TEI TE260 Installation and user guide

SERVICE AND

MAINTENANCE MANUAL

TE260

HYDRAULIC

DRIFTER

Blast hole and Foundation Drilling

January 2015

SERVICE AND MAINTENANCE MANUAL

FOR TE260 HYDRAULIC DRIFTER

This manual contains instructions for the maintenance, troubleshooting, and field repair of the TEI

ROCK DRILLS TE260. It is intended to help you maintain the drill and perform on-site repairs.

Read and understand this manual before operating or servicing this machine.

Keep this manual handy for future reference.

Both operator and service personnel must read this service

manual, particularly the warnings and cautions in Section

2, before operating this equipment. Your failure to do so

may result in dangerous practices which can cause serious

personal injury.

TEI ROCK DRILLS

The Hydraulic Drifter described in this literature is manufactured to TEI ROCK DRILLS exacting

standards.

For maximum utilization and efficiency in operating this equipment, we urge you to

thoroughly read the entire contents of this manual before you begin to drill.

ADDITIONAL MANUALS ARE AVAILABLE

Additional copies of this manual are available for purchase from TEI ROCK DRILLS. To order

please specify equipment model and serial number, quantity desired, type of manual, and remit $25

per manual with order. Make check payable to TEI ROCK DRILLS and mail to:

TEI ROCK DRILLS

P O Box 1309

Montrose, Colorado 81402

USA

TE260 SERVICE AND MAINTENANCE MANUAL

TABLE OF CONTENTS

INTRODUCTION SECTION 1

Specifications 1-1 thru 1-2

PRECAUTIONARY NOTICES SECTION 2

Operator Warnings 2-1

Equipment Cautions 2-2

MAINTENANCE SECTION 3

General Maintenance Tips 3-1

Maintenance Schedule 3-2 thru 3-5

Troubleshooting 3-6 thru 3-12

Nitrogen Charging Instructions 3-13

PARTS BOOK SECTION 4

TE260 Drill 4-1

TE260 Percussion Group 4-2

TE260 Parts Listing by Number 4-3 thru 4-4

TE260 Shank Listing by Number 4-5

TE2689X Mounting Slide 4-6

JB779X Nitrogen Charging Kit 4-7

INTRODUCTION

Section 1

Specifications 1-1 Thru 1-2

BEFORE ATTEMPTING MAINTENANCE OR REPAIR OF ANY COMPONENTS OF THIS MA-

CHINE, READ THE WARNINGS AND CAUTIONS LISTED IN SECTION 2

Section 1 Page 1-1

Section 1 Page 1-2

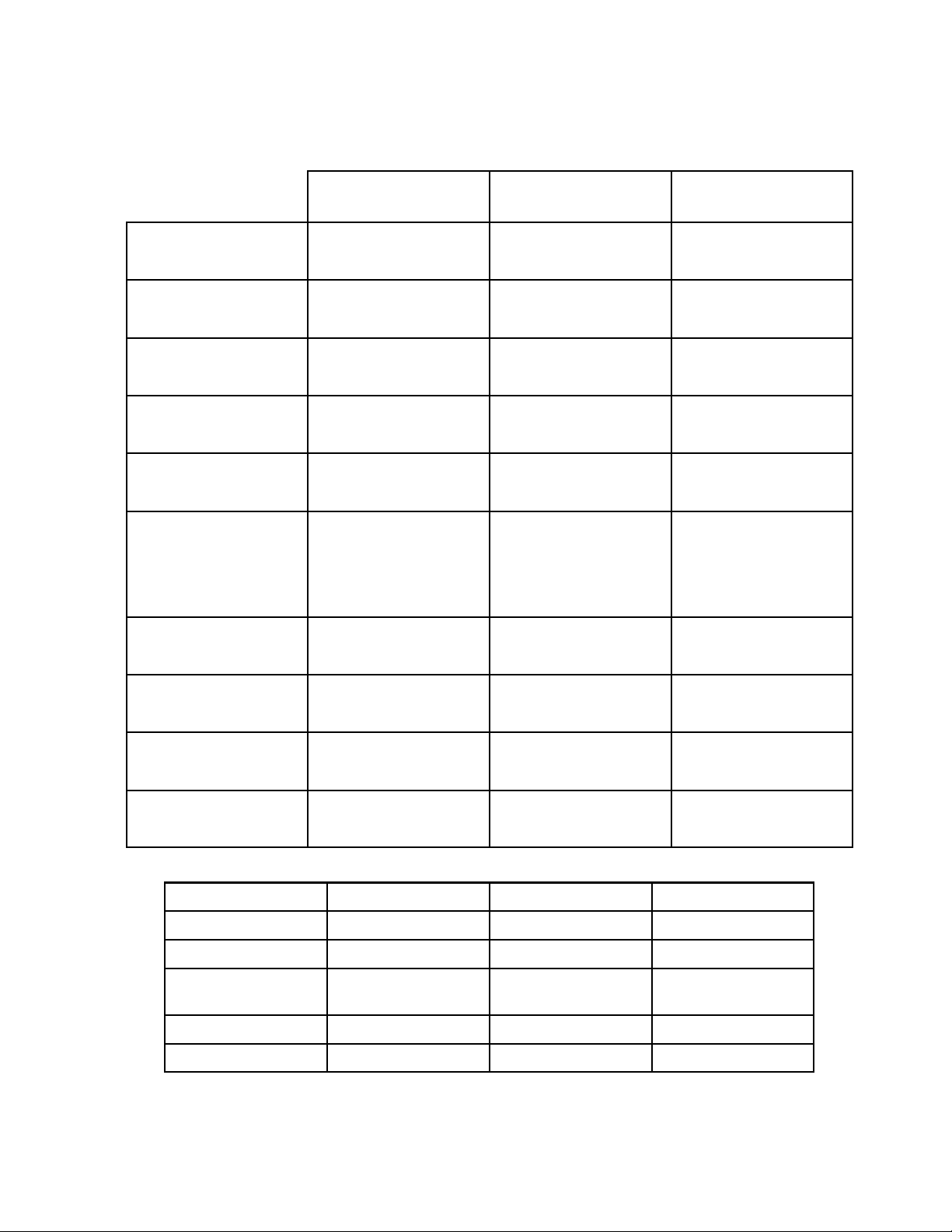

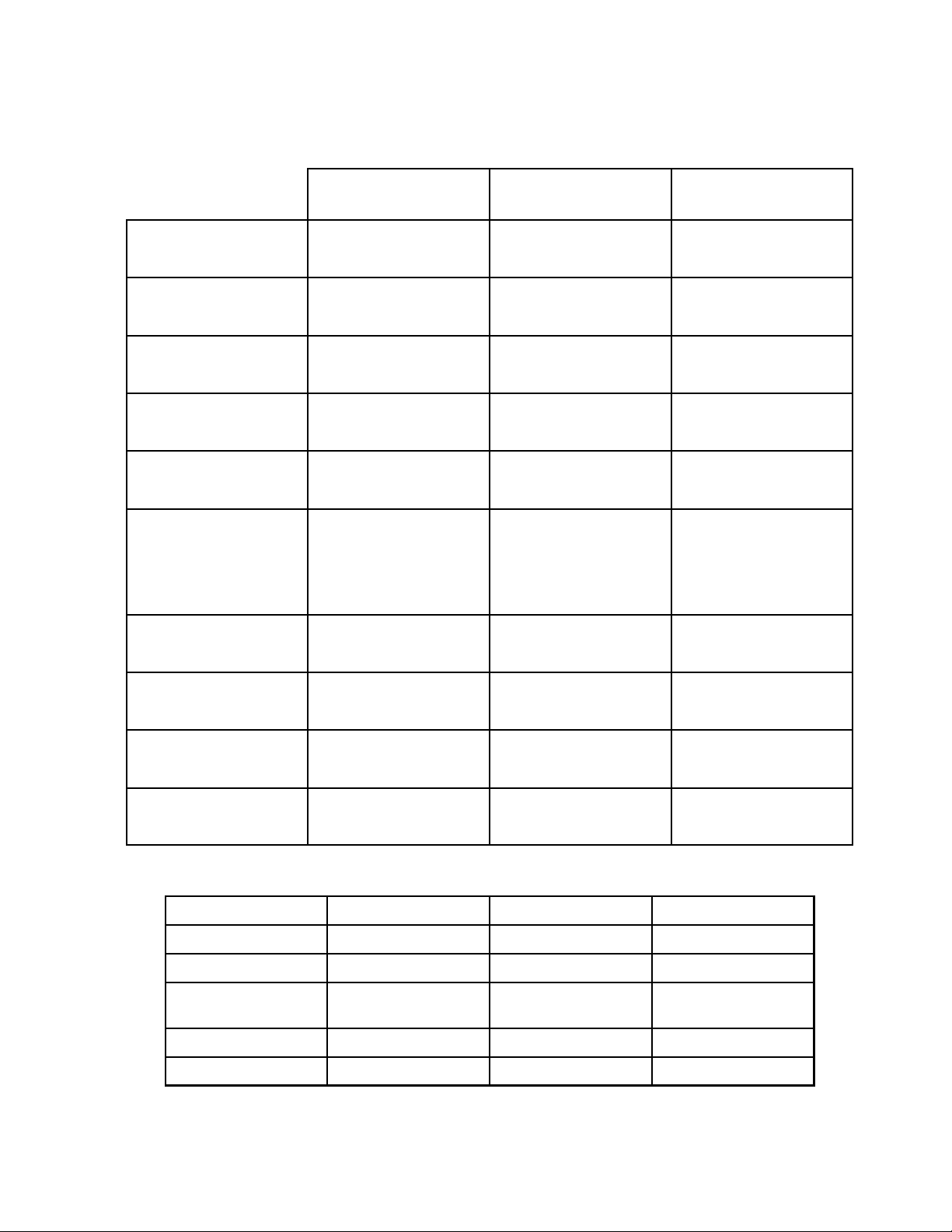

HYDRAULIC OIL SPECIFICATIONS

Mobile

DTE 24

Mobile

DTE 25

Mobile

DTE 26

Product Number 60262-3 60263-1 60264-9

Gravity, API 30.4 28.4 27.5

Specific Gravity 0.874 0.885 0.890

Pour point, ºC (ºF),

max

-23 (-10) -23 (-10) -23 (-10)

Flash point, ºC (ºF),

min

202 (395) 202 (395) 204 (400)

Viscosity,

cSt at 40º C

cST at 100º C

SUS at 100º F

SUS at 210º F

32

5.3

165

44

46

6.7

238

49

68

8.5

335

55

ISO Viscosity Grade 32 46 68

Viscosity index 95 95 95

Rust Protection,

ASTM D 665, A B

Pass Pass Pass

Color,

ASTM D 1500, max

3.5 4.0 4.0

