6Winterhalter Gastronom GmbH

Postfach 1152

D-88070 Meckenbeuren

89003809

09/98 sch

6.The wash cycle

Before you put the utensils in the machine,

you should remove the worst of the food

leavings. Sauce remnants should be

tipped away and dried-on residues left to

soak.

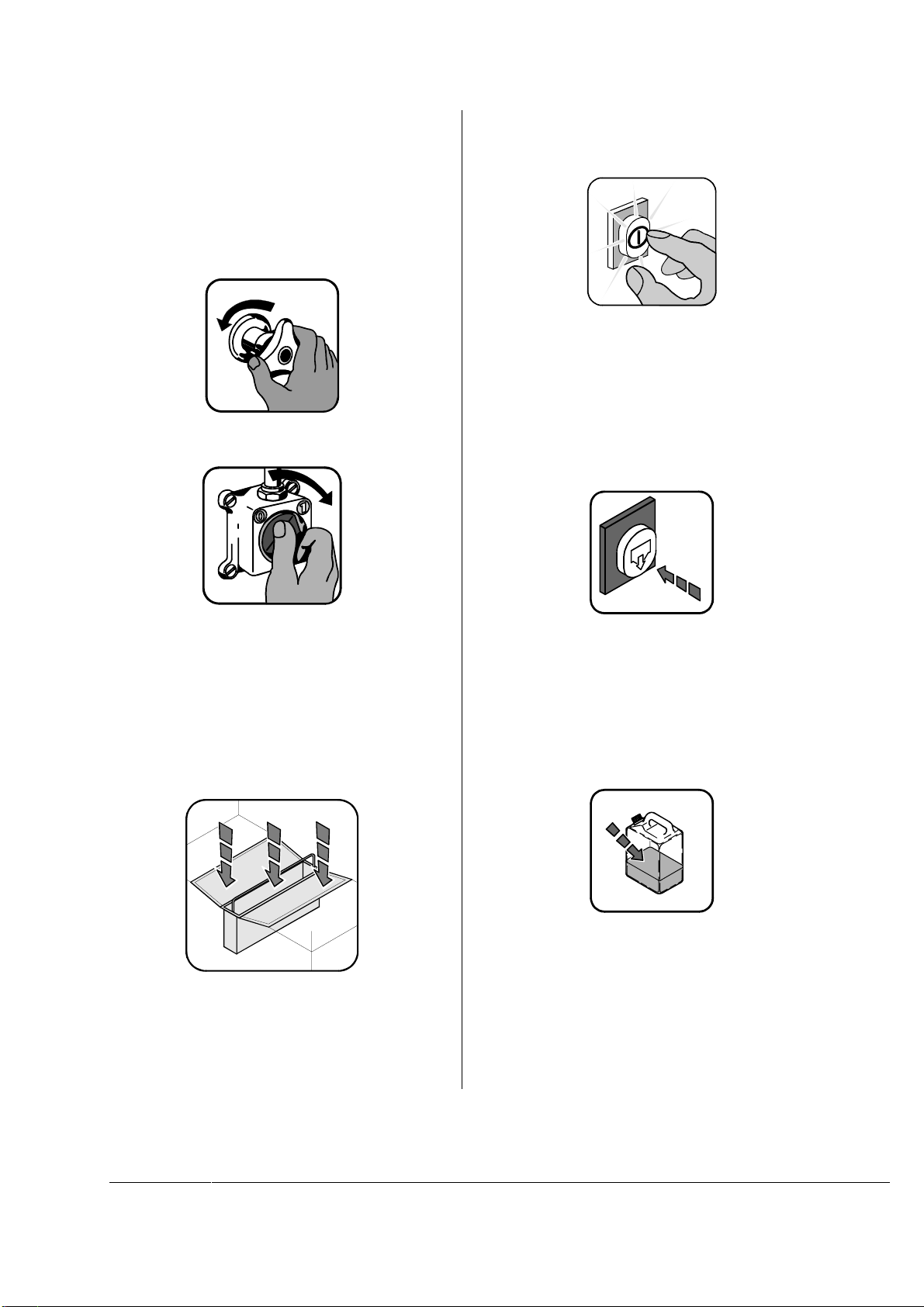

Place items such as bowls, pots, pans,

meat trays and so on in the utensil rack

with the opening facing downwards. You

can fill the spaces in between with small

items such as serving spoons, etc. The

utensils should not be piled on top of each

other, however, as this prevents the spray

jet from reaching all the items and leads to

imperfect results.

