Tecnico cb250 User manual

Introduction

This

service

manual describes

the

service procedures

fór

the

CB250.

This

Model

Specific Manual includes every service proce-

dure

that

is

of

a

specific

natura

to

this

particular

model.

Basic service procedures

that

are

common

to

other

Honda

Motorcycle/Motor

Scooter/ATVs

are

coveredin

the

Corn-

mon

Service

Manual.

This

Model

Specific

Service

Manual

should

be used

together

with

the

Common

Service

Manual

in order

to

provide

complete

service

information

on all

aspects

of

this

motorcycle,

Throughout

the

manual,

the

following

abbreviations

are

used to

identify

individual

rnodels.

CODE

AREA

(TYPE)

E

U.K.

U

Australia

Performing

the

first

scheduled

maintenance

is

very

im-

portant.

It

compensates

for

the

initial

wear

that

occurs

duríng

the

break-in

periodo .

Sections

1

and

3

applv

whole

motorcycle.

Sectíon

2 íl-

lustrates

procedures

for

removal/installation

of

cornpo-

nents

that

may

be required

to

perform

service

described

in

the

followinq

sections.

Sections

4

through

17 describe parts

of

the

motorcycle,

grouped

according

to

location.

Find

the

section

you

want

on

this

page,

then

turn

to

the

table

of

contents

on

the

first

page of the

section,

\I1ost

sections

describe

the

service

prccedure

throuqh

svstern

illustration.

Refer to

the

next

page

for

details

on

",OW

to use thís

manual.

f you

dont

know

the

source

of

the

trouble,

go

to

sec-

ion

18

Troubleshooting.

ALL

INFORMATION,

ILLUSTRATIONS,

DIREC-

TIONS AND SPECIFICATIONS INCLUDED IN THIS

PUBLlCATION

ARE BASED ON THE

LATEST

PRODUCT

INFORMATION

AVAILABLE

AT

THE

TIME

OF

APPROVAL

FOR PRINTING.

HONDA

MOTOR

CO.,

LTD.

RESERVES THE RIGHT TO

MAKE

CHANGES

AT

ANY

TIME

WITHOUT

NO-

TICE

AND

WITHOUT

INCURRING

ANY

OBLlGA-

TION

WHATEVER.

NO

PART

DF

THIS

PUBLlCA-

TION

MA

y BEREPRODUCED

WITHOUT

WRITTEN

PERMISSION. THIS

MANUAL

IS WRITTEN FOR

PERSONS

WHO"

HAVE

ACQUIRED

BASIC

KNOWLEDGE OF

MAINTENANCE

ON

HONDA

MOTORCYCLES,

HONDA

MOTOR

CO.,

LTD.

SERVICE PUBLlCATION OFFICE

rte

of

Issue:

March,

1992

Hnl\lnil.

~~nTnp

rn

I

Tn

e

ro

...

t-

(1)

>

"¡:

CI

-a

e

ro

.(1)

e

el

e

w

en

en

en

ro

..l:

U

ro

C)

"¡:

.....

C)

(1)

w

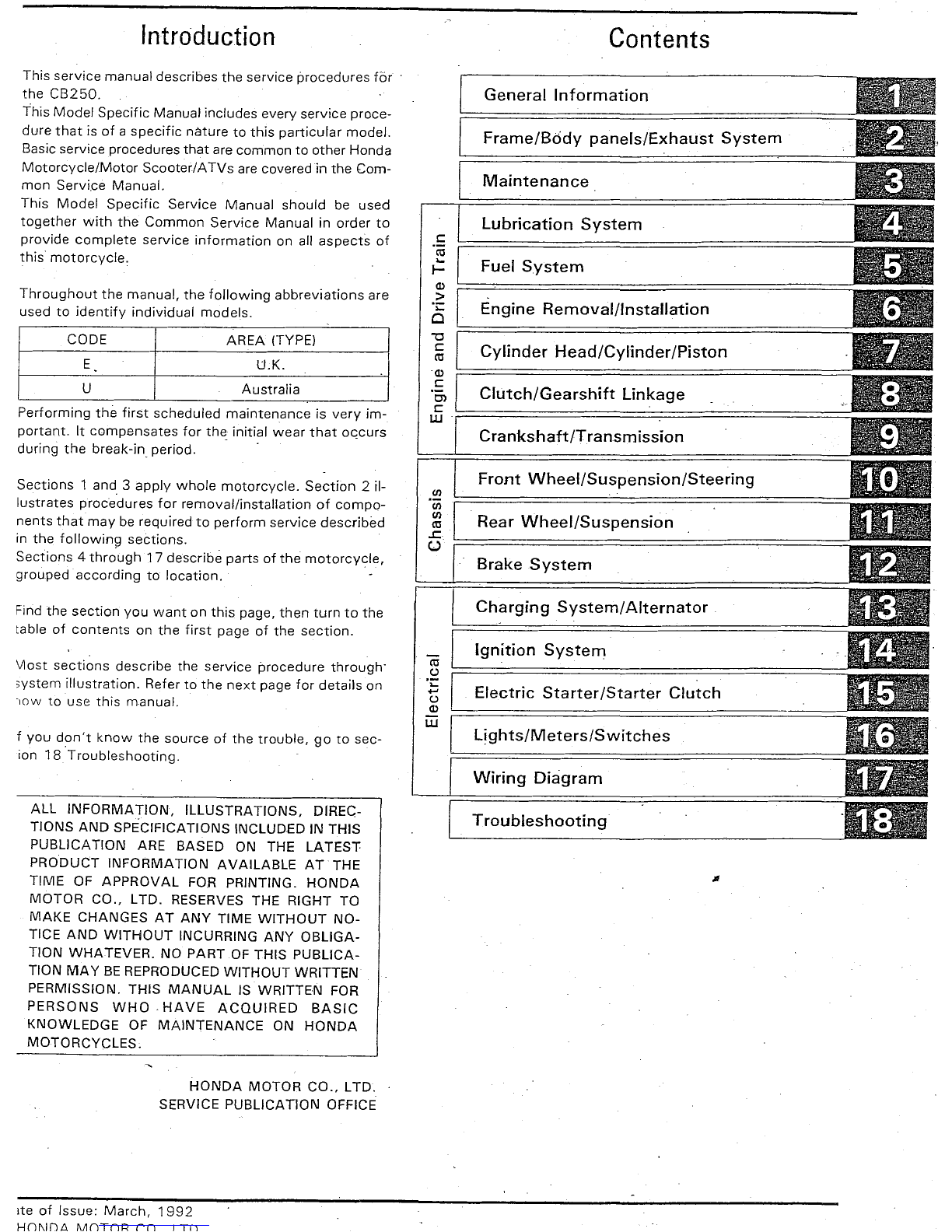

Contents

General

Information

Frame/B6dy

panels/Exhaust

System

Maintenance

Lubrication

System

Fuel

System

Engine

Removal/lnstallation

Cylinder

Head/Cylinder/Piston

Clutch/Gearshift

Linkage

Crankshaft/T

ransm

ission

Front

Wheel/Suspension/Steering

Rear

Wheel/Suspension

Brake

System

Charging

Systeml

Alternator

Ignition

System

Electric

Starter

IStarter

Clutch

Lights/Meters/Switches

Wiring

Diaqrarn

Troubleshooting

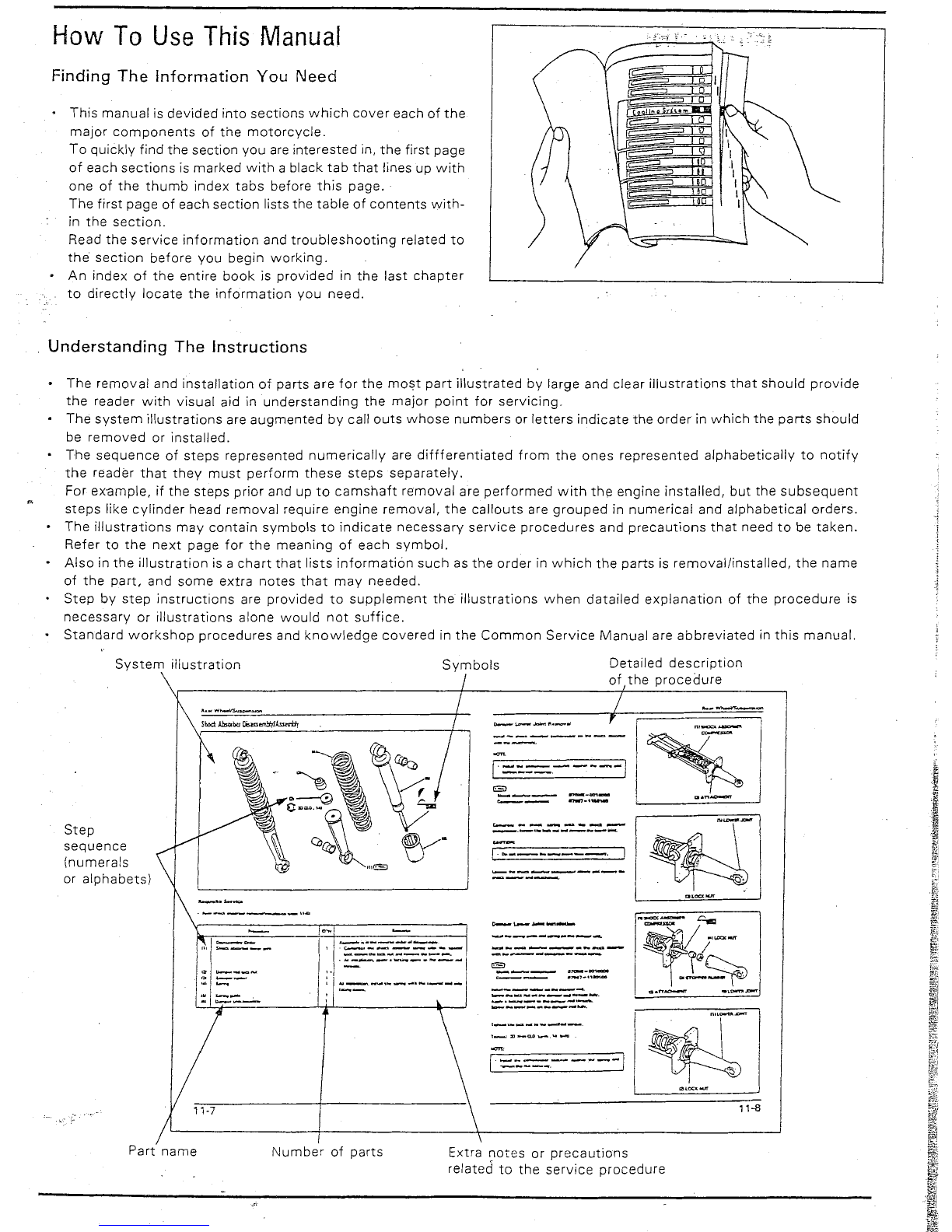

How

To

Use

This

Manual

Finding

The

Information You Need

This

manual

is

devided

into

sections

which

cover

each of

the

major

components

of

the

motorcycle.

