TERSO TS088 User manual

EDOC00092 –ULT RFID Freezer User Manual, REV6 –8/16/2023 1

Ultra Low

Temperature

RFID Freezer

TS088

EDOC00092 –ULT RFID Freezer User Manual, REV6 –8/16/2023 2

TABLE OF CONTENTS

INTRODUCTION ...................................................................................... 3

PRECAUTIONS FOR SAFE OPERATIONS ...................................................... 3

CAUTIONS WHEN USING.......................................................................... 6

ENVIRONMENTAL CONDITIONS................................................................. 6

COMPONENTS......................................................................................... 7

INSTALLATION........................................................................................ 9

OPERATING INSTRUCTIONS ................................................................... 10

MAINTENANCE ...................................................................................... 11

TROUBLESHOOTING .............................................................................. 12

SPECIFICATIONS .................................................................................. 13

MODEL SPECIFICS................................................................................. 13

SAFETY CHECKLIST ............................................................................... 14

APPENDIX A: HANDLING LIQUID NITROGEN............................................. 15

APPENDIX B: HANDLING LIQUID CO2...................................................... 17

APPENDIX C: EXPECTED TEMPERATURE PERFORMANCE ............................. 18

EDOC00092 –ULT RFID Freezer User Manual, REV6 –8/16/2023 3

INTRODUCTION

Read this manual carefully before using the device and follow the instructions for safe operation.

Terso Solutions does not guarantee safe operation if the device is not used as outlined in this manual.

Keep this manual in an easily accessible place to refer to as necessary.

The contents of this manual are subject to change without notice due to improvement in performance or

functions.

Contact Terso Solutions Technical Support with operational questions or if a replacement manual is

needed.

PRECAUTIONS FOR SAFE OPERATIONS

User compliance with operational guidelines outlined in this manual are imperative for user safety and

device longevity.

Items and procedures are described so that this device may be used correctly and safely. Following the

precautions advised will prevent possible injury to the user and any other person.

Precautions are illustrated in the following way:

Failure to observe WARNING signs could result in

a hazard to user possibly resulting in serious

injury or death.

Only use the system as specified in these

instructions.

Failure to observe CAUTION signs could result in

injury to user and damage to the device and

associated property.

This symbol means an action is prohibited.

This symbol means an instruction must be

followed

Caution, read all accompanying documents before

operating the device.

This label is on the cover in which the electrical

components of high voltage are enclosed to

prevent electrical shock.

This mark indicates the location of the protective earth conductor. Do not disconnect. Disconnection of

the protective earth conductor may impair the protection provided by the device.

EDOC00092 –ULT RFID Freezer User Manual, REV6 –8/16/2023 4

Risk of shock is present inside the device. The cover should be removed by qualified engineers

or service user only.

Do not use the device outdoors. Current leakage or electric shock may result if device is

exposed to rainwater.

Install the device on a sturdy floor. If the floor is not strong enough or the installation site is not

adequate, injury may result from the device falling or tipping over.

Do not install the device in a flammable or volatile location. This may cause explosion or fire.

Do not install the device where acid or corrosive gases are present as current leakage or

electrical shock may result due to corrosion.

Make sure a dedicated power source is used as indicated on the rating label attached to the

device.

Make sure to remove dust from the power supply plug before inserting in a power source. A

dusty plug or improper insertion may pose a hazard.

Use a power supply outlet with ground (earth) to prevent electric shock. If the power supply

outlet is not grounded, it will be necessary to have qualified engineers install a ground.

When removing the plug from the power supply outlet, grip the power supply plug, not the cord.

Pulling the cord may result in electric shock or fire by short circuit.

Do not damage or break the power supply plug or cord. Do not use the supply plug if its cord is

loose. This may cause fire or electric shock.

Do not touch any electrical parts such as power supply plug or any switches with a wet hand.

This may cause electric shock.

Do not ground the device through a gas pipe, water main, telephone line or lightening rod. Such

grounding may cause electric shock in the case of an incomplete circuit.

Do not insert metal objects such as a pin or wire into any outlet, vent or gap for inner air

circulation. This may cause electric shock.

If this device is to be used for storing poisons, radioactive material or other harmful products,

ensure that it is in a safe area. Failure to do so may lead to an adverse effect on the health of

others in the area and local environment. In this case, a request for repair or maintenance will

necessitate a safety check sheet for maintenance personnel and that the device is clearly

labeled to show such materials.

