FOREWORD

This manual contains an introductory

description

on

the SUZUKI SV1000S and procedures for its

inspection/service and overhaul of its main compo-

nents

.

Other information considered as generally known is

not included

.

Read the GENERAL INFORMATION section to

familiarize yourself with the motorcycle and its main-

tenance

. Use this section as well as other sections

to use as a guide for proper inspection and service

.

This manual will help you know the motorcycle bet-

ter so that you can assure your customers of fast

and reliable service

.

* This manual has been prepared on the basis

of the latest specifications at the time of publi-

cation

. If modifications have been made since

then, differences may exist between the con-

tent of this manual and the actual motorcycle

.

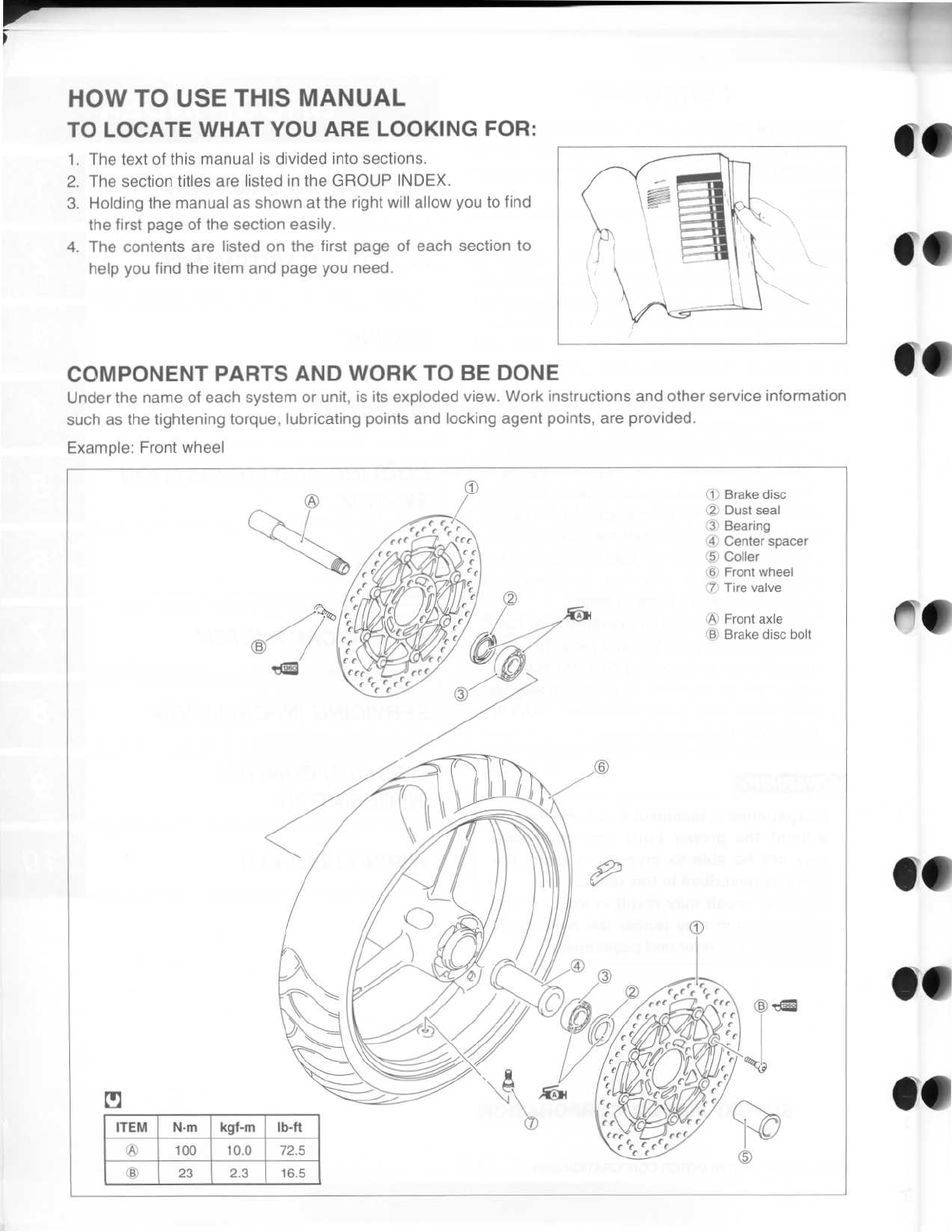

* Illustrations in this manual are used to show

the basic principles of operation and work

procedures

. They may not represent the

actual motorcycle exactly in detail

.