To

quickly

find

the

section you are

interested

in,

the

first

page

of each

sections

is

marked

with

a

black

tab

that

lines up

with

one of

the

thumb

index

tabs

before

this

page.

The

first

page of each

section

lists the

table

of

contents

with-

in

the

section.

Read

the

service

information

and

troubleshooting

related

to

the

section

before

you

begin

working.

• An

index

of

the

entire

book

is

provided

in

the

last

chapter

to

directly

locate

the

information

you

need.

Understanding

The

Instructions

•

The

removal

and

installation

of

parts

are

for

the

rnost

part

illustrated

by large and

clear

illustr

ations

that

should

provide

the

reader

with

visual

aid in

understanding

the

major

point

for

servicing.

The

system

illustrations

are

augmented

by call

outs

whose

numbers

or

letters

indicate

the

order

in

which

the

parts

should

be

removed

or

installed.

The

sequence

of

steps

represented

numerically

are

diffferentiated

from

the

ones

represented

alphabetically

to

notify

the

reader

that

they

must

perform

these

steps

separately.

For ex-ample, if

the

steps

prior

and up

to

camshaft

rernoval

are

performed

with

the

engine

installed,

but

the

subsequent

steps

like

cylinder

head

removal

require

engine

removal,

the

callouts

are

grouped

in

numerical

and

alphabetical

orders.

The

illustrations

may

contain

symbols

to

indicate

necessary

service

procedures

and

precautions

that

need

to

be

taken.

Refer

to

the

next

page

for

the

meaning

of

each

symbol.

•

Also

in

the

illustration

is a

chart

that

lists

informatión

such

as

the

order

in

which

the

parts

is

removal/installed,

the

name

of

the

part.

and

some

extra

notes

that

may

needed.

Step

by

step

instructions

are

provided

to

supplement

the

illustrations

when

datailed

explanation

of

the

procedure

is

necessary

or

illustrations

alone

would

not

suffice.

Standard

workshop

procedures

and

knowledge

covered

in

the

Common

Service

Manual

are

abbreviated

in

this

manual.

11-8

r

Detailed

description

of

the

procedure

----

---

.,..,-

..

--

~--

..........

_--

-_.-

...

_------.

"----------

-----

------_-.

-_-..._-----_.

-.-._----_--.

---------.

----------

---------

I~-

1---

-1

I

~:::.::.::=:

- - - -]

Symbols

_

....

_-----

.e-...o_-..

_

.:.::

-::'-:'::"-::'::::-':::'-1

11-7

System

illustration

Step

sequence

(numerals

or

alphabets)

Part

name

Number

of

parts

Extra

notes

or

precautions

related

to

the

service

procedure

CB250

Addendum

Specifications

General

Item

Specifications

Dimensions

Frame

Engine

Overall

length

Overall

width

Overall

height

Wheel

base

Seat

height

Footpeg

height

Ground

clearance

Dry

weight

Curb

weight

Maximum

weight

capacíty

Frame

type

Front

suspensión

Front

wheel

travel

Rear

suspension

Rear

wheel

travel

Hear

damper

Front

tiresize

Rear

tire

size

Tire

brand

(Bridgestone)

Tirebrand

(Dunlop)

Tire

brand

(Yokohama)

Tire

brand

(IRC)

Tire

brand

(Pirelli)

Front

brake

Hear

brake

Caster

angle

Traillength

Fuel

tank

capacity

Fuel

tank

reserve

capacity

Bore

and

stroke

Displacement

Compression

ratio

Valve

train

Intake

valve

opens'

(att

mm

lift)

Intake

valve

closes (at 1

mm

lift)

Exhaust

valve

opens

(at 1

mm

lift)

Exhaust

valve

closes (at 1

mm

lift)

Lubrication

system

Oil

pump

type

ICo

olinp

system

.•- Ai r

fi/tration

Crankshaft

type

Engine

weight

Firing

order

"

Cylinder

arranqernent

Cylinder

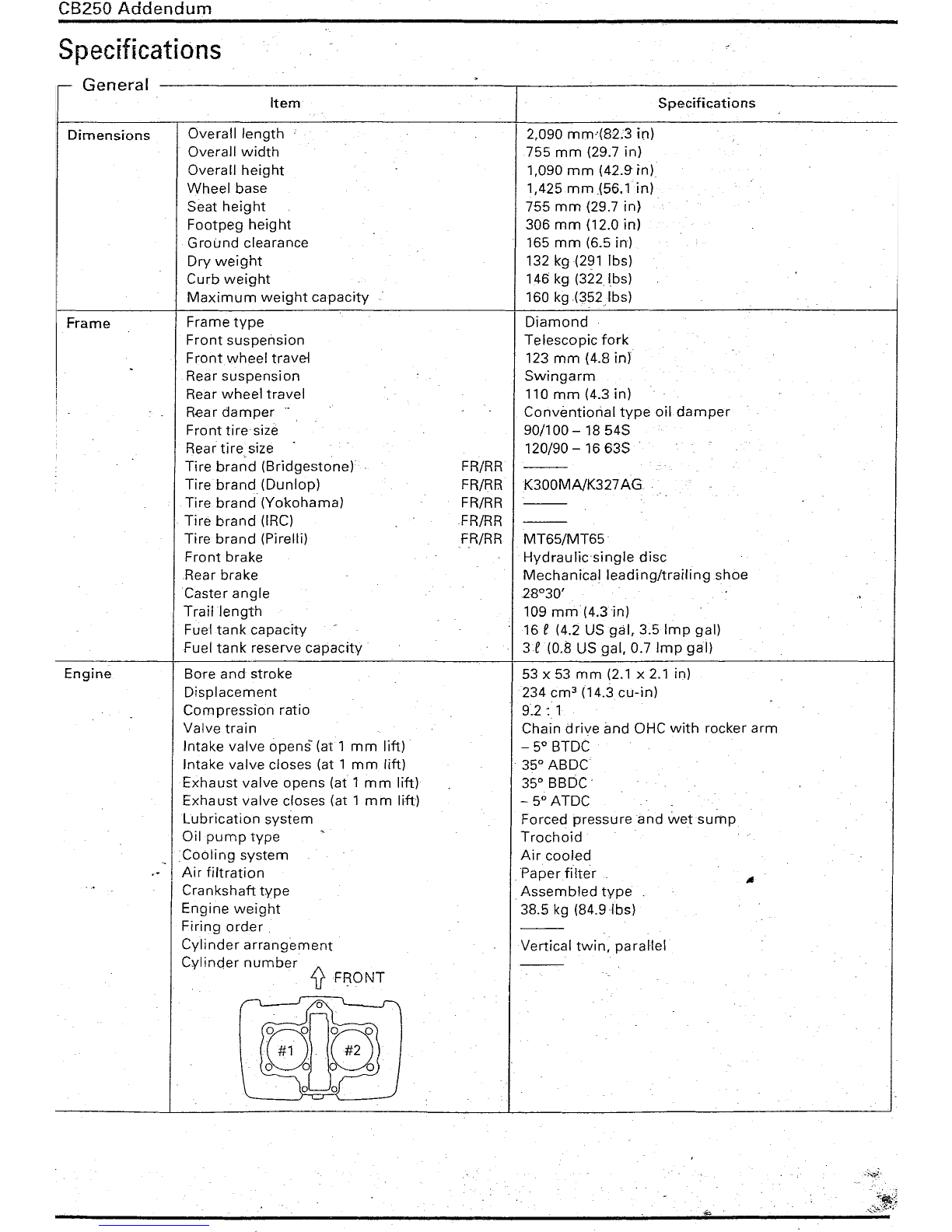

number

i'I.

ti

FRONT

FR/RR

FR/RR

FR/RR

FR/RR

FR/RR

2,090

mm"{82;3

in)

755

mm

(29.7 in)

1,090

mm

(42.9"in)

1,425

mm

(56.1 in)

755

mm

(29.7 in)

306

mm

(12.0 in)

165

mm

(6.5 in)

132

kg(291

lbs)

146 kg

(322

lbs)

160

kg(352Ibs)

Diamond

Telescopic

fork

123

mm

(4.8

in)

Swingarm

110

mm

(4.3 in)

Conventiorial

type

oildamper

90/100 - 18

545

120/90 -

16635

K300MNK327

AG

MT65/MT65"

Hydraulicsingle

disc

Mechanical

leading/trailingshoe

28°30'

109

mm

(4.3 in)

16 e(4.2 U5

gal,

3.5

Imp

gal)

3e

(0.8

U5gal,

0.7

Imp

gal)

53 x 53

mm

(2.1 x 2.1 in)

234 cm" (14.3

cu-in)

9.2:

1

Chain

drive

and

OHC

with

rocker

arm

- 5° BTDC

"35°

ABDC

35°

BBDC'

- 5°

ATDC

Forced

pressureand

wetsurnp

Trochoid

Air

cooled

.

Paperfilter

"Assembled

type

38.5 kg (84.9Jbs)

Vertical

twin,

paral1el

-;~;

CB250

Addendum

G I (C

td)

-

enera

on

,

Item

Specifications

Carburetor

Carburetor

tvpe

Constant

Velocity

single

carburetor

Throttlé

bore

26mm

(1.0 in)

Drive

Train

Clutch

system

Multi-plate,

wet

Clutch

operation

system

Mechanical

type

Transmission

5

speeds

Primaryreduction

3.631 (69/19)

Secondary

reduction

---

Third

reduction

---

Final

reduction

2.214 (31/14)

Gear

ratio

1st 2.846 (37/13)

Gear

ratio

2nd

1.777 (32/18)

Gear

ratio

3rd

1.333 (28/21)

Gear

ratio

4th 1.083 (26/24)

Gear

ratio

5th 0.913 (21/23)

Gear

ratio

6th

---

Gear

ratio

reverse

---

Gearshift

pattern

Left

foot

operated,

return

system,

1- N - 2 - 3 - 4 - 5

Electrical

...

