Terra WhisperFlow RSR User manual

Explosion-Proof RSR Fan/Filter Unit

Quick-Start Operating Guide Doc . 1788-12

© Copyright 2015 Terra Universal Inc.

All rights reserved Revised November 2019

Terra Universal, Inc. • TerraUniversal.com • 800 S. Raymond Ave. • Fullerton, CA 92831 • TEL: (714) 578-6000 • FAX: (714) 578-6020 1

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

Proprietary Notice

This manual pertains to proprietary

devices manufactured by Terra

Universal, Inc. Neither this

document nor any portion of it may

be reproduced in any way without

prior written permission from Terra

Universal.

Safety Notice

A thorough familiarity with all operating guidelines is

essential to safe operation of the product. Failure to

observe safety precautions could result in poor

performance, damage to the system or other

property, or serious bodily injury or death. The

following symbols are intended to call your attention

to two levels of hazard involved in operation.

Terra Universal makes no

warranties applying to information

contained in this manual or its

suitability for any implied or inferred

purpose. Terra Universal shall not

be held liable for any errors this

manual contains or for any

damages that result from its use.

CAUTION

Cautions are used when failure

to observe instructions could

result in significant damage to

equipment.

WARNING

Warnings are used when failure

to observe instructions or

precautions could result in

injury or death.

The information presented here is subject to change without notice.

1.0 Introduction

This manual documents installation and operation of Terra Universal’s Room-Side

Replaceable (RSR) Explosion-Proof WhisperFlow™ Fan/Filter Unit (FFU). The FFU

provides uniform, laminar flow, HEPA-filtered air to the area below the mounted unit.

2.0 Operation

The unit consists of a ¼-HP, explosion-

proof motor driving a forward-curved

centrifugal blower. Air is drawn into the

unit through a pleated pre-filter and in

turn to an insulated chamber where it is

then directed to an exit HEPA filter with

a built-in diffuser.

The unit can also be equipped with a

3/8”-diameter challenge port, shown in

photo to the right. Take differential

pressure measurements to monitor filter performance, and insert aerosols for leak-test

certification. Port is capped when not in use.

