9 of 36 Copyright © D 362 -12/08

Section C1

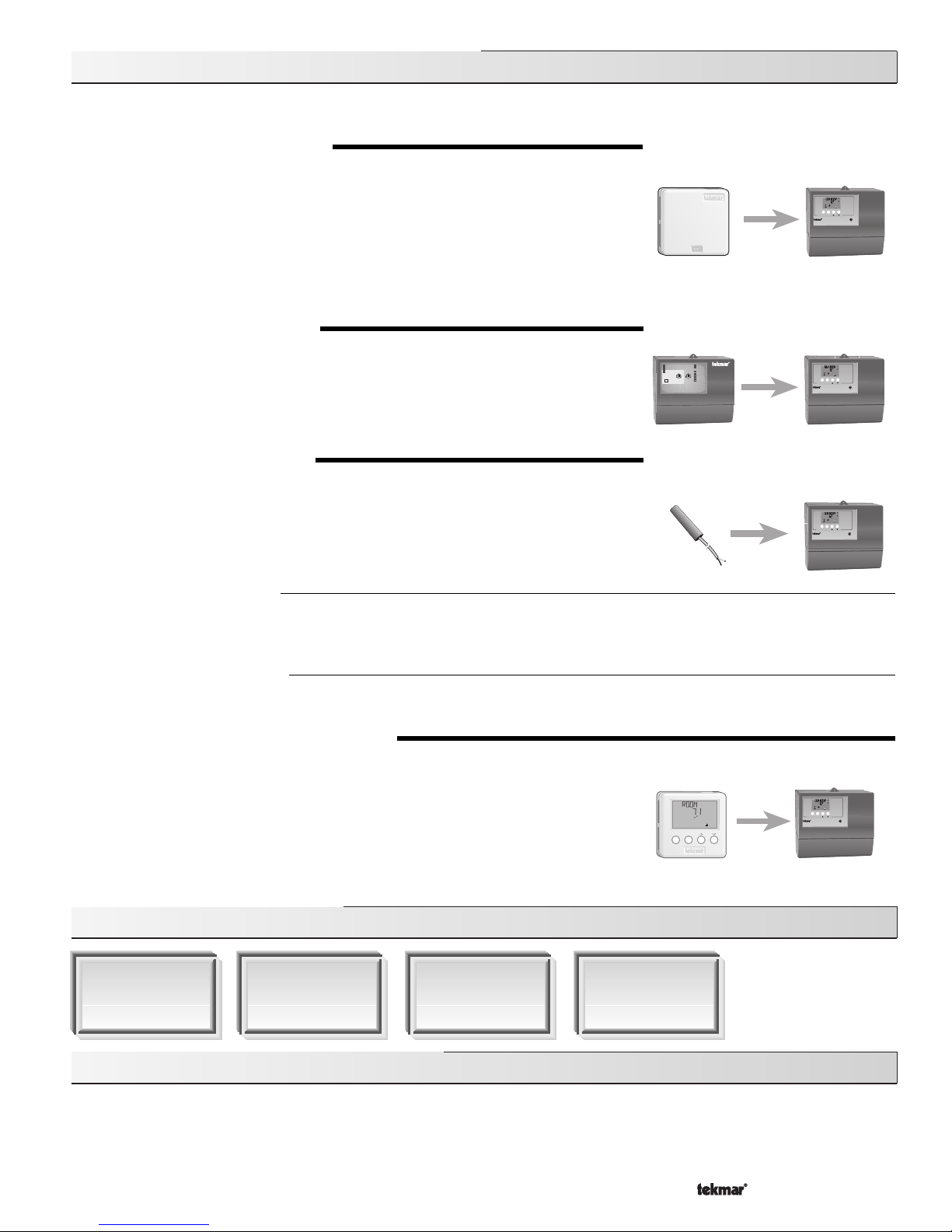

General Snow

Melting

Section C2

Snow Melting

Enable / Disable

Section C3

With Slab Sensor

Section C4

Without Slab

Sensor

tekmar

Indoor Sensor

tekmar

362 Control

LR58233 E150539

2

1

%

LR 58223

NRTL/C

Universal Reset Control 363

Mixing,Boiler & DHW

MixDemand

BoilerDemand

DHWDemand

SetpointDemand

Minimum

Maximum

R

Menu Item

°

F

View

DHW

1

tekmar 362

Control

LR58233 E150539

2

1

%

LR 58223

NRTL/C

Universal Reset Control 363

Mixing,Boiler & DHW

MixDemand

BoilerDemand

DHWDemand

SetpointDemand

Minimum

Maximum

R

Menu Item

°

F

View

DHW

1

tekmar

Zone Control

Zone Control 368

One& Two Stage

Power

HeatRequired

Zone2 Hi stage

SystemPump

24hr. Timer

•Dialthe desired duration

ofthe UnOccupied period.

•Pressstart button at the time of day

youwant the UnOcc. period to begin.