Do not splash water directly onto the device as this may cause electric shock or short circuit.

EDOC00092 –ULT RFID Freezer User Manual, REV6 –8/16/2023 5

Do not disassemble, repair, or modify this device yourself. Any such work carried out by

unauthorized personnel may result in fire or injury due to a malfunction.

Disconnect the power supply plug if there is something wrong with the device. Continued

abnormal operation may cause electric shock or fire.

If the device is to be stored unused in an unsupervised area for an extended period, ensure that

children do not have access and that doors cannot be closed completely.

Make sure to prepare a safety check sheet when you request any repair or maintenance for the

safety of service personnel.

Select a level and sturdy floor for installation. This precaution will prevent the device from

tipping. Improper installation may result in injury from the device tipping over.

Do not disconnect the protective earth conductor. Disconnection may impair the protection

provided by the device.

Do not place any switches or disconnect devices in the earth conductor.

Do not touch any internal items, especially metal, without a glove. This may cause frostbite.

Do not climb onto the device. This may cause injury by tipping or damage to the device.

Always hold the handle when closing the door. This will reduce the likelihood of hand injury.

Do not lean on the door. This may cause injury if the device tips.

Always disconnect the power supply plug before moving the device. Take care not to damage

the power cord. A damaged cord may cause electric shock or fire.

Be careful not to tip over the device during movement to prevent damage or injury.

Always disconnect the power plug when the device is not in use for long periods of time.

Always disconnect the power supply to the device prior to any repair or maintenance of the

device to prevent electric shock or injury.

EDOC00092 –ULT RFID Freezer User Manual, REV6 –8/16/2023 6

CAUTIONS WHEN USING

1. Always use gloves when handling items within the device.

2. Never store corrosive materials such as acid or alkali unless container is completely sealed up.

Corrosion may lead to failure of the device in time.

3. Always close the door firmly. The door open alarm will sound after the door is open longer than

predetermined time, normally about five seconds. Alarm condition will be canceled automatically

when the door is closed.

4. Always open and close the door gently. Rough operation may lead to shifting of stored products,

incomplete closing, or damage of the door and/or locking mechanism.

5. A vacuum can be created after a door opening. This device is equipped with a vacuum relief port

to equalize the pressure within the device after a door opening. Allow up to two minutes for the

pressure to equalize. The device door may not be accessible until the device has equalized.

6. Product should be added to the device in small batches to minimize temperature instability.

7. If condensation forms on the inside of the door or shelves it may be wiped off with a dry soft cloth.

ENVIRONMENTAL CONDITIONS

The device is designed to be safe under the following conditions:

1. Indoor use only

2. Up to 2000 m / 6550 ft altitude

3. 15 °C to 30 °C, ≤ 80% relative humidity

4. Over Voltage Category II

5. Pollution Degree 2 (normal office conditions)

6. Peak operating noise level of 54 dB

7. Mains supply voltage fluctuations up to ± 10% of the nominal voltage.

EDOC00092 –ULT RFID Freezer User Manual, REV6 –8/16/2023 7

COMPONENTS

Device Component Locations

Figure 1

A. Freezer Bezel Panel

B. Terso Electronics Top Face

C. Terso Electronics Bottom Face

Figure 1

EDOC00092 –ULT RFID Freezer User Manual, REV6 –8/16/2023 8

Freezer Bezel Panel

Figure 2

A. Pass reader

B. USB interface jack

C. Terso alarm mute switch

D. LCD display

E. Hardware reset

F. Emergency door release

G. Freezer control panel

Terso Electronics

Figure 3

A. Ethernet jack

B. AC circuit breaker

C. RFID system power switch

Figure 2

Figure 3

EDOC00092 –ULT RFID Freezer User Manual, REV6 –8/16/2023 9

INSTALLATION

Site

The device should be installed in a location that meets the following conditions:

•Reference local state and federal requirements prior to installing device in a medical setting.

•Select a level and sturdy floor for installation to avoid tipping and shifting inventory.

•Do not install device where it could be exposed to water (outdoors, humid locations, or under

water or steam pipes). Water exposure can lead to current leakage or electric shock.

•Never install the device in a flammable or volatile location. This may cause explosion or fire.

•Never install the device where acid or corrosive gases are present. This may cause current

leakage or electric shock.

