Telephonics RT-1601 Instructions for use

TM109902 (5/03) 3-1

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS DOCUMENT.

COMMAND SYSTEMS DIVISION

3.1 GENERAL

This chapter contains applicable maintenance practices related to the RT-1601 Receiver –

Transmitter. Included in this section are inspection, adjustments and troubleshooting test point

waveforms, cleaning and repair information; and disassembly/assembly instructions.

3.2 VISUAL INSPECTION

A routine visual inspection should be performed any time the receiver transmitter is removed from

the aircraft. The following areas are of prime importance.

A. Chassis

Inspect the chassis for loose or missing hardware, deformation, damaged fasteners, or damaged

connectors.

B. Connectors

Inspect the connector bodies for broken parts; check the insulation for cracks; and check the

contacts for damage, misalignment, corrosion or bad plating. Check for broken, loose, or poorly

soldered connections to the terminals of the connectors. Inspect connector hoods and cable

clamps for pinched wires.

C. Terminal Connections

Inspect for corrosion and loose connections.

D. Wiring

Inspect the wiring of the chassis and subassemblies for any signs of physical damage or

charring.

E. Capacitors

Inspect capacitors for case or body damage and for loose, broken or corroded terminal

connections.

F. Resistors and Diodes

Inspect for blistered, charred, or cracked bodies; also check for loose, broken, or corroded

terminal connections.

The document reference is online, please check the correspondence between the online documentation and the printed version.

3-2 TM109902 (5/03)

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS DOCUMENT.

COMMAND SYSTEMS DIVISION

G. Filters and Inductors

Inspect for damage to body or casing and for loose, broken, or corroded terminal connections.

Check for secure mounting to chassis.

H. Transformers

Inspect for damage to case and for signs of excessive heating; also check for loose, broken or

corroded terminal connections.

I. Transistors

Inspect for damage to body or casing and for secure and appropriate attachment into their

respective sockets.

J. Terminal Connections, Soldered

(1) Inspect for cold soldered or rosin joints. Bad joints can be recognized by a dull, porous

appearance.

(2) Check for excessive solder, insufficient solder, or solder splashes resulting from a previous

repair.

(3) Check for corrosion at the terminal connections.

3.3 CLEANING

Do not use cleaning solvent on electrical parts.

cleaning solvent can soften and permanently

damage insulating materials.

Wipe the exterior of the unit with a lint-free cloth dampened with an approved cleaning solvent

conforming to Federal Specification PD-680. Remove any foreign matter from the interior using a clean

soft-bristled brush and/or a clean, dry, compressed air stream at a pressure of not more than 15 psi.

3.4 USE OF PROPER TEST EQUIPMENT

Frequently semiconductor devices and integrated circuits, are damaged by accidentally applying too

much voltage or current to the device elements. These causes for failure can be reduced by using

proper test equipment.

A. Multimeters with sensitivities of less than 5000-ohms-per-volt should never be used. Either a

20,000 ohms-per-volt multimeter or a vacuum tube voltmeter should be used.

CAUTION

The document reference is online, please check the correspondence between the online documentation and the printed version.

TM109902 (5/03) 3-3

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS DOCUMENT.

COMMAND SYSTEMS DIVISION

B. Test equipment with transformerless power supplies should never be used unless an isolation

transformer is used in the ac power line.

C. Some test equipment is designed with a line filter across the ac input. This could result in

accidentally applying 55 volts ac to the semiconductor device. To eliminate this possibility,

always connect a ground wire from the chassis of the test equipment to the chassis of the RT

unit prior to making any other connections.

3.5 CAPACITOR CHECKING

When checking tantalum capacitors, care should be taken to ensure that the maximum DC working

voltage, as marked on the capacitor, is not exceeded and that the polarity markings on the capacitor

are observed when applying voltage. Disregard of polarity markings or exceeding the DC working

voltage may permanently damage the capacitor.

3.6 REPAIR

Voltage dangerous to life exists; remove all

power to unit before proceeding.

A. Repair Precautions

(1) Refer to paragraph 3-6B. for special handling precautions required for electrostatic

discharge sensitive (ESDS) devices.

(2) Perform repairs and replace components with power disconnected from the equipment.

(3) Use a conductive table top for repairs and connect the table to the ground conductor of the

60 Hz power line.

(4) Replace connectors, coaxial cable, shielded conductors, and twisted pairs ONLY with

identical items.

(5) Reference to "component side" of a printed circuit board in this manual means the side on

which the components are located; "solder side" refers to the other side.

(6) When repairing circuits, carefully observe lead dress and component orientation. Keep

leads as short as possible and observe correct repair techniques.

(7) Observe cable routing throughout instrument assembly, prior to disassembly, to enable a

proper reinstallation of the cabling during reassembly procedures.

WARNING

The document reference is online, please check the correspondence between the online documentation and the printed version.

3-4 TM109902 (5/03)

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS DOCUMENT.

COMMAND SYSTEMS DIVISION

B. Electrostatic Discharge Sensitive (ESDS) Devices

Devices sensitive to electrostatic discharge are used in this equipment. These devices, including

Metal Oxide Semiconductors, some metal film resistors, and other devices, are susceptible to

damage by electrostatic charges or high-voltage fields. Because of the very high resistances in

ESDS devices, they can be damaged by electrical sources that cannot deliver enough current to

damage conventional semiconductors. Therefore, special precautions must be taken during

handling and repair procedures to prevent damaging the device. The most common low-energy

source causing damage to ESDS devices is the human body, which generates and retains static

electricity, in conjunction with non-conductive garments and floor covering. An individual can

easily develop several thousand volts of electrostatic charge while simply walking across the

floor or moving around in a chair. Electrostatic charges of 20 kV have been measured on

personnel, and 35 kV has been measured on their garments.

The capacitive elements in all MOS devices can be destroyed by a voltage field, even when

assembled into the circuit. Similar capacitive elements in linear integrated circuits, hybrids, and

in bipolar integrated circuits are also susceptible to field voltages.

Not all electrostatic damage will result in immediate catastrophic failure. Damaged devices may

remain operating within the minimum limits but could experience early field failure or erratic

performance.

The following precautions are recommended for ESDS circuits, and are especially important in

low humidity or dry conditions when electrostatic problems are more prevalent.

ESDS devices include, but are not limited to,

C-MOS, J-MOS, PMOS, NMOS, SOCMOS,

HMOS, MOS/FET, microwave mixer diodes,

some bipolar devices, and some metal film

resistors.

(1) Storage

Store and transport all ESDS devices in conductive material. Do not insert ESDS devices

into conventional plastic “snow” or plastic trays used for storing and transporting standard

semiconductor devices. Special bags or containers must have a maximum resistivity of 104

ohms/cm, or the leads of the device must be shorted together through a conductive material

(special foam) having a maximum resistivity of 104ohms/cm.

Modules, circuit boards, or assemblies containing ESDS devices must be stored in static

shielding bags with a maximum resistivity of 104ohms/cm in the outer layer of the bag,

and 1012 ohms/cm resistivity in the inner layer.

A caution label shall be attached to the outside of all containers containing ESDS devices.