Product: Primrose #327

NLGI Grade: 2SUS @ 100ºF: 2752

Non-Soap Base: Moly-Disulfide SUS @ 210ºF: 160

Penetration@

77º F, Worked:

280 cSt @ 40ºC: 512

Structure: Smooth/Tacky cSt @ 100ºC: 33

Drop Pt. ºF, min: None (non-melt) Color Visual Dark Green

GREASE SPECIFICATIONS

PRECAUTIONARY NOTICES

Section 2

Operator Warnings 2-1

Equipment Cautions 2-2

BEFORE ATTEMPTING MAINTENANCE OR REPAIR OF ANY COMPONENTS OF THIS MA-

CHINE, READ THE WARNINGS AND CAUTIONS LISTED IN SECTION 2

OPERATOR WARNINGS

Your first consideration, when servicing your TE260,

must be your personal protection and that of others.

Correct servicing is a matter of being completely

familiar with your machine and the job it is intended to

do. Carefully read and understand the warnings listed

below, and most of all remember to apply good common

sense at all times.

1. DO NOT OPERATE DRILLING CONTROLS

UNLESS YOU ARE THOROUGHLY FAMILIAR

WITH FUNCTIONS.

2. DO NOT OPERATE THE TE260 HYDRAULIC

DRILL UNLESS ACCUMULATORS HAVE BEEN

CHARGED.

3. WEAR A PROTECTIVE HELMET AND EYE

PROTECTION WHEN OPERATING OR NEAR THE

DRILL CARRIER.

4. WEAR NOISE-REDUCING EAR PROTECTION

WHEN NEAR THE MACHINE FOR EXTENDED

PERIODS WHILE THE MACHINE IS RUNNING.

5. DO NOT ATTEMPT LUBRICATION OR

SERVICE WHILE MACHINE IS RUNNING.

6. BE SURE THE HYDRAULIC AND PNEUMATIC

SYSTEMS ARE NOT PRESSURIZED BEFORE

LOOSENING ANY CONNECTIONS OR PARTS.

7. REMOVE DRILLSTEEL AND LOWER THE

DRILL TO CENTRALIZE BEFORE TRAMMING.