Ignition

system

CDI

Starting

system

Electric

starter

Charging

sy.stem

Tripple

phase

output

type

Regulator/rectifier

type

SCR

shorted

tripple

phase,

full-wave

rectification

Lighting

system

Alternator

AC

regulatortype

---

(

CB250

Addendum

Lubrication

Unit:

mm

(in:

Item

Standard

Service

limit

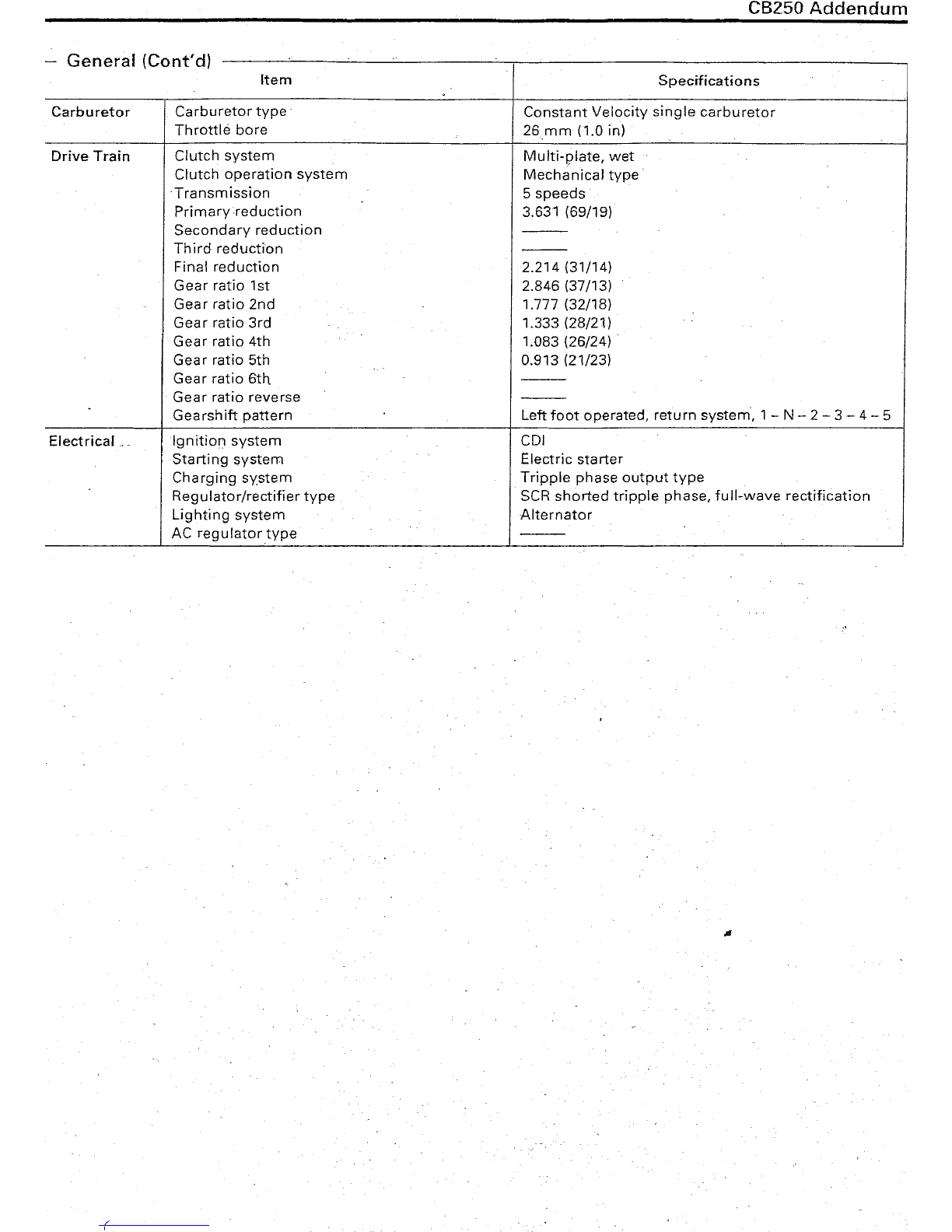

Other

viscosities

shown

in

the

chartmay

be

used

when

the

average

temperature

in

your

riding

area is

within

the

indicated

range.

1.5 e

(1.6US

qt.

1.3

Imp

qt)

1.8 e(1.9 US

qt,

t.s.lmp

qt)

Use

Honda

4-stroke

Oil

or

equivalent

API

Service

Classífication:

SE,

SF

or

SG

Viscosity:

SAE

10W

- 40

01020304.O"C

I

5On%e

'

,,,

....

I

i

~Imm

Engine

oil

capacity

at

draining

at

disassembly

at

oil

filter

change

Recommended

engine

oil

20

40

lKl 80

Oil

pressure

at

oil

pressure

switch

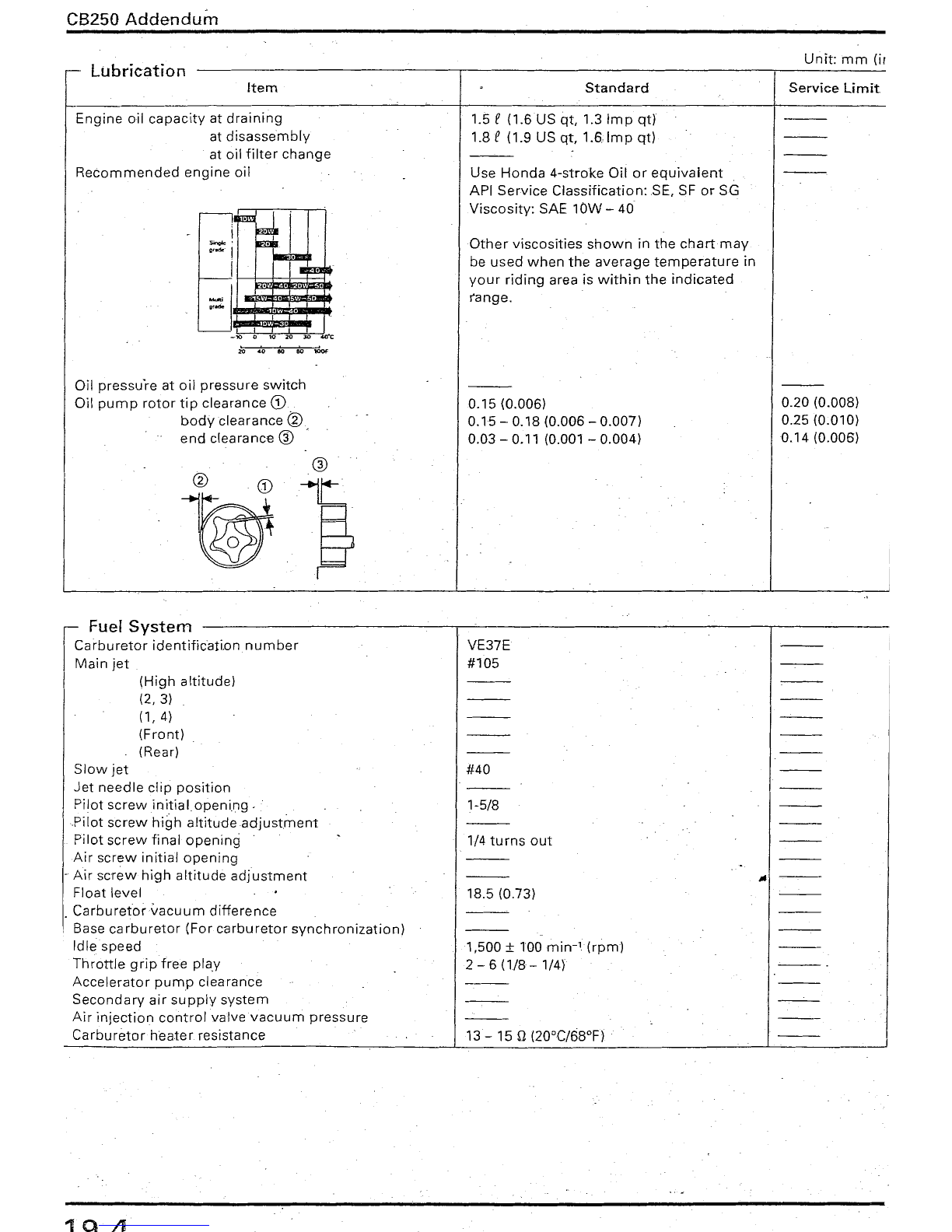

Oil

pump

rotor

tip

clearance

CD

body

c1earance ®

end

clearance

®

0.15

(0.006)

0.15

-

0.18

(0.006 - 0.007)

0.03

- 0.11 (0.001 -

0.004)

0.20

(O.OOS)

0.25 (0.010)

0.14

(0.006)

r-

Fuel

System

Carburetor

identification

number

Main

jet

VE37E

#105

(High

altitude)

(2,3)

(1, 4)

(Front)

(Rear)

Slow

jet

Jet

needle

clip

position

Pilot

screwinitialopening.

Pilot

screw

high

attitudeadjustrnerrt

Pilot

screw

final

opening

Air

screw

initial

opening

.

Air

screw

high

altitude

adjustment

Float

level

Carburetorvacuurn

difference

!Base

carburetor

(For

carburetor

synchronization)

Idle

speed

Throttle

grip

free

play

Accelerator

pump

clearance

Secondary

air

supply

svstern

Air

injection

control

valve

vacuum

pressure

Carbur

etor

he

ater

resistance

#40

1-5/8

1/4 tu rns

out

lS.5

(0.73)

1,500 ±

TOO

min-'(rpm)

2 - 6

(l/S-

1/4)

I

1Q

.11

CB25D

Addendum

Lubrication

Item

Engine

oil

capacity

at

draining

at

disassembly

at

oil

filter

change

Recommended

engine

oil

20

40

80 80

Oil

pressure

at

oil

pressure

switch

Oil

pump

rotor

tip

clearance

CD

body

c1earance ®

end

clearance

CID

Standard

1.5 e

(1.6US

ot. 1.3

Imp

qt)

1.8 e(1.9 US

qt,

1.S.lmp

qt)

Use

Honda

4-stroke

Oil

or

equivalent

API

Service

Classification:

SE,

SF or SG

Viscosity:

SAE

10W

- 40

Other

viscosities

shown

in

the

chartmay

be

used

when

the

average

temperature

in

your

riding

area is

within

the

indicated

ranqe.

0.15

(0.006)

0.15

-

0.18

(O.OOS

-

0.007)

0.03 - 0.11 (0.001 -

0.004)

Unit:

mm

(ir

Service

Limit

0.20 (0.008)

0.25 (0.010)

0.14

(0.006)

~

Fuer

System

Carburetor

identification

number

Main

jet

(High

altitude)

(2,3)

(1, 4)

(Front)

(Re ar)

Slow

jet

Jet

needle

clip

position

Pilot

screwinitialopening.

