Telemetrics PT-HP-S4 User manual

Operation Manual

HP Servo P/T Head (48V)

Model PT-HP-S4

92 56156 000

P/N 92 56156 000-11 Rev. A

6 Leighton Place

Mahwah, New Jersey 07430

www.telemetricsinc.com

Table of Contents

1.0 Scope..................................................................................................................... 1

2.0 Introduction ............................................................................................................1

3.0 Specifications......................................................................................................... 2

4.0 System Cables....................................................................................................... 3

4.1 Power Cable...................................................................................................................................................3

4.2 Serial Data Connection..................................................................................................................................3

4.3 Auxiliary Connections...................................................................................................................................4

5.0 Camera Power & Camera Control.......................................................................... 4

6.0 Lens Interface Information...................................................................................... 8

7.0 Connector Input/Output Signals .............................................................................9

8.0 PC Boards............................................................................................................ 13

APPENDIX A Telemetrics Serial Data Protocol.............................................................15

APPENDIX B Controller Board 53915 DIP Switch Setting............................................ 28

List of Figures

Figure 1. Pan/Tilt Head..................................................................................................1

Figure 2 Power Cable CA-PWR-7XLR- XXX ................................................................3

Figure 3 Serial Data Cable...........................................................................................3

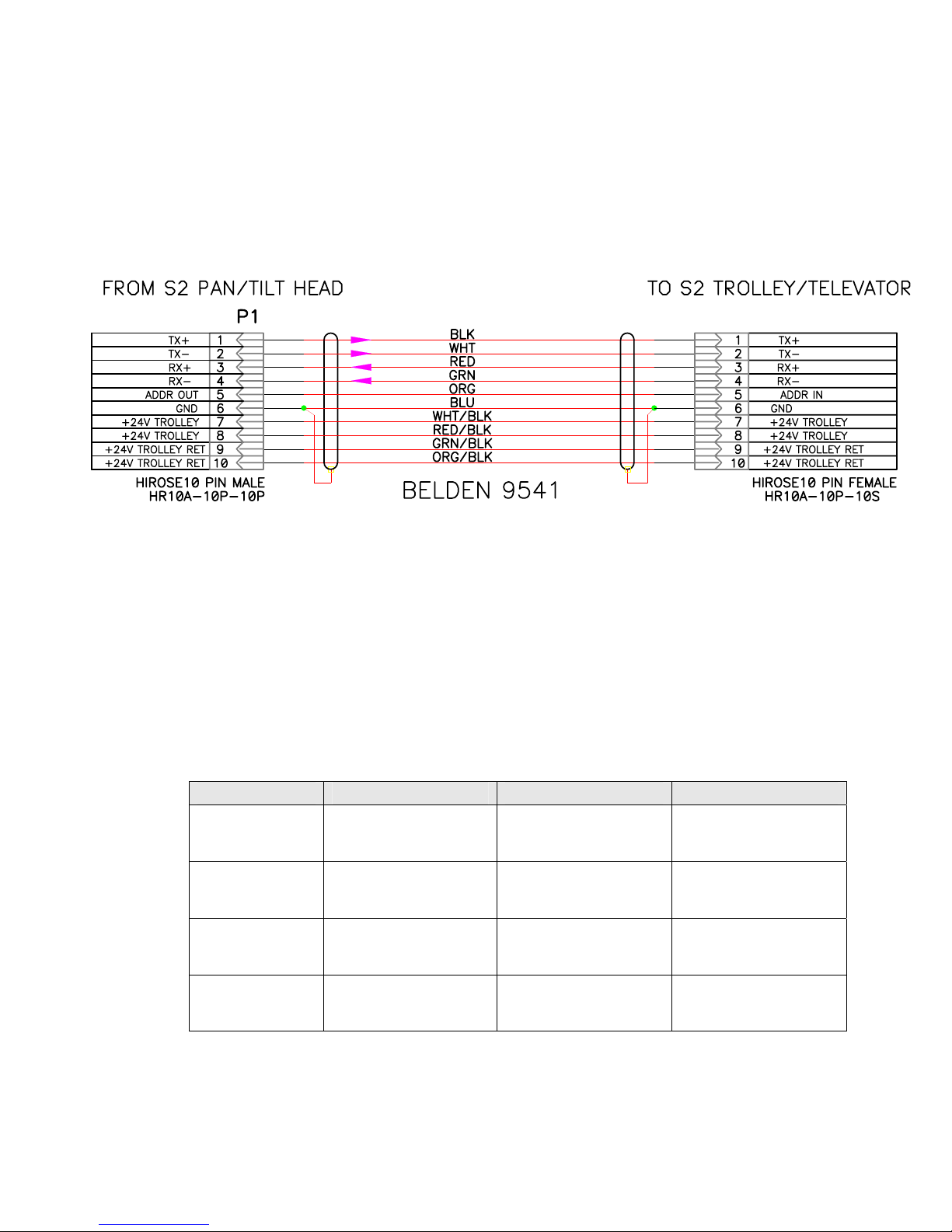

Figure 4. Trolley/Televator Cable CA-S2-AUX.............................................................4

Figure 5 Sony DXC-950/990 Power Cable ...................................................................5

Figure 6 Sony DXC-950/990 Data Cable ......................................................................5

