1

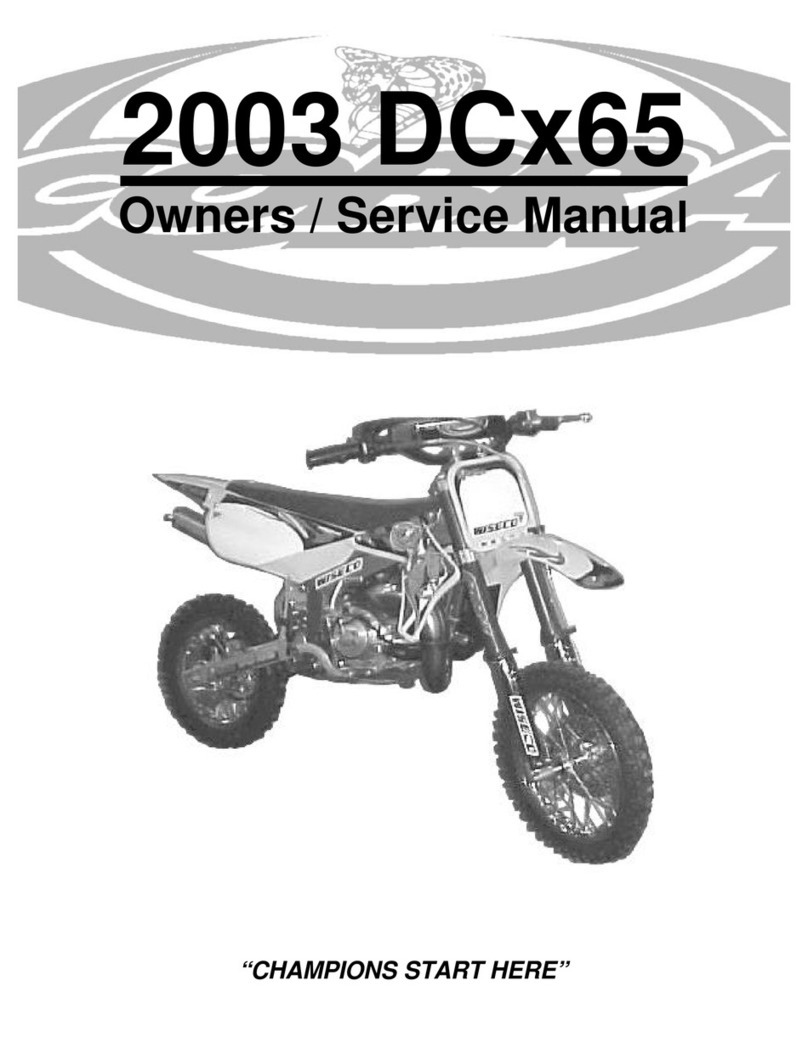

Table of Contents

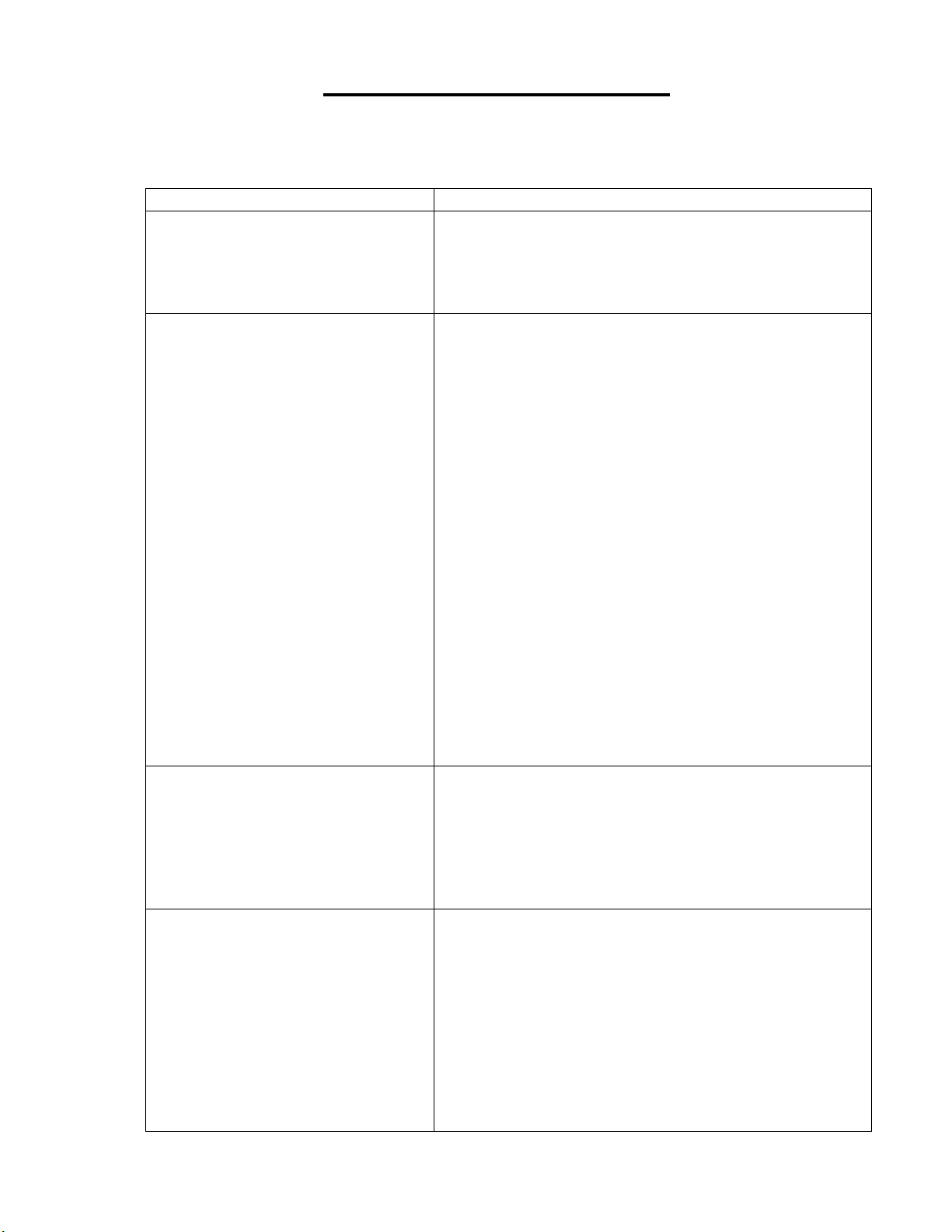

GENERAL INFORMATION ....................................................................................3

SPECIFICATIONS -GENERAL....................................................................................3

OPTIONAL COMPONENTS........................................................................................4

SPECIFICATIONS -TORQUE VALUES.........................................................................4

BREAK-IN PROCEDURE...........................................................................................5

STARTING PROCEDURE ..........................................................................................6

MAINTENANCE......................................................................................................7

TIPS......................................................................................................................7

SCHEDULE.............................................................................................................7

REPLACING TRANSMISSION /CLUTCH LUBRICANT.....................................................8

CHAIN ADJUSTMENT ...............................................................................................9

AIR FILTER CLEANING ..........................................................................................10

FORK OIL REPLACEMENT......................................................................................11

IGNITION TIMING...................................................................................................12

PARTS..................................................................................................................13