The ESDS labels are identified in the advisory information located in the front of this

manual. Do not remove device from container until actually used or tested.

CAUTION

The document reference is online, please check the correspondence between the online documentation and the printed version.

TM109902 (5/03) 3-5

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS DOCUMENT.

COMMAND SYSTEMS DIVISION

(2) Work Station

All equipment, tools, materials, and personnel at the workstation must be maintained at the

same electrical potential. All grounding connections shall have a common point, and that

point shall be connected to electrical ground.

Soldering irons shall be isolated from the power line by transformer, or shall be direct

current isolated. The soldering iron must be grounded and have a resistance of less than 0.2

ohm from the tip to ground when the iron is hot.

Test equipment shall have all exposed metallic surfaces electrically connected to the test

equipment power system ground (through 200 ohms or less).

Do not use rubber mats, carpets, and rugs in the workstation area. Use grounded conductive

mats.

Do not allow nonconductive items on the workbench. This includes such items as plastic

ashtrays, cellophane wrappers, plastic tools, styrofoam coffee cups, etc.

Maintain the relative humidity higher than 40 percent (minimum) in the work area.

Keep all material and work surfaces CLEAN in the work area. Wash with damp cloth when

necessary.

Keep the workstation static-safe. Periodically check the area with a static meter. When a

dangerous reading is observed, remove the nonconductor or take precautions to prevent

contact with ESDS devices.

(3) Personnel

When handling electrostatic discharge sensitive devices or assemblies, wear a skin-contact

wrist strap connected to the workstation common ground.

Do not connect personnel directly to earth or

building ground. Commercial grounding straps

contain an internal resistance of about 1

megohm in the cord to bleed the electrostatic

charge from the body while protecting personnel

from electrical shock.

WARNING

The document reference is online, please check the correspondence between the online documentation and the printed version.

3-6 TM109902 (5/03)

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS DOCUMENT.

COMMAND SYSTEMS DIVISION

Do not wear ground strap when troubleshooting

or testing high voltage circuits with power

applied.

Do not wear smocks, gloves, finger cots, or sleeve protectors made of plastic, nylon, or

rubber in the area where ESDS devices are handled.

When the operator is properly grounded, contact with the operator's hand will provide

sufficient ground for hand tools or other tools that many be electrically isolated from

ground.

(4) Special Troubleshooting Precautions

In addition to the above considerations, the following specific precautions should be

observed when troubleshooting or repairing modules containing ESDS devices.

Do not use high velocity dry air for applying heat during troubleshooting. Special infrared

heat devices should be used.

Do not use Freon spray during troubleshooting. To cool components, use antistatic quick-

chill sprays.

Remember, even when the ESDS device is installed on a printed circuit board it can STILL

be damaged by electrostatic discharge.

C. Printed Circuit Boards

Components on the PC boards can be replaced, reference should be made to the applicable

Repair paragraph for replacement and removal of components. All PC boards have been

protected with a moisture protected sealant. A sealant such as “Humi Seal Protective Coating

1831” should be re-applied to the repaired area.

“Humi Seal Protective Coating 1B31” is manufactured by the Humi Seal Division of the

Columbia Technical Corporation, Woodside, New York 11377.

D. Components Replacement, Feed-Thru Capacitors or Filters

(1) From both sides of chassis, remove components connected to the feed-thru; clear

disconnected components from the vicinity of the feed-thru.

(2) Locate side of chassis on which feed-thru rim is mounted.

(3) Unsolder component (use a 250 watt five tipped soldering iron) by heating the chassis near

the component.

WARNING

The document reference is online, please check the correspondence between the online documentation and the printed version.

TM109902 (5/03) 3-7

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS DOCUMENT.

COMMAND SYSTEMS DIVISION

(4) Insert replacement. Ensure component orientation is the same as that noted in step (2).

(5) Using fine-solder (against component shoulder on rim) heat chassis with iron [step (3)]

until a minimal amount of solder flows between chassis and rim.

(6) Replace attaching components removed in step (1).

E. Replacement of Power Transistors

(1) Unsolder leads and remove heat sink nut and washer. Remove transistor and insulator.

(2) Apply silicone thermal compound Wakefield #120 heat-conductive grease to both sides of

the insulator and re-install the insulator.

(3) Install replacement transistor. Re-install and tighten nut. After assembly remove any excess

compound on heat sink around transistor.

(4) With an ohmmeter verify an open circuit (> 10 megohms) between the metal mounting tab

and the mounting stud to which the nut is attached.

(5) Solder leads in place.

F. PC Board, Two-Lead Component Removal (Resistors, Capacitors, Diodes, etc.)

(1) Heat from component side of board until solder flows and lift one lead from board; repeat

for other lead and remove component (note orientation).

(2) Remove all solder from board holes using desoldering suction tool. Avoid runs on

trackside.

(3) Dress and form leads of replacement component; insert leads into board holes.

(4) Solder in place and clip leads on trackside of board.

G. PC Board, Multi-Lead Component Removal (ICs, etc.)

(1) Remove component by clipping each lead along one side. Clip off leads as close to the

board surface as possible. Lift and bend back component repeating until leads on other side

snap. Discard component.

(2) On trackside of board, straighten or clip off component leads.

(3) On component side of board melt the solder in each hole; using the desoldering suction tool

remove solder and clipped leads from each hole.

(4) Insert replacement component observing correct orientation.

(5) Solder component in place from the trackside of the board. Avoid solder runs. No solder is

required on contacts where no track exists.

The document reference is online, please check the correspondence between the online documentation and the printed version.

3-8 TM109902 (5/03)

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS DOCUMENT.

COMMAND SYSTEMS DIVISION

H. TR Limiter

If the TR Limiter is found to be defective replace the component as a complete assembly. When

assembling replacement component observe correct port orientation; input and output ports are

denoted by stencilled words “INPUT” “OUTPUT”. After replacement perform the following

tests located in “Chapter 2 Receiver-Transmitter Testing.”

Log Receiver Tests Paragraph 4.10.

I. Mixer Duplexer

Other than replacement of diodes CR1001 and CR1002, the assembly is non-repairable and

should be replaced as a complete assembly if found defective. After replacement of any diode or

the assembly perform the following tests located in “Chapter 2 Receiver-Transmitter Testing.”

(1) RF Power Test Paragraph 4.6.

(2) AFC Test Paragraph 4.7.

(3) Crystal Currents Paragraph 4.8.

(4) Receiver Tests Paragraph 4.10.

J. Power Supply Fuse F1001 Replacement

Refer to Figure 4-1 located in Chapter 4, Parts List. The power supply fuse F1001 is located on

the interconnect PC board, visible from the left side view of the unit (cover removed).

Replacement of the fuse (10A, AGC10) can be accomplished by using a suitable fuse puller.

After replacement perform the following tests located in “Chapter 2 Receiver-Transmitter

Testing.”

Power Supply Voltage Checks Paragraph 4.1 and 4.2.

K. Magnetron

If the magnetron is found to be defective, replace this component as a complete assembly. After

replacement perform the following tests located in “Chapter 2 Receiver-Transmitter Testing.”