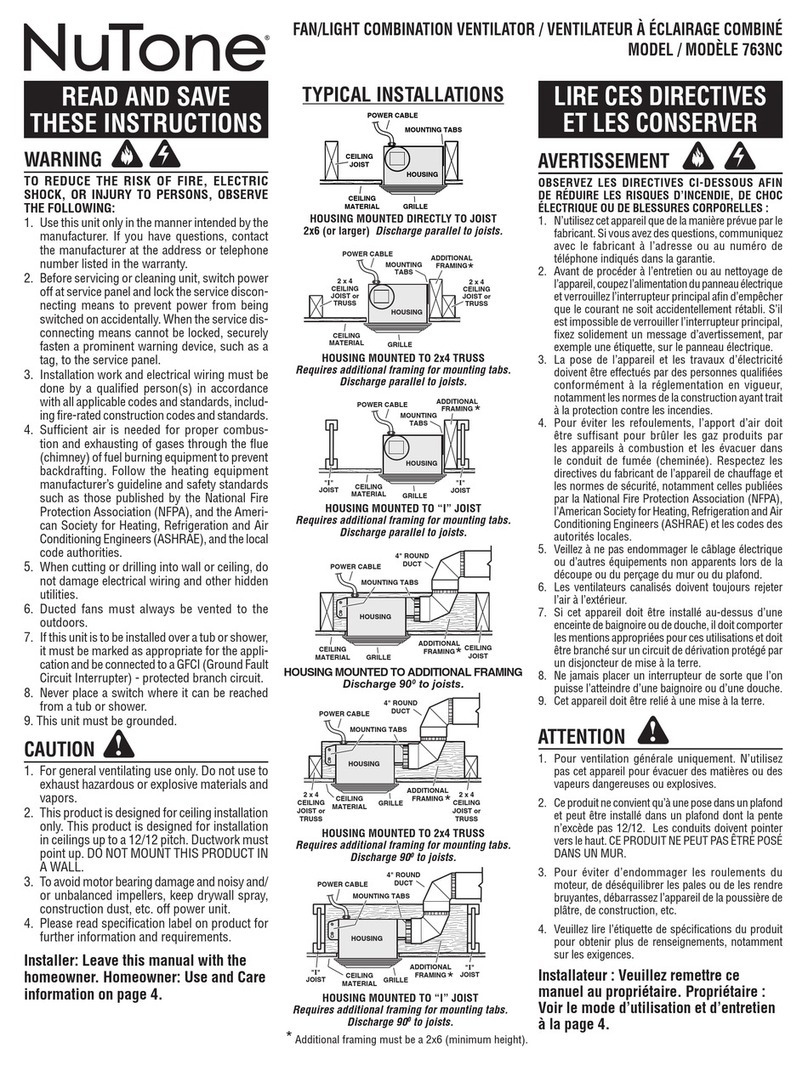

3.0 Installation

The RSR WhisperFlow FFU is designed to allow filter replacement from the inside of the

cleanroom, without breaching the seal. A gel-sealed filter can be separated from the fan

module for replacement. The fan module stays in place on top of a standard 2’x4’ clean

room ceiling grid and includes a threaded fixture at each corner to accommodate four

eye-bolts (not provided) that can be used to assist in positioning the unit.

All metal components are grounded. A grounding wire is clipped to metal hardware on the

filter screen as well as the metal threads running through the pre-filter mesh. Make certain

that these wires are in place before final installation.

WARNING:

To reduce the risk of fire, electric shock, or injury to persons, do not

use this fan with any solid-state speed control device, and observe the

following:

A) Use this unit only in the manner intended by the manufacturer. If you have questions,

contact the manufacturer.

B) Before servicing or cleaning unit, or replacing a filter, switch power OFF at the

service panel and lock the service disconnecting means to prevent power from being

accidentally switched on. When the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a tag, to the service panel.

C) When the removal/disconnection of either filter is required due to service or

component replacement, they are to be remounted as previously installed.

D) Installation work and electrical wiring must be done by qualified person(s) in

accordance with all applicable codes and standards, including fire-rated construction.

All metal components must be properly grounded.

E) When cutting or drilling into a wall or ceiling, do not damage electrical wiring and

other hidden utilities.

4.0 Start up

WARNING:

Keep unit disconnected from power supply during inspection

Prior to providing power to the unit, check that no damage has occurred during shipping.

This can be accomplished via a visual check to make sure there are no visible dents or

penetrations. If the unit is intact, unclip the grounding wire and remove the pre-filter.

Manually rotate the fan wheel to make sure it is not in contact with any stationary parts

and that there are no visible loose screws or bolts obstructing the wheel’s rotation. Once

visual inspection is completed, have a professional perform the installation who is familiar

with Class I, Groups C & D and Class II, Groups F & G hazardous location requirements.

NOTE: Remember to replace the filter-screen and pre-filter grounding wires. After

installation, with power applied, the fan will rotate, and filtered air will exit the HEPA filter.

5.0 Cleaning and Maintenance

WARNING:

Disconnect from power supply before servicing unit or replacing

filters. When servicing or replacing either filter, the new filter is to be

installed in the same manner as the filter it replaces.

The scheduled maintenance of the unit depends on the installed location and consists of

cleaning or changing the pre-filter and the HEPA filter. It is recommended that the pre-

filter be inspected and cleaned every three months or sooner depending on the

cleanliness of the external environment. The HEPA filter cannot be cleaned and must be

replaced when the laminar flow rate falls below 70 feet/min.

Explosion-proof FFU to be installed with wiring embedded in filled rigid conduit.

5.1 Replacing the RSR Filters

The RSR filter is designed so that the HEPA or ULPA filter can be replaced from inside

the cleanroom without breaching the controlled environment. The filter assembly is

detached from the fan module, which stays in place in the ceiling grid. Follow these

instructions to replace the filter.

First, you must remove the outer screen covering the filter that is held in place with friction

catches (Photo 1). This screen protects the filter from damage and enhances airflow

uniformity. While gently pulling on the screen to disengage the catches, detach the

grounding wire clip as shown in Photo 2. The clip is attached to a steel rivet holding one

of the catches in place.

