Teryair EW 1103-110V Instruction Manual

High Pressure Washers

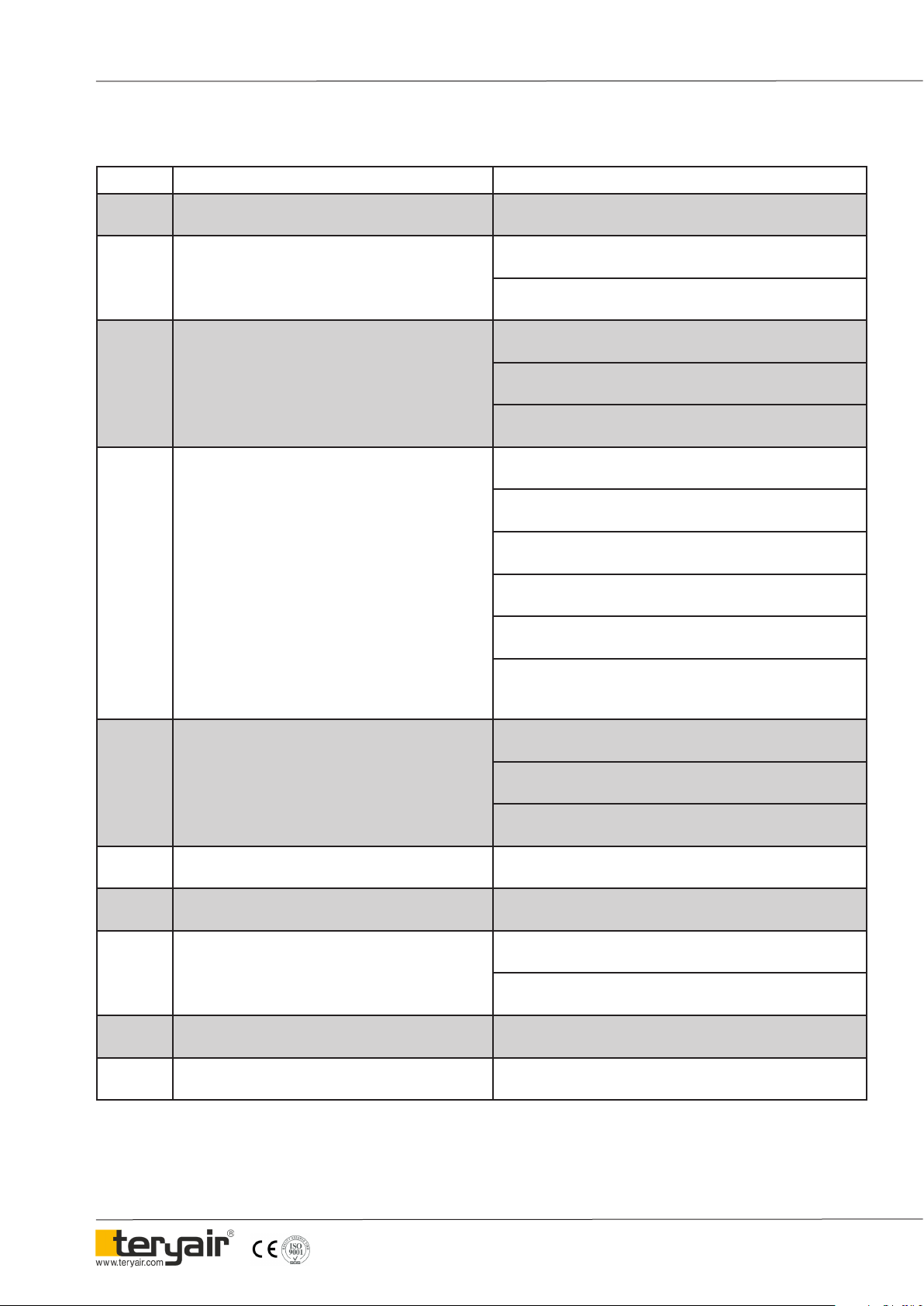

Models Descriptions IMPA Number

EW 1103-110V Electric High Pressure Washer, 110Bar, 110V-1ph, 2.2kW 590857

EW 1103-220V Electric High Pressure Washer, 110Bar, 220V-1ph, 2.2kW 590852

EW 1106-220V Electric High Pressure Washer, 110Bar, 220V-3ph, 2.2kW 590853-OLD

EW 1106-440V Electric High Pressure Washer, 110Bar, 440V-3ph, 2.2kW 590854-OLD

EW 1706-220V Electric High Pressure Washer, 170Bar, 220V-3ph, 4.4kW 590853

EW 1706-440V Electric High Pressure Washer, 170Bar, 440V-3ph, 4.4kW 590854

EW 200-220V Electric High Pressure Washer, 200Bar, 220V-3ph, 5.5kW 590855

EW 200-440V Electric High Pressure Washer, 200Bar, 440V-3ph, 5.5kW 590856

Read this manual carefully before installing, operating or servicing this equipment. It’s the responsibility

of the employer to ensure this manual is read by the operator. Please preserve this manual.