Installation

Inspection

Before unpacking the device, check for any damage that may have occurred during transit. If any damage

has occurred, contact Terso Solutions Technical Support at +1 888.376.0257.

Unpacking

Remove device packaging. Gently position the device in place on the ground. Remove accessories from

inside the device. Included accessories are a power cord and Ethernet cable. Other device accessories

such as cables and bins, or other device specific items may be included.

Proper Handling

Device can be rolled to desired location for installation. For easiest transport, disengage wheel locks and

roll device by firmly pushing the middle section of the body. Do not use the door handle to pull the device.

Always move the device with the door facing you. Carefully roll device into desired location allowing 6

inch (in.) clearance between the device and the wall.

Connecting AC Power

Plug the device into a grounded wall outlet with a minimum of a 20 A rating. See specifications for further

details on outlet electrical requirements. The power outlet must be within 10 feet (ft.) of the device and be

an easily accessible outlet. Position device so on/off switch is easily accessible. In an emergency, the

power cord can act as an off switch.

Connecting Communications

Plug included Ethernet cable into the back panel and then into the appropriate wall data jack or cellular

router.

EDOC00092 –ULT RFID Freezer User Manual, REV6 –8/16/2023 10

Initial Loading

Allow the device to operate at the desired temperature for a minimum of 12 hours before loading with

inventory. Load the device one shelf at a time, beginning with the top shelf. After stocking each shelf

allow the device to recover to desired temperature set point before loading the next shelf. Repeat this

process until the device is fully loaded.

Access Verification

Present access pass to the pass reader located next to the LCD display on the front panel. Once

presented, the display should indicate the door is unlocked. The door will automatically relock and scan

inventory when closed. This can be verified by gently pulling on the door handle.

Remote Alarm Contacts

Alarm contacts on the back of the device are available to wire the device into an alarm system. Contacts

can alarm on high/low temperature, power outages, and control probe failures. Additionally, a 4-20 mA

output is available for remote temperature monitoring.

Backup System Installation

The installation of the backup system should be performed by a qualified representative. Reference

Appendix A and B for details about the dangers and proper handling of LN2and CO2.

OPERATING INSTRUCTIONS

Basic Access Process

User will present an access pass to the pass reader on the device. The LCD display will indicate granted

access when a valid access pass has been presented.

The user will now be able to open the device door to interact with products. The device will unlock for five

seconds, if it is not opened within this time the user will have to present their access pass again. The

device will give an audible alarm if the door is left open for one minute or other predetermined time.

Once products have been added or retrieved, firmly close the device door. The door will automatically

lock, and the inventory process will begin. The inventory process will take about a minute to complete.

Resulting updated inventory will then be sent to Terso Solutions for processing. The device will not be

accessible during the inventory process. Access is restored after completion of the inventory scan and the

process can be repeated.

Alarms

All device alarms are automatically sent to Terso Solutions. Terso Solutions staff may contact on-site

personnel to assist in correcting any potential problem.

Alarm Types

Door Open

When the device door is left open for longer 2 minutes (may vary from device to device as it is dependent

on preconfigured device settings), an audible alarm will sound, and the LCD display will show “Please

close door” until the door is closed. If the door appears to be closed, verify nothing is obstructing the door

and attempt to re-close.

Power Outage

In the event of a power outage, an audible alarm will sound, the LCD display will show “AC power fail,”

and the freezer display will show “E04”. The alarm will continue until AC power has been restored or the

onboard UPS system runs out of power. Once power has been restored, the device will perform an

inventory scan and return to normal function.

EDOC00092 –ULT RFID Freezer User Manual, REV6 –8/16/2023 11

Temperature

The device continuously monitors its internal temperature where inventory items are kept. If the device

temperature becomes too warm or cold, Terso Solutions staff will contact on site staff to attempt to

troubleshoot and/or transfer temperature sensitive products to a safe location. The device may prevent

access if the integrity of any inventory items has been compromised.

Hardware Failure

The device will automatically attempt to correct any hardware errors preventing regular function.

However, in the event of a hardware component failure, the device may lock down to prevent access.

Terso Solutions staff will be in contact with on-site staff if this occurs.

Door Breach

If the device door is forced open a notification indicating unauthorized access occurred will be sent to

Terso Solutions. Any removed products will be reported.

MAINTENANCE

There are no user-serviceable parts in the device. Please contact Terso Solutions for any service-related

inquiries.