Pilot

screw

high

altitudeadjustment

Pilot

screw

final

openinq

Air

screw

initial

opening

.

Air

screw

high

altitude

adjustment

Float

level

Carburetorvacuurn

difference

Base

carburetor

(For

carburetor

synchronization)

Idle

speed

Throttle

grip

free

play

Accelerator

pump

clearance

Secondary

air

supply

system

Air

injection

control

valvevacuum

pressure

Carburator

heater

resistance

1Q

Ji

VE37E

#105

#40

1-5/8

1/4

turns

out

18.5 (0.73)

1,500 ±100

rnirr

lIrprrrl

2 - 6

(1/8-

1/4)

13 - 15 n(20°C/68°F)

CB25D

Addendun

Unit:

mm

(in

Cylinder

Heacl

-----~~----_._--------------___,__------:.-

Item

Standard

Service

Limit

Cylinder

com

pression

{kPa

(kgf/cm

2,psi)/500 - 600

min-

1(rprnl)

Cylinder

compression

difference

{kPa

(kgf/cm

2,psi)/500 - 600

mirr

'

(rprnl}

Valve

clearance

IN

EX

Cylinder

head

warpage

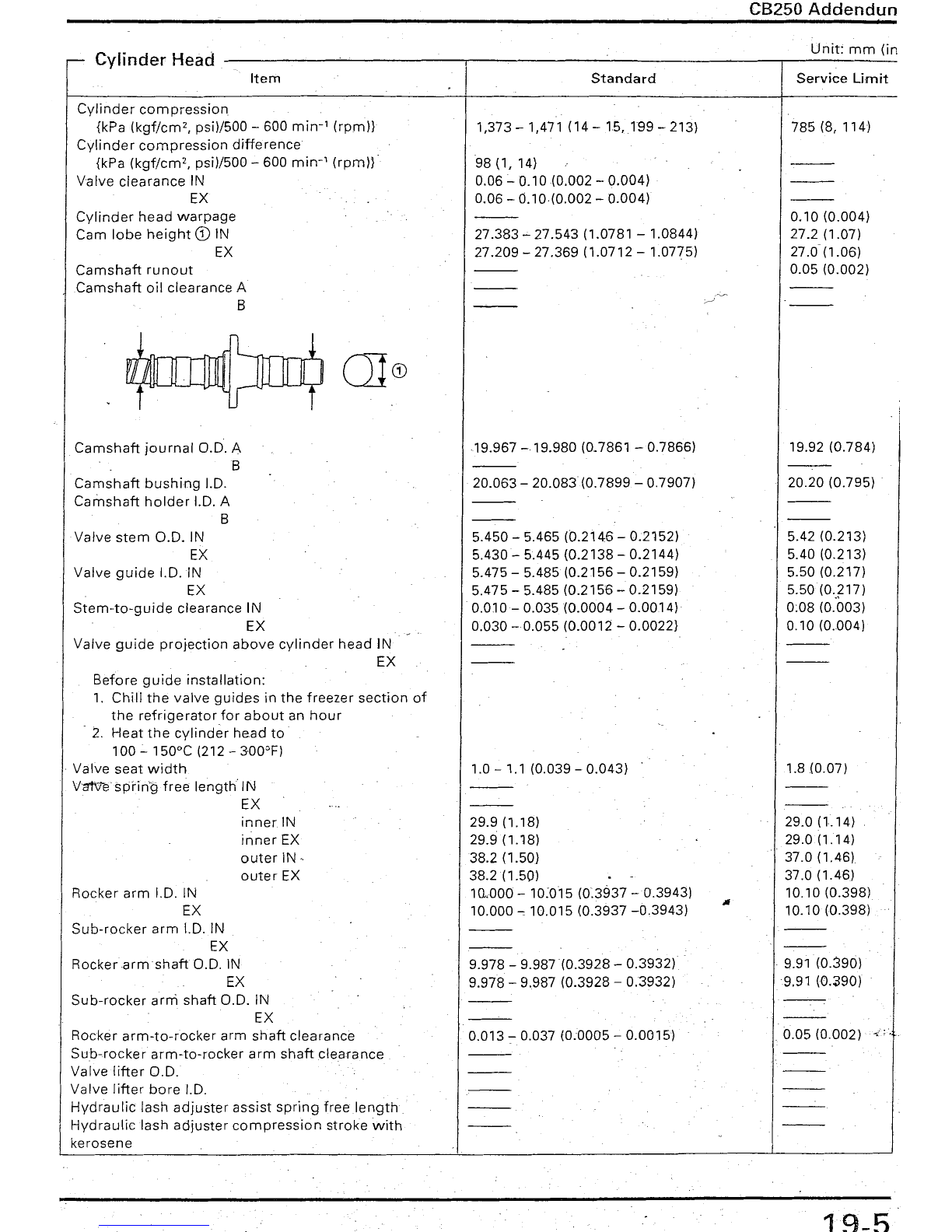

Cam

lobe

height

CD

IN

EX

Camshaft

runout

Camshaft

oil

clearance

A

B

1,373 - 1,471 (14 -

15,199

- 213)

98

(1,14)

0.06 -

0.10(0.002

-0.004)

0.06 -0.10·(0.002 -0.004)

27.383..c 27.543 (1.0781 - 1.0844)

27.209 -27.369 (1.0712 -1.0775)

785 (8, 114)

0.10 (0.004)

27.2 (1.07)

27.0(1.06)

0.05 (0.002)

OJCD

Camshaft

journal

0.0.

A

B

Camshaft

bushing

1.0.

Carnshaft

holder

1.0. A

B

Va/ve

stem

0.0.

IN

EX

Valve

guide

1.0. IN

EX

Stem-to-guide

clearance IN

EX

Valve

guide

pr

ojection

aboye

cylinder

head

IN

EX

Before

guide

installation:

1.

Chill

the

valve

guides

in

the

freezer

section

of

the

refrigeratorfor

about

an

hour

- 2.

Heat

the

cylinder

head

to

100 - 150°C (212 - 300°F)

.Valve

seat

width

Vert\re

sprin'g

free

length

IN

EX

inner

IN

inner

EX

outer

IN

-.

outerEX

Rocker

arm

1.0. IN

EX

Sub-rocker

arm

1.0. IN

EX

RockerarmshaftO.D.

IN

EX

Sub-rocker

arrn

shaft

0.0.

IN

EX

Rocker

arrn-to-rocker

arrn

shaft

clearance

Sub-rocker

arrn-to-rocker

arrn

shaft

clearance

Valve

lifter

0.0.

Valve

lifter

bore

1.0.

Hydraulic

lash

adjuster

assist

spring

freelength

Hydrauliclash

adjuster

compression

stroke

with

kerosene

19.967

-19.980

(0_7861 - 0.7866)

20.063 -20.083 (0.7899 -0.7907)

5.450 - 5.465 (0.2146 -0.2152)

5.430 - 5.445 (0.2138 -0.2144)

5.475 - 5.485 (0.2156 -0.2159)

5.475 - 5.485 (0.2156 -0.2159)

0.010-

0.035

(0.0004

-0.0014)

0.030

-0.055

(0.0012 -0.0022)

1.0 - 1.1 (0.039 - 0.043)

29.9 (1.18)

29.9 (1.18)

38.2 (1.50)

38.2(1.50)

1

Q.OOO

-10:015 (0.3937

-0.3943)

10.000.., 10.015 (0.3937

-0.3943)

9.978 -

9.987(0.3928

-0.3932)

9.978 - 9.987 (0.3928 -0.3932)

0.013:-

0.037 lO.0005 -0.0015)

19.92 (0.784)

20.20 (0.795)

5.42 (0.213)

5.40 (0.213)

5.50 (0.217)

5.50 (0..

;217)

0:08 (0.003)

0.10 (0.004)

1.8 (0.07)

29.0

(l.14)

29.0(1.14)

37.0 (1.46)

37.0 (1.46)

10.10 (0.398)

10.10 (0.398)

. 9.91 (0.390)

9.91 (0.390)

0.05 (0.002) ..

19-5

CB25ü

Addendum

Cvlinder/Piston

Item

Cylinder

I.D.

out

of

round

taper

warpage

Piston

mark

direction

Pisto

n O.D. (O)

Piston

O.D.

measurement

point

(H)

Piston

pin

hole

I.D. (d)

(d)

Cylinder-to-piston

clearance

Pisten

pin

O.D.

Piston-to-piston

pin

clearancé

Connectinq

rod-to-piston

pin

clearance

Top

ring-to-ring

groove

clearance

Second

ring-to-ring

groove

c1earance

Top

ring

end

gap

Second

ring

end

gap

Oil

ring

(side

rail)

end

gap

Top

ring

mark

Second

ring

mark

-Crankshaft

Connecting

rod

small

end I.D.

Connecting

rod

bigendside

clearancs

radial clé

arance

-

Crankshah

runout

(at

both

ends)

G)

(at

bearing

holder)

@

bG)

39.5

mm

(1.56 in)

U .

IJ

l'9.5

mm

(0.37 in)

Crank

pin

oil

clearance

Crank

pin

bearing

selection

Main

journal

oil

clearance

Main

journal

bearing

selsction

Standard

53.000

-

53.010

(2.0866

-

2.0870)

"IN"

mark

facing

toward

the

intake

side

52.970

-

52.990

(2.0854

-

2.0862)

10

mm

(0.4 in)

from

the

bottom

15.002

-

15.008

(0.5906 -

0.5909)

0.010

-

0.040

(0.0004

-

0.0016)

14:994

-

15.000

(0.5903 -

0.5906)

0.002

-

0.014(0.0001

-

0.0006)

0.016

-

0.040

(0;0006 -

0.0016)

0.015

-

0.040

(0.0006 -

0.0016)

0.015

-0.040(0.0006

-

0.0016)

0.15 -

0.30

(0.006 -0.012) .

0.30

-0.45 (0.012 -0.018)

0.2 - 0.7 (0,01 - O.03)

"N".mark

side

facing

up

"N"

markside

facing

up

15.016

-

15.034

{0.59 J2 -

0.5919)

0.10-0.40

(0.004-0.016)

0,004

-

0.012

(0.0002 -

0.0005)

.""

Unit:

mm

(in)

Service

Limit

53.10

(2.091)

0.05 (0.002)

0.05 (0.002)

0.05(0.002)

52.90

(2.083)

15.05 (0.593)

0.10

(0.004)

14.98

(0.590)

0.07 (0.003)

0.10

(0.004)

0.10

(0.004)

0.10 (0.004)

0.45(0.018)

0.60

(0.024)

0.90

(0.036)

15.08 (0.594)

0.6 (0;02)

0.05

(0.002)

0.03

(0.001)

0.05

(0.002)

..