is document is issued with Product Serial No

Operation and Maintenance Guide

FF-MM-391-REV - 01

Page 2

Operation and Maintenance Guide High Pressure Washer Series

Table of Contents

3 Technical Data

3 OperangandSafetyInstrucons

5 IntendedandProhibiveuse

6 UnPacking

7 Assembly&Diassembly

10 SafetychecksbeforeandaeroperangtheHighPressureWasher

11 Maintenance

13 ExplodedViewpfHighPr.Pump110Bar

14 ExplodedViewpfHighPr.Pump170Bar/200Bar

15 Repair Kit

16 Troubleshoong

17 ListofMainPartsofHighPressureWasher

18. WarrantyCard-TermsandCondions.

19 ProductInstallaonandRegistraon

FF-MM-391-REV - 01

Page 3

Operation and Maintenance Guide High Pressure Washer Series

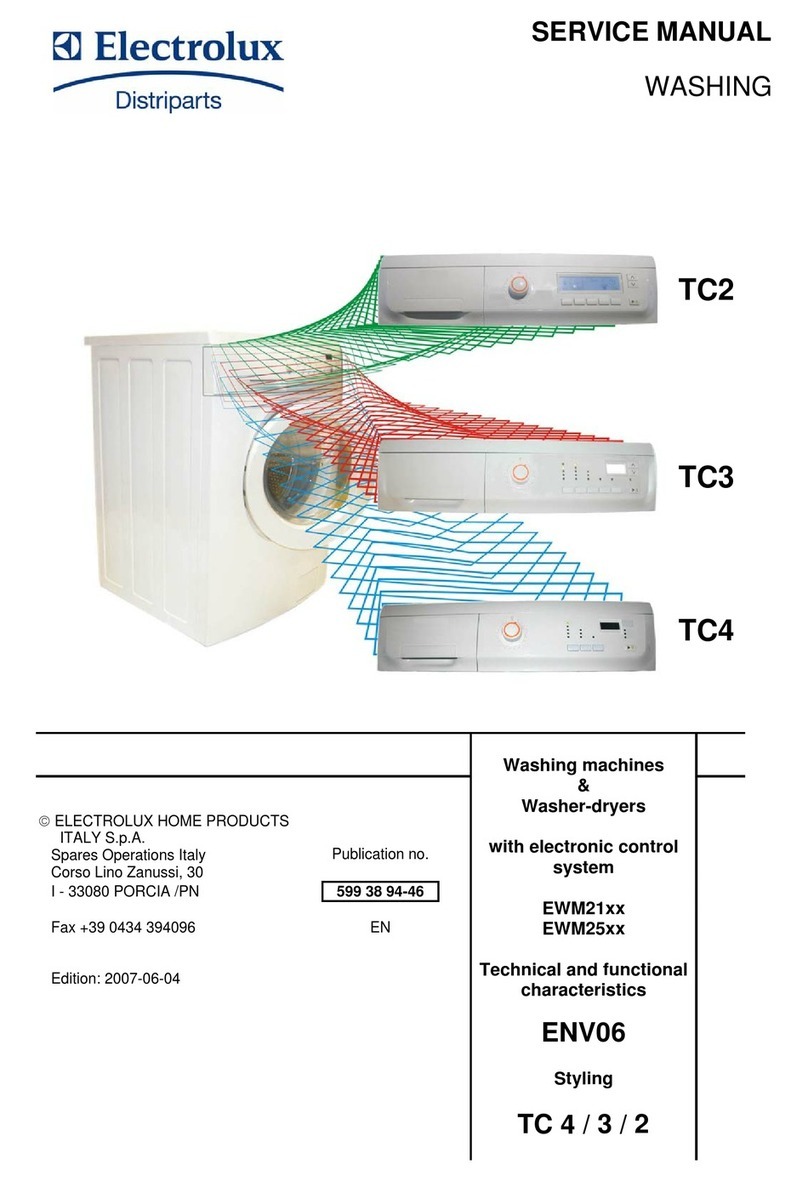

Following symbols are used throughout this manual.

Warning: If not followed could cause personal injuries

Caution: If not followed could result in damage to High Pressure Washer.

Operating and Safety Instructions

Warning

is manual must be read and

the operating instructions carefully followed,

because of the high pressure developed, severe

injuries can be caused by negligent operation

Warning

Use only for high pressure cleaning, do not use for any

other application

Caution

Do not run the high pressure washer without a

proper and adequate supply of water connected.

Insucient water supply will cause damage to

the seals in a few minutes of use.

Warning

Safety and protective clothing, eyewear, headgear, ear pro-

tection, gloves and footwear to be worn during operation

of this High Pressure Washer. Please see Table C at end of

this section.

Warning

Completely turn o the High Pressure Washer

and disconnect water supply line before attemp-

ting any service. Read Assembly and Disassemb-

ly instructions.

Caution

Source of power must contain ELCB (Earth leakage Cir-

cuit Breaker) to be present from where the power is to be

taken

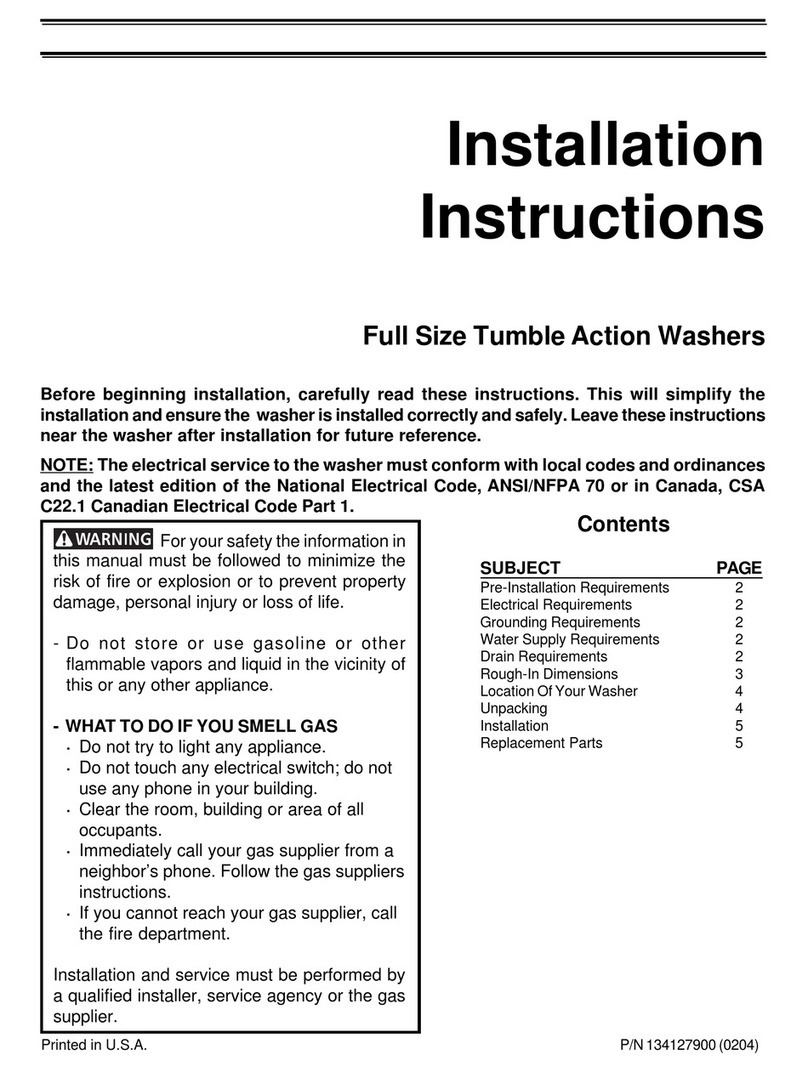

IMPANo. 590857 590852 590853-Old 590854-Old

ModelNo. EW1103P - 110V EW1103P - 220V EW1106P-220V EW1106P-440V

PowerSupply Single Phase, 110V,

60 Hz

Single Phase, 2200V,

60 Hz

ree Phase, 220V,

60 Hz

ree Phase, 440V,

60 Hz

PoweConsumption 3 HP (2.2 KW) 3 HP (2.2 KW) 6 HP (4.4 KW) 6 HP (4 KW)

WorkingPressure 110 Bar 110 Bar 110 Bar 110 Bar

FlowCapacity 11.7 ltr/min 11.7 ltr/min 11.7 ltr/min 11.7 ltr/min

PumpNumber Pe200 Pe200 Pe200 Pe200

OverallDimensions 97 x 51 x 76 cm 97 x 51 x 76 cm 97 x 51 x 76 cm 97 x 51 x 76 cm