8. BEFORE STARTING THE ENGINE, BE SURE

ALL HYDRAULIC CONTROLS ON THE DRILL

AND CARRIER ARE IN THE OFF OR NEUTRAL

POSITION.

9. BE SURE ALL HYDRAULIC HOSE

CONNECTIONS ARE TIGHT, AND HOSE

RETAINERS IN PLACE.

10. KEEP ALL PERSONNEL AWAY FROM THE

HOLE WHILE DRILLING IS IN PROGRESS.

11. DO NOT REDRILL ANY BLAST HOLE.

12. DO NOT STRIKE THE DRILL STEEL TO

DISLODGE IT WHILE THE DRILL IS OPERATING.

FRAGMENTATION OF THE DRILL STEEL MAY

RESULT.

13. BE SURE THE DRILL STEEL COUPLING DOES

NOT UNTHREAD TOTALLY FROM BOTH DRILL

STEEL AND SHANK.

14. IF BIT BECOMES PLUGGED, DETATCH BIT FROM

STEEL TO REMOVE OBSTRUCTION. NEVER

HAMMER ON BIT OR STEEL. FRAGMENTATION CAN

PRODUCE SERIOUS INJURY.

15. BEFORE ATTEMPTING TO REMOVE DRILL FROM

FEED, RELIEVE STANDING PRESSURE.

16. USE CAUTION WHEN CHECKING FOR LEAKS.

FLUID UNDER PRESSURE MAY PENETRATE THE

SKIN.

17. DRILL AND FEED MUST BE IN THE HORIZONTAL

POSITION FOR DISASSEMBLY.

18. IF RIG IS TO BE OPERATED WITH DRILL

DISMOUNTED, SECURE AND CAP ALL LOOSE

FITTINGS AND CONNECTIONS.

19. DO NOT REMOVE THE ACCUMULATOR COVERS

BEFORE COMPLETELY BLEEDING OFF THE GAS

CHARGE IN THE ACCUMULATOR.

20. THOROUGHLY TEST ALL REPAIRS BEFORE

PUTTING EQUIPMENT INTO SERVICE.

Section 2 Page 2-1

EQUIPMENT CAUTIONS

The following are good practices to observe

for protecting the equipment and drills from

damage, and to provide maximum life for the

machine:

1. MAINTENANCE OF TE260 HAMMER,

BEARINGS, ACCUMULATORS, VALVE

ASSEMBLY OR STROKE CONTROL MUST BE

PERFORMED IN A CLEAN SHELTERED AREA.

THE ONE OVERRIDING RULE IN MAINTAINING

HYDRAULIC EQUIPMENT IS CLEANLINESS.

PREVENTION OF CONTAMINATION IN

HYDRAULIC FLUIDS IS THE MOST IMPORTANT

FACTOR IN MAINTAINING HIGH PERFORMANCE

IN TODAYS HYDRAULIC EQUIPMENT. AT ONE

TIME WHEN MACHINES OPERATED AT LOW

SPEEDS AND LOW TEMPERATURES

CLEANLINESS WAS A VIRTUE, TODAY IT IS A

NECESSITY.

2. KEEP THE DRILL LUBRICATED. APPLY

GREASE DAILY, OR WHEN INDICATED (MORE

OFTEN IN HOT CLIMATES) TO THE GREASE

FITTINGS AT THE CHUCK END OF THE DRILL.

3. PERIODICALLY INSPECT HOSE RETAINERS

AND HOSES FOR INDICATION OF WEAR,

LOOSENESS, CRACKING, OR FRAYING.

4. FREQUENTLY CHECK ALL NUTS, BOLTS,

AND ADJUSTMENTS FOR PROPER TENSION.

5. BE SURE THE HYDRAULIC RESERVOIR IS

ALWAYS FILLED TO THE RECOMMENDED

LEVEL WITH THE PROPER TYPE HYDRAULIC

FLUID. DO NOT MIX TYPES OF FLUID.

6. KEEP ALL BITS SHARP AND PERIODICALLY

CHECK FOR BROKEN OR LOOSE CARBIDES.

7. EXCESSIVELY WORN THREADS ON THE

DRILL STRING CAN CAUSE PREMATURE WEAR

AND BREAKAGE OF NEW PARTS MATED WITH

THE STRING.