-Kickstarter

--------'--------'-------,-----------~----~-,------

Kickstarterpinion

gear

I.D.

Kickstarter

spindle

O.D.

Kickstarter

id le

gear

I.D.

Countershah

O.D. at

kickstarter

id le

gear

Kickstarter

idle

gearbushing

O.D.

I.D.

19-6

Transrnrssion

Item

Transmission

gear

I.D. M5

Cl

C4

Transmission

gear

bushing

O.D. Cl

Transmission

gear

bushing

I.D.

el

Gear-to-bushing

clearance

at

Cl

gear

Mainshaft

O.D. at M5

gear

at c1utch

outer

guide

G)

Countershaft

O.D. at Cl

gear

at C4

gear

Gear-to-shaft

clearance

at M5

gear

at C4

gear

Gear

bush

ing-to-shaftclearance

al

Cl

gear

Shift fork

claw

thickness

L

C

R

Shift

fork I.D. L

C

R

Shift

fork

shaft

O.D. L

C

R

Shift

drum

O.D.

Standard

20.020

-20.041 (0.7882 -0.7890)

20.020

-20.041

(0.7882

-0.7890)

20.020

-20.041 (0.7882 -0.7890)

19.979-

20.006

(0.7866

-0.7874)

16.516

-

16.534

(0.6502 -0.6509)

0.020

-0.062 (0.0008 -0.0024)

19.959

-19.980

(0.7858

-0.7866)

19.959

-19.980

(0.7858 -0.7866)

16.446

-16.484

(0.6475

-0.6490)

19.959

-19.980

(0.7858

-0.7866)

0.040

-0.082 (0.0016 -0.0032)

0.040 -0.082 (0.0016

-0.0032)

0.032

-0.068 (0.0013 -0.0027)

4.93 -

5.00(0.194

-

0.197)

4.93 -5.00 (0.194 -

0.197)

4.93 - 5.00 (0.194

-0.197)

12.000 -

12.018

(0.4724

-0.4731)

12.000

-12.018

(0.4724

-0.4731)

12.000 -12.018

(0.4724-0.4731)

"'"19 :976"';

11.994

(0.4715

-0.4722)

11.976 -

11.994

(0.4715

-0.4722)

11.976

-

11.994

(0.4715

-0.4722).

CB250

Addendum

Unit:

mm

(in)

Servica

Umit

20.08

(0.791)

20.08

(0.791)

20.08

(0.791)

19.93(0.785)

16.58

(0.653)

0.10(0.004)

19.91 (0.784)

19.91 (0.784)

16.41 (0,646)

19.91 (0.784)

0.10(0.004)

0.10 (0.004)

0.10 (0.004)

4.80 (0.189)

4.80 (0.189)

4.80 (0.189)

12.05 (0.474)

12.05 (0.474)

12.05 (0.474)

11.93 (0.470)

11.93 (0.470)

11.93 (0.470)

19-7

Unit:

mm

(in)

r-

Cfutch

System

Item

Standard

Service

Limit

Clutch

lever

free

play

10 - 20 (3/8

~

3/4)

---

Recornrnended

clutch

fluid

--- ---

Clutch

master

cylinder

I.D.

---

---

Clutch

master

piston

O.D.

--- ---

Clutch

outer

I.D.

26.000

-

26.012

(1.0236

-

1.0241)

26.04

(1.025)

Clutch

outer

guide

O.D.

25.959

-

25.980

(1.0220 -

1.0228)

25.90

(1.020)

I.D.

20.000

-

20.021

(0.7874

-

0.7882)

20.05

(0.789)

Mainshaft

O.D. at

ciutch

outer

guide

--- ---

Clutch

spring

free

heigJ;ot:"

---

---

Clutch

spring

free

length

37.~

(1.49)

36.0

(1.42)

Clutch

disc

thickness

2.8

- 2.9 (0.11 - 0.15)

2.6

(0.10)

Clutch

disc

thickness

A

--- ---

B

--- ---

Clutch

plate

warpage

---

0.20

(0.008)

Centrifugal

clutch

drum

I.D.

---

---

bushing

O.D.

---

---

Centrifugal

clutch

center

guide

I.D.

---

---

0.0.

---

---

Centrifugal

clutch

center

guide

collar.heiqht

---

---

Centrifugal

clutch

weight

lining

thickness

---

---

Centrifugal

clutch

spring

free

length

---

---

Clutch

lining

thickness

---

---

Crankshaft

O.D. at

clutch

center

---

~.

---

~

CoolingSystem

Coolant

capacito

y_

(Radiato.r and

engine)

(Reserve

tank)

Radiator

cap

relief

pressure

Thermostat

begin

to

open

I

Thermostat

fully

open

.

Thermostat

valva

lift

-

Drive

Train

Recommended

final

drive

oil

Final

drive

gear

oil

capacity

at

disassembly

at

draining

Final

drive

gear

backlash

Final

drive

gear

backlash

difference

between

measurement

Ring

gear-to-stop

pin

clearance (A)

Stop

pin

shim

Ring

gear

spacer

Pinion

spacer

Final

drive

gear

assembly

preload

Output

gear

backlash

Output

gear

I.D.

Output

gear

bushing

0:0.

I.D.

Output

drive

shaftO.D.

Output

geardamper

spring

free

length

Output

shaft

adjustment

shirn

Countershaft

drive

shaft

adjustment

shim

19-8

CB250

Addendum

Unit:

mm

(in)

-

Wheels/Tires

Item

Standard

Service

Limit

Minimum

tire

thread

depth

(FR)

---

1.5 (0.06) I

(RR)

---

2.0(0.08)

I

Cold

tire

pressure

Up 1'090 kg (200 lb)

load

(FR) 200

kPa(2.00

kgf/cm

2,29 psi)

---

Up

1'090 kg (200 lb)

load

(RR) 200 kPa (2.00 kqf/crn", 29 psi)

---

Up

1'0

maximum

weight

capacity

(FR) 200

kPa(2.00

kgf/cm

2,29 psi)

---

Up

1'0

maximum

weight

capacity

(RR) 200 kPa (2.00

kgf/cm

2,29 psi)

---

,

Front

and

rear

axle

runout

0.2 (0.01)

Front

and

rear

wheel

rirn

runout

(Radial)

---

2.0 (0.08)

(Axial)

---

2.0 (0.08)

Front

wheel

hub-to-rirn

distance

,

---

---

Front

wheel

hub

standard

surface

---

----

Rear

wheef

hub-to-rim

distance

---

---

I

Rear

wheel

hub

standard

surface

I

---

---

,

Wheel

balance

weight

(Front)

---

609

(2.1

oz)max.

(Rear)

---

609

(2.1

oz)

max.

Orive

cha in

slack

20 - 30 (3/4 - 1-1/4)

---

,

Orive

chain

size/link

(010) 520VC.6-106LE

---

\

(RK)

520MO-Z9-106LE

---

r-r-'

Front

Suspension

Fork

spri

ng

free

length

Fork

spring

free

length

A

8

Fork

spring

direction

Fork

tube

runout

Recommended

fork

oil

Fork

oil

level

Fork

oil

level

(R)

(U

Fork

oil

capacity

Fork

oil

capacity

(R)

{U

_

Fork

air

pressure

Steering

bearing

preload

59.7 (2.35)

488.7 (19.24)

Tightly

wound

coil

facing

down

Forkfluid

162

(6.4)

150

cm"

(5.1 US oz, 5.3

Impoz)

0.1 - 0.15

kgf-m

58 (2.3)

479 (18.86)

0.2 (0.01)

r-r-

'Rear

Suspension

Shock

absorber

spring

free

length

Shock

absorber

spring

free

leriqth

(A)

(8)

Oamper

gas

pressure

Oamper

compressed

gas

Oaniper

rod

compressed

force

at 10

mm

(0.4 in)

compressed

Oamper

driUing

point

Shock

absorber

spring

installed

length

(Standard)

(Adjustable

range)

Shock

absorberspríng

adjuster

standard

position

2nd

groove

Shock

absorber

spring

direction

Recommended

shock

absorber

oil

Shock

absorber

oil

capacity

air

pressure

19-9

CB250

Addendum

Unit:

mm

(in)

Brakes

---------------....-------~-----------,....-----~-.-:.

Item

Standard

Service

Limit

Front

brake

fluid

brake

lever

free

play

brake

pad

wear

indicator

DOT

3 or

DOT

4

10 - 20 (3/8 -

314)

.To

the

groove

CD

CD

brake

disc

thickness

brake

disc

runout

master

cylinder

1.0.

master

piston

0.0.

caliper

cylinder

1.0.

caliper

cvlinder

1.0.

(Upper).

(Lower)

caliper

piston

0.0.

caliper

piston

0.0.

(Upper)

(Lower)

brake

drum

1.0.

brake

Iining

thickness

Rear

brake

fluid

brake

pedal

height

brake

pedal

free

play

brake

pad

wear

indicator

..

If0í

~

J01?"

,':1

/

,')<~~~j

brake

disc

thickness

brake

disc

runout

master

cylinder

1.0.

master

piston

0.0.

caliper

cylinder

1.0.

caliper

piston

0.0.

brake

drum

1.0.

brake

lining

thickness

4.0 (O.16)

11.0 - 11.043 (0.4331 - 0.4348)

10.957

-10.984

(0.4314 -0.4324)

27.000 -27.050 (1.0630 - 1.0650)

26.918 -26.968 (1.0598 -1.0617)

20 - 30 (3/4 -1-1/4)

130 (5.1)

4.0 (O.16)

3.5 (0.14)

0.30 (0.012)

11.05 (0.435)

10.95 (0.431)

27.06 (1.065)

26.91 (1.059)

131 (5.2)

2.0 (0.08)

r-r-

Battery/Charging

System

Alternator

chargingcoil

resistance

(At

20°C/68°F)

Regulator/rectifier

regulated

voltaqe/arnperaqe'

Battery

capacity

Battery

specific

gravity

(Fullv

charging)

(Needs

charging)

Battery

chargíng

rate

(Normal)

(Quick)

Battery

voltage

(Fully

charged

20°C!68°F)

(Needs

charging

20°C/68°F)

Alternator

lightingcoil

resistance (At

20°C/68°F)

. AC

regulator

regulated

voltage

(With

analog

type)

(With

digital

type)

0.2 - 0.6 n

13.5

-14.0

V/1 A

12 V - 6 Ah

0.6A/10h

3

A/1.0

h

13-13.2V

Below

12.3 V

CB250

Addendum

i!