Figure 7 Sony DXC-950/990 Power/Data Cable...........................................................6

Figure 8. Panasonic AW-E600/800 Power Cable ........................................................6

Figure 9. Panasonic AW-E600/800 Data Cable ...........................................................6

Figure 10. Panasonic AW-E600/800 Power/Data Cable..............................................7

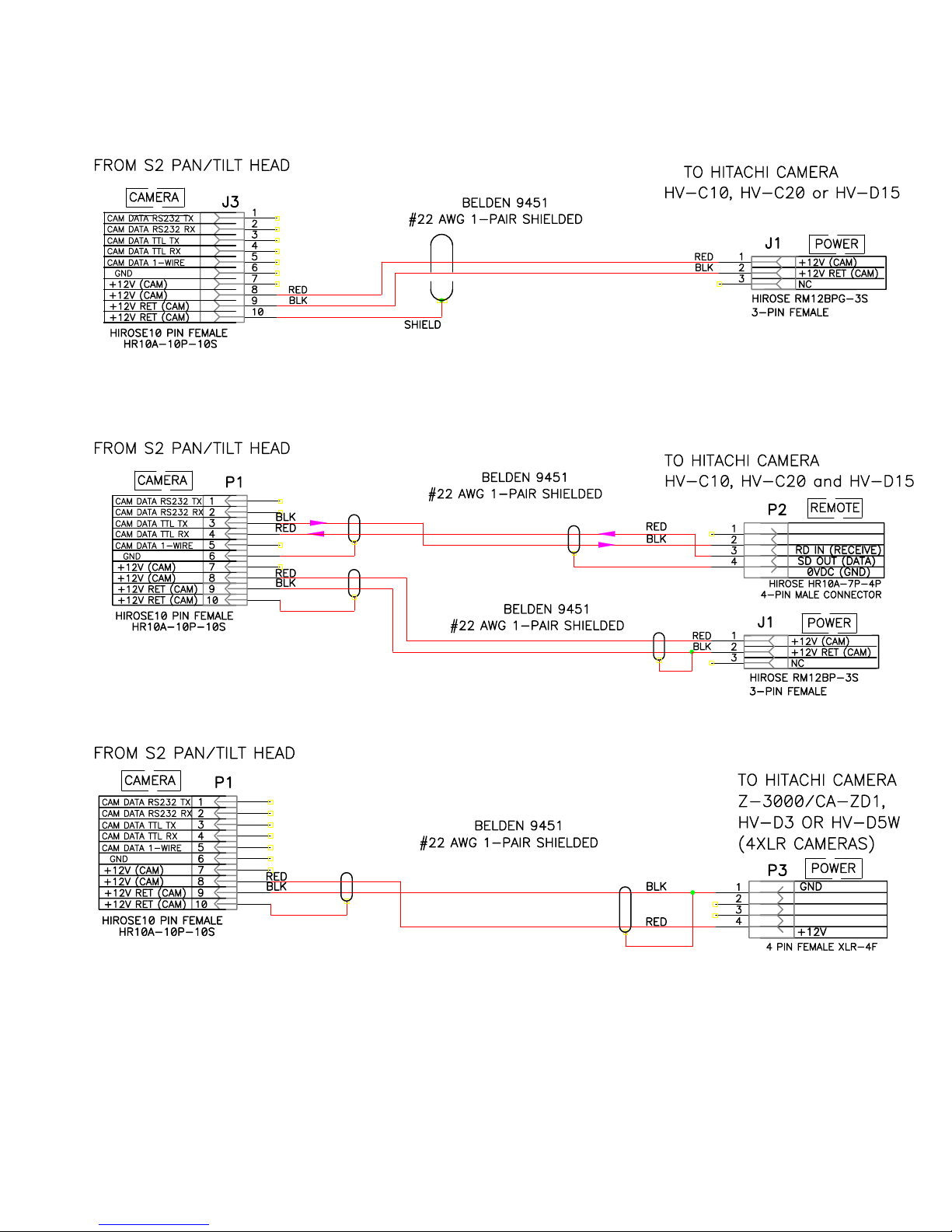

Figure 12. Hitachi HV-D15 Power/Data Cable .............................................................7

Figure 13. Hitachi Z-3000W Power Cable....................................................................8

Figure 14. Hitachi Z-3000W Power/Data Cable ...........................................................8

LITHIUM BATTERY CAUTION, Danger of explosion if the internal lithium battery

is replaced incorrectly. Replace only with the same or equivalent type

recommended by the manufacturer. Dispose of used batteries according to the

battery manufacturer’s instructions.

The Lightning Flash With Arrowhead symbol, within an equilateral triangle,

alerts the user to the presence of uninsulated dangerous voltage within the

product’s enclosure that may be of sufficient magnitude to constitute a risk of

electric shock.

The Exclamation Point symbol, within an equilateral triangle, alerts the user to

the presence of important operating and maintenance (servicing) instructions in

product literature and instruction manuals.

1

1.0 Scope

This manual contains information for the Telemetrics HP Servo Pan/Tilt Head Model

PT-HP-S4, Part No. 92 56156 000. This Pan/Tilt is designed for use with ENG and

smaller type cameras. Due to the different types of cameras and lenses the

Pan/Tilt interfaces with, many options are manufactured. Some of those options

are described in the following paragraphs. Please consult the factory for the

specific options available.