8. DO NOT OPERATE THE DRILL ROTATION AND

FEED AT FULL THROTTLE UNTIL SURE OF ROCK

CONDITIONS. OVER FEEDING AND OVER ROTATION

CAN CAUSE BREAKAGE OF DRILL ROTATION

PARTS AND THE DRILL STRING

9. FREE OSCILLATION (DRY FIRING) OF DRILL

WILL RESULT IN PREMATURE WEAR OR FAILURE

OF CYLINDER AND HAMMER SEALS.

10. BEFORE REMOVING ANY LINES OR HOSES, TAG

EACH TO FACILITATE REASSEMBLY.

11. CAP OR PLUG ALL HYDRAULIC AND

PNEUMATIC CONNECTIONS AFTER DISASSEMBLY

TO PREVENT CONTAMINATION OF THE SYSTEM.

12. CLEAN THE EXTERIOR OF ALL PARTS AND

HOSE CONNECTIONS BEFORE REMOVING.

13. DO NOT OPPERATE THE TE260 HYDRAULIC

DRILL UNTIL ACCUMULATORS HAVE BEEN

CHARGED.

14. BEFORE REASSEMBLING HYDRAULIC

COMPONENTS, CLEAN ALL METAL PARTS IN A

NON-FLAMMABLE CLEANING FLUID.

15. THOROUGH CHECKS MUST BE MADE OF ALL

REASSEMBLIES TO BE SURE THEY ARE

ASSEMBLED PROPERLY ACCORDING TO

INSTRUCTIONS. DO NOT DRILL UNTIL ALL CHECKS

HAVE BEEN MADE.

Section 2 Page 2-2

MAINTENANCE

Section 3

General Maintenance 3-1

Tips

Maintenance Schedule 3-2 thru 3-5

Troubleshooting 3-6 thru 3-12

Parts Wear Tolerances 3-13

Nitrogen Charging 3-14

Instructions

BEFORE ATTEMPTING MAINTENANCE OR REPAIR OF ANY COMPONENTS OF THIS

MACHINE, READ THE WARNINGS AND CAUTIONS LISTED IN SECTION 2

GENERAL TIPS ON DRILL

MAINTENANCE

These general instructions will be helpful when

using the maintenance and adjustment

procedures outlined on the following pages.

1. Cover all hydraulic or air openings with an

appropriate dust cover when any hydraulic

or air openings are exposed. A clean part in

a dirty opening does little good.

2. Carefully examine all filters for evidence

of metal or rubber particles. Replace the

filters as necessary.

3. Before servicing the drill or any part of the

hydraulic system, neutralize the pressure in

the complete hydraulic system.

4. Before reassembling hydraulic

components, clean all metal parts in a non-

flammable cleaning fluid. Carefully

lubricate all components to aid in

reassembly.

5. Thorough checks must be made of all

reassemblies to be sure they are assembled

properly according to the instructions. Do

not drill until all checks have been made.

6. Frequent inspection of the TE260 is very

good practice. A minor adjustment can

many times prevent costly repairs later on.

7. Maintenance of hammer, bearings,

accumulators, valve assembly or stroke

control must be performed in a clean

sheltered area.

8. Maintenance of chuck end or rotation

assemblies may be performed on a

mounted drill.

9. It is not necessary to bleed off nitrogen

charge in accumulators unless maintenance

is performed on accumulator assemblies.

IMPORTANT

All TEI ROCK DRILL parts are

manufactured with care and precision.

Each part is carefully inspected before and

after assembly. Every step has been taken

to provide you with the quality product you

expect. Eventually some parts of your drill

will become worn. The description of

damaged parts in this section is general,

and is intended to help the servicemen in

the field to service and repair the TE260. It

is not meant to imply that all such parts

will fail in the described manner, or that

damage is due to faulty manufacture.

Section 3 Page 3-1

Before performing any maintenance make certain of the following:

1. Only qualified personnel should perform service on the TE260 Drifter.

2. Use only original TEI factory parts

3. Make certain maintenance is performed in a clean/sheltered area.

4. Only qualified personnel should perform cleaning, lubricating, service and repair of the drill.

5. Make certain all bolts and screws are properly torqued according to manufacturers

recommendations.

6. Ensure that all waste is disposed of according to environmental regulations.

DAILY MAINTENANCE

Normal operation of the TE260 requires daily greasing of the front rotation housing every 2

percussion hours using a moly disulfide high temperature type grease. This is most important to

prevent galling and failure of the rotation gears and bearings. During the first week of operation or

after replacement of the accumulator diaphragm, the charge pressure must be checked daily. In

addition all hydraulic hoses must be inspected for chafing and pinched or damaged sections. The

hydraulic oil must be checked for proper level and color. A white or milky appearance or foaming

of hydraulic oil indicates water contamination. Continued operation with contaminated oil will

damage both the drill and pump. Hydraulic oil must be equivalent to mobile DTE-24 through DTE-

26 depending on ambient operating temperature.