,\

Unit:

mm

(in)

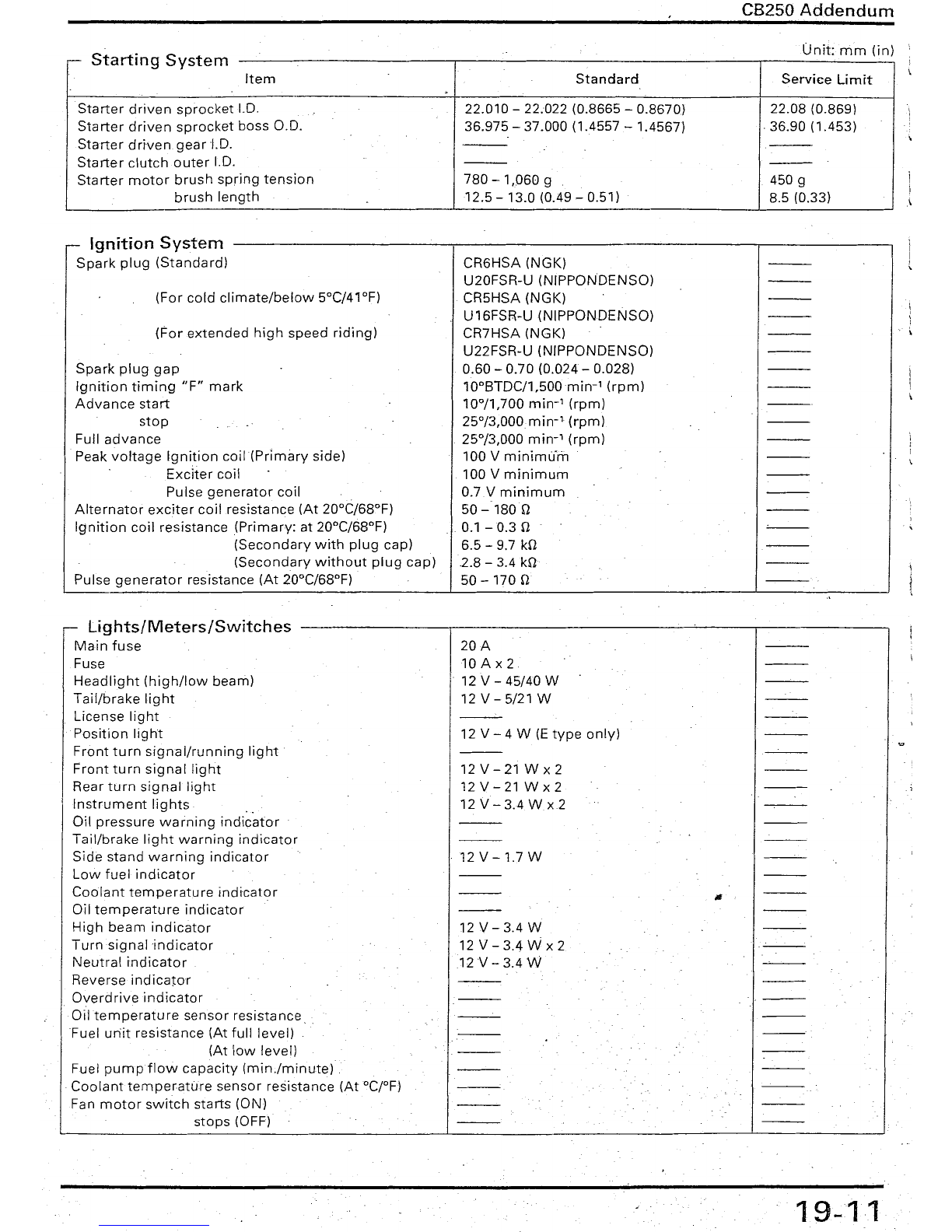

s

St

tO

r-

ar

mg

ystem

Item

Standard

Service

Limit

Starter

driven

sprocket

1.0.

22.010-

22.022

(0.8665

-

0.8670)

22.08

(0.869)

Starter

driven

sprocket

boss

0.0.

36.975

-

37.000

(1.4557 -

1.4567)

,

36.90

(1.453)

Starter

driven

gear

'1.0.

'---

---

Starter

clutch

outer

1.0.

---

---

Starter

motor

brush

spring

tension

780

-1,060

9450 9

brush

length

12.5

-13.0 (0.49 -0.51) 8.5 (0.33)

-

Ignition

System

Spark

plug

(Standard)

(For

cold

climate/below

5°C/41°F)

(For

extended

high

speed

riding)

Spark

plug

gap

Ignition

timing

"F"

mark

Advance

start

stop

Full

advance

Peak

voltage

Ignition

coilIf'rirnarv

side)

Exciter

coil

PuIse

generator

coil

Alternator

exciter

coil

resistance

(At

20°C/68°F)

Ignition

coil

resistance

(Prirnarv: at 20°C/68°F)

(Secondary

with

plug

cap)

(Secondary

without

plug

cap)

Pulse

generator

resistance

(At

20°C/68°F)

CR6HSA

(NGK)

U20FSR-U

(NIPPONOENSO)

CR5HSA

(NGK)

U16FSR-U

(NIPPONDENSO)

CR7HSA

(NGK)

U22FSR-U

(NIPPONDENSO)

0.60

-

0.70

(0.024 -

0.028)

10

0BTDC/1,500min-'

(rpm)

10°/1,700

min-'

(rpm)

25°/3,000min-

1

(rpm)

25°/3,000

min-'

(rprn)

100 V rninimurn

100 V

minimum

0.7V

mínimum

50-1800

0.1-0.30

6.5 - 9.7 kO

2.8

- 3.4 kO

50 - 170 O

Lights/Meters/Switches

Main

fuse

Fuse

Headlight

(high/low

beam)

Tail/brake

light

License

light

Position

light

Front

turn

signal/running

light

Front

turn

signallight

Rear

turn

signal

light

Instrument

lights

'.

Oil

pressure

warning

indicator

Tail/brake

light

warning

indicator

Side

stand

warning

indicator

Low

fuel

indicator

Co

olant

temperature

indicator

Oil

temperature

indicator

High

beam

indicator

Tu

rnsig

n

ali

ndicator

Neutral

indicator

Reverse

indicator

Overdrive

indicator

Oil

temperature

sensor

resistance

Fuel

uriit

resistance

(At

fu"

level)

(At

low

level)

Fuel

pumpflow

capacity

(min./minute)

Coolant

temperatúre

sensor

resistance

(AtOC¡OFj

Fan

motor

switch

starts

(ON)

stops

(OFF)

20A

10 Ax2

12V-45/40W

12 V - 5/21 W

12 V - 4 W (E

type

only)

12V-21Wx2

12V-21

Wx2

12 V - 3.4 W

x2

12V-l.7W

12V-3.4W

12 V - 3.4 Wx 2

12 V - 3.4 W

19-11

CB250

Addendum

Torque

Values

r-r-:

Standard

Fastener

Type

Torque

Fastener

Type

Tarque

.

N'm

[kgf-m,

Ib-ft)

N'm

(kgf'm,

Ib-ft)

5

mm

hex

bolt

and

nut

5 (0.5, 3.6) 5

mm

screw

4 (0.4, 2.9)

6

mm

hex

bolt

and

nut

10 (1.0, 7) 6

mm

screw

9 (0.9, 6.5)

8

mm

hex

bolt

and

nut

22 (2,2, 16) 6

mm

flange

bolt

(8

mm

head)

9 (0.9, 6.5)

10

mm

hex

bolt

and

nut

34(3.5,

25} 6

mm

flange

bolt

(10

mm

head)

and 12 (1.2, 9)

12

mm

hex

bolt

and

nut

54 (5.5, 40)

nut

8

mm

flange

bolt

and

nut

26 (2.7, 20)

1°

mm

flange

bolt

and nut 39 (4.0, 29)

Torque

specifications

listed

below

are

for

important

fasteners.

Others

should

be

tightened

to

standard

torque

values

listed

aboye.

NOTE

1.·

Apply

sealant

to

the

threads.

2.

Applya

locking

agent

to

the

threads.

3.

Apply

molybdenum

disulfide

oil

to

thethreads

and

flange

surface.

4.

Left

hand

threads.

5. Stake.

6.

Apply

oil

to

the

threads

and

flange

surface.

7.

Apply

clean

engine

oil

to

the

O-ringo

8.

Torque

wrench

scale

reading

usinga

special

tool.

9.

Apply

grease

to

the

threads

and

flange

surface.

10. UBS

bolt.

11.U-nut.

12.

Alock

bolt.

Do

not

reuse.

E

r--

ngme

I

Item

O'tv

Thread

dia.

Tarque

Remarks

(mm)

N'm

(kqf-rn,

Ib-ft)

.,

Lubrication

System:

Oil

pump

mounting

screw

3610 (1.0, 7)

Cylinder

Head/Cvlinder:

Spark

plug

210

12(1.2,9)

Va/ve

adjusting

lock

nut

I

45¡

10(1.0,7)

Cylinder

head/camshaft

holder

nut

88I23 (2.3, 17)

Cvlinder

head

bolt

3 6 i12 (1.2, 9)

Cam

sprocket

bolt

2 7 20 (2.0, 14)

Note

2

Cylinder

h~d

cover

bolt

26,10 (1.0, 7)

Clutch/Gearshift

Linkage:

Clutch

lifter

bolt

46

12(1.2,9)

Clutch

center

locknut

116 74

(7.6,55)

Note

5, 6

Shift

drum

stopper

arm

bol!

.I16

12(1.2,9)

Gearshift

return

spring

pin

18

25(2.5,18)

Note

2

Primary

drive

gear

lock

nut

116 53 (5.4, 39)

Crankcase/Cran

kshaft:

A

Drive

sprocket

bolt

2 6

12(1.2,9)

Oil

drain

bolt

112 25 (2.5, 18)

Crankshaft

mounting

bolt

5823 (2.3, 17)

Crankshaft

mounting

nut 1612 (1.2, 9)

Oil

passage

plate

mounting

screw

36

10(1.0,7)

Note

2

Starter

Clutch/

Alternatar:

Flywheel

bolt

110 59 (6.0, 43)

Starter

clutch

mounting

screw

369 (0.9, 6.5)

Note

2, 5

Stator

mountíng

screw

35I6 (0.6, 4.3)

Stator

wire

clamp

screw

15I6 (0.6, 4.3)

Pulse

generator

mounting

screw

2610 (1.0, 7)

Starter

motor

terminal

nut

166 (0.6, 4.3)

19-12

CB250

Addendum

F

r-r-'

rame

.

Thread

día.

Torque

,i

ltern

Q'ty

Remarks

Lo.