(1) RF Power Output Test Paragraph 4.6.

(2) AFC Tests Paragraph 4.7.

L. Local Oscillator

If the local oscillator is found to be defective replace the component as a complete assembly.

After replacement perform the following tests located in “Chapter 2 Receiver-Transmitter

Testing.”

(1) AFC Test Paragraph 4.7.

The document reference is online, please check the correspondence between the online documentation and the printed version.

TM109902 (5/03) 3-9

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS DOCUMENT.

COMMAND SYSTEMS DIVISION

(2) False Alarm Check Paragraph 4.9.

(3) Receiver Tests Paragraph 4.10.

3.7 SEMICONDUCTOR SERVICE INFORMATION

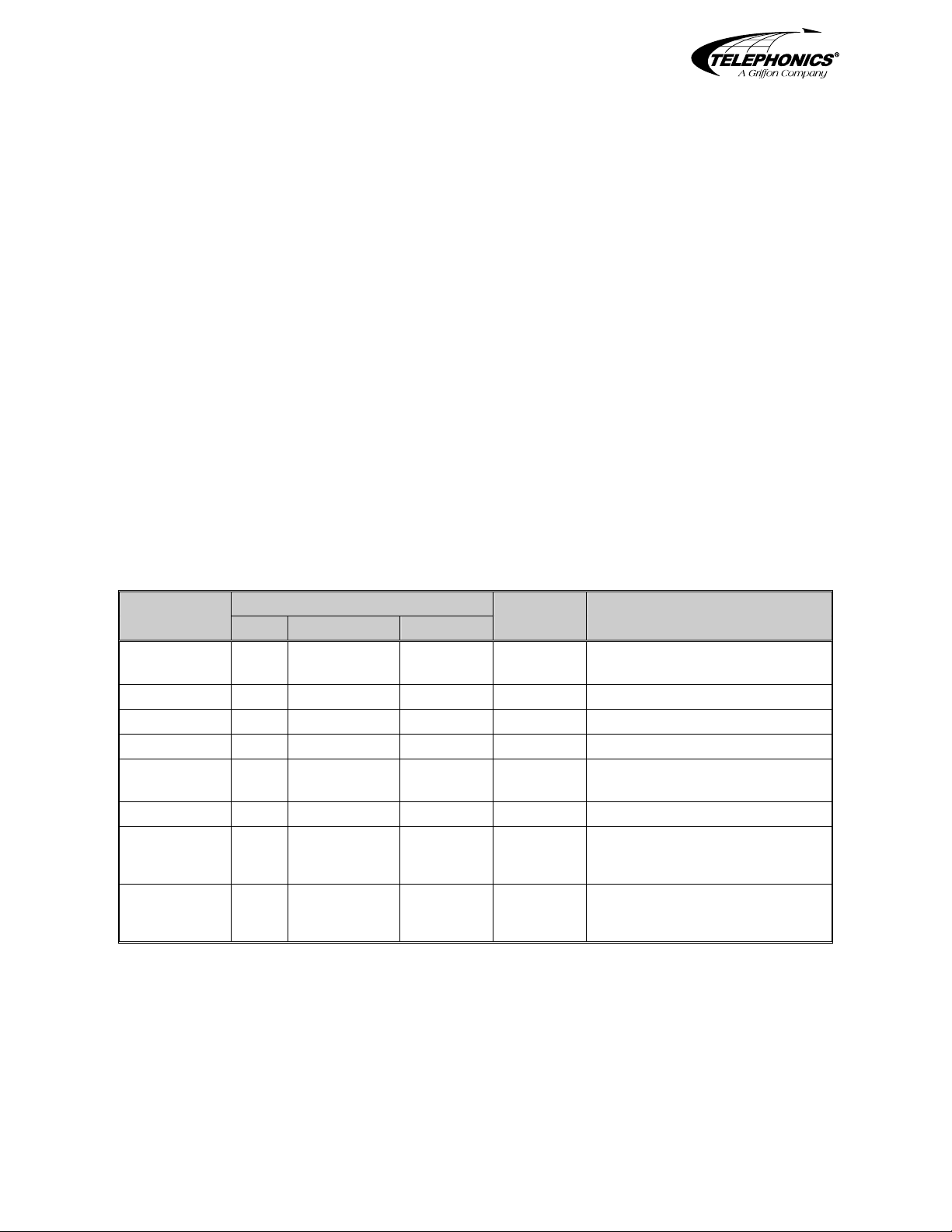

A. Transistor Testing and Base Connection

Tables 3-1 and 3-2 provide typical testing data for PNP and NPN transistors.

NOTE

The information in Tables 3-1 and 3-2 is not

applicable for Darlington transistors.