WEEKLY MAINTENANCE

During the weekly check, the front end cap (TE26234G) and grout/water swivel (TE26823G40)

must be removed to check the chuck. Pull the shank from the housing. Remove the thrust washer

(TE30835SK), chuck (TE357) and thrust block (TE35161). Check for burning of the splines

indicating lack of lubrication. The thrust blocks (TE35161) must be checked for cracks and

deformation at the shank spline contact surface. Replace if worn more than 1/16”(2mm) into face.

Charge pressure of the accumulator must also be checked weekly. Excessive cab vibration and/or

hose jumping and overheating of the hydraulic oil indicates a blown or uncharged accumulator. The

high pressure accumulator should be charged between 800 to 950 psi using nitrogen gas. The low

pressure accumulator requires 95 to 125 psi charge pressure depending on the system back

pressure.

Caution: Remember that disassembly beyond the removal of the chuck end cap or removal of

the rotation motor should be done in a clean, dust free area. It is essential that no dirt

particles enter the internal part of the drill and especially in the hydraulic fluid.

MONTHLY MAINTENANCE

With the shank removed as above, remove the 4 bolts retaining the front retaining plates (TE25557)

to the rotation housing. The front plate (RD25281) is then removed. Check the pinion thrust bearing

(RB24338) for wear and breakage. Replace if necessary.

Section 3 Page 3-2

MONTHLY MAINTENANCE cont’d

Push the chuck driver and pinion gear sideways to check bearing wear, if motion is greater than

1/32”(1mm) it requires replacement of the chuck driver and pinion bearings. Check the inner

bearings as above.

Every six months or 1,000 percussion hours, the drill must be inspected for hammer and bearing

seal wear. Maintenance of hammer, bearings, accumulators, valve assembly or stroke control

must be performed in a clean sheltered area.