Always disconnect the power supply prior to any repair or maintenance to prevent shock or injury.

Exterior Cleaning

If the device accumulates dust, a dry cloth can be used to wipe off the outside and inside of the device

and/or accessories. If needed on the outer panels, they can be cleaned with a diluted neutral dishwashing

detergent. (Undiluted detergent can damage the plastic components. For the dilution refer to the

instruction of the detergent.) After cleaning with diluted detergent, always use a damp cloth to get rid of

excess detergent. Finally wipe off the device and/or accessories with a dry cloth. Never pour water onto

or into the device, this can cause electric shock or a short circuit.

Do not clean the device with scrubbing brushes, acid, thinner, solvents, powdered soap, cleanser, or hot

water. These agents can damage paint and wrap on the device. Do not use any volatile solvent to clean

the plastic or rubber parts on the device. When a neutral dishwashing detergent is used to clean the

device, wipe it up thoroughly with a cloth soaked in clean water and sanitize with a 70% IPA solution.

Interior Cleaning

If the interior of the device requires cleaning the device must first be defrosted. Refer to any in-house

safety procedures to ensure any frozen materials are handled correctly.

Cleaning the Door Gasket

The door gasket should be cleaned monthly. Using a soft cloth, remove any frost build-up from the gasket

and door(s). The door gasket may need to be cleaned more frequently if dirt or excessive frost build-up

prevents the door from closing properly.

EDOC00092 –ULT RFID Freezer User Manual, REV6 –8/16/2023 12

Cleaning the Air Filter

Device air filter should be cleaned four times a year at a minimum. To clean the air filter:

1. Locate filter on the front of the device.

2. Open the lower door and remove filter from grille.

3. Clean filter by washing in mildly soapy water, then allow to air dry.

4. Reinstall the filter in the grille.

Cleaning the Condenser

Device condenser should be cleaned once per year at a minimum. To clean the condenser:

1. Open the lower door.

2. Clean the condenser using a vacuum cleaner exercising care to not damage the condenser fins.

Depending upon environmental conditions, the condenser may need to be cleaned more frequently.

Defrosting the Chamber

Device chamber should be defrosted promptly if any ice accumulation inhibits normal use of the device or

whenever deemed necessary by in-house procedures. To defrost the device:

1. Relocate all products to another device.

2. Switch device power off and disconnect it from the power source.

3. Select “YES” on the device display by pressing the check mark, confirm “YES” a second time to

power off the device. If not confirmed within 5 minutes the device will go into alarm mode (error

code “E04” will display) until the RFID battery backup is drained or power is restored.

4. Open all the doors and place towels on the chamber floor and beneath the device door.

5. Press the reset button to shut down the control system (see Figure 3)

6. Allow any frost to melt and become loose.

7. Remove remaining frost with a soft cloth.

8. Clean interior of device with a non-chloride detergent after defrosting is complete. Rinse

thoroughly with clean water and dry with a soft cloth.

9. Plug device in and turn the device and the Terso electronics power switch on.

10. The device will automatically begin cooling to the set temperature.

11. Allow the device to operate empty until desired operating temperature is reached before reloading

the products.

High Temperature Alarm Test

The following process will simulate high temperature alarm for system validation.

1. Simultaneously hold the plus (up arrow) and checkmark buttons (square) for 5 seconds to initiate

the warm alarm test.

2. During the warm alarm test the actual cabinet temperature will not be displayed. The display

temperature will increase.

3. Once the display temperature reaches the warm alarm setpoint the alarm is activated.

4. After 5 seconds the test will automatically end, and the display will return to the actual cabinet

temperature.

TROUBLESHOOTING

If the device appears to not be operating correctly, check to ensure that it is plugged into a wall outlet and

powered on. For additional assistance contact Terso Solutions Technical Support at +1 888.376.0257.

Support can also be contacted by visiting http://support.tersosolutions.com.