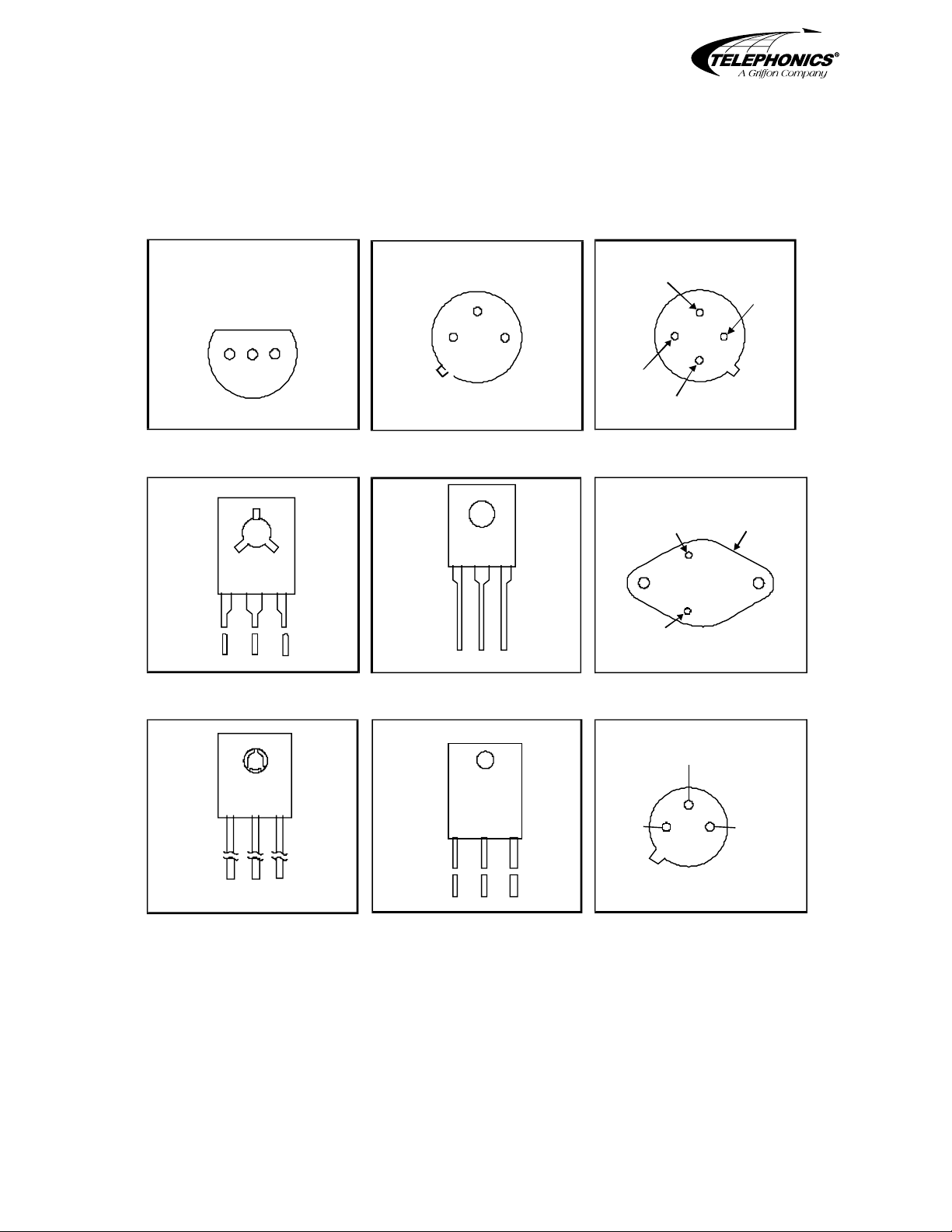

Table 3-3 lists the transistors used in RT-1601. Column 2 references Figure 3-1 which shows a

base arrangement view of the transistor. Transistors having in-line leads must have leads formed

to the standard three pin socket configuration.

Table 3-1.

PNP Transistor Testing Procedure

OHMMETER CONNECTIONS

CHECK NO. BASE COLLECTOR EMITTER RANGE RELATIVE RESISTANCE

1 – +

RX100 or

RX1,000

Low (1,000 ohms or less)

2 + – RX10,000 High (100,000 ohms or more)

3 – + RX10,000 High (100,000 ohms or more)

4 + – RX10,000 High (100,000 ohms or more

5 – +

RX100 or

RX1,000

Low (1,000 ohms or less)

6 + – RX10,000 High (100,000 ohms or more)

7

Connect base

to collector

– +

RX100 or

RX1,000

Resistance should decrease from that

obtained in check 3.

8

Connect base

to emitter

– + RX10,000 High (100,000 ohms or more)

The document reference is online, please check the correspondence between the online documentation and the printed version.

3-10 TM109902 (5/03)

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS DOCUMENT.

COMMAND SYSTEMS DIVISION

Table 3-2.

NPN Transistor Testing Procedure

OHMMETER CONNECTIONS

CHECK N0. BASE COLLECTOR EMITTER RANGE RELATIVE RESISTANCE

1 + –

RX100 or

RX1,000

Low (1,000 ohms or less)

2 – + RX10,000 High (100,000 ohms or more)

3 + – RX10,000 High (100,000 ohms or more)

4 – + RX10,000 High (100,000 ohms or more)

5 + –

RX100 or

RX1,000

Low (1,000 ohms or less)

6 – + RX10,000 High (100,000 ohms or more)

7

Connect base

to collector

+ –

RX100 or

RX1,000

Resistance should decrease from

that obtained in check 3.

8

Connect base

to emitter

+ – RX10,000 High (100,000 ohms or more)

Table 3-3.

Transistors and Base Configurations

TRANSISTOR

TELEPHONICS

PART N0.

VENDOR

TYPE NO.

BASE

CONFIGURATION

(FIGURE 3-1)

NOTE

12044-0009 2N5192 Q62 NPN, power, silicon

12044-0048 ZN6043 T61 NPN, power, silicon

12044-0054 MJE182 T41 NPN, power, silicon

12044-0065 D44HIl T61 NPN, power, bipolar

12047-0070 2N918 T30 NPN, silicon

12047-0075 MRF502 T30 NPN, silicon

12047-0078 2N2897 T23 NPN, silicon

12047-0095 MPS-A06 T2 NPN, silicon

12048-0047 MPSA56 T2 PNP, silicon

12050-0003 2N4092 T66 FET, silicon, N-channel

12051-0001 2N708 T23 Switching, silicon

12051-0003 2N2222A T23 Switching, silicon

12051-0009 2N2907A T23 Switching, silicon

12064-0001 K6001 T30 RF, low noise

12074-0003 MJ11014 T49 Power, Darlington

14006-0021 2N6405 T44 SCR

The document reference is online, please check the correspondence between the online documentation and the printed version.

TM109902 (5/03) 3-11

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS DOCUMENT.

COMMAND SYSTEMS DIVISION

E

T2

BC

T30

CASE

3

1

2

E

B

C

4

T41

E C B

T49

EMITTER 2

BASE1

COLLECTOR

(CASE)

E

(CASE)

SOURCE

DRA IN

GATE(CAS

E

CB

T62 T66

E CB

EB

C

T23

T44

E

CB

T67

0757

Figure 3-1. Transistors Base Configurations

The document reference is online, please check the correspondence between the online documentation and the printed version.

3-12 TM109902 (5/03)

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS DOCUMENT.

COMMAND SYSTEMS DIVISION

3.8 INTEGRATED CIRCUIT SERVICE INFORMATION

A. Series 54/74 Integrated Circuits

Type-number identification is becoming increasingly complex for the 54/74 series of integrated

circuits, which were originally referred to as TTL chips. Today, many different type numbers

may apply to chips that perform the same function, although specifications (temperature, speed,

power, etc.) and interior configurations may be different. Usually, the only difference in the type

numbers involves the alpha characters immediately following the 54/74 designation.

Consider the quadruple D-type flip-flop chip 74LS175. This logic circuit may be manufactured

with type numbers 54175, 545175, 54LS175, 54AS175, 54ALS175, 54HC175, 54HCT175,

74175, 745175, 74AS175, 74ALS175, 74HC175, and 74HCT175. All these devices perform the

same logic function, but each has a different specification, different internal construction, and

are not interchangeable in all circuit applications. However, the pin arrangement and IC diagram

is usually the same for all these devices. Most chips are available in both 54 series and 74 series

type numbers. The 54 series have an operating temperature specification of -55°C to 125°C, and

the 74 series have a temperature specification of 0°C to 70°C. Table 3-4 describes the primary

differences corresponding to the alpha characters in the type number.

The 54HC175, 54HCT175, 74HC175, and 74HCT175 devices are CMOS versions of the above

and may be shown in a separate IC diagram.

The 54AC175 and 54ACT175 devices are advanced CMOS logic (ACL) versions of the above.

ACL matches bipolar FAST and AS in speed, performance, and logic type output drive, but at

CMOS power levels.

