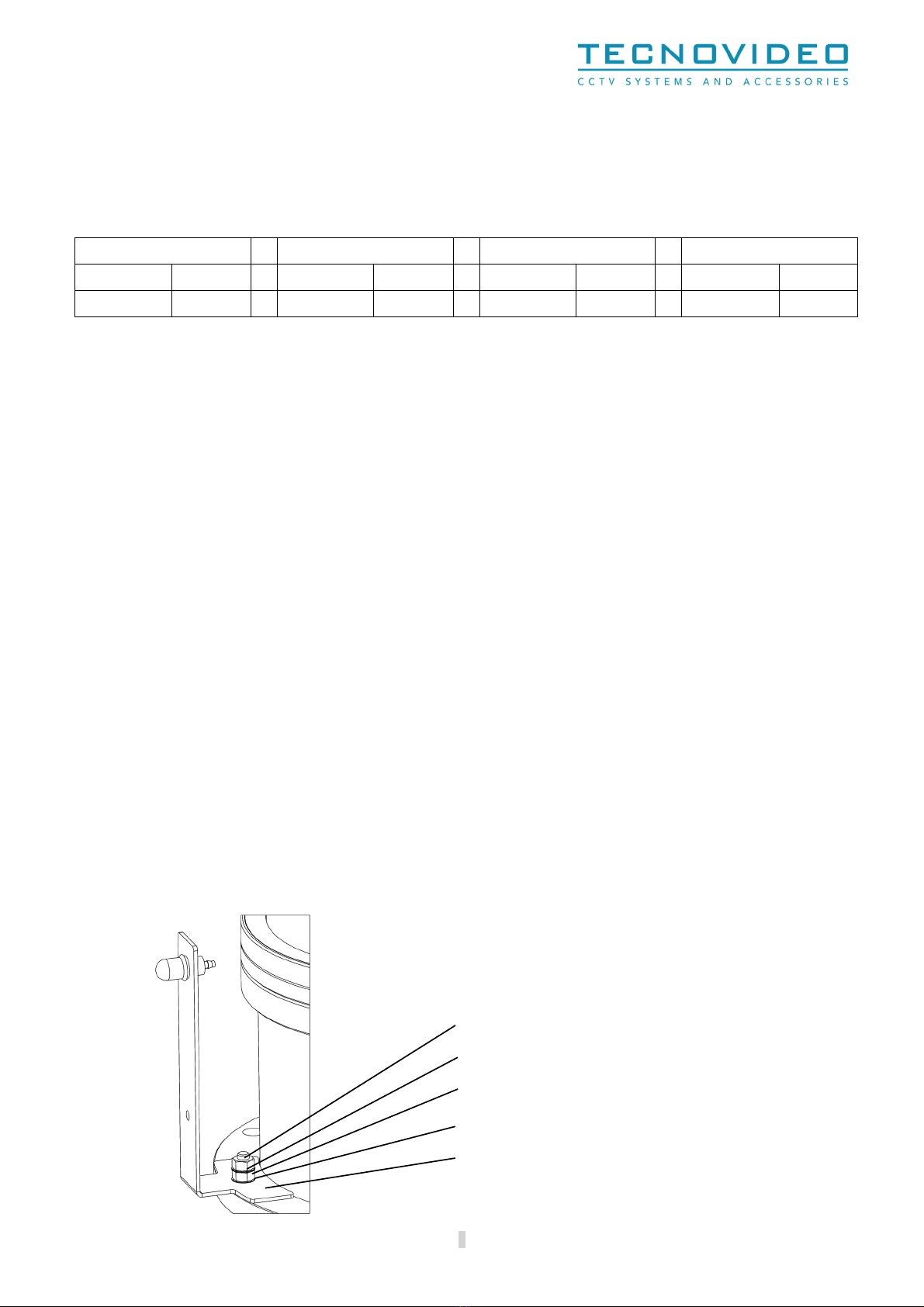

INSTALLING THE UNIT

i

Prior to installation and op ration, r ad car fully all instructions in this manual and h d all warnings.

Unpack this quipm nt and handl it car fully. If th packag app ars to b damag d, notify th shipp r imm diat ly.

Us th original packaging to transport th unit. Disconn ct pow r supply b for moving it. In cas of r turning th quipm n

th original packaging must b us d.

Mak sur that th installation surfac can support at l ast four

tim s th w ight of th unit in normal op rating conditions. In cas

of xc ssiv xt rnal str ss ( .g. vibration, strong winds or impact), th quipm nt may n d additional m ans of prot ction.