2.0 Introduction

The PT-HP-S4 is a robotic camera pan/tilt head with smooth variable operating

speed. Heavy duty cross roller bearings and swings motors with isolation mounts

provide quiet operation. The lens connector provides direct connection and

interface to lens functions. Lens interface options are also available. The Pan/Tilt

head is powered from the Rack Mount Power Supply PS-RM-48 and converts the

48V to appropriate voltage levels for the head, auxiliary robotics devices, camera,

lens and viewfinder.

The unit is controlled through serial data interface using RS-232 standard or RS-

422 optional or 10/100 BASE-T Ethernet connections. Manual smooth motion is

accomplished using velocity servo controls. Two hundred and fifty five (255)

presets are available. Presets are called using shot convergence technology,

allowing for smooth motion like presets. An optional camera control feature is

available for certain cameras. It has Tally LED on front panel to indicate camera

“On Air”.

The PT-HP-S4 is typically controlled by a Telemetrics Rack Serial Control Panel

(CP-R-3A or CP-R-2A), Desktop Serial Control Panel (CP-D-3A or CP-D-2A) or

Remote Control Panel (RCP). Second party RS-232/422 control systems can also

be used to interface with the unit. Please consult factory for configuration

assistance. See Appendix A for Serial Protocol specifications.

Figure 1. Pan/Tilt Head

6"

Ethernet

DC POWER ETHERNET

CAMERA LENS AUX SERIAL

12.505"

7" 10"

Power

Lens Serial

Cam Ctl Aux

2

3.0 Specifications

Input voltage 38-53VDC

Input current 6.8 A max

Input Power 50 W

(P/T head only)

Input Power Conn. 7-pin Male XLR

Camera Power 40 W (13.5 VDC, 3 A max)

Pan travel ±170° w/endstops, ±200° w/o endstops

Tilt travel ±35° (+35°, -90° PTO-HP-S4-EA)

*End stops Resolution Continuous Angular Adjustable – Abrupt Stop

Electronic: Smooth Stop

*Min/Max pan velocity 0.01° - 25°/sec (40°/sec High Speed PTO-HP-S4-HS)

*Min/Max tilt velocity 0.01° - 25°/sec (40°/sec High Speed PTO-HP-S4-HS)

Stopping Accuracy ±5 arc min/0.08°

Audible Noise 37 dB(A) max, IEC Free Field

Operating Modes 32 bit velocity and positional servo control

Preset position with multi-axis convergence

Mounting Upright or inverted

Dynamic Load 35 lbs. max. (16 kg)

Weight 14 lbs. (6.3 kg)

Dimensions 10” H x 11 ¼” W x 6” D

18”H x 11 ¼” W x 6” D (Extended Yoke)

14 ½”H x 11 ¼” W x 6” D (Extended Arms)

* End stops are set to ±170° Pan and ±35° Tilt unless otherwise specified by customer.

3

4.0 System Cables

4.1 Power Cable

Power to the unit is made via interconnect cable CA-PWR-7XLR-XXX to the

7-pin XLR power connector located on the rear of the unit (Note: XXX=Feet).

The other end of interconnect cable connects to the external power supply.

Figure 2 Power Cable CA-PWR-7XLR- XXX

4.2 Serial Data Connection

Communication to the unit is made via serial data cable CA-RS to the 9 pin

serial data connector located on the rear of the unit. The other end of the

cable connects to the control panel. Units configured for RS-232 can have a

maximum distance of 100 feet between the unit and the control panel. Units

configured for RS-422 can have a maximum distance of 4000 feet between the

unit and the control panel. (Note: Units are set to accept either RS-232 or RS-

422 at the factory. See Table 1 for proper DIP switch settings.)

Figure 3 Serial Data Cable

LENGTH: VARIABLE (CUT CABLE XXX' +5")

RTN

GREENGREEN6

1

3

2

4

5

7

J1

NEUTRIK - NC7MX

CONN 7-PIN XLR MALE

LENGTH

STRIP

SHIELD

SLEEVING

LABEL

1/2"

LABEL

SUPPLY

TO PWR

QUABBIN #4177

BROWN

WHITE

BLUE

BLACK

RED

ALPHA #25836

BLUE

ORANGE

WHITE

RED

BLACK

+48V

RTN

RTN

+48V

+48V 2

6

5

4

3

1

7

J2

NEUTRIK - NC7FX

CONN 7-PIN XLR FEMALE

STRIP

LENGTH

1/2"

SLEEVING

SHIELD

TO P/T

4

4.3Auxiliary Connections

Power and control of the Telemetrics Trolley and Televator units is

accomplished using the auxiliary connector on the pan/tilt. It is important to

remove power from the pan/tilt prior to connecting or disconnecting the

auxiliary cable. Damage may occur if the unit is powered when connecting or

disconnecting the cable. Note: Refer to Appendix for information on Aux Axis

Soft Limit configuration.

Figure 4. Trolley/Televator Cable CA-S2-AUX

5.0 Camera Power & Camera Control

Telemetrics pan/tilt systems are capable of providing power and data to virtually all

manufacturers’ cameras. A Telemetrics power supply that includes a 15V module

for the camera must be used when camera power is required. In addition, the

Telemetrics control panel must be configured to accept the camera ROP to provide

camera control. See Table 3 for currently available accessory cables.