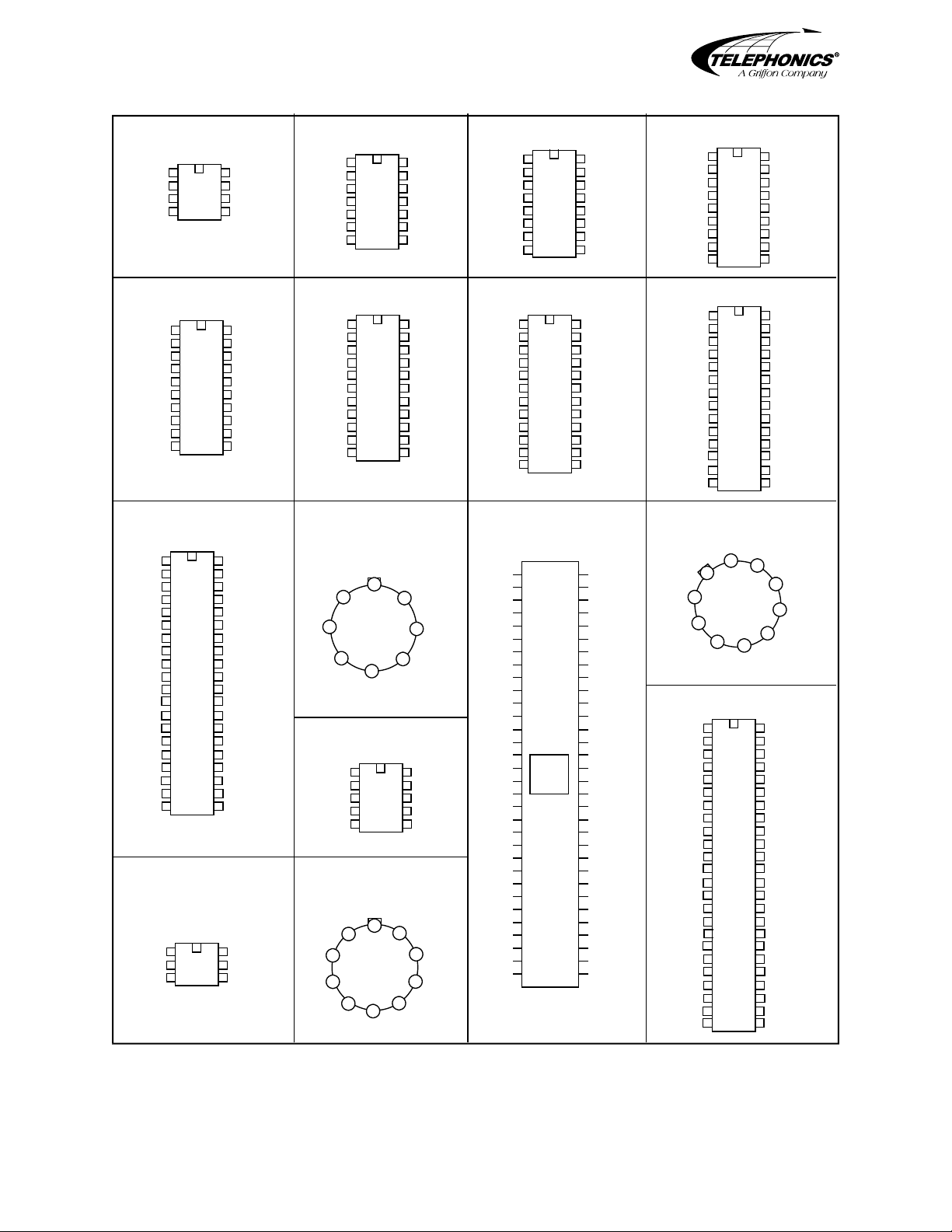

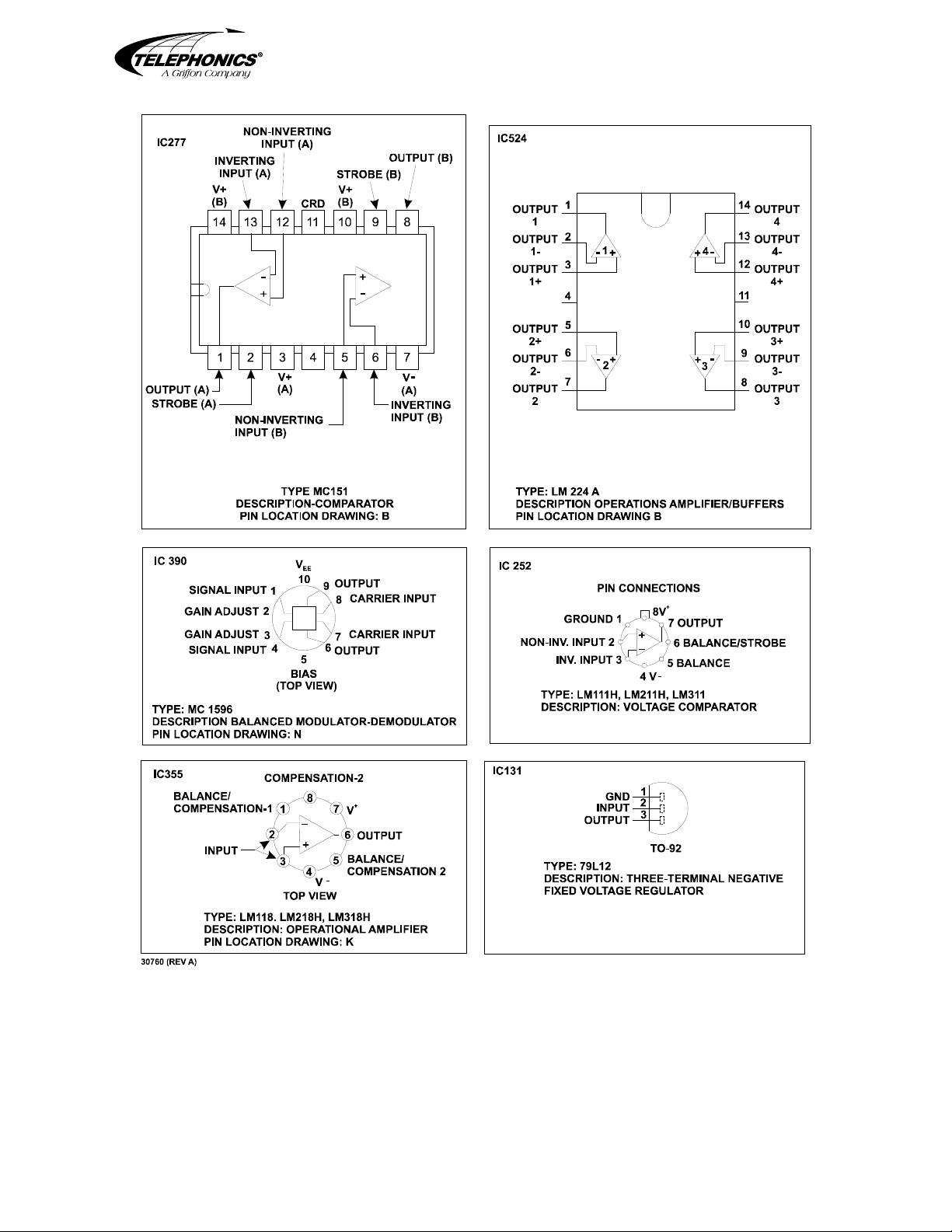

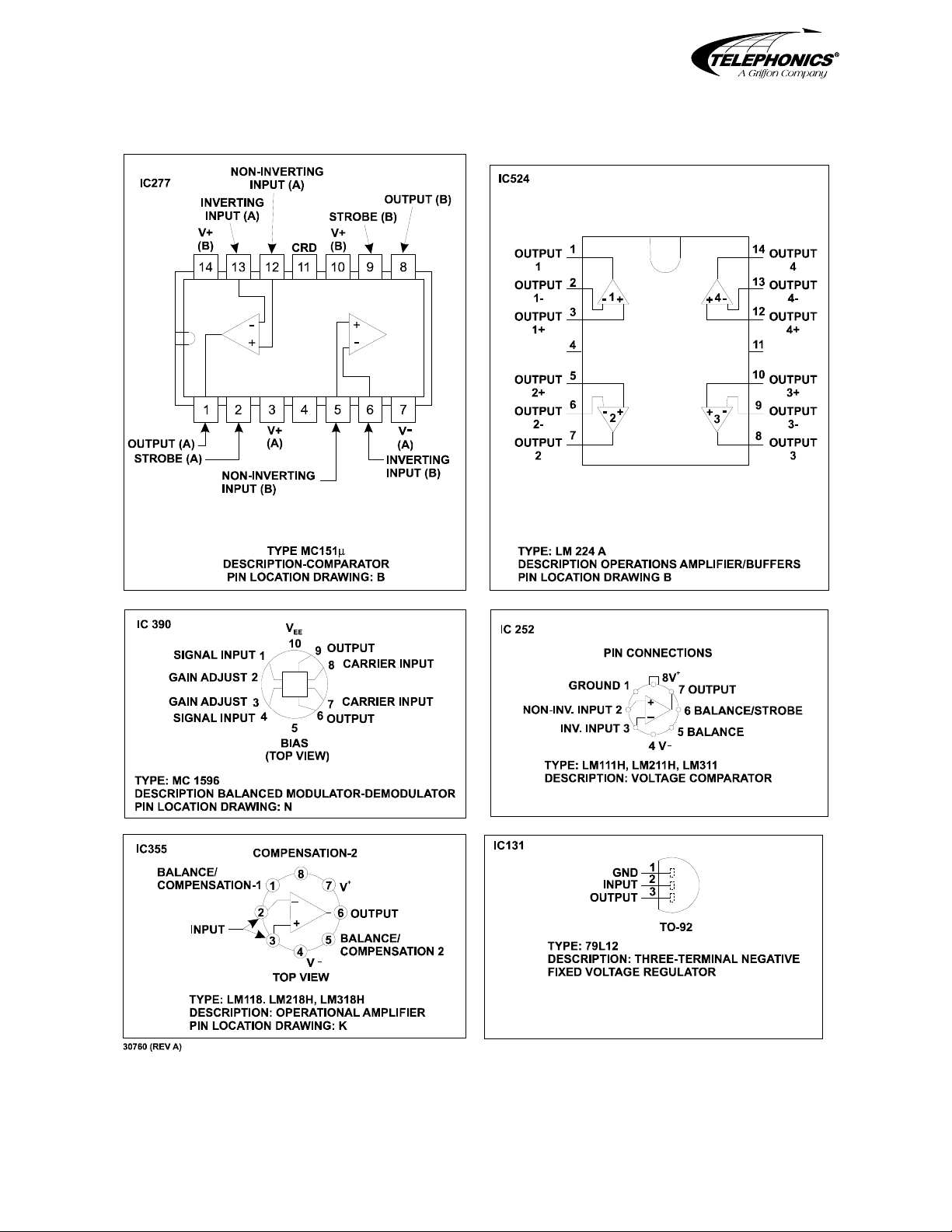

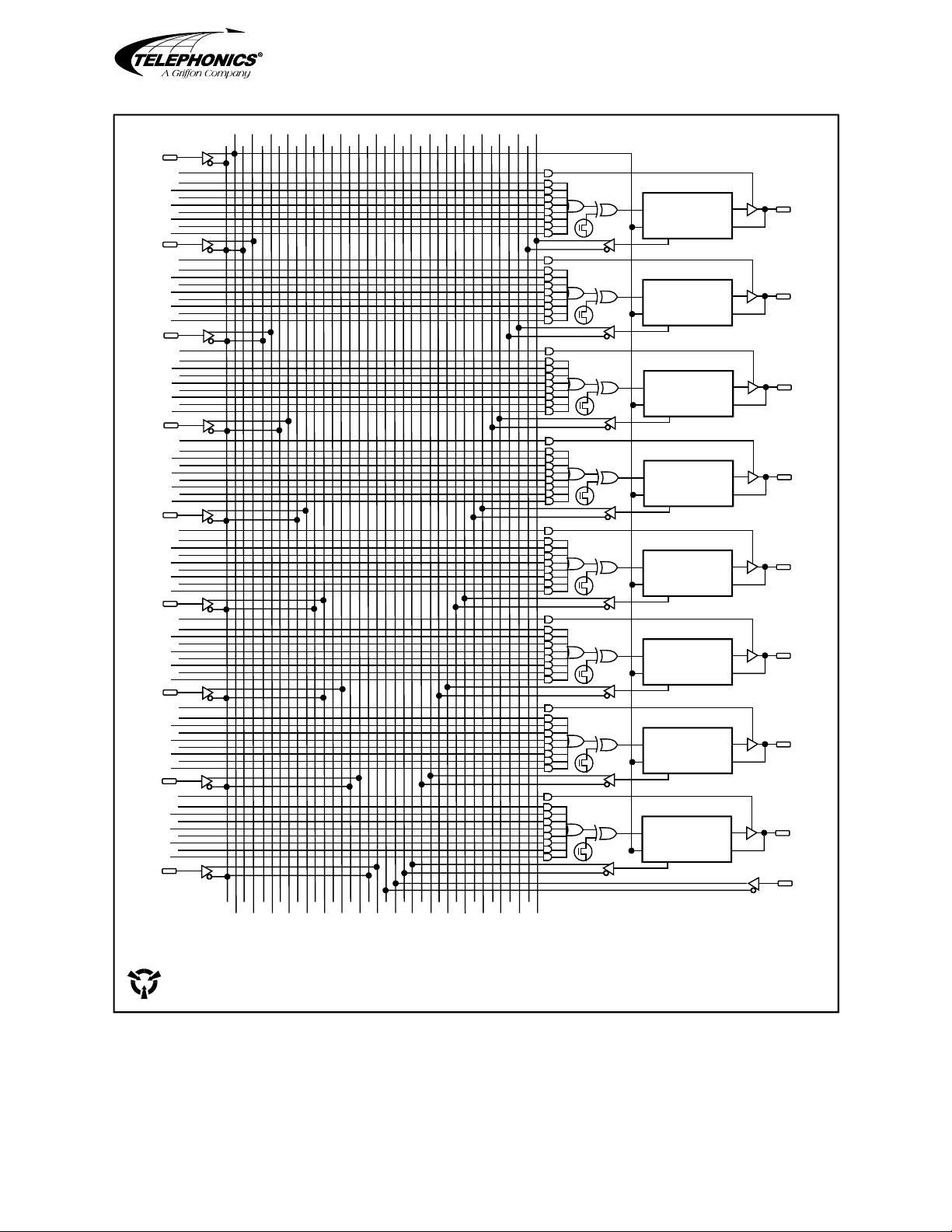

Integrated Circuit Diagrams

A small functional circuit diagram of each integrated circuit in the RT-1601 is provided in the

following figures. First, Table 3-6 contains a list or index of the circuit diagrams. Figure 3-2

illustrates all the various pin numbering configurations, and Figure 3-3 contains several sheets of

IC diagrams.

