screws

then slide the panel downward and pull it toward you.

If either rear, right, or front tubing is needed, punch out the

knockout hole with a hammer or similar tool.

•After punching out the Knockout holes, mount accessory

rubber bushings or plastic protector on the tubing outlets.

These accessories are packed inside the unit and can be

accessed through the access panel.

•Use tube benders to extend internal tubing to the outside.

4. HOW TO INSTALL THE OUTDOOR UNIT

Compressor

Plastic spacer*

Anchor

bolts

(not supplied)

Inter-unit

wiring outlets Rear

power

supply

wiring

outlets

Right

Down

Tubing

outlets

Front

Access panel

Height:

min: 15 cm

Packing

skid

Fig. 4-1

Fig. 4-2

Fig. 4-3

EG

CAUTION •To mount the tube co-

ver, use 4 x8 tapping

screws. Do not use

long screws as they

may puncture the

drain pan and cause

water leakage.

3-13. Checking the drainage

After wiring and drain piping are completed, use the following

procedure to check that the water will drain smoothly. For this,

prepare a bucket and wiping cloth to catch and wipe up spilled

water.

(1) Connect power to the power terminal board (L, N

terminal) inside the electrical component box.

(2) Remove the tube cover and through the opening, slowly

pour about 1,200 cc of water into the drain pan to check

drainage.

(3) Short the check pin (CN5 withe) on the indoor control

CAUTION •Be careful since the

fan will start when you

short the pin on the in-

door control board.

board and operate the drain pump. Check the water

flow and see if there is any leakage.

(4) When the check of drainage is complete open the

check pin (CN5 white) and remount the insulator and

drain cap onto the drain inspection port.

Capacity Max. Wire

Diameter

18

5-1. General Precautions on Wiring

(1) Before wiring, confirm the rated voltage of the unit as

shown on its nameplate, then carry out the wiring

closely following the wiring diagram.

(2) Provide a power outlet to be used exclusively for

each unit, and a power supply disconnect and

circuit breaker for overcurrent protection should be

provided in the exclusive line.

(3) To prevent possible hazard due to insulation failure,

the unit must be grounded.

(4) Each wiring connection must be done in accordance

with the wiring system diagram. Wrong wiring may

cause the unit to misoperate or become damaged.

(5) Do not allow wiring to touch the refrigerant tubing

compressor, or any moving parts of the fan.

(6) Unauthorized changes in the internal wiring can be

very dangerous. The manufacturer will accept no

responsibility for any damage or misoperation that

occurs as a result of such unauthorized changes.

5. ELECTRICAL WIRING

(7) Regulations and wire diameters differ from locality to

locality. For field wiring rules, please refer to your

LOCAL ELECTRICAL CODES before beginning.

You must insure that installation complies with all

relevant rules and regulations.

(8) To prevent malfunction of the air conditioner caused by

electrical noise, care must be taken when wiring as

follows:

•The remote control wiring and the inter-unit control

wiring should be wired apart from the inter-unit power

wiring.

•Use shielded wires for inter-unit control wiring

between units and ground the shielded on both sides.

(9) If the power supply cord of this appliance is damaged,

it must be replace by a repair shop appointed by the

manufacturer, because special purpose tools are

required.

5-2. Recommended Wire Lenght and Wire Diameter for Power Supply System

(1) Single Type (One indoor unit / one outdoor unit)

Type

(A) Power Supply - 4 mm2(B) Inter-unit wiring - 2,5 mm2

Power Supply Terminal Base

425 type (3 phase) 102 m 97 m 50 m 50 m 15 A 15 A 25 A 5.5 mm

2

436 type (3 phase) 96 m 60 m 50 m 50 m 15 A 20 A 25 A 5.5 mm

2

448 type (3 phase) 63 m 54 m 50 m 50 m 25 A 25 A 25 A 5.5 mm

2

425 type (1 phase) 17 m 17 m 50 m 50 m 40 A 40 A 50 A 14 mm

2

R 22 R 407 C R 22 R 407 C

Time Delay

Fuse or

Circuit Capacity

CONTROL WIRING

(C) Inter-Unit Control Wiring (D) Remote Control Wiring

0.75 mm

2

0.75 mm

2

Use Shielded Wiring

Max. 1000 m Max. 500 m

NOTE

(1) Refer to the Wiring System Diagrams (See next page)

for the meaning of “A”, “B”, “C”, and “D”in the above

tables.

(2) Inter-Unit Control Wiring (C) has no polarity. But for

other wiring, respect polarity. Be sure to connect as

shown in the Wiring System Diagram.

(3) The basic connection diagram of the indoor unit shows

the 8P terminal board, so the terminal boards in your

equipment may differ from the diagram.

(4) For accordance with conformity of EC Directive No.

89/336/EEC, supply connection at the time of installtion

work it should be consider guidance showing below.

•Do not share a common installation group with other

equipment.

•Be sure that supply network impedance is sufficiently

low (

ZSYS

RΩ).

It may be necessary to consult the power supply

authority before connection of the air conditioner to

a low-voltage public network.

≥

RΩ

Models R22

R407C

Remarks

425 type (3 phase) –– Care is not needed

436 type (3 phase) 0.270 0.192 confortms to the local code

448 type (3 phase) 0.122 0.167 Ditto

425 type (1 phase) 0.126 0.126 Ditto

8P terminal board

U1U2

Inter-unit

control wiring

1 (L)2(N)

Power

supply

R1R2R3

Remote

controller

EG

R 22 R 407 C

19

5-3. Wiring System Diagrams

(1) Basic wiring diagram for standard control

Single type (one indoor unit)

3-phase outdoor unit

Indoor Unit

Inter-unit

control wiring

(Low voltage)

Inter-unit

power wiring

(Line voltage)

Outdoor Unit

R.C. Address on the PCB: 0 (S2, BLK)

(0: Factory shipped state)

Power supply

380 - 415 V - 3 N ~50 Hz

Ground

Ground

Remote controller

(Option)

RED

WHT

BLK

Single phase outdoor unit

Indoor Unit

Inter-unit

control wiring

(Low voltage)

Inter-unit

power wiring

(Line voltage)

Outdoor Unit

R.C. Address on the PCB: 0 (S2, BLK)

(0: Factory shipped state)

Power supply

220 - 240 V - 3 N ~50 Hz

Ground

Ground

Remote controller

RED

WHT

BLK

EG

This manual suits for next models

14

Table of contents

Other Tecnibel Air Conditioner manuals

Popular Air Conditioner manuals by other brands

Fujitsu

Fujitsu ASYG 09 LLCA installation manual

York

York HVHC 07-12DS Installation & owner's manual

Carrier

Carrier Fan Coil 42B Installation, operation and maintenance manual

intensity

intensity IDUFCI60KC-3 installation manual

Frigidaire

Frigidaire FAC064K7A2 Factory parts catalog

Sanyo

Sanyo KS2432 instruction manual

Mitsubishi Electric

Mitsubishi Electric PUHZ-RP50VHA4 Service manual

Panasonic

Panasonic CS-S18HKQ Service manual

Panasonic

Panasonic CS-E15NKE3 operating instructions

Gree

Gree GWH18TC-K3DNA1B/I Service manual

Friedrich

Friedrich ZoneAire Compact P08SA owner's manual

Daikin

Daikin R32 Split Series installation manual