EDOC00092 –ULT RFID Freezer User Manual, REV6 –8/16/2023 13

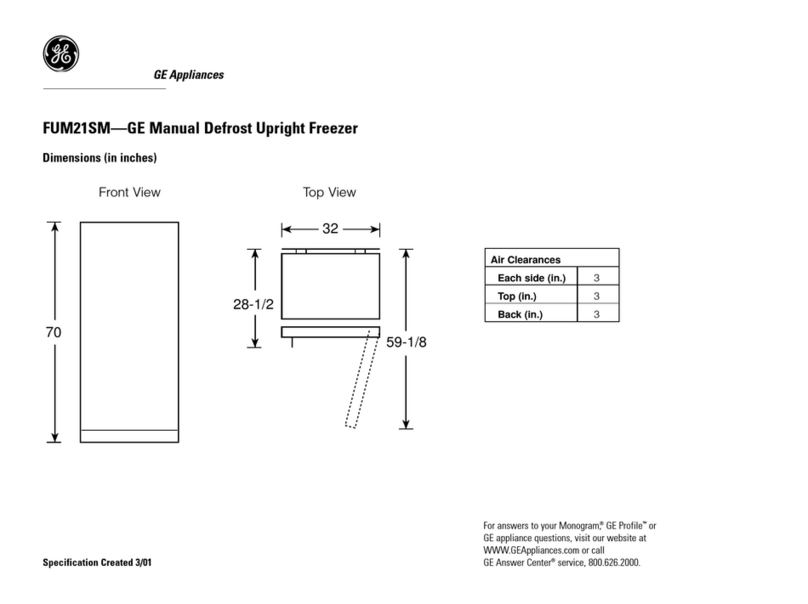

SPECIFICATIONS

FEATURE

SPECIFICATION (IMPERIAL)

SPECIFICATION (METRIC)

External dimensions (H x W x D)

78.0 in. x 23.0 in. X 38.5 in.

1981 mm. x 584 mm. x 978 mm.

Internal dimensions (H x W x D)

51.2 in. x 17.8 in. x 28.3 in

1300 mm. x 452 mm. x 719 mm.

External clearance (H x W x D)

78.0 in. x 50.0 in. x 58.8 in

1981 mm. x 1275 mm. x 1493 mm.

Volume

14.9 ft3

422 L

Device weight

622 lbs.

282 kg

Operating temperature range

-58 °F to -123 °F

-50 °C to -86 °C

Defrost type

Manual

Maximum shelf capacity

40 lbs.

18 kg

Electrical power & frequency

115 VAC, 60 Hz, 13 A

208/230 VAC, 60 Hz, 6 A

Power consumption

10.7 kW/day

RFID battery backup

12 VDC, 1.3 A, SLA, qty 2

Security mechanism

Electronic door lock

Access control

LF: EM4102/EM4200 or HF: multi-band pass reader

Environmental protection

IP41

Refrigerant

CFC/HCFC-Free Environmentally Safe Refrigerant

R290 / R170+R290

Cooling method

2-stage cascade system

CO2and LN2backup systems available upon request

Communications

Ethernet, optional cellular

MODEL SPECIFICS

MODEL

COUNTRY

RFID FREQUENCY

PLUG STYLE

TS088-US-115

US

902-928 MHz

NEMA 5-20P x 1

TS088-US-230

US

902-928 MHz

NEMA 6-15P x 1

Note: Specifications can change without notice

EDOC00092 –ULT RFID Freezer User Manual, REV6 –8/16/2023 14

SAFETY CHECKLIST

Please fill out this form before servicing and ensure that the device is properly marked with any applicable

markings to denote any hazards inside.

Provide this form to the service engineer to keep for safety purposes.

SAFETY CHECKLIST

Device contents:

Risk of infection ...………………………………………………

Yes

No

Risk of toxicity ..…………………………………………………

Yes

No

Risk of radioactive sources ……………………………………

Yes

No

Please list any potentially hazardous materials that have been

stored in this device:

Contamination of the device

No contamination ……………………………………………….

Yes

No

Decontaminated ………………………………………………...

Yes

No

Contaminated …………………………………………………...

Yes

No

EDOC00092 –ULT RFID Freezer User Manual, REV6 –8/16/2023 15

APPENDIX A: HANDLING LIQUID NITROGEN

The safe handling and use of liquid nitrogen in cryogenic refrigerators and dewar flasks are largely a

matter of knowing the potential hazards and using common-sense procedures based on that knowledge.

There are two important properties of liquid nitrogen that present potential hazards:

At atmospheric pressure, liquid nitrogen boils at -196 °C. Very small amounts of liquid vaporize into large

amounts of gas. One liter of liquid nitrogen becomes 24.6 ft3 (700 L) of gas.