(mm)

N·m

(kqf-rn,

Ib-ft)

Front

Suspension:

L

Steering

stem

nut

1 22

74

(7.5, 54)

Steering

stem

adjustment

nut

1 22 3(0.3, 2.2)

;~

Handlebar

holder

bolt

4o' 824

(2.4,17)

Fork

top

bridge

pinch

nut

2822 (2.2, 16)

Note

11

Fork

bottom

bridge

pínch

bolt

2 8 24 (2.4, 17) 1'-

Steering

lock

mounting

bott

2 6 9(0.9, 6.5)

Note

2

Fork

cap

2 27 23 (2.3, 17)

Fork

socket

bolt

2820

(2.0,14)

Note

2'1

i

Rear

Suspension:

'-

Swingarm

pivot

nut

114 59 (6.0, 43)

Note

11

Rear

shock

absorber

lower

mounting

bolt

210 42

(4.3,31)

Wheels:

Front

axle

nut

114 59

(6.0,43)

Note

11

~

Rear

axle

nut

114 59

(6.0,43)

Note

11

Brake

arm

torque

link

bolt

2822

(2.2,16)

~

Driven

sprocket

nut

410 44 (4.5, 33)

Note

11

Brake

system:

Pad

pin

plug

1 8 3

(0.3,2.2)

"i

Pad

pin

1818 (1.8, 13) ". o'

Caliper

pin

bolt

(bracket

side)

1 8 13

(1.3,9)

Note

2

t-

(caliperside)

1 8 23 (2.3, 17)

Note

2

Caliper

bleed

valve

166

(0.6,4.3)

Frorit

caliper

mounting

bolt

30

(3.1, 22) I

210 I

Brake

disc

bolt

4 8 42

(4.3,31)

"-

Master

cylinder

reservoir

cap

screvv 2I42(0.2, 1.4)

Brake

hose

oil

bolt

2la

34

(3.5, 25) J

Brake

lever

pivot

nut

166(0.6, 4.3) l1

o,

....

Rearbrake

arm

pinch

bolt

1610 (1:0, 7)

Other

Fasteners:

L

Engine

rear

mounting

bolt

2 10 83 (8.5,

61)

Exhaust

pipe

joint

nut

46I14

(1.4,10)

Side

stand

switch

mounting

bolt

1 6 29

(3.0,22)

Note

12

~J

Side

stand

bracket

bolt

2i836 (3.7, 27)

,ti

CB250

Addendum

Lubrication

&

Seal

Points

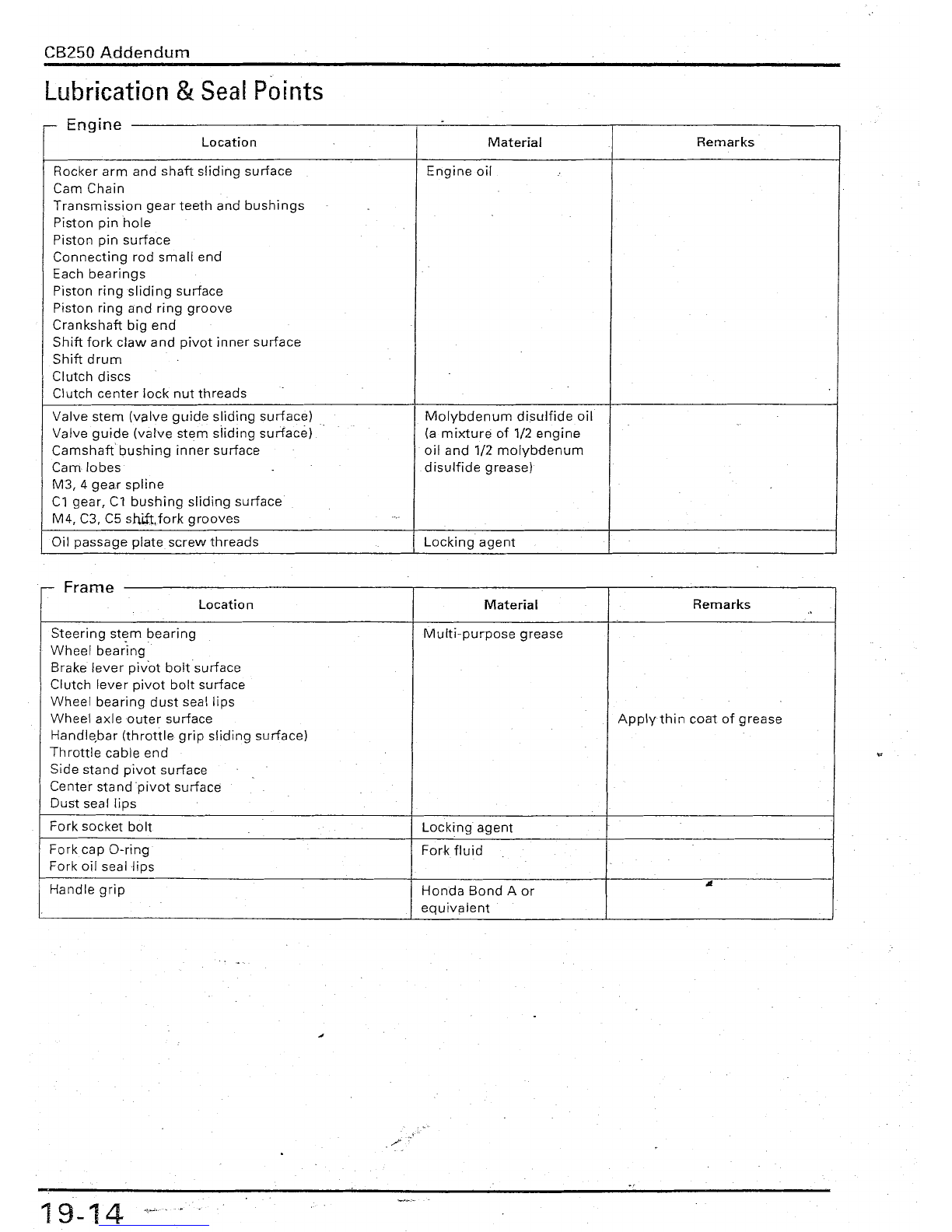

E

~

ngme

Location

Material

Remarks

Rocker

arm

and

shaft

sliding

surface

Engine

oil

Cam

Chain

Transmission

gear

teeth

and

bushings

Piston

pin

hole

Piston

pin

surface

Connecting

rod

small

end

Each

bearings

Piston

ringsliding

surface

Piston

ring

and

ring

groove

Crankshaft

big

end

Shift

fork

claw

and

pivot

inner

surface

Shift

drum

Clutch

discs

Clutch

center

lock

nut

threads

Valve

stem

(valve

guide

sliding

surface)

Molybdenum

disulfide

oil

Valve

guide

(valve

stem

slidinq

surface)

(a

mixture

of

1/2

engine

Camshaft

bushing

inner

surface

oil

and

1/2

molybdenum

Cam

lo bes

disulfide

grease)

M3,

4

gear

spline

Cl

gear,

Cl

bushing

sliding

surface

M4, C3, C5 shift.fork

grooves

Oil

passage

plate

screw

threads

..

Locking

agent

F

~

rarne

Location

Material

Remarks

..

Steering

stern

bearing

Multi-purpose

grease

Wheel

bearing

.

Brake

lever

pivot

boltsurface

Clutch

lever

pivot

bolt

surface

Wheel

bearing

dust

seallips

Wheel

axle

outer

surface

Applythin

coat

of

grease

Handlebar

(throttle

grip

sliding

surface)

Throttle

cable

end

Side

stand

pivot

surface

Center

standpivot

surface

Dust

seal

lips

Fork

socket

bolt

Locking

agent

Forkcap

O-ring

Fork

fluid

Fork

oil

seallips

Handle

grip

Honda

Bond

A

or

"-

equivalent

./

19-14

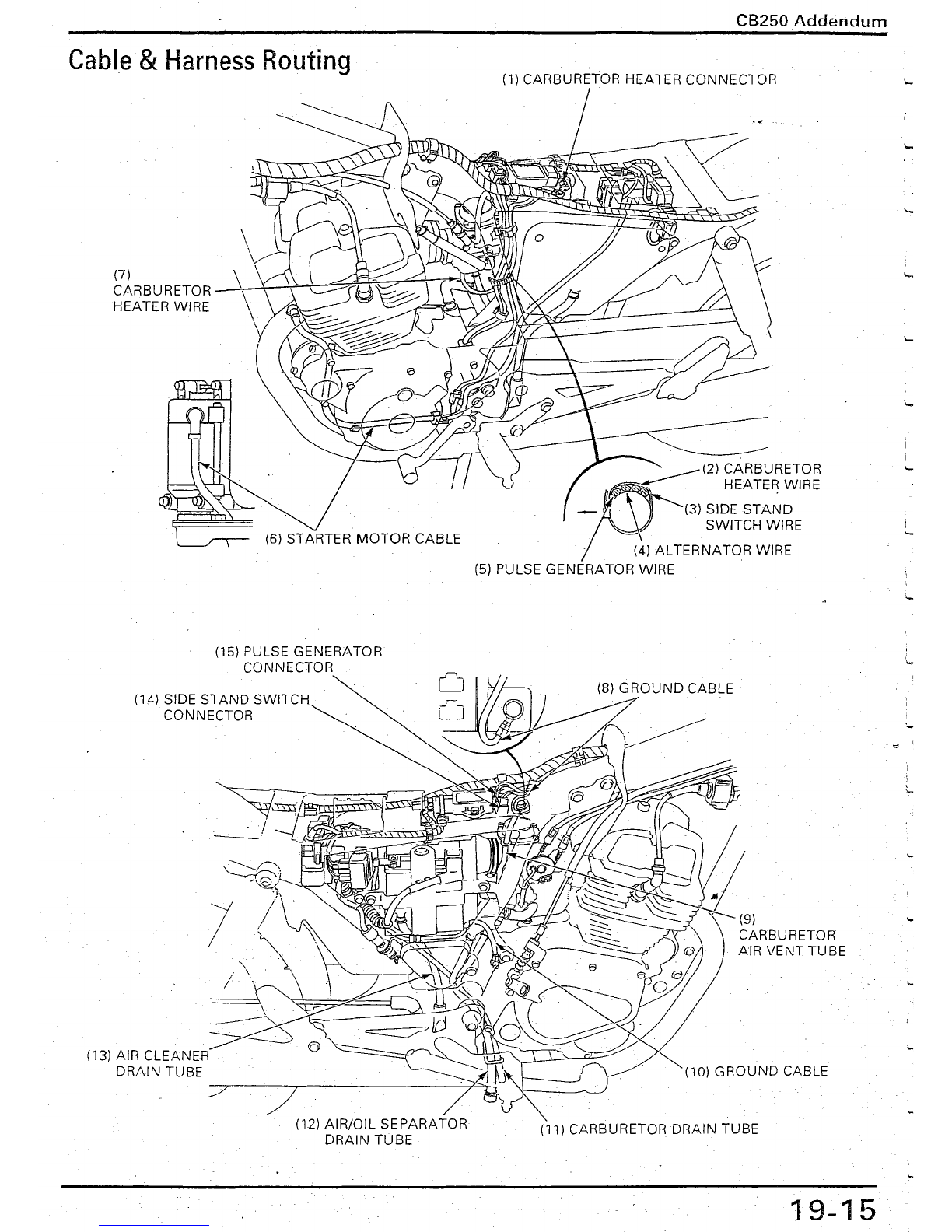

Cable

&

Harness

Routing

(7)

CARBURETOR

HEATER WIRE

(15) PULSE GENERATOR

CONNECTOR

(14) SIDE

STAND

SWITCH

CONNECTOR

CB250

Addendum

(1) CARBURETOR HEATER CONNECTOR

___

(2) CARBURETOR

~

HEATER WIRE

r

Q

~

(

3

}

S

I

D

E

STA~D

'=-V

.