Weight 50 Kgs 50 Kgs 53 Kgs 53 Kgs

Technical Data

IMPANo. 590853 590854 590855 590856

ModelNo. EW1706P-220V EW1706P-440V EW200P-220V EW200P-4400V

PowerSupply ree Phase, 220V,

60 Hz

ree Phase, 440V,

60 Hz

ree Phase, 220V,

60 Hz

ree Phase, 440V,

60 Hz

PoweConsumption 6 HP (4.4 KW) 6 HP (4.4 KW) 7.5 HP (5.5 KW) 7.5 HP (5.5 KW)

WorkingPressure 170 Bar 170 Bar 200 Bar 200 Bar

FlowCapacity 15.2 ltr/min 15.2 ltr/min 16.5 ltr/min 16.5 ltr/min

PumpNumber Pe250 Pe250 Pe250 Pe250

OverallDimensions 97 x 51 x 76 cm 97 x 51 x 76 cm 107 x 61 x 84 cm 107 x 61 x 84 cm

Weight 60 Kgs 60 Kgs 74 Kgs 74 Kgs

FF-MM-391-REV - 01

Page 4

Operation and Maintenance Guide High Pressure Washer Series

Safety wear mandatory while operating high pressure washer

Eye and face and ear protection must be worn at all

times during operation of the High Pressure Washer.

ere is a chance of ying debris from the jobsite

and the quality of wear should be such to protect

against such ying debris such as akes of the re-

moved layer.

Suitable heavy duty gloves must be worn at all times

during operation.

Eye and face and ear protection must be worn at

all times during operation of the High Pressure

Washer. ere is a chance of ying debris from

the jobsite and the quality of wear should be

such to protect against such ying debris such as

akes of the removed layer.

Suitable heavy duty gloves must be worn at all

times during operation.

Warning.

Operators under 18 not allowed to operate this High

Pressure Washer. Operators must be made familiar with

the instructions in this manual before attempting to

operate the High Pressure Washer. Ensure that job site

is clear of bystanders. e high pressure jets are capable

of causing serious injury do not direct spray on people

or animals. Do not spray electried equipment.

Warning

While starting operation and also during operati-

on there is a considerable kickback force from the

lance due to the high energy generated, be aware

of this at all times and keep a rm control on the

direction of the spray jet. Always use both hands

to operate the gun

Caution

Use only genuine Teryair or Teryair approved

accessories

Warning

is High Pressure Washer is not designed for use

in an explosive environment

Warning

Medical attention

Personnel who sustain injuries caused by high pressure

jets MUST be given immediate hospital attention. It‘s

important to apprise the medical attendants of the

manner in which the injury has been caused, namely a

high pressure jet.

Caution

Keep the gun trigger locked when not operating.

Warning

Completely turn o the High Pressure Washer and dis-

connect water supply line before attempting any ser-

vice. Read Assembly and Disassembly instructions.

Caution

Source of power must contain ELCB (Earth leaka-

ge Circuit Breaker) to be present from where the

power is to be taken

FF-MM-391-REV - 01

Page 5

Operation and Maintenance Guide High Pressure Washer Series

Intended and Prohibitive use

Intended use

Biological growth from concrete or steel constructions

Hard caked mud from construction machinery like dozer tracks.

Paint, dirt, mud from walls and oors

Oil and grease from High Pressure Washer.

Dirt, paint from sea going vessels.

Prohibitive use

Any use in an explosive atmosphere is prohibited

Use on materials containing asbestos is prohibited

Use by an underage, untrained or operator who is under the inuence of drugs or alcohol.

Use with non genuine spare parts or accessories is prohibited

Use with safety devices un functional or in need of service is prohibited

Do not use with hot water, this High Pressure Washer is for use with cold water.

FF-MM-391-REV - 01

Page 6

Operation and Maintenance Guide High Pressure Washer Series

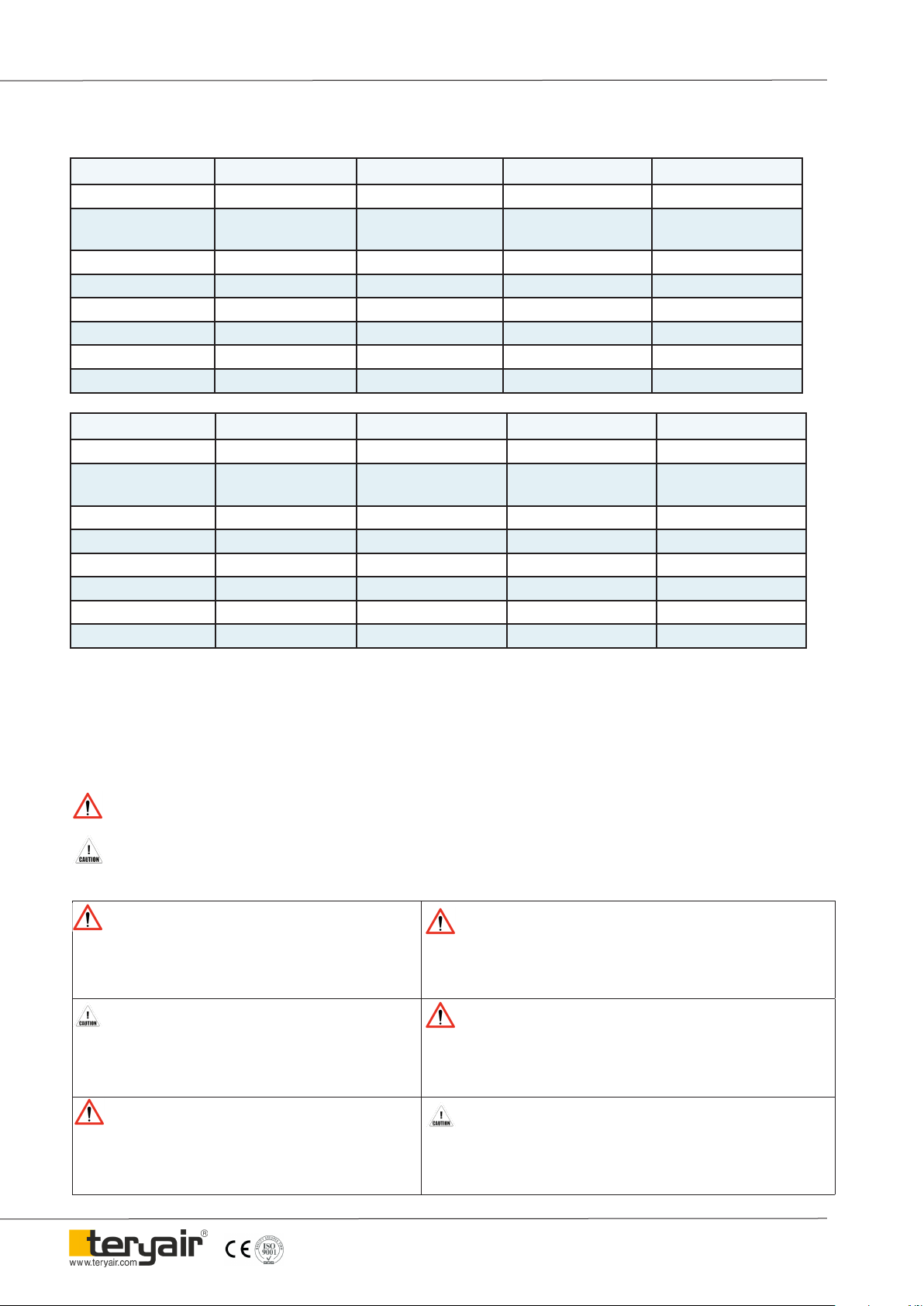

Un Packing

Identify all the components as shown earlier, contact your supplier if any parts are missing or dam-

aged.