Photo 1: Friction catches hold the screen to the fan module housing.

Pre-Filter

Lid

Assembly

HEPA/ULPA

Filter

Grounding

Wire

Optional

Challenge

Port

Explosion-Proof RSR Fan/Filter Unit

Quick-Start Operating Guide Doc . 1788-12

© Copyright 2015 Terra Universal Inc.

All rights reserved Revised November 2019

Terra Universal, Inc. • TerraUniversal.com • 800 S. Raymond Ave. • Fullerton, CA 92831 • TEL: (714) 578-6000 • FAX: (714) 578-6020 1

Photo 2: Remove grounding clip from the steel rivet post on the back side of the outer

filter screen.

Next, remove the anodized aluminum face grille by rotating the metal tabs that help hold

the grille in place and provide grounding (see Photo 3). The tabs fit tightly and will scrap

across the anodized layer, exposing the metal beneath; this is critical for successful

grounding as the anodized layer is non-conductive.

Photo 3: Filter-face grille’s metal tabs.

Gently let the used filter drop down, and set aside. The filter assembly is surrounded by

a channel containing gel seal. Wipe any residual gel from the knife-edge of the fan

module still in the ceiling to prepare for the replacement filter. Position your new filter

carefully before pushing into place; the knife-edge of the fan module should be centered

in the channel (equal amounts of gel on both sides). Photo 4 shows the gel-filled

channel of the RSR filter.

Photo 4: Gel-filled channel of RSR filter.

Replace the face grille and rotate the metal tabs so that they cover the frame. Check to

be sure that the tabs are in direct contact with areas of the frame where the anodized

layer has been scraped off. This is important for grounding. Reattach the grounding clip

to the rivet on the outer screen, and then re-engage the friction catches.

To replace or clean the pre-filter located at the top of the fan module, qualified personnel

will need access to the ceiling grid. Un-clip the grounding wire and slide the filter out of

the two tracks holding it in place. When finished, put the filter back in place and make

certain that the grounding wire is clipped to metal threads running through the filter mesh.

Photo 5: Clipping the grounding wire to metal threads in the pre-filter.

6.0 Specifications

Dimensions: 23.625"W x 47.625"L x 20.2"H (600 mm x 1210 mm x 513 mm)

Housing: Stainless steel

HEPA Filter: 99.99% efficient on removal of particles 0.3 microns and larger

Pre-Filter: 20" x 20" x 1" - 30% efficient ASHRAE rated

Blower: Forward-curved centrifugal type factory balanced. Entire motor/blower

assembly is removable from top of housing for service

Motor: 1/4 HP Direct drive, Explosion-proof, 1 Phase

Electrical: Motor wiring should only be connected to an appropriate control unit. All

wiring should be housed by UL-listed rigid conduit

Power Cord: None supplied

Face Grille: Perforated anodized aluminum

Noise Level: 50 dBA (measured at 30" from filter face)

Weight: 76 lbs. (35.5 kg) shipping weight

Support: Threaded screw receptacles provided for insertion of optional eyebolts

Power Options: ¼ HP motor with voltage of 115/1/60Hz, 208-230/1/60Hz

Power Specifications: for 2 ft. x 4 ft. HEPA, 115VAC (Model No. 6601-24HE)

Full Load Amps 6.8

Watts 190

Specification Notes:

• All FFU data is based on a standalone unit using 1” prefilter and clean filters.

• Data will vary depending on filter media and configurations with other

products/systems, such as ductwork or hoods.

7.0 Warranty

See last section.