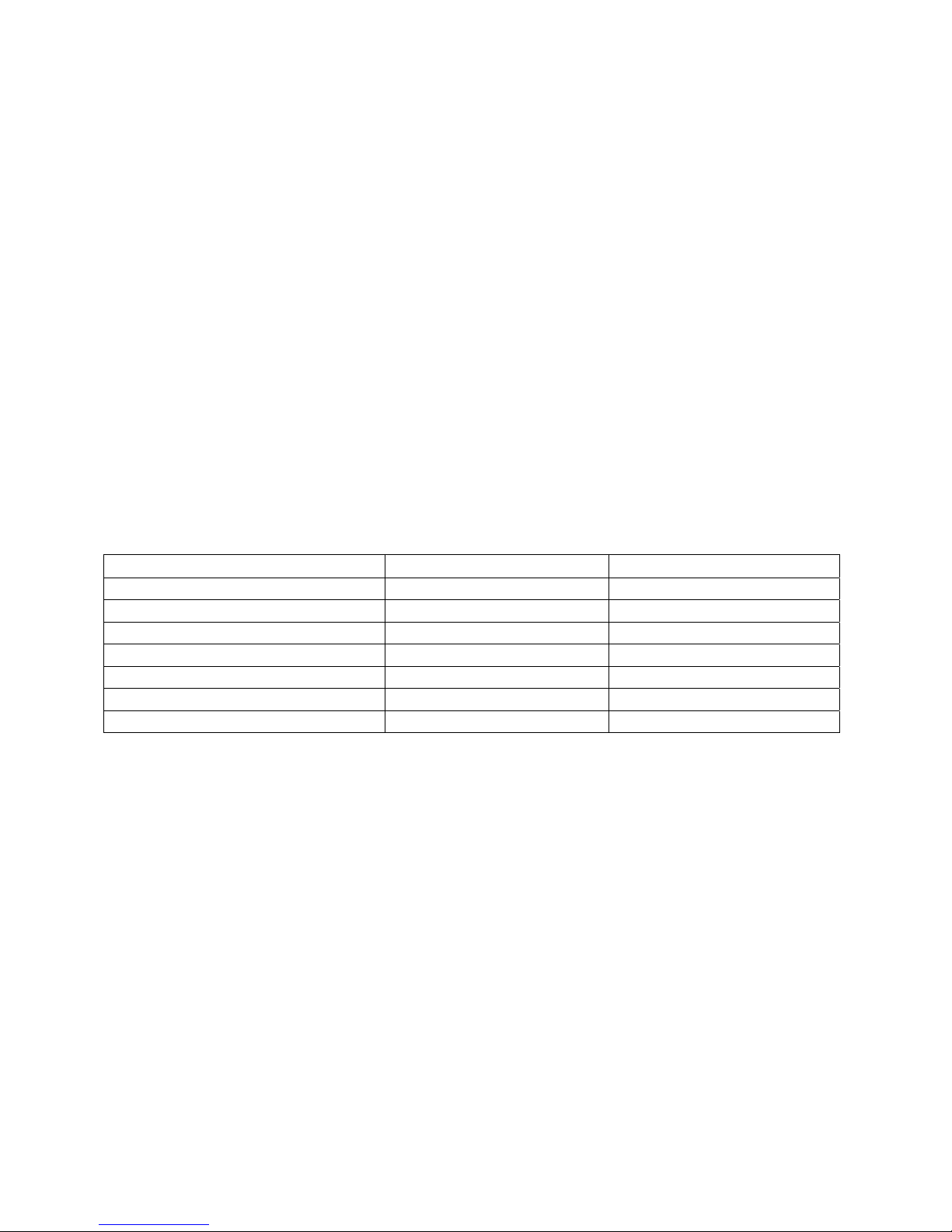

Table 1 Camera Power and Data Cables

Camera Power Data Power/Data

Sony

DXC-950/990 CA-S2-P-DXC990 CA-S2-D-DXC990 CA-S2-PD-DXC99

Panasonic

AW-E600/800 CA-S2-P-E600 CA-S2-D-E600 *CA-S2-PD-E600

Hitachi

HV-D15 CA-S2-P-HVD15 CA-S2-PD-HVD15

Hitachi

Z-3000W CA-S2-XLR-4F CA-S2-PD-Z3000

*Note: The Panasonic Camera Control Cable requires removal of the screw

terminals on the 50 Pin connector.

