RSR ECM Fan/Filter Unit

Installation and Operation Manual Doc. 1788-25

© Copyright 2018 Terra Universal Inc.

All rights reserved Revised November 2019

Terra Universal, Inc. • TerraUniversal.com • 800 S. Raymond Ave. • Fullerton, CA 92831 • TEL: (714) 578-6000 • FAX: (714) 578-6020 1

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

This manual pertains to proprietary

devices manufactured by Terra

Universal, Inc. Neither this

document nor any portion of it may

be reproduced in any way without

prior written permission from Terra

A thorough familiarity with all operating guidelines is

essential to safe operation of the product. Failure to

observe safety precautions could result in poor

performance, damage to the system or other

property, or serious bodily injury or death. The

following symbols are intended to call your attention

to two levels of hazard involved in operation.

Terra Universal makes no

warranties applying to information

contained in this manual or its

suitability for any implied or inferred

purpose. Terra Universal shall not

be held liable for any errors this

manual contains or for any

damages that result from its use.

CAUTION

Cautions are used when failure

to observe instructions could

result in significant damage to

equipment.

WARNING

Warnings are used when failure

to observe instructions or

precautions could result in

injury or death.

The information presented here is subject to change without notice.

1.0 Introduction

This manual documents the operational guidelines for Terra Universal’s Smart

WhisperFlow™ RSR (Room-Side Replaceable) EC (Electronically Commutated)

Motor Fan/Filter Unit.

The Smart WhisperFlow™ ECM FFU provides uniform, laminar flow HEPA-filtered air to

the area below the mounted unit. This unit incorporates Whisperflow™ advanced

baffling technology to reduce noise and ensure uniform airflow.

The Smart WhisperFlow™ ECM Fan/Filter Unit uses an integrated control module

referred to in this manual as the EC Motor Control Card. The Control Card features can

be accessed at the EC Motor Control panel located on the motor housing, above the

HEPA filter housing.