Prop r stainl ss st l hardwar should b car fully chos n to fast n th unit to th surfac s.

Us caution wh n lifting and ass mbling th unit. It is r comm nd d that non-

slip prot ctiv glov s b worn during installation.

Th unit could b ar sharp dg s.

Trying to manually forc th motors will r sult in damaging th d vic and will void th warranty.

WARNING: Hazardous moving parts: th d vic is r mot ly controll d and may chang position at any tim . Wh n installing,

choos a plac wh r moving parts could not hit anyon or any obj ct, cr ating hazardous situations.

To maintain th IP rating of th unit, ad quat cabl glands must b us d. Th unit must b tightly clos d wh n op rating and

cabl glands must b tight n up till an 8 Nm torqu ratio. Ch ck th prop r position of th s al in its groov on th flang s.

For s curity r asons, do not install th unit in th proximity of wat r contain rs and n v r push obj cts or pour liquids int

Th unit can b saf ly us d in damp nvironm nts or outdoors, as long as th conn ctors ar prop rly s al d.

Compl t th installation p rforming th l ctrical and vid o conn ctions according to th instructions in th cam ra install

manual.

Vid o and data cabl s should not shar th sam conduit with supply voltag cabl s. Wh n v r EMC is

shi ld d cabl s must b us d.

Op n only th cov rs point d out in this installation manual. Oth r cov rs should b op n only by th manufactur r.

Tight ning/loosing th scr ws using automatic tools such as drill driv rs may r sult in damag d thr ads.

This quipm nt has b n d sign d to fit in harsh nvironm nts r quiring littl or no maint nanc . Sugg st d insp ction int rv

is 6 months, but xtr m ly harsh nvironm nts may r quir mor fr qu nt insp ction and maint nanc ch cks. O

ch ck th O-ring s als and th v ntual window wip r blad int grity. R plac th m if n c ssary.

Ch ck cabl s, l ctrical conn ctions and mounting hardwar for int grity and tightn ss. R plac or tight n any damag d/loos

part.

Aft r th installation of th unit, th d siccant bag must b plac d insid th Pan & Tilt unit, assuring it won't b damag d

rotating and moving parts.

Pr s t Recall 99 calibrat s th Cam ra Pots in cas of motoriz d l ns (n d d th first tim th cam ra is conn ct d).

Op rating t mp ratur : -20° +60° C (-4° +140° F).

H ating l m nt may still b hot for som tim , v n aft r b ing shut off.

h

B for

p rforming any op ration, turn off th pow r. Th installation of th unit can b p rform d only by qualifi d p rsonn l in

accordanc with th r gulations in forc . Do not conn ct th unit to a supply circuit unl ss th installation is compl t d.

Ch ck car fully th supply voltag mark d on th lab l. Incorr ct Pow r Supply Voltag may damag th unit. Do not ov rload t

t rminal conn ction, as it may caus a fir or l ctrical shock hazard. Supply voltag tol ranc = ±10%.

An all-pol mains

switch with an op ning distanc b tw n th contacts at l ast 3 mm in ach pol must b incorporat d in th

l ctrical installation. Th switch must b quipp d with prot ction against th fault curr nt towards th ground (diff r nti

th ov rcurr nt

(magn toth rmal, maximum 15A). It must b v ry quickly r cognizabl and r adily acc ssibl . A suitabl blow fus

must also b install d for prot ction.

For conn ction to th mains, us a multipolar cabl having minimum 3x1,5 mm

2

(15 AWG). Th main cabl

prot ct d by an ordinary PVC sh ath.

Fast n all th cabl s insid th housing with cabl s ti s or oth r fixing m ans to avoid th l ctrical contact with surround

in cas that t rminal blocks scr w off.

El ctrical

conn ctions (such as plugs and cords) must b prot ct d from pot ntial hazardous nvironm ntal factors ( .g. foot traffic,

hitting obj cts).

Ensur that th unit cas is prop rly arth d, conn cting all th arth ground studs. Earth cabl should b about

th oth r cabl s on th conn ctor, in such way that it won't b accid ntally disconn ct d if th cabl is str tch d or pull d.

Wh n l aving th unit unus d for long p riods, disconn ct supply cabl s.

CERTIFICATIONS

Ingr ss Prot ction (EN 60529) IP66/IP67

EMC EN 61000-6-3:2007; EN 50130-4:1995 + A1:1998 + A2:2003

LVD EN 60950-1:2006 + A11:2009

RoHS 2011/65/EU

WEEE 2012/19/EU

3