5

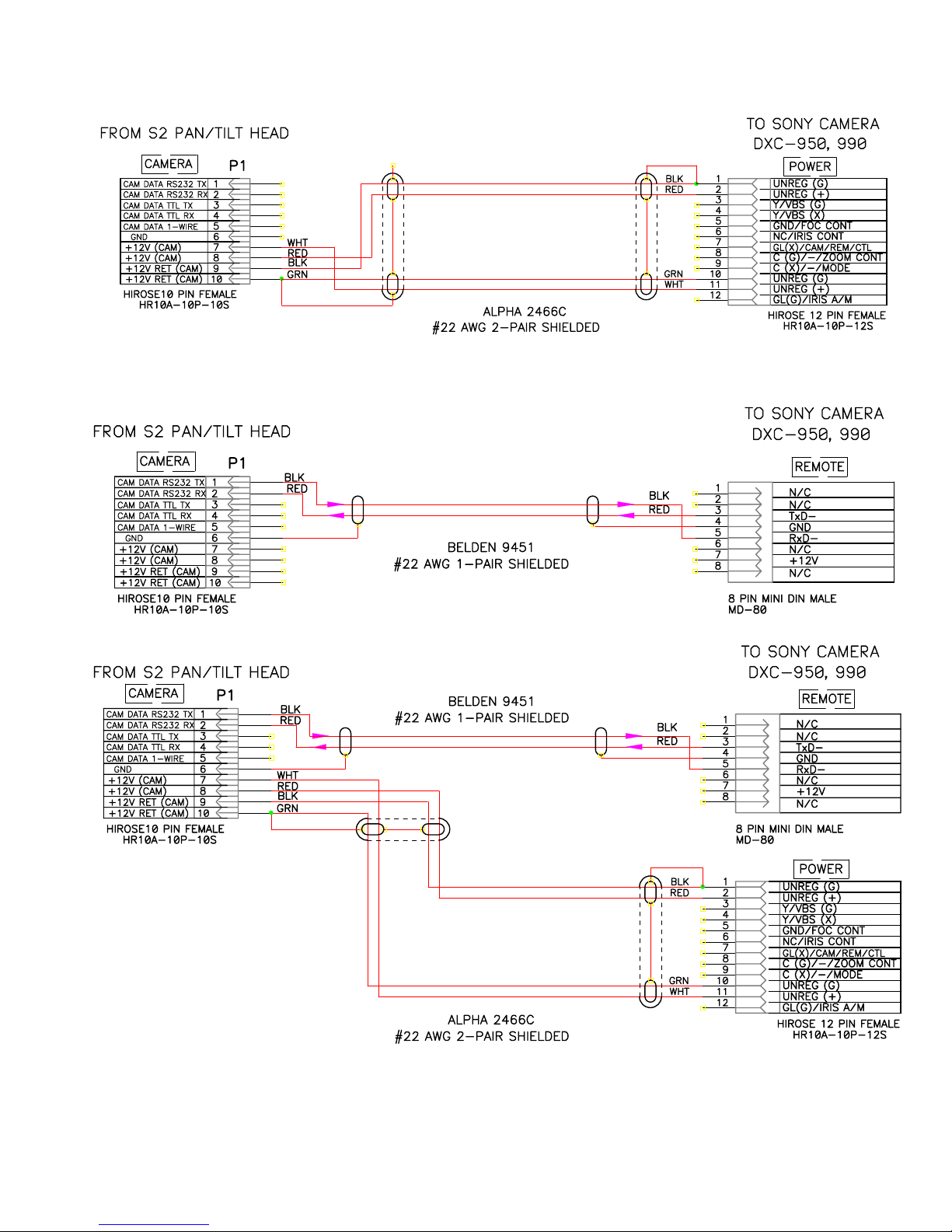

Figure 5 Sony DXC-950/990 Power Cable

Figure 6 Sony DXC-950/990 Data Cable

6

Figure 7 Sony DXC-950/990 Power/Data Cable

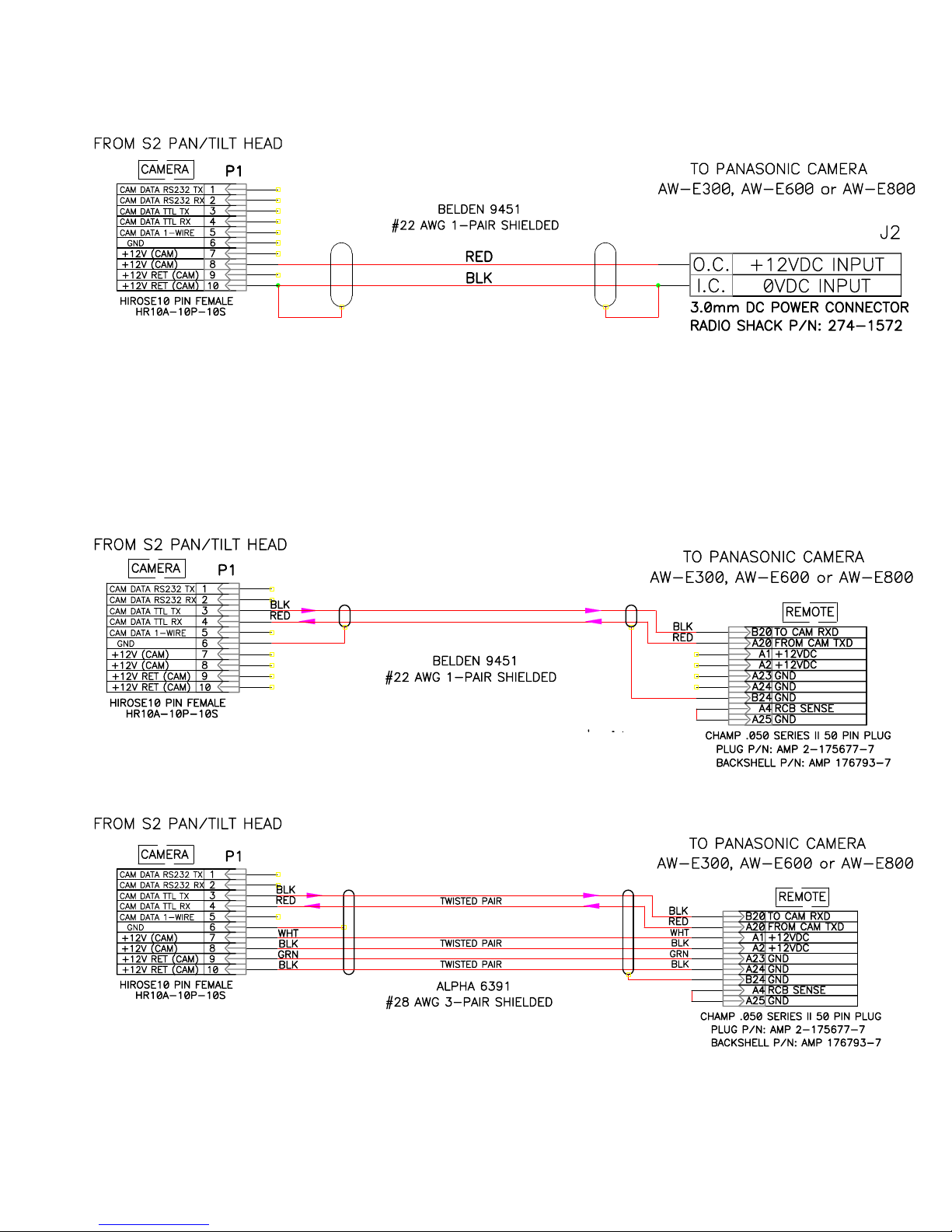

Figure 8. Panasonic AW-E600/800 Power Cable

Figure 9. Panasonic AW-E600/800 Data Cable

7

Figure 10. Panasonic AW-E600/800 Power/Data Cable

Figure 11. Hitachi HV-D15 Power Cable

Figure 12. Hitachi HV-D15 Power/Data Cable

8

Figure 13. Hitachi Z-3000W Power Cable

Figure 14. Hitachi Z-3000W Power/Data Cable

6.0 Lens Interface Information

1. In order to use Fujinon BMD or Canon KTS series teleconferencing lenses

with the Pan/Tilt, simply plug lens controls pendant into the Pan/Tilt lens

connector. NOTE

If the controller is a Telemetrics preset system, additional modifications

must be performed to bring the focus and zoom positional voltages out of

the lens. Please refer to preset controller manual for complete instructions.

2. If the zoom lens is not a teleconference style lens (a teleconference lens

has an integral zoom and focus amplifier), an interface cable will be

supplied. The connector marked “zoom” plugs into the zoom servo and

the connector marked “focus” plugs into the focus servo. Please refer to

the lens/camera manuals for connections other than remote zoom and

focus inputs. NOTE