PARTS –AIRBOX &INLET SYSTEM.........................................................................13

PARTS –BARS AND CONTROLS.............................................................................14

PARTS -CARBURETOR .........................................................................................15

PARTS –COOLANT SYSTEM..................................................................................16

PARTS –ELECTRICAL SYSTEM ..............................................................................17

PARTS –ENGINE CLUTCH.....................................................................................18

PARTS –ENGINE –CLUTCH /KICK COVER.............................................................19

PARTS –ENGINE –IGNITION SIDE .........................................................................20

PARTS –ENGINE –KICK MECHANISM ....................................................................21

PARTS –ENGINE –SHIFT MECHANISM...................................................................22

PARTS –ENGINE –TOP END.................................................................................23

PARTS –ENGINE –TRANSMISSION ........................................................................24

PARTS –EXHAUST SYSTEM ..................................................................................25

PARTS –FORKS –LEG ASSEMBLY.........................................................................26

PARTS –FRAME &TRIPLE CLAMPS .......................................................................27

PARTS –FRONT WHEEL .......................................................................................28

PARTS –FRONT BRAKE........................................................................................29

PARTS –BODYWORK............................................................................................30

PARTS –REAR BRAKE..........................................................................................31

PARTS –REAR WHEEL .........................................................................................32

PARTS –SHOCK ..................................................................................................33

PARTS –SHOCK -INSIDE......................................................................................34

PARTS –SWINGARM ASSEMBLY ............................................................................35

SERVICE ..............................................................................................................36

ENGINE SERVICE .................................................................................................36

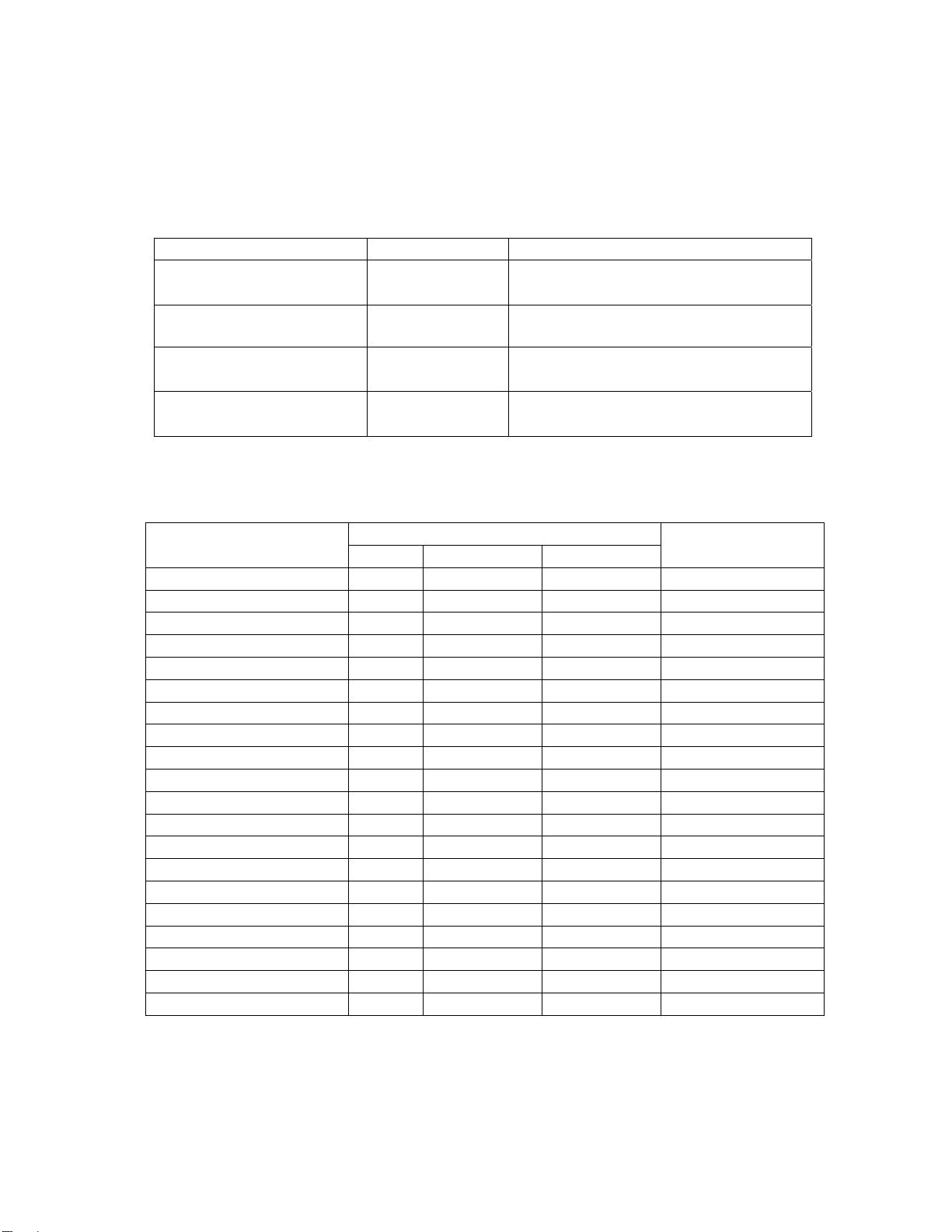

Base Gasket Selection...................................................................................37

FUEL &AIR SYSTEM.............................................................................................38

CARBURETOR:.....................................................................................................38

TUNING ................................................................................................................42