Column one of Table 3-6 lists alphanumerically each integrated circuit by the vendor type

number. Column two specifies the sheet of Figure 3-3 where the IC circuit diagram is located.

Column three contains the IC drawing reference number (IC33, IC297, etc.) which appears in

the upper left corner of each IC diagram.

Figure 3-2 illustrates the pin location drawings for the popular IC's. Pin connections are

numbered as viewed from the top of the IC case. A mark representing pin 1 is etched on the

circuit boards for proper orientation of the component. Each pin location drawing is identified

with a letter (A, B, C, etc.). The circuit diagram for each IC contains a reference to one of the

pin location drawings on Figure 3-2.

The type numbers appearing on the IC circuit diagrams in Figure 3-3 are representative vendor

types for the device. The actual vendor type number used in the equipment (listed in Table 3-6)

may be a different type number for the same device.

The document reference is online, please check the correspondence between the online documentation and the printed version.

TM109902 (5/03) 3-13

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS DOCUMENT.

COMMAND SYSTEMS DIVISION

C. Digital Integrated Circuit Testing

Digital circuit element output logic levels change with changes in the input logic level. By

checking the input versus output logic states faults can be isolated to a defective IC. In

operation, the logic levels at the input or output of the digital integrated circuits will be a logic 1

or logic 0 depending on the function in progress. A logic 1 voltage is between +2.4 to +5.5 volts

and a logic 0 is +0.8 volts or less.

Exact voltage measurements are not necessary in testing digital components other than to verify

that the voltage is at a logic 1 (HI) or logic 0 (LOW) level. When the input or output levels are

toggling HI and LOW at short durations (example 10 microseconds) an oscilloscope should be

used, since these level changes could not been seen otherwise. Table 3-5 is a summary of

possible IC failure.

Table 3-4.

54/74 Series IC Alpha Character Significance

ALPHA CHARACTER SIGNIFICANCE

None Standard Transistor-Transistor-Logic (TTL).

S Schottky-clamped TTL device. Contains the integrated Schottky-

Barrier diode-clamped transistor circuitry.

LS Low-power Schottky TTL device.

AS Advanced Schottky TTL device.

ALS Advanced Low-power Schottky TTL device.

HC High-speed CMOS device. Requires special ESDS handling.

HCT High-speed CMOS with TTL input voltage level compatibility.

Requires special ESDS handling.

AC Advanced CMOS device. Requires special ESDS handling.

ACT Advanced CMOS with input TTL compatibility. Requires special

ESDS handling.

Table 3-5.

Summary of Possible IC Failures

FAILURE SYMPTOM

Inputs Shorted Together (Quite Common) Identical signals/changes in signal level

between normally isolated inputs.

Ground Open No LO can be obtained.

Vcc Open No HI can be obtained.

Inputs or Output Open Constant Incorrect Logic Level

Inputs or Output Shorted to Vcc Constant HI

Inputs to Ground or Output Shorted Constant LO

The document reference is online, please check the correspondence between the online documentation and the printed version.

3-14 TM109902 (5/03)

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS DOCUMENT.

COMMAND SYSTEMS DIVISION

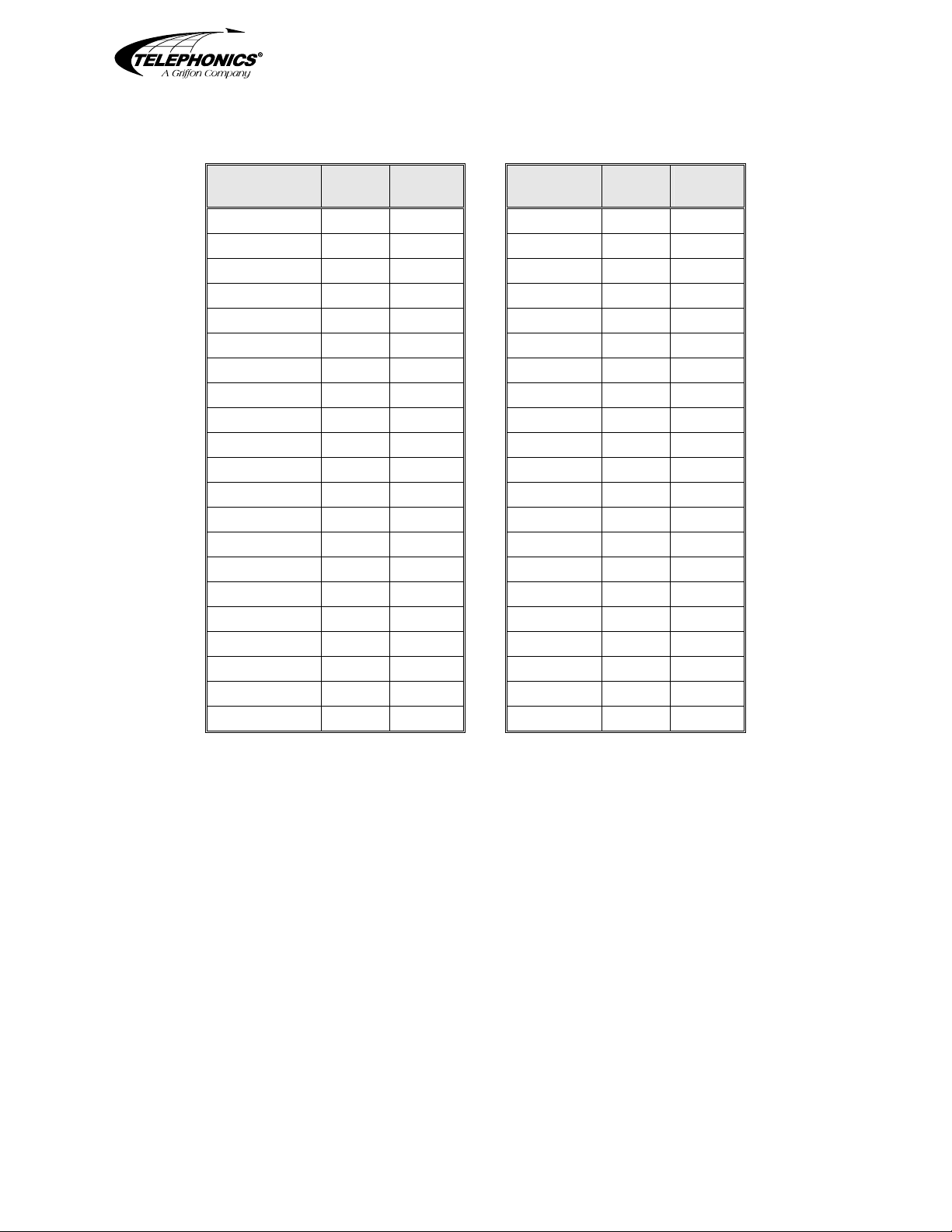

Table 3-6.