YEARLY INSPECTION AND OR COMPLETE REBUILD

Send to TEI Factory or Authorized TEI Distributor

Section 3 Page 3-3

Section 3 Page 3-4

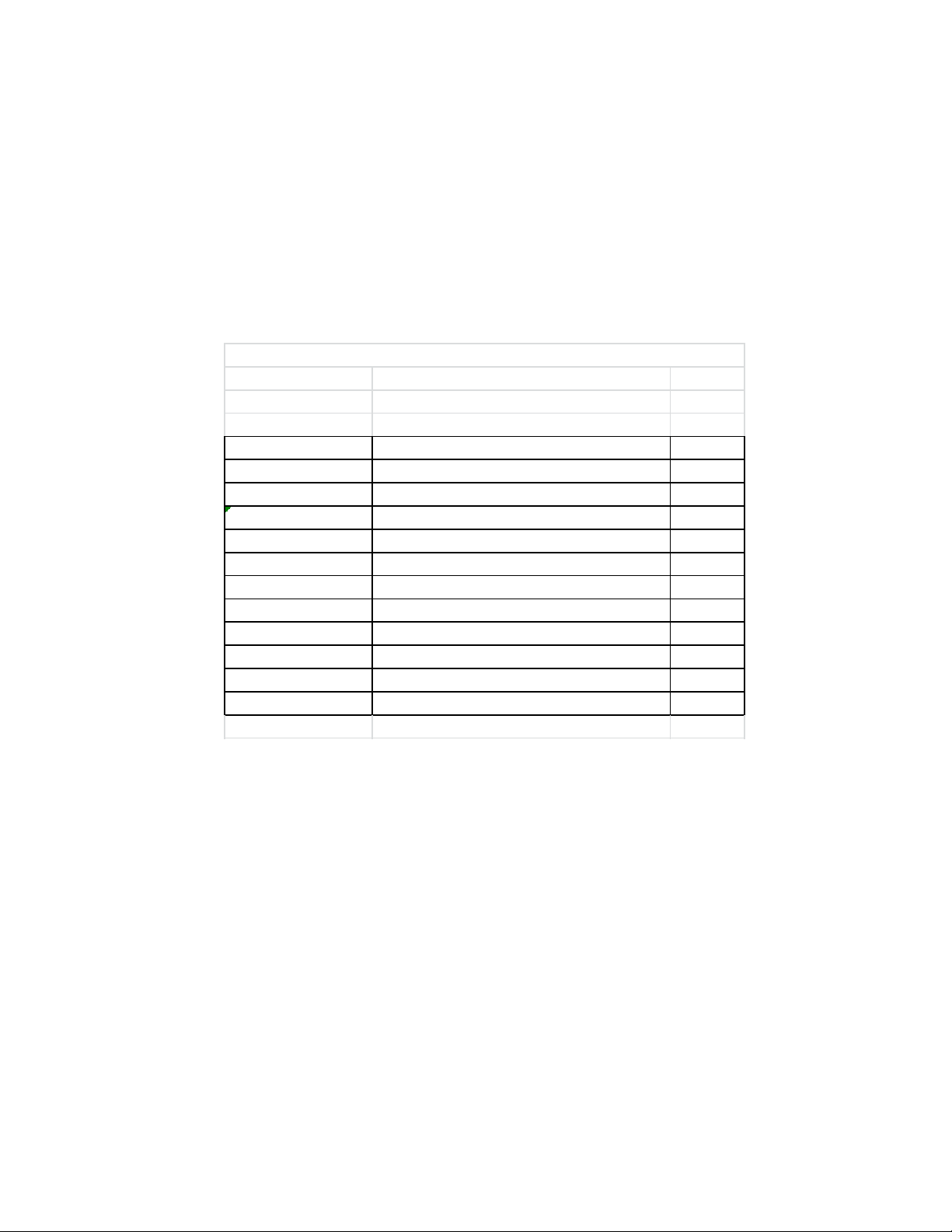

PART NUMBER DESCRIPTION QTY

TE26778 COMPLETE SEAL KIT 1

TE30706SK GROUT/WATER SEAL 8

TE30350 DIAPHRAGM 2

1050094 VALVE 1

TE55183SX BOLT, GROUT SWIVEL 2

TE35161 THRUST BLOCK 1

TE357 CHUCK 1

TE30835SK THRUST WASHER 1

TE3549---- SHANK, SPECIFY THREAD 1

ST16204 BUSHING, STEEL 2

SB48528 BEARING, BRONZE 1

RB24338 BEARING, ROLLER 2

TE260 Recommended Spare Parts

HYDRAULIC OIL SPECIFICATIONS

Mobile

DTE 24

Mobile

DTE 25

Mobile

DTE 26

Product Number 60262-3 60263-1 60264-9

Gravity, API 30.4 28.4 27.5

Specific Gravity 0.874 0.885 0.890

Pour point, ºC (ºF),

max

-23 (-10) -23 (-10) -23 (-10)

Flash point, ºC (ºF),

min

202 (395) 202 (395) 204 (400)

Viscosity,

cSt at 40º C

cST at 100º C

SUS at 100º F

SUS at 210º F

32

5.3

165

44

46

6.7

238

49

68

8.5

335

55

ISO Viscosity Grade 32 46 68

Viscosity index 95 95 95

Rust Protection,

ASTM D 665, A B

Pass Pass Pass

Color,

ASTM D 1500, max

3.5 4.0 4.0

GREASE SPECIFICATIONS

Product: Primrose #327

NLGI Grade: 2SUS @ 100ºF: 2752

Non-Soap Base: Moly-Disulfide SUS @ 210ºF: 160

Penetration@

77º F, Worked:

280 cSt @ 40ºC: 512

Structure: Smooth/Tacky cSt @ 100ºC: 33

Drop Pt. ºF, min: None (non-melt) Color Visual Dark Green

Section 3 Page 3-5

TE260 TROUBLESHOOTING

PROBLEM

A. Drilling rate falls off quickly,

supply hoses pulsate

excessively, hoses heat up,

drill vibrates excessively

B. Drill bounces and vibrates

excessively

C. Rotation speed rapidly drops

or rotation fails to work

D. Loss of blowing air

E. Drilling rate decreases slowly

but steadily

PROBABLE CAUSES

High pressure accumulator has lost

pressure

Too little feed pressure

High pressure accumulator has lost

pressure

Hydraulic lines blocked

Failure of rotation motor or drill

rotation assembly

Broken shank

Lose of pressure due to leakage

Plugged drill bit

Air line to drill has been

interrupted

Dull or broken drill bits

Accumulators not charged to

correct pressures

Oil temperature to high

Hydraulic pump not maintaining

pressure

REMEDY

Recharge or replace high pressure

accumulator diaphragm or fill

valve

Adjust feed compensator relief

valve

Recharge or replace high pressure

accumulator diaphragm or fill

valve

Check hoses and fittings for leaks,

replace

Check rotation motor and rotation

assembly; replace worn parts

Replace shank; check related parts

for damage

Check hoses and fittings for leaks;

replace

Detach bit from steel and remove

obstruction;