Most focus servos require a modification, please consult factory.

9

7.0 Connector Input/Output Signals

Controls

9 Pin D Type

Pin Assignment Mating View of

Bulkhead 9 Pin D Female

1

6

5

9

RS-232

1 Reserved *

2 TX Data (From P/T)

3 RX Data (to P/T)

4 Reserved *

5 Ground

6 No Connection

7 No Connection

8 No Connection

9 No Connection

RS-422

1 TX Data + (From P/T)

2 TX Data - (From P/T)

3 RX Data - (to P/T)

4 RX Data + (to P/T)

5 Ground

6 No Connection

7 No Connection

8 No Connection

9 No Connection

Power

7 Pin XLR Type

Mating View

Pin Assignment

1 +48VDC

2 +48VDC

3 +48VDC

4 RETURN

5 RETURN

6 RETURN

7 GND

11

Lens

12 Pin Male Type

Pin Assignment

Mating View of

Bulkhead 12 Pin

Circular Male

1

2

310

11 12

456

7

8

9

1. Focus Mode

2. Zoom Mode

3. Ground

4. Iris L/C

5. Iris Ctl

6. Zoom Ref. (Non-teleconferencing

Lens)

7. Lens Ref or Focus Ref. (Non-

teleconferencing Lens)

8. Focus Control

9. Zoom Control

10.Iris Mode

11.Zoom Pot

12.Focus Pot

Camera ROP

10 Pin Male Type

Pin Assignment

Mating View of

Bulkhead 10 Pin

Circular Male

1

2

3910

45

6

7

8

1. Cam Data RS-232 TX

2. Cam Data RS-232 RX

3. Cam Data TLL TX

4. Cam Data TLL RX

5. Cam Data 1-Wire

6. GND

7. +12V (CAM)

8. +12V (CAM)

9. +12V RET (CAM)

10. +12V RET (CAM)