Be aware that minor visual dierences may be noticed between actual motor/frame/pump and High

pressure hoses because this components vary depending on the model ordered. is illustration is for

identication only.

Unless specially requested the motor, pump and frame are factory tted to each other.

Product Main Components and Description

Sr. No Description Quantity Instructions & Remark

1Gun 1 no -

2Lance 1 no -

3 Handle with Nozzle Sets & MCB NO/OFF switch 1 Set -

4 Trolley with Motor and H.P. Pump 1 Set -

5 Suction Pipe with Strainer 1 Set -

6 Chemical suction pipe with Strainer 1 Set -

7 High Pressure Hose Complete with end ttings 1 Set -

8 Breathing Cap 1 Set User has to remove Oil plug and replce with breathing Cap is

MUST.

9 Holding Bracket with Fasteners 1 Set -

10 Spanner and Screwdriver Set 1 Set -

FF-MM-391-REV - 01

Page 7

Operation and Maintenance Guide High Pressure Washer Series

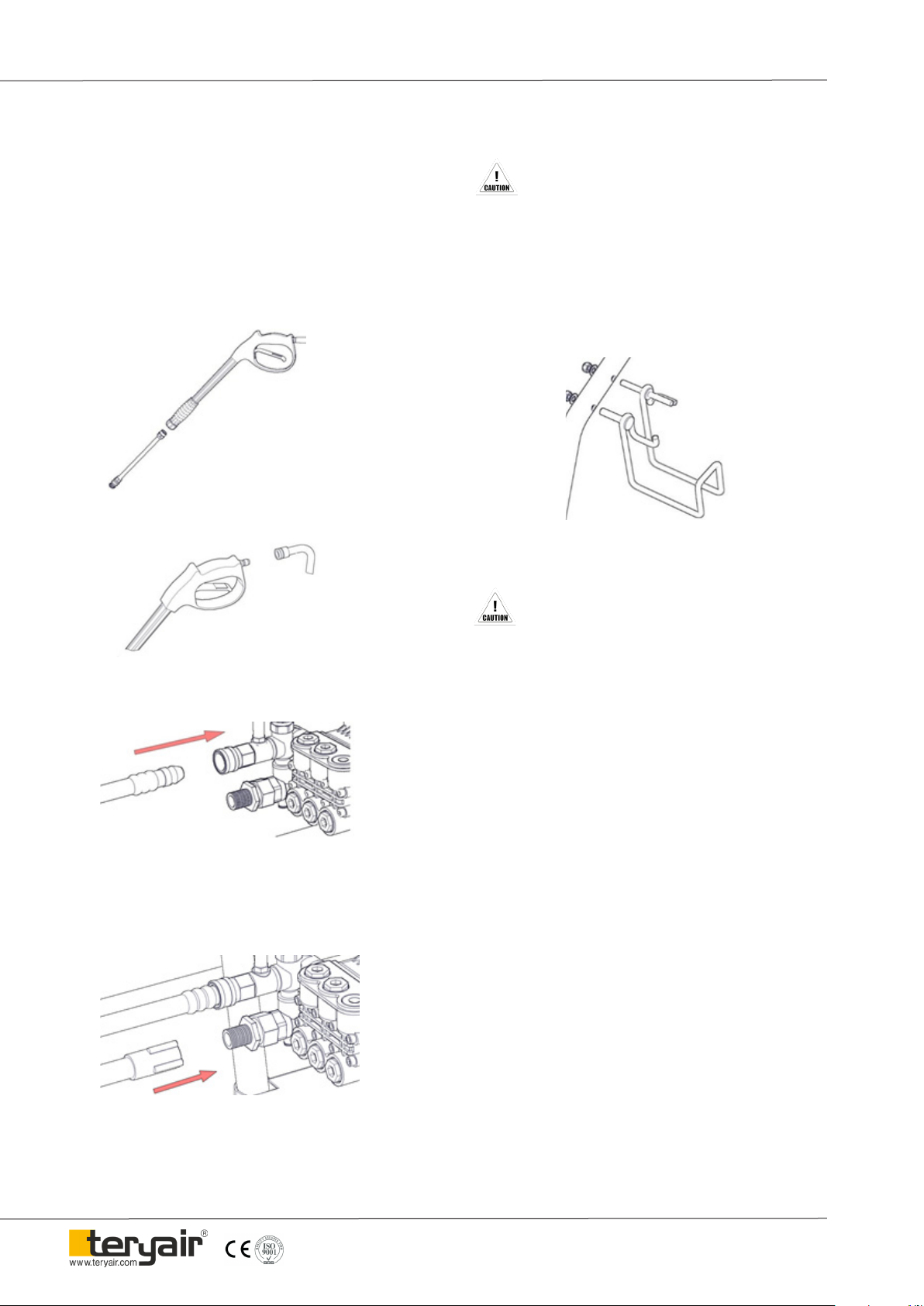

5. Connect high pressure hose to gun

6. Connect other end of high pressure hose to

upper connector on pump as shown

7. Connect the water inlet hose to the lower

connector on pump.