* This manual is written for persons who have

enough knowledge, skills and tools, including

special tools, for servicing SUZUKI motorcy-

cles

. If you do not have the proper knowledge

and tools, ask your authorized SUZUKI

motorcycle dealer to help you

.

may

not

be

able

to

properly

perform

the

services described in this manual

.

Improper repair may result in injury to the

mechanic and may render the motorcycle

unsafe for the rider and passenger

.

SUZUKI MOTOR CORPORATION

© COPYRIGHT SUZUKI MOTOR CORPORATION 2003

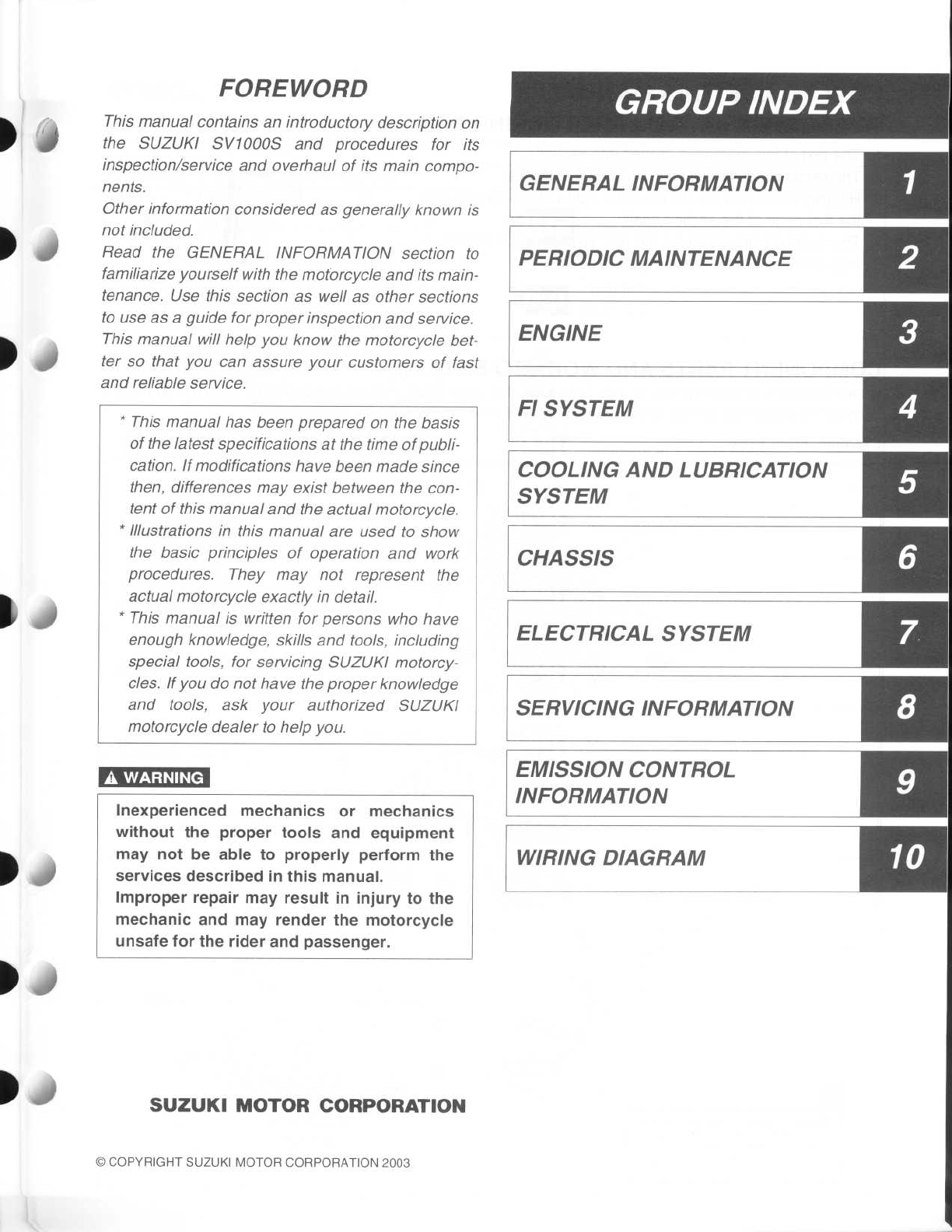

GROUP /NDE

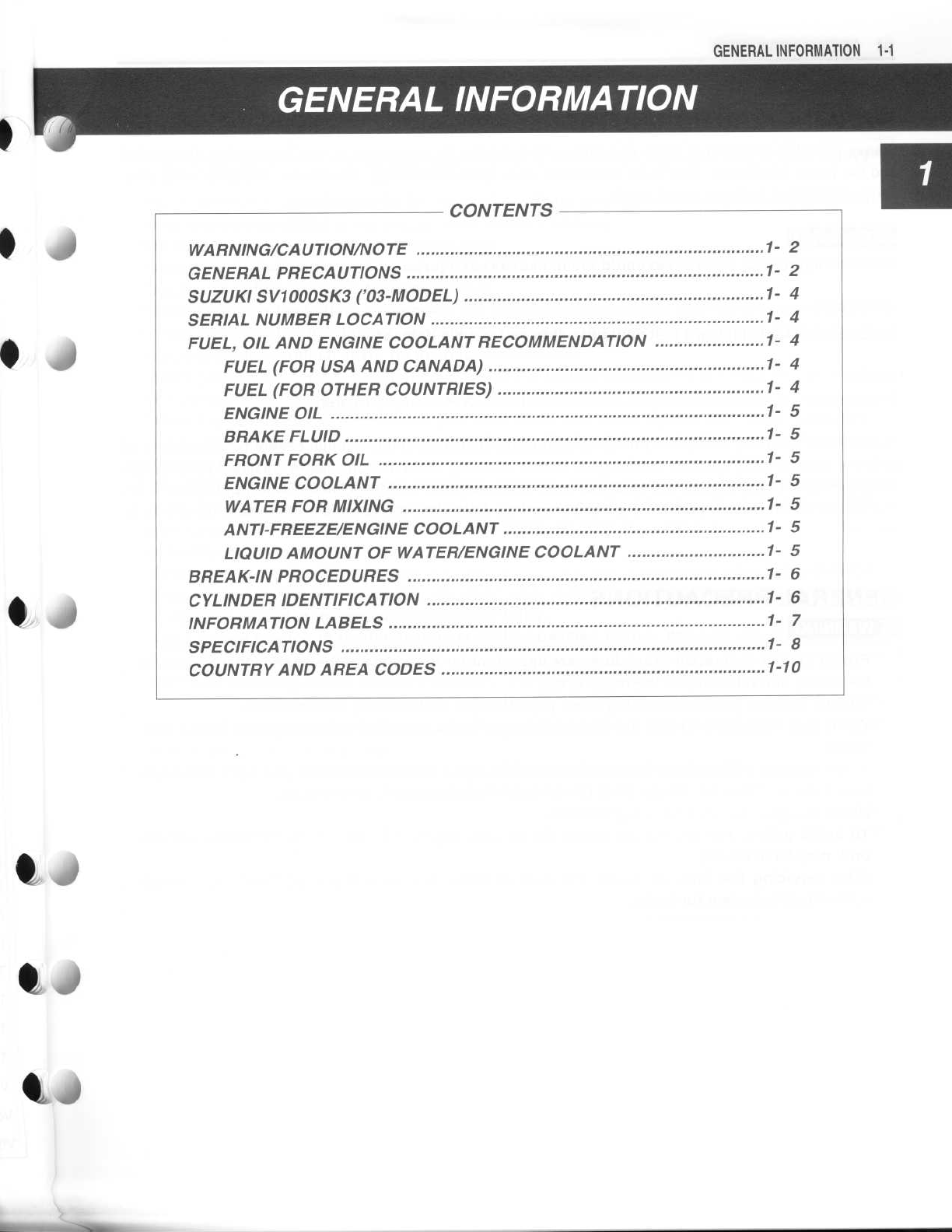

GENERAL INFORMATION

PERIODIC MAINTENANCE

ENGINE

FI SYSTEM

4

COOLING AND LUBRICATION

SYSTEM

CHASSIS

ELECTRICAL SYSTEM

E

SERVICING INFORMATION

EMISSION CONTROL

INFORMATION

WIRING DIAGRAM

A

WARNING

Inexperienced

mechanics

or

mechanics

without the proper tools

and

equipment