WARNING: Do not

Hammer on Bit or Steel

Check blowing system

Sharpen bits; periodically check

for broken or loose carbides

Check charging pressures; charge

if necessary

Check hydraulic system

Check pump; replace if necessary

Section 3 Page 3-6

TE260 TROUBLESHOOTING

PROBLEM

F. Drilling rate falls off quickly

G. Hammer oscillation stops

immediately or won’t start

H. Drill will hammer but won’t

rotate

PROBABLES CAUSES

Hydraulic lines have been torn or

crushed

Severe hydraulic leakage

Shank failure

Hammer inside cylinder is

damaged

Stuck or broken shuttle valve

Stuck or broken hammer (oil will

leak from rotation housing and

backhead if hammer is broken)

Supply or return hose damaged or

clogged

Hose to rotation collapsed or

kinked

Coupling failure

Rotation motor fouled with

foreign material

Broken shank

Worn chuck (splines completely

gone)

Hydraulic control valve failure

Rotation gear failure

REMEDY

Check hydraulic system

Check and replace faulty part

Replace shank and check related parts

for damage

Inspect cylinder, backhead, and

hammer for galling and/or scoring;

replace assembly if necessary

Remove tie rod and inspect shuttle

valve and valve body

Inspect cylinder, backhead, and

hammer for galling and/or scoring;

replace assembly if necessary

Check for drill supply pressure at

console

Replace

Replace

Clean and inspect; replace worn parts

Replace

Replace

Repair or replace valve

Replace worn parts

Section 3 Page 3-7

TE260 TROUBLESHOOTING

PROBLEM

I. Drill rotates but won’t hammer

J. Drill operates inefficiently

PROBABLE CAUSE

Leaky oil hose

Broken hammer

Lines are backwards

Hose to drill collapsed or kinked

Improper feed adjustment

Leaking oil hose

Worn bit

Hydraulic system out of adjust-

ment

Poor hole cleaning

Hole misalignment (bent drill rod)

Low drill pressure

Low feed pressure

Broken shank or drill rod

Thrust collar broken

Accumulator not charged correctly

REMEDY

Replace

Replace complete cylinder and

hammer assembly

Check supply and return lines

Check and replace hose

Adjust

Replace

Sharpen bit; check for loose or

broken carbides

Check pump pressure and flow

Check bit and steel for plugged air

passage

WARNING: DO NOT

HAMMER ON BIT OR

STEEL

Align feed properly

Set high pressure compensator to

2500 psi

Adjust pressure

Replace broken parts

Replace thrust collar. [check for

1/2”-1” (13-25mm) exposure of

shank guiding diameter beyond

front seal with shank pushed into

drill against the stop.]

Charge accumulator

Section 3 Page 3-8

TE260 TROUBLESHOOTING

PROBLEM

K. Rapid chuck driver bushing

wear

L. Rapid failure of rotation

bearings

M. Oil leak around shank

N. Oil leak around backhead

O. Oil leaking from accumulator

charge valve

P. Hydraulic oil in blowing air

PROBABLE CAUSE

Worn and scored shank

Improper feed pressure

Insufficient lubrication

Contamination in chuck end of

drill

Bearings dirty

Dull bit

Misapplication

Shank seals in chuck end worn or

ruptured

Hammer seal failure

O ring on hammer bearing leaking

Hammer seal failure

Accumulator diaphragm ruptured

Valve worn

Check hydraulic and air system of

rig for leaks

REMEDY

Replace

Adjust

Grease chuck end more frequently

Clean parts; check front seal and

grout swivel seals, replace

Clean parts; blow all hoses before

assembly

Sharpen bit

Attempting too large a hole for

ground conditions and equipment

Remove chuck end cap and chuck

end; replace shank seals, ruptured

and worn parts

Replace

Replace

Replace

Replace diaphragm and recharge

accumulator

Replace

Repair or replace as necessary

Section 3 Page 3-9

Table of contents