The safety precautions must be followed to avoid potential injury or damage which could result from these

two characteristics. Do not attempt to handle liquid nitrogen until you have read and fully understand the

potential hazards, their consequences, and the related safety precautions. Keep this manual handy for

ready reference and review.

Use only containers designed for low temperature liquids.

Cryogenic containers are specifically designed and made of materials that can withstand the rapid

changes and extreme temperature differences encountered in working with liquid nitrogen. Even these

special containers should be filled SLOWLY to minimize the internal stresses that occur when any

material is cooled. Excessive internal stresses can damage the container.

Do not cover or plug the entrance opening of any liquid nitrogen refrigerator or dewar. Do not use any

stopper or other device that would interfere with venting of gas.

These cryogenic liquid containers are generally designed to operate with little or no internal pressure.

Inadequate venting can result in excessive gas pressure which could damage or burst the container. Use

only the loose-fitting necktube core supplied or one of the approved accessories for closing the necktube.

Check the device periodically to be sure that venting is not restricted by accumulated ice or frost.

Use proper transfer equipment.

Use a phase separator or special filling funnel to prevent splashing and spilling when transferring liquid

nitrogen into or from a dewar or refrigerator. The top of the funnel should be partly covered to reduce

splashing. Use only small, easily handled containers for pouring. For larger, heavier containers, use a

cryogenic liquid withdrawal device to transfer liquid from one container to another. Be sure to follow

instructions supplied with the withdrawal device. When liquid cylinders or other large storage containers

are used for filling, follow the instructions supplied with those devices and their accessories.

EDOC00092 –ULT RFID Freezer User Manual, REV6 –8/16/2023 16

Do not overfill containers.

Never use hollow rods or tubes as dipsticks.

When a warm tube is inserted into liquid nitrogen, liquid will spout from the top of the tube due to

gasification and rapid expansion of liquid inside the tube.

Nitrogen gas can cause suffocation without warning.

Store and use liquid nitrogen only in a well-ventilated place.

As the liquid evaporates, the resulting gas tends to displace the normal air from the area. In closed areas,

excessive amounts of nitrogen gas reduce the concentration of oxygen and can result in asphyxiation.

Because nitrogen gas is colorless, odorless, and tasteless. It cannot be detected by the human senses

and will be breathed as if it were air. Breathing an atmosphere that contains less than 18% oxygen can

cause dizziness and quickly result in unconsciousness and death.

Note: The cloudy vapor that appears when liquid nitrogen is exposed to the air is condensed moisture;

not the gas itself. The issuing gas is invisible.

Never dispose of liquid nitrogen in confined areas or places where others may enter.

Disposal of liquid nitrogen should be done outdoors in a safe place. Pour the liquid slowly on gravel or

bare earth where it can evaporate without causing damage. Do not pour the liquid on pavement.

EDOC00092 –ULT RFID Freezer User Manual, REV6 –8/16/2023 17

APPENDIX B: HANDLING LIQUID CO2

High concentrations of CO2gas can cause asphyxiation!

OSHA Standards specify that employee exposure to carbon dioxide in any eight-hour shift of a 40-hour

work week shall not exceed the eight-hour time weighted average of 5000 PPM (0.5% CO2). The short-

term exposure limit for 15 minutes or less is 30,000 PPM (3% CO2). Carbon dioxide monitors are

recommended for confined areas where concentrations of carbon dioxide gas can accumulate.

Store and use liquid CO2only in a well-ventilated place.

As the liquid evaporates, the resulting gas tends to displace the normal air from the area. In closed areas,

excessive amounts of CO2gas reduce the concentration of oxygen and can result in asphyxiation.

Because CO2gas is colorless, odorless, and tasteless, it cannot be detected by the human senses and

will be breathed as if it were air. Breathing an atmosphere that contains less than 18% oxygen can cause

dizziness and quickly result in unconsciousness and death.

Note: The cloudy vapor that appears when liquid CO2is exposed to the air is condensed moisture; not the

gas itself. The issuing gas is invisible.

Never dispose of liquid CO2in confined areas or places where others may enter.

Disposal of liquid CO2should be done outdoors in a safe place. Pour the liquid slowly on gravel or bare

earth where it can evaporate without causing damage. Do not pour the liquid on pavement.

EDOC00092 –ULT RFID Freezer User Manual, REV6 –8/16/2023 18

APPENDIX C: EXPECTED TEMPERATURE PERFORMANCE

Table of contents

Other TERSO Freezer manuals