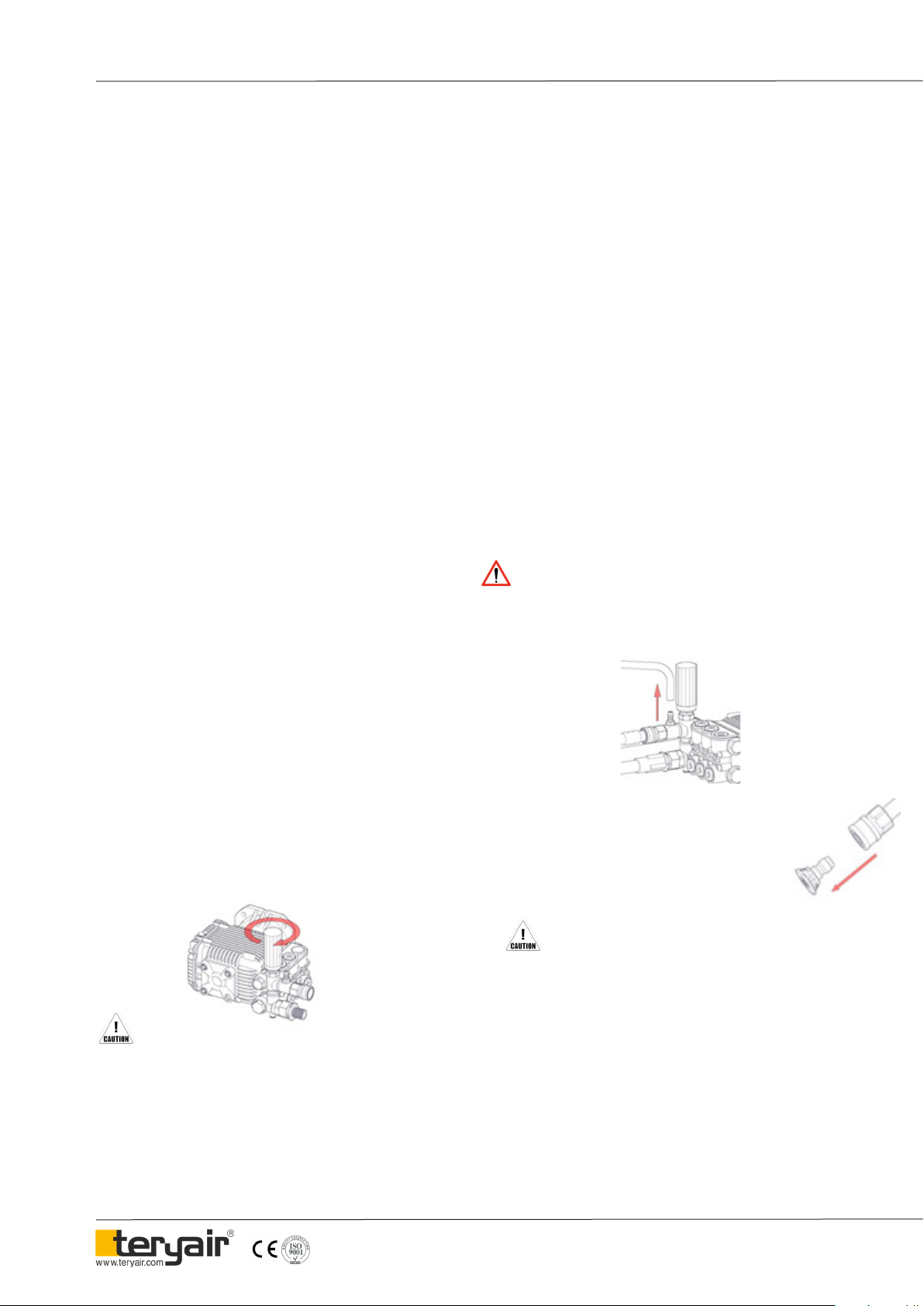

11. Connect the spray tip to the gun lance

Caution

12. Always engage trigger lock on gun before

connecting/changing spray tip. Pull back

collar and remove existing spray tip if any.

Insert desired spray tip and click back collar.

13. Connect the electric motor cable (see table D

for correct motor number)

14. Check that the electrical voltage and

frequency are consistent with what is

mentioned on the electric motor nameplate.

15. e motor must be grounded properly.

16. Please ensure that the necessary thermal

overload protection and short circuit

protection has been installed prior to the

starting of the high pressure washer.

17. Place the High Pressure Washer on a

level ground and ll up the pump oil

level to ½ the sight glass.

Assembly & Diassembly

1. e motor and the pump are factory tted to the

Trolley

2. Connect the Handle to the frame

3. Connect the hoses to the Pump (see table A for

correct High Pressure hose) ( see table A for

correct Pump Number)

4. Connect gun to lance

8. Connect other end of water inlet hose to a

water supply source.

Caution

9. Water supply source must provide a

minimum of 20 litres/min ow at least 20

psi of pressure. Insucient water supply can

damage the pump pre maturely.