Quick-Start Operating Guide

High- Filter/Fan Unit

© Copyright 2015 Terra Universal Inc. All rights reserved • Revised November 2019 • Document 1788-12

Terra Universal, Inc. • TerraUniversal.com • 800 S. Raymond Ave. • Fullerton, CA 92831 • TEL: (714) 578-6000 • FAX: (714) 578-6020 3

Limited Warranty

Products Manufactured by Terra: Terra Universal, Inc., warrants products that it manufactures to be free from defects for

a period of 12 months for parts and 90 days for labor, commencing from the date of shipment. Terra’s sole responsibility is

to repair or replace, at its option, any part of the product that proves defective or malfunctioning during this time limit. In

some cases, components incorporated in Terra Universal products are covered by additional warranties from component

manufacturers; obtain specific information from Terra sales representatives. This warranty is void if the equipment is

abused or modified by the customer, is operated outside Terra’s operating instructions or specifications, or is used in any

application other than that for which it is specified. This warranty does not include routine maintenance or service

procedures, breakage of quartz baths after 60 days, shipping damage, nor damage from misuse, intentional or

unintentional abuse, neglect, natural disasters, or acts of God.

Products Manufactured by Others: Terra Universal, Inc., warrants that, to the best of its ability, Terra’s representations

of products that are manufactured by others reflect the manufacturer’s representations, subject to change without notice.

Sole warranty for these products is the original manufacturer’s warranty that is passed forward to the purchaser and

constitutes the customer’s sole remedy for these products. Detailed warranties for distributed products are available

through Terra sales representatives.

Freight Shortage or Damage: Upon receipt of any equipment from Terra Universal, Inc., customer shall immediately

unpack and inspect for damage or shortage. The customer shall not accept a damaged package or a short shipment until

the carrier makes a "damage or shortage" notation on both the carrier's and customer's copy of the freight bill or delivery

receipt. Service title passes when the shipment is loaded, so customer is responsible for filing and collecting a freight

claim. Any replacement products must be ordered and paid for separately. For Terra's "Policy and Procedures for

Returning Goods," see Terra's Internet site: www.TerraUniversal.com.

Generally, customers can improve the chance of collecting on a freight claim by following these procedures: 1) formally

requesting that the carrier inspect the shipment immediately upon suspecting damage or shortage to verify condition; 2)

notifying the carrier upon discovery of concealed damage and requesting an inspection within 15 days of receipt, both in

person or phone and following up via mail; 3) keeping the shipment as intact as possible, including retaining original

packaging materials and keeping the product as close to the original receiving location as possible; 4) holding salvage for

disposition by the carrier.

All Claims: Terra Universal expressly disclaims all other warranties, expressed or implied or implied by statute, including

the warranties of merchantability or fitness for intended use. Terra Universal is not responsible for consequential or

incidental damages arising out of the purchase or use of the products supplied by Terra Universal. Terra Universal is not

liable for damage to facilities, other equipment, products, property or personnel of others, or of their agents, suppliers, or

affiliated parties, which is caused or alleged to have been caused by products supplied by Terra Universal. In any event or

series of events, Terra Universal’s total liability for any and all damages whatsoever is limited to the lesser of the actual

damages or the original invoice cost of the items alleged to have caused the damage. The customer’s sole and exclusive

remedy for any cause of action whatsoever is repair or replacement of the non-conforming products or refund of the actual

purchase price, at the sole option of Terra Universal. All claims must be made in writing within 90 days of the date the

product was shipped. Any claims not made within this time limit shall be deemed waived by the customer. Terra Universal

is not responsible for any additional costs of repair caused by poor packaging or in-shipment damage during return.

Warranty Returns: All warranty returns must be authorized in advance by Terra Universal and approved under an RMA.

Unless approved in advance for good reason, all returns must be in original condition, including all manuals, and must be

packaged in original packaging materials. All returned goods are to be shipped to Terra Universal, freight prepaid at

customer’s expense. See Terra’s “Policy and Procedure for Returned Goods.”

Thank you for ordering from

Terra Universal!

This manual suits for next models

1

Popular Fan manuals by other brands

ELTA FANS

ELTA FANS H03VV-F installation guide

Fanimation

Fanimation AMPED FP7634 Series manual

OBO Bettermann

OBO Bettermann EÜK VK Series Mounting instructions

Vortice

Vortice EVOLUTION LIGHT KIT ES Instruction booklet

Hunter

Hunter Metro FAN24211METBN installation manual

Westinghouse

Westinghouse 73001 manual