Aux/Trolley

10 Pin Female Type

Pin Assignment

Mating View of

Bulkhead 10 Pin

Circular Female

12

3

910

45

6

78

1. TX+

2. TX-

3. RX+

4. RX-

5. ADDR OUT

6. GND

7. +24V Trolley

8. +24V Trolley

9. +24V Trolley RET

10. +24V Trolley RET

12

Tally

12 Pin Female Type

Pin Assignment

Mating View of

Bulkhead 12 Pin

Circular Female

123

101112

4

5

6

789

1. N/C

2. N/C

3. Tally-

4. N/C

5. N/C

6. Tally+

7. N/C

8. N/C

9. N/C

10. N/C

11. N/C

12. N/C

Ethernet

RJ 45 Type

Mating View

Pin Assignments

1. TX+

2. TX-

3. RX+

4. EPWR+

5. EPWR+

6. RX-

7. EPWR-

8. EPWR-

81

13

8.0 PC Boards

8.1 Controller Board 53915

53915 REV 01

11

Controller Board Parts Location 82 53915 000-20

14

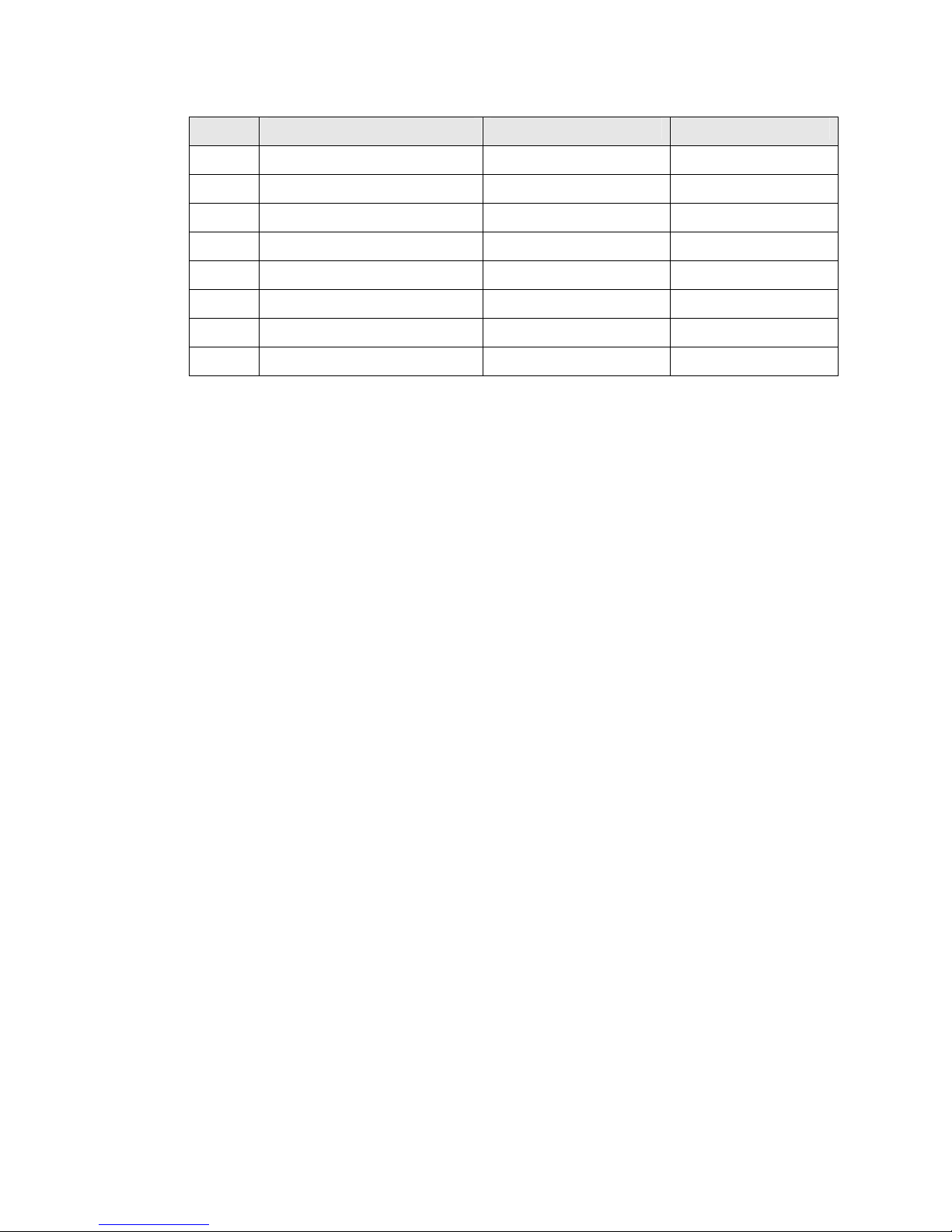

Table 1 Pan/Tilt 53915 Bd DIP-Switch Description (S1)

PIN DESCRIPTION OFF ON

1 PAN DIRECTION UPRIGHT INVERTED

2 TILT DIRECTION UPRIGHT INVERTED

3 TRACK DIRECTION NORMAL REVERSE

4 ZOOM DIRECTION LENS SPECIFIC LENS SPECIFIC

5 FOCUS DIRECTION LENS SPECIFIC LENS SPECIFIC

6 IRIS DIRECTION LENS SPECIFIC LENS SPECIFIC

7 AUXILIARY DIRECTION NORMAL REVERSE

8 RS232/RS422 RS422 RS232

15

APPENDIX A Telemetrics Serial Data Protocol

USER’S NOTICE

Warning Labels

The labels and their meaning are described below.

The Exclamation Point Symbol, within an equilateral triangle, alerts the user to the

presence of important operating and maintenance (servicing) instructions in product

literature and instruction manuals.