10. Attach the gun hook to frame

FF-MM-391-REV - 01

Page 8

Operation and Maintenance Guide High Pressure Washer Series

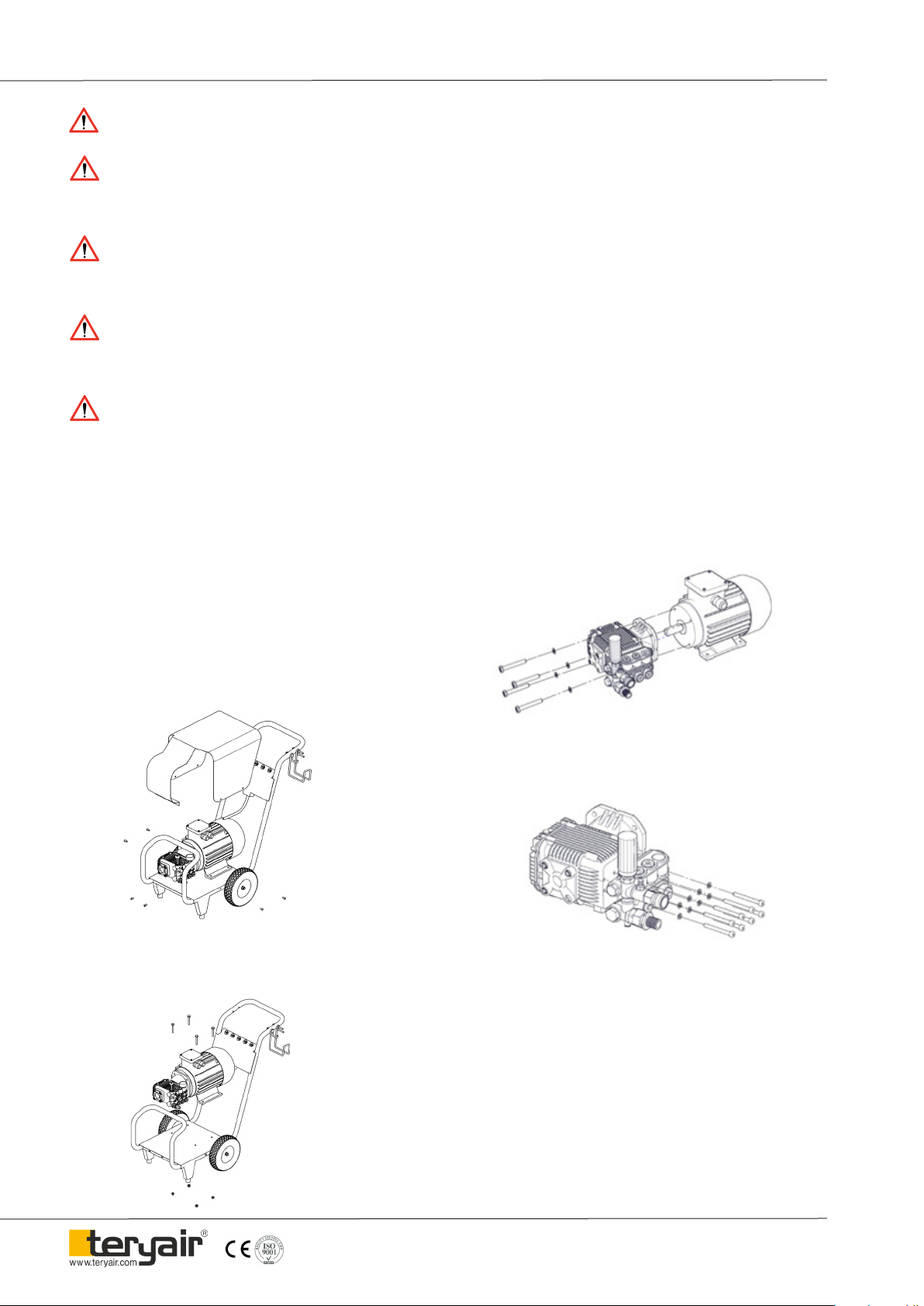

Fill lubricating oil

Make Sure that the tted oil plug is removed. Fill lubricating oil 10W15 up to half way mark of Oil

Indicating Glass window.

And Fit Breathing cap provided with pump. Do not t Oil Plug.

Caution – a) If oil plug tted aer lling oil instead of breathing cap- Pump will over heat during use

and will damage all internal parts of pump and machine will stop working / developing pressure.

b) If oil is lled fully in pump up to top / maximum level of Oil indicating window, there will be no

space for breathing of oil during use and pump will be over heated which will damage pump internal

parts.

Ok Level

Make Sure to ll Oil in the pump as shown below befor start.

Plug (Red Colour) For Transportation

Purpose Only To Replace With

Breathing Cap (Shown As Above)

Breathing Cap

Excess Oil Level Low Oil Level

FF-MM-391-REV - 01

Page 9

Operation and Maintenance Guide High Pressure Washer Series

18. Types of nozzle provided as shown & can be

use according to user requierment.

Spray Tip detail

Electric motor connection detail

FF-MM-391-REV - 01

Page 10

Operation and Maintenance Guide High Pressure Washer Series

Safety checks before and after operating the High Pressure Washer

Lubrication.

• e oil sump in the Pump unit should contain

SAE15W40 / 10W15 grade oil.

• Ensure that the oil is at the half level by looking at the

transparent window.

• If the number of hours has crossed y, drain out the

oil by opening the Oil drain plug at the end of the pump

housing. Re x the plug and open theBreathing oil cap to

top up oil to the correct level (Refer g on page 11). ereaf-

ter repeat aer every 500 hours of use or whenever the level

of oil has dropped or looks contaminated.

Check list before starting the High Pressure

Washer

• Check safety wear mentioned earlier in warnings.

• Check the hoses, especially the high pressure hoses for

damage or leaks.

• Make sure that the electrical supply voltage and

frequency match the motor. Refer electrical connection

detail on page 5 for termination.

• Make sure that the High Pressure Washer is grounded

properly

• Make sure that the electrical cables are not damaged and

all the connectors between gun, lance, hoses and pump

are secure.

• Make sure that the lter cone on the water supply in place

• Turn on the water supply.

Changing spray nozzle tips

• Choose appropriate nozzle.

• Engage the trigger lock

• Pull back the collar

• Remove spray tip

• Install desired tip,

• Release collar

• Tug on tip to ensure proper seat

Cleaning solution injection

• All Teryair high pressure washers have a facility of

injection of Cleaning Fluids to aid in the cleaning

process. ere are several brands & types of cleaning

solutions available in the market today. Whichever you

choose make sure it designed for use in high pressure

washer. It should say so on the level, if it does not say it,

don’t use it.

Warning: Never use bleach or bleach based products

as they can damage the pump.

• Once you have your cleaning solution is ready to go,

check to make sure that injector tube is securely attached

to the pump as shown.

Starting the High Pressure Washer

• Hold the gun securely with both hands, ( the gun will kick

back when rst started )

• Switch on the electricity, and depress trigger of the gun to

start the jetting.

• Adjust the output pressure as required by the pressure

regulator.

• en insert the other end into the cleaning

solution.

• A pressure washer will only siphon cleaning

solution when in low pressure mode. So a low

pressure soap nozzle must be use on the gun +

lance ( Refer Spray tip detail on page 5).

Caution

• Aer cleaning Fluid application it is

recommended to disconnect the injection

system to allow clean water to rinse through

the system for few minutes.

Bypass mode-In bypass mode, the pump

reticulates the water because the trigger of the spray gun

is not being pulled. If unit is le in bypass mode For more

than two minutes, the water temperature will rise to a

dangerous Level and could damage internal components

of the pump.

Note- Any damage to pump due to these causes will not

be covered under Warranty.

FF-MM-391-REV - 01

Page 11

Operation and Maintenance Guide High Pressure Washer Series

Warning keep distance from gun tip to job at least 8

inches.

Warning: is high pressure washer is a high powered

High Pressure Washer and it is imperative that it must

be operated by a competent and trained operator. See

warnings

Warning: is high pressure washer is a high powered

High Pressure Washer and it is imperative that it must

be operated by a competent and trained operator. See

warnings

Warning: e high pressure washer needs a constant

supply of water during operation, any starvation of

water to the High Pressure Washer will result in

overheating and quick damage to High Pressure Washer.

Warning: With the motor running and the jetting o,

the high pressure water circulates in the circuit. DO

NOT pause jetting for more than TWO minutes.

Instead shut down the high pressure washer see

“Shutting down” later in this section.

Shutting down

• DO NOT turn o water source before switching o the

motor.

• Switch o motor or remove the plug from mains.

• Turn o the water source.

• Pull the lance trigger to relieve any residual water pressure

Storage

• Disconnect the gun from the high pressure hose and the

hose from the pump.

• Hold gun vertically and depress trigger to remove all

residual water from the gun and lance.

• Drain the hose too in a similar way.

• Remove the water supply hose and drain.

• Run the pump for ten seconds to eject any residual water

that may have remained in.

• Store in a clean and dry place.

Servicing the Pump

Follow instructions in “Shutting Down” section earlier in the

manual.

Dis assemble the hoses and the electrical cable from the High

Pressure Washer.

Dis assemble the cover from the trolley by opening the six

screws as shown below.

Maintenance

Dis assemble the pump from the motor.