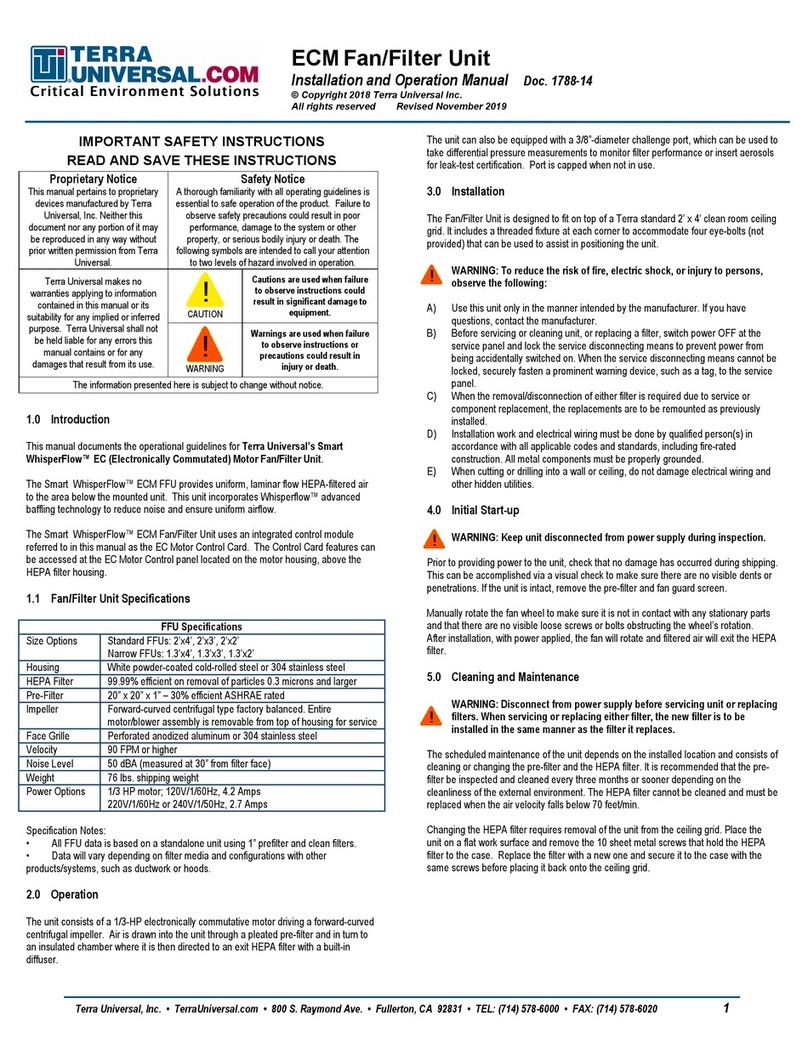

1.1 Fan/Filter Unit Specifications

White powder-coated cold-rolled steel or 304 stainless steel

99.99% efficient on removal of particles 0.3 microns and larger

20” x 20” x 1” – 30% efficient ASHRAE rated

Forward-curved centrifugal type factory balanced. Entire

motor/blower assembly is removable from top of housing for service

50 dBA (measured at 30” from filter face)

76 lbs., 58 lbs., 49 lbs.

1/3 HP motor; 120V/1/60Hz, 4.2 Amps

220V/1/60Hz or 240V/1/50Hz, 2.7 Amps

Specification Notes:

• All FFU data is based on a standalone unit using 1” prefilter and clean filters.

• Data will vary depending on filter media and configurations with other

products/systems, such as ductwork or hoods.

2.0 Operation

The unit consists of a 1/3-HP electronically commutative motor driving a forward-curved

centrifugal impeller. Air is drawn into the unit through a pleated pre-filter and in turn to

an insulated chamber where it is then directed to an exit HEPA filter with a built-in

diffuser.

The unit can also be equipped with a 3/8”-diameter challenge port, which can be used to

take differential pressure measurements to monitor filter performance or insert aerosols

for leak-test certification. Port is capped when not in use.

3.0 Installation

The Fan/Filter Unit is designed to fit on top of a Terra standard 2’ x 4’ clean room ceiling

grid. It includes a threaded fixture at each corner to accommodate four eye-bolts (not

provided) that can be used to assist in positioning the unit.

WARNING: To reduce the risk of fire, electric shock, or injury to persons,

observe the following:

A) Use this unit only in the manner intended by the manufacturer. If you have

questions, contact the manufacturer.

B) Before servicing or cleaning unit, or replacing a filter, switch power OFF at the

service panel and lock the service disconnecting means to prevent power from

being accidentally switched on. When the service disconnecting means cannot be

locked, securely fasten a prominent warning device, such as a tag, to the service

panel.

C) When the removal/disconnection of either filter is required due to service or

component replacement, the replacements are to be remounted as previously

installed.

D) Installation work and electrical wiring must be done by qualified person(s) in

accordance with all applicable codes and standards, including fire-rated

construction. All metal components must be properly grounded.

E) When cutting or drilling into a wall or ceiling, do not damage electrical wiring and

other hidden utilities.

4.0 Initial Start-up

WARNING: Keep unit disconnected from power supply during inspection.

Prior to providing power to the unit, check that no damage has occurred during shipping.

This can be accomplished via a visual check to make sure there are no visible dents or

penetrations. If the unit is intact, remove the pre-filter and fan guard screen.

Manually rotate the fan wheel to make sure it is not in contact with any stationary parts

and that there are no visible loose screws or bolts obstructing the wheel’s rotation.

After installation, with power applied, the fan will rotate and filtered air will exit the HEPA

filter.

5.0 Cleaning and Maintenance

WARNING: Disconnect from power supply before servicing unit or replacing

filters. When servicing or replacing either filter, the new filter is to be

installed in the same manner as the filter it replaces.

The scheduled maintenance of the unit depends on the installed location and consists of

cleaning or changing the pre-filter and the HEPA filter. It is recommended that the pre-

filter be inspected and cleaned every three months or sooner depending on the

cleanliness of the external environment. The HEPA filter cannot be cleaned and must be

replaced when the air velocity falls below 70 feet/min.