SWITCH

WIRE

. (4)

ALTERNATOR

WIRE

(5) PULSE GENERATOR WIRE

/

(/

(9)

CARBURETOR

AIR VENT

TUBE

(10)

GROUND

CABLE

19-15

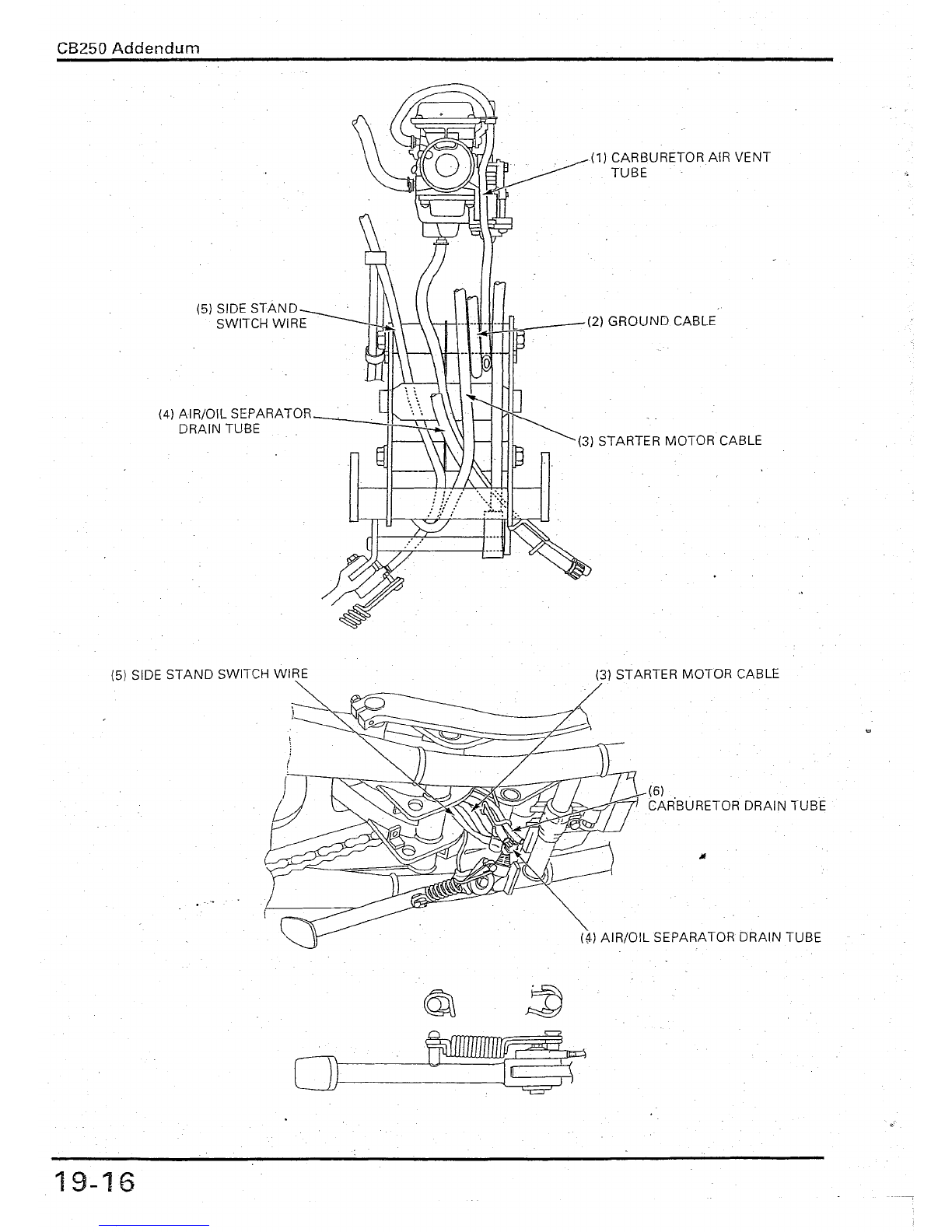

j

i

'-

I

'-

L

CB25D

Addendum

(3) STARTER MOTOR CABLE

(5) SIDE

STAND

SWITCH WIRE (3) STARTER MOTOR CABLE

(6)

CAR'BURETOR DRAIN TUBE

(M AIR/OIL SEPARATOR DRAIN TUBE

~

~

0\--------1

----l.,)...~-~

o'g1r

19-16

CBZ50

Addendum

Carburetor

Removal/lnstallation

Gasoline

is

extremely

flammable

and is

explosive

under

certain

conditions.

Work

in

well

ventilated

area.

Smoking

or

allow

flames

or

sparksinthe

working

area

or

wheregasolineis

stored

can

cause

a

fire

or

explosion.

NOTE

Before

removal,

turn

the

fuel

valve

OFF.

Route

the

tubes

and

wires

properly

(page

19-15).

Requisite

Service

I

'-

Rear

fairing

removal/installation

(page

2-3)

Fuel

tank

removal/installation

(page

2-4)

Carburetor

draíning

Procedure

I

Q'ty·

Remarks

Removal

Order

lnstallation

is in

the

reverseorder

of

removal

(1)

Carburetor

heater

2P

connector

1

'"

(2)

Wire

barid/Clurnp

1/1

(3)

Clutch

cable

1

(4)

Th

rottle

cables

2

(5)

Choke

cable

1

(6)

Drain

tube

1

(7)

Carburetor

mounting

nut

2

(8)

Connecting

tube

band

screw

1

Onlyloosen.

(9)

Carburetor

assembly

1

..

(10)

O-ring

1

(11)

Gasket

~.-

1

19-17

CB25ü

Addendum

bly/Assembly

..

sem

__

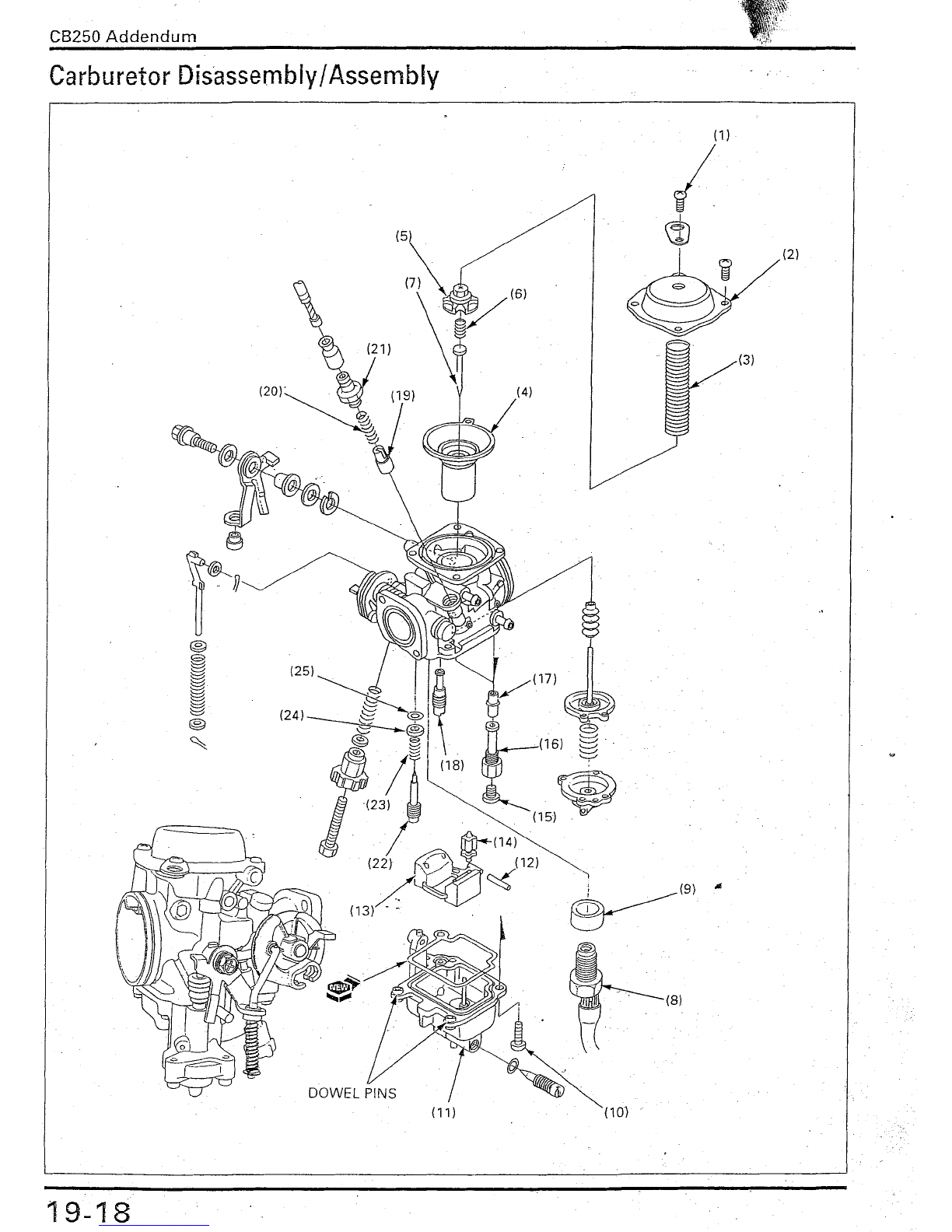

Carburetor

Dlsas

.

(3)

(1)

I

.

-(8)

1(9) A

~

(4)

(11 )

19-18

Table of contents