TimerActive light turns on.

Start

UnOccupied

Duration

0= always Occupied

24= always UnOccupied

Zone1 Lo stage

2

3

4

1

Zone4 Hi stage

Zone3 Lo stage

70°F

(21°C)

40

(4)

100

(38)

UnOccupied

Occupied

OptimumStart / Stop

UnOccupied

TimerActive

0

12hrs.

24

618

tekmar

362 Control

LR58233 E150539

2

1

%

LR 58223

NRTL/C

Universal Reset Control 363

Mixing,Boiler & DHW

MixDemand

BoilerDemand

DHWDemand

SetpointDemand

Minimum

Maximum

R

Menu Item

°

F

View

DHW

1

tekmar

Slab Sensor

tekmar

362 Control

LR58233 E150539

2

1

%

LR 58223

NRTL/C

Universal Reset Control 363

Mixing,Boiler & DHW

MixDemand

BoilerDemand

DHWDemand

SetpointDemand

Minimum

Maximum

R

Menu Item

°

F

View

DHW

1

ItemMenu

UnOcc 1

°

F

View

Heat

tekmar

RTU

Section C: Snow Melting (Mode —2—)

Section B2: Alternate Mixing Demands (Mode —1—)

In addition to using conventional thermostats to provide a mixing demand as described in Section B1, the 362 can use a number of other

methods to provide a mixing demand.

10K INDOOR SENSOR (10K = INDR)

Set the 10K item to INDR to add an indoor sensor for temperature control of a single zone

mixing system. The indoor sensor is connected to the

Com

and

10K

terminals (14 and 15).

In addition, power must be applied to the

Mix Demand

terminals (1 and 2) as described in

section B1. With the indoor sensor connected, the 362 is able to sense the actual room

temperature. With this information, the 362 provides a more constant water flow through the

mixing system. At the same time, indoor temperature feedback fine tunes the supply water

temperature in the mixing system to prevent over heating or under heating. To adjust the room

temperature for the mixing zone, use the ROOM

Occupied

or

UnOccupied

setting in the Adjust

menu at the control.

10K ZONE CONTROL (10K = ZoIn)

Set the 10K item to ZoIn to add indoor temperature feedback control of multiple mixing zones.

Control of mixing zones is provided by connecting a tekmar zone control to the 362. The zone

control provides its own internal

mixing demand

to the 362. In this case, there is no need to

provide an external

Mix Demand

as described earlier in Section B1. The zone control is

capable of automatically adjusting the MIX TRG temperature to improve building occupant

comfort and system performance.

10K SLAB SENSOR (10K = SLAB)

Set the 10K item to SLAB to add a slab sensor for temperature control of a single zone mixing

system. The 362 can use a slab sensor to control the actual slab temperature. A slab sensor

is placed in the slab and connected to the

Com

and the

10K

terminals (14 and 15). Power must

be applied to the

Mix Demand

terminals (1 and 2) as described in Section B1. With the slab

sensor connected, the 362 will limit the mixing supply temperature in order to maintain the slab

sensor between the SLAB MIN and SLAB MAX settings.

Slab Minimum

(SLAB MIN)

The SLAB MIN sets the minimum allowed core temperature of the slab as long as the control is not in a WWSD. Caution should be

used when adjusting the SLAB MIN setting as this may lead to overheating of the zone during mild conditions. If the AWAY setting

is selected in the Schedule menu, the 362 ignores the SLAB MIN setting.

Slab Maximum

(SLAB MAX)

The SLAB MAX sets the maximum allowed core temperature of the slab. If the slab is to be maintained at a fixed core temperature,

set SLAB MAX and SLAB MIN items to the same setting.

ROOM TEMPERATURE UNIT (RTU) 062, 063

If the mixing system consists of a single zone, temperature control of that zone can be provided

by using an RTU. The RTU is connected to the

Com

and tekmar NetTM

tN1/tN2

terminals

(11 and 13). In addition, power must be applied to the

Mix Demand

terminals (1 and 2) as

described in Section B1. With the RTU connected, the 362 measures the actual room

temperature. With this information, the 362 provides a constant water flow through the mixing

system. At the same time, indoor temperature feedback fine tunes the supply water

temperature in the mixing system to prevent over heating or under heating. The RTU allows

the user to adjust the desired room temperature at the RTU. Remote sensor capability is also

available through an RTU as described in the RTU data brochure.

Section C1: General Snow Melting

The Mixing Control 362 is capable of controlling a single zone snow melting system. In order to provide the best control of the snow

melting system, the 362 should be equipped with an optional tekmar Slab Sensor 072 or 073 and an optional Universal Sensor 071 that

measures the slab return temperature. These can be purchased separately or as part of the Snow Melt Enable Kit 092. The Kit also

includes alternate Start / Stop module 039. With these installed, the 362 is capable of providing the features listed in the following section.

Also described in this section are several different methods of starting and stopping the snow melting system.