Dis assemble the un pump housing valve assembly

from the pump. (refer exploded view page)

Proceed to disassemble the Pump and pump

Remove bolts (13) to dismantle pump housing (10)

valve from the pump.

Dis assemble the motor and pump from the trolley

by opening the bolts and nuts as shown below

FF-MM-391-REV - 01

Page 12

Operation and Maintenance Guide High Pressure Washer Series

Dis-Assembly insrtructions for High Pre. Washer

1. Remove the Plugs (14) & take out vale kits (15). ere

are total 6 plugs & 6 valve kits (3nos on front side &

3nos on top side of pump housing. Now observe it for

wear and tear (if found replace it with new one)

2. Remove the Bolts & washers (13 & 12) to dis assem-

ble pump hsg. from body (1) to Remove the Seal kits

(17) from the Pump Hsg.(10). ere are total 3 sets of

seal kit for 3 pistons & observe it for wear and tear (if

found replace it with new one).

3. Using spanner open the QC tting with chemical

injector (11).

4. Open the unloader valve assembly (22) by opening it’s

side Bolt using spanner.

5. Pull out unloader valve cap (16) from the unloader

valve assembly(22).

6. Open the inlet assly. (23) by opening it’s side Bolt

using spanner.

7. Open inlet adaptor (25) using spanner from inlet assem-

bly (23) & remove inlet Strainer (24). Observe strainer

for chock up (If chock up found it can be cleaned manu-

ally or replace it with new one).

8. Open the inlet nipple (26) using spanner from inlet adap

tor (25).

9. 9. Before further proceeding for any further assembly,

Open the Drain plug (5) and drain the Oil from the

Pump Body(1).

10. Open Screws (18) and remove the Oil seal (19), Flange

(20) and O-ring (21). Observe it for wear and tear or

leakages (if found replace it with new one).

11. Open Screws (7) and remove the Side Cover (20) and

O-ring (21), Observe it for wear and tear or leakages (if

found replace it with new one).

12. Open Screws (6) to remove End cover (4) and end cover

O-ring (3), Observe it for wear and tear or leakages (if

found replace it with new one).

FF-MM-391-REV - 01

Page 13

Operation and Maintenance Guide High Pressure Washer Series

Exploded View pf High Pr. Pump 110 Bar

Bill Of Material High Pressure Pump - EW110 Bar

Illu. No. Description Qty.

1 Pump Body 1

2 PLUG (RED) with O-Ring 1

3 O- Ring for End Cover 1

4 End Cover 1

5 Drain Plug 1

6 Bolt for End Cover 4

7 Bolt for Said Cover 4

8 Said Cover 1

9 O-Ring Said Cover 1

10 Pump Housing (Brass) 110Bar 1

11 QC with Chemical Injector 1

12 Washer For Pump Hsg. 8

13 Bolt For Pump Hsg. 8

14 Plug with O-Ring for Pump Hsg. 6

15 Valve With O-Ring 6

Illu. No. Description Qty.

16 Cap For Pressure Regulator 1

17 Seal Kit (Set of 5 pcs) 3

18 Bolt For Flange 4

19 Oil Seal For Flange 1

20 Flange 1

21 O-Ring For Flange 1

FF-MM-391-REV - 01

Page 14

Operation and Maintenance Guide High Pressure Washer Series

Exploded View pf High Pr. Pump 170 Bar / 200 Bar

Bill Of Material High Pressure Pump - EW170 Bar / EW200 Bar

Illu. No. Description Qty.

1 Pump Body 1

2 PLUG (RED) with O-Ring 1

3 O- Ring for End Cover 1

4 End Cover 1

5 Drain Plug 1

6 Bolt for End Cover 4

7 Bolt for Said Cover 4

8 Said Cover 1

9 O-Ring Said Cover 1

10 Pump Housing (Brass) 170 Bar / 200 Bar 1

11 QC with Chemical Injector 1

12 Washer For Pump Hsg. 8

13 Bolt For Pump Hsg. 8

14 Plug with O-Ring for Pump Hsg. 6

Illu. No. Description Qty.

15 Valve With O-Ring 6

16 Cap For Pressure Regulator 1

17 Seal Kit (Set of 5 pcs) 3

18 Bolt For Flange 4

19 Oil Seal For Flange 1

20 Flange 1

21 O-Ring For Flange 1

22 Unloader Valve Assy 1

23 Inlet Assy 1

24 Inlet Strainer 1

25 Inlet Adopter 1

26 Inlet Nipple 1

FF-MM-391-REV - 01

Page 15

Operation and Maintenance Guide High Pressure Washer Series

Repair Kit

Description Images EW110 Bar EW170 Bar /

EW200 Bar Qty / Assembly

Seal

Replacement Kit 644 97 02 642 97 42 x 3 Sets

Valv e

Replacement Kit 644 97 03 642 97 43 x 6 Sets

FF-MM-391-REV - 01

Page 16

Operation and Maintenance Guide High Pressure Washer Series

Troubleshooting

Serial No Causes Remedial Action

1e motor does not turn aer energizing A loose connection

Check connections and retry

2e motor hums but does not turn

Low voltage

Check voltage and verify correct and re try

Pump is stuck

Service Pump see Maintenance section

3Pump is noisy

Pump is sucking air along with water

Check hose ttings

Valves are tight

Service pump

Bearings worn

Service Pump

4 Low pressure when new

Water supply not adequate

20 litres per min at 20 PSI recommended

Leak in high pressure hose tting

Check use sealant tape if needed.

Nozzle obstructed

Clean Nozzles, see maintenance section

Water lter is clogged

Clean and ensure clean supply

Defective un loader valve

Service Pump

Air in hose

Switch o motor, disconnect water hose from pump inlet

and allow water to ow removing air bubbles, reconnect.