Index to Integrated Circuits

TYPE

NUMBER

FIG 3-3

SHT N0.

IC DWG

REF N0.

TYPE

NUMBER

FIG 3-3

SHT N0.

IC DWG

REF N0.

AM1408-L81 1 98 TL082IP 1 114

CA3083 4 287 TL084IN 1 104

CA3102E 6 829 TL604IP 8 205

D2732A-2 3 612 TMS2532JL 7 543

D27C256 4 622 51023-0006 7 233

EP320DC 5 732 52720N 4 IC277

LM1596H 2 390 54121 15 IC400

LM218H 2 355 54LSOO 6 19

LM224N 2 524 54LS04 8 220

LM311N 2 252 54LS08 8 127

LM320T-12 6 228 54LS11 8 187

LM340T-05 6 124 54LS151 9 192

LM340T-12 6 124 54LS163A 10 273

LM393 7 369 54LS193 11 197

MC1514L 2 277 54LS221 14 746

MC1558UDS 1 177 54LS32 8 147

MC3302P 6 244 54LS374 12 274

MC3403 6 706 74LS629 13 597

MH0026CN 1 70 78L02 8 314

NE555N 12 17 7912UC 2 IC131

REF-012 1 511 825123 15 IC832

The document reference is online, please check the correspondence between the online documentation and the printed version.

TM109902 (5/03) 3-15

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS DOCUMENT.

COMMAND SYSTEMS DIVISION

A

IC-0

1

1

4

4

3

3

2

2

8

10

5

7

6

8

7

9

1

4

5

6

7

3

214

11

10

9

8

12

13

BC

1

4

5

6

7

3

2

8

16

13

12

11

10

14

15

9

C

1

4

5

6

7

3

2

8

16

13

12

11

10

14

15

9

D

1

4

5

6

7

3

2

8

18

15

14

13

12

11

10

16

17

9

1

4

5

6

7

3

2

8

18

15

14

13

19

20

12

11

16

17

9

10

18

15

14

13

19

20

12

21

22

16

17

1

4

5

6

7

3

2

8

9

10

11

18

15

14

19

20

21

22

23

24

16

17

1

4

5

6

7

3

2

8

9

10

11

12 13

21

18

17

22

23

24

25

26

27

28

19

20

1

4

5

6

7

3

2

8

9

10

11

12 16

15

14

13

33

30

29

34

35

36

21

22

23

24

25

37

38

39

40

31

32

11

3

4

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

2

4

5

6

7

3

2

8

9

10

11

12 28

27

26

14

13

EF

TAB

TAB

GH

15

16

17

18

19

20

181

2

345

6

7

10 9

8

7

6

5

4

3

2

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

56

1

3

24

6

5

TAB

110 9

8

7

6

5

4

3

2

41

38

37

42

43

44

29

30

31

32

33

45

46

47

48

39

40

1

4

5

6

7

3

2

8

9

10

11

12 36

35

34

14

13

15

16

17

18

19

20 2821 27

22 2623 25

24

JK

L

M

N

R

QP

30663

Figure 3-2. Integrated Circuit Base Configurations

The document reference is online, please check the correspondence between the online documentation and the printed version.

3-16 TM109902 (5/03)

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS DOCUMENT.

COMMAND SYSTEMS DIVISION

Figure 3-3. Integrated Circuit Logic Diagrams (Sheet 1 of 15)

The document reference is online, please check the correspondence between the online documentation and the printed version.

TM109902 (5/03) 3-17

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS DOCUMENT.

COMMAND SYSTEMS DIVISION

Figure 3-3. Integrated Circuit Logic Diagrams (Sheet 2 of 15)

The document reference is online, please check the correspondence between the online documentation and the printed version.

3-18 TM109902 (5/03)

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS DOCUMENT.

COMMAND SYSTEMS DIVISION

A7

A6

A5

A4

A3

A2

A1

A0

Q1

Q2

Q3

GND

VCC

A8

A9

A11

C/VPP

A10

E

Q8

Q7

Q6

Q5

Q4

1

2

3

4

5

6

7

8

9

10

11

12

IC62

VCC

QE

QE

CE LOGIC

QE AND

V

DECODER

OUTPUT BUFFERS

DATA OUTPUTS

00-07

Y GATING

32.768 BIT

CELL MATRIX

32.768 BIT

CELL MATRIX

CE

VPP

GND

PIN NOMENCLATURE

AQ-A11

E

C/VPP

Q1-Q8

VCC

13

14

15

16

17

18

19

20

21

22

23

24

A

DDRESS

CHIP ENABLE

OUTPUT/ENABLE/+21V

OUTPUTS

+15V POWER SUPPLY

X

DECODER

30761

AC-ALL

ADDRESS

INPUT

TYPE: 2732

DESCRIPTION: 32K (4KXB) UY ERASABLE FROM

PIN LOCATION DRAWING: G

MOS DEVICE: USE SPECIAL HANDLING PROCEDURE

•

•

•

•

•

•

•

•

Figure 3-3. Integrated Circuit Logic Diagrams (Sheet 3 of 15)

The document reference is online, please check the correspondence between the online documentation and the printed version.

TM109902 (5/03) 3-19

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS DOCUMENT.

COMMAND SYSTEMS DIVISION

Figure 3-3. Integrated Circuit Logic Diagrams (Sheet 4 of 15)

The document reference is online, please check the correspondence between the online documentation and the printed version.

3-20 TM109902 (5/03)

USE OR DISCLOSURE OF DATA CONTAINED ON THIS PAGE IS SUBJECT TO THE

RESTRICTION ON THE TITLE PAGE OF THIS DOCUMENT.

COMMAND SYSTEMS DIVISION

0

30

7

63

36

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

534

1

TYPE: EP320DC

DESCRIPTION: ERASABLE PAROGRAMABLE LOGIC DEVICE

PN LOCATION DRAWING: E

ESDS DEVICE: USE ESPECIAL

HANDLING PROCEDURES

2

0

1

8

7

6

5

4

3

36

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

534

1

IC732 2

I

/O

ARCHITECTURE

CPNTROL

19

276

54

32

10

0E

I

/

O

A

RCHITECTURE

CPNTROL

18

76

54

32

10

0E

I

/

O

A

RCHITECTURE

CPNTROL

17

76

54

32

10

0E

I

/

O

A

RCHITECTURE

CPNTROL

16

76

54

32

10

0E

I

/

O

A

RCHITECTURE

CPNTROL

15

76

54

32

10

0E

I

/

O

A

RCHITECTURE

CPNTROL

14

76

54

32

10

0E

I

/

O

A

RCHITECTURE

CPNTROL

13

76

54

32

10

0E

I

/

O

A

RCHITECTURE

CPNTROL

12

76

54

32

10

0E

11

9

Figure 3-3. Integrated Circuit Logic Diagrams (Sheet 5 of 15)

The document reference is online, please check the correspondence between the online documentation and the printed version.