The Lightning Flash with Arrowhead Symbol, within an equilateral triangle, alerts the

user to the danger of rendering the unit inoperable.

Disclosure Statement

This document contains information proprietary to Telemetrics Inc. Except by written

authorization from Telemetrics Inc., the information contained in this document shall not,

in whole or in part, be disclosed to third parties, reproduced for any purpose, or used

except for evaluation and operation of equipment supplied by Telemetrics Inc.

Copyright

The Telemetrics Inc. S2 Serial Protocol Users Manual is copyrighted with all rights

reserved. Copyright of this manual belongs to Telemetrics Inc. No part of this manual,

including the products and software described in it may be reproduced, transmitted or

translated into any language in any form or by any means without written permission of

Telemetrics Inc., except for backup or archival purposes.

© 2003 by Telemetrics Inc.

16

Telemetrics Serial Data Protocol

Telemetrics provides for serial control of many of our camera control products. This

summary briefly describes the protocol for serial control of these devices. In the

summary, the Telemetrics controlled device will be referred to as the “controller” and the

device commanding the controller will be referred to as the “host”.

Control is accomplished by sending commands consisting of ASCII characters

terminated by an ASCII carriage return (<CR>, hex 0D). In most cases, several

commands may be sent together on the same line before sending the <CR>. However,

in the case of the recall preset command, other commands may precede it but any

control commands following it on the same line are ignored. Feedback commands will

still continue to respond. A control command line will not be executed until the <CR> is

received. ASCII backspace (<BS>, hex 08) can be used to correct errors in the

command line. After the command line has been executed, a <CR> will be sent back to

the host to acknowledge completion.

Communication rate is 9600 BAUD. Protocol is 8 data bits, one stop bit, and no parity.

Each command consists of letters and may be followed by numerical parameters

needed for the command. (Note: The commands are CASE SENSITIVE.) Numerical

parameters are specified by the string of ASCII digits representing the decimal value.

For example, a value of 26 is sent as a ‘2’ followed by a ‘6’, (i.e., hex 32, hex 36).

Where a command has more than one parameter, the parameters should be separated

by a space. No other spaces are necessary, though they may be used if desired.

Important Note: In cases where the host does not monitor responding

carriage returns from the controller, the host will not know whether a command

line has been completed. The controller can receive new commands while it is

processing previous commands except when the controller is processing a

preset position recall. During a preset recall, all incoming characters are

ignored except for an ASCII cancel character (<CAN>, control-X, hex 18)

which tells the controller to abort the recall. Therefore, the host should send a

<CAN> preceding all command lines. This way, if a recall was in progress, it

will be aborted and the controller will accept the command. If no recall was in

progress, the <CAN> will be ignored.

The remainder of this summary describes the general methods for serial camera

control. Commands will be introduced as they are needed. Note that while examples

are shown enclosed in single quotes, only the characters within the quotes are to be

sent; the quotes are simply for clarity. In addition, the examples may use unnecessary

spaces for clarity, which need not be used for the actual application.

17

Manual Camera Motion

The procedure for manually moving a camera is as follows:

•Reset motion voltages with the ‘R’ command.

•Move the camera using ‘P’, ‘T’ “Z’ and ‘F’ commands.

The following 2 sections discuss the commands used.

Camera Control Voltages

Camera motion is controlled by four voltages corresponding to the velocity of pan, tilt,

zoom and focus which are set using the ‘P’, ‘T’ ‘Z’ and ‘F; commands respectively. (An

‘X’ and ‘Y’ commands are also available to control the trolley and dolley, if used.) Iris

control may be available depending on the control panel options and lenses. The

commands have a single numerical parameter determining the voltage to which the

output is set. The value of the parameter is in the range of 0 to 32767. A parameter

value of 16383 is the point at which no motion occurs. As the value moves away from

16383, the speed of motion increases, and the direction of motion is determined by

whether the value is greater or less than 16383 as follows:

Command < Less than 16383 > Greater than 16383

‘P’ Pan Right Left

‘T’ Tilt Down Up

‘Z’ Zoom In (Tele) Out (Wide)

‘F’ Focus Near Far

‘X’ Televator/Trolley Down/Right Up/Left

‘Y’ Dolley Right Left

“I” Iris Close Open

In addition, the ‘R’ command, which has no parameters, will reset all control voltages to

the no motion value.

There are many methods for determining control voltages. For instance, a joystick can

be used and the value it outputs converted to the range 0 to 32767 for control voltages.

Another example is with buttons. Each function has two buttons, one for each direction

of motion (i.e. pan left and pan right). When a button is pressed, the camera is enabled.

Initially the control voltage for the function is set for slow movement. Then the longer

the button is held down, the faster the camera moves. If there is limited processing

ability, button control can be done with simple on/off type control where pressing a

button moves the corresponding function at a fixed speed.

Table of contents

Popular Camera Accessories manuals by other brands

Trojan

Trojan GC2 48V quick start guide

Calumet

Calumet 7100 Series CK7114 operating instructions

Ropox

Ropox 4Single Series User manual and installation instructions

Cambo

Cambo Wide DS Digital Series Main operating instructions

Samsung

Samsung SHG-120 Specification sheet

Ryobi

Ryobi BPL-1820 Owner's operating manual