5Cleaning solution not getting sucked

Cleaning solution lter clogged

Clean or replace

Wrong Cleaning uids

See section

Cleaning solution residue clogging the pump

Service pump

6Low pressure aer normal use Pump needs service

Service Pump

7Water leaking at Gun Check hose ttings

Use sealant tape or replace ttings

8Water leaking at Pump

Check ttings

Use sealant tape or replace ttings

If not solved

Service Pump

9Oil Leaking at Pump Seals or O rings worn

Service Pump

10 Pump pulsates Clogged nozzle

Clear nozzle

FF-MM-391-REV - 01

Page 17

Operation and Maintenance Guide High Pressure Washer Series

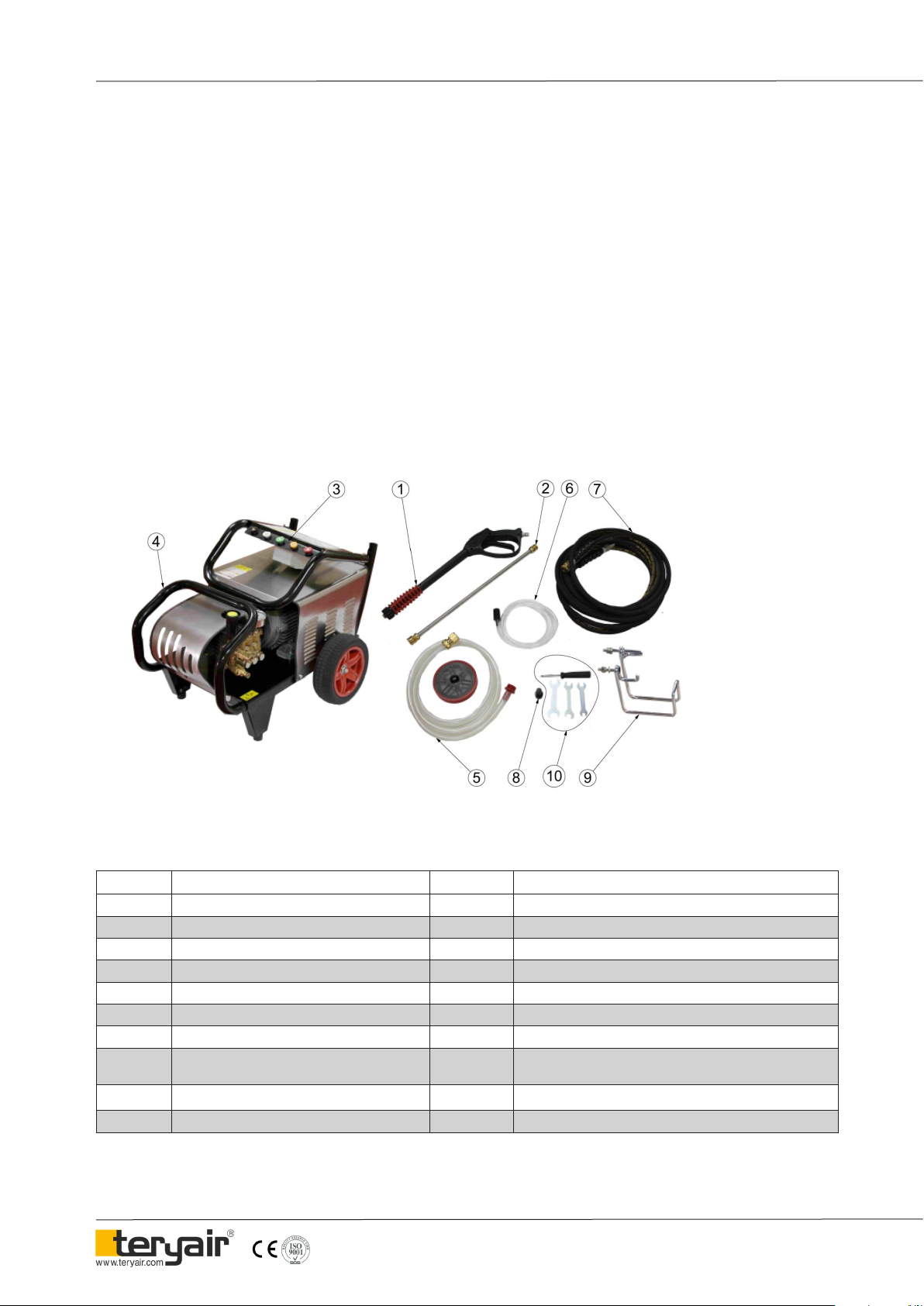

Illustration

Number EW1103-110V EW-1103-220V EW-1106-220V EW-1106-440V

59.08.57 59.08.52 59.08.53-OLD 59.08.54-OLD

1 500mm lance 500mm lance 500mm lance 500mm lance

2 2.2kW-110V-1ph 2.2kW-220V-1ph 2.2kW-220V-3ph 2.2kW-440V-3ph

3 Pe200 Pe200 Pe200 Pe200

4 F1 F1 F1 F1

5 Standard Nozzle Set Standard Nozzle Set Standard Nozzle Set Standard Nozzle Set

67mm ID X 10mtr Plastic

Hose

7mm ID X 10mtr Plastic

Hose

7mm ID X 10mtr Plastic

Hose

7mm ID X 10mtr Plastic

Hose

7 6.5mmID X 1.5mtr 6.5mmID X 1.5mtr 6.5mmID X 1.5mtr 6.5mmID X 1.5mtr

8 15mmID X 3mtr 15mmID X 3mtr 15mmID X 3mtr 15mmID X 3mtr

9Cover Cover Cover Cover

10 MCB - ON/OFF Switch MCB - ON/OFF Switch MCB - ON/OFF Switch MCB - ON/OFF Switch

Illustration

Number EW-1706-220V EW-1706-440V EW-200-220V EW 200- 440V

59.08.53 59.08.54 59.08.55 59.08.56

1 500mm lance 500mm lance 500mm lance 500mm lance

2 4.4kW-220V-3ph 4.4kW-440V-3ph 5.5kW-220V-3ph 5.5kW-440V-3ph

3 Pe250 Pe250 Pe250 Pe250

4 F3 F3 F3 F3

5 Standard Nozzle Set Standard Nozzle Set Standard Nozzle Set Standard Nozzle Set

68mmID X 10 Mtr Steel

Braided hose

8mmID x 10 Mtr Steel

Braided hose

8mmID x 10 Mtr Steel

Braided hose

8mmID x 10 Mtr Steel

Braided hose

7 6.5mmID X 1.5mtr 6.5mmID X 1.5mtr 6.5mmID X 1.5mtr 6.5mmID X 1.5mtr

8 15mmID X 3mtr 15mmID X 3mtr 15mmID X 3mtr 15mmID X 3mtr

9Cover Cover Cover Cover

10 MCB - ON/OFF Switch MCB - ON/OFF Switch MCB - ON/OFF Switch MCB - ON/OFF Switch

List of Main Parts of High Pressure Washer

FF-MM-391-REV - 01

Page 18

Operation and Maintenance Guide High Pressure Washer Series

FF-MM-391-REV - 01

Page 19

Operation and Maintenance Guide High Pressure Washer Series

User requested to ll this warranty card aer installation of product for its intended use.

Product Installation and Registration

Note :- User is requested to email this duly lled and signed product registration to our

company email – service@teryair.com, within 3 days from the date of Installation and start

of use, along with proof of purchase scan copy. In absence of this receipt. Warrenty start date

will be assumed as date of rst sales from factory.

Product Model No :--

Product Sr. No :--

Date of Installation for use - :-

Customer Name / company Seal -

With Address.

Contact Person Name & Contact Details:-

Signature of Customer / User

Authorized Personnel :-

FF-MM-391-REV - 01

Page 20

Operation and Maintenance Guide High Pressure Washer Series

is page is intentionally

Le blank.

This manual suits for next models

7

Table of contents