Baking trays should be tilted forwards in

the insert, making sure that the dirty sides

are facing downwards.

Use the plastic accessory rack for cutlery

and other small items. Once loaded, this is

placed on top of the utensil rack.

Push the rack into the machine and close

the door.

NOTE

Lightweight parts made of plastic etc. may

slip or turn over during the wash.

If necessary, you can place a plastic rack

on top of these.

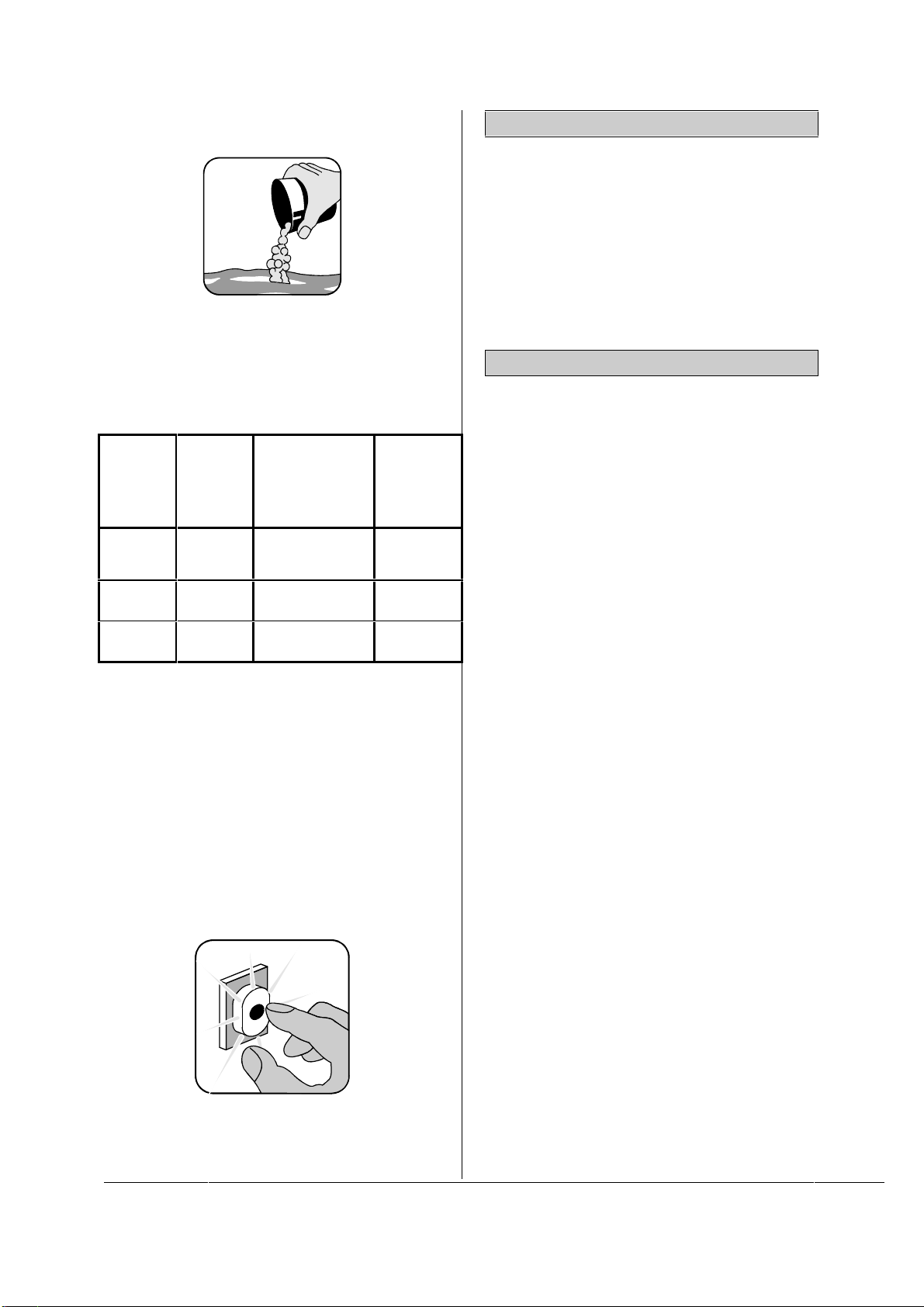

The machine has two alternative cycle

times. The correct programme is chosen

according to the degree of soiling of the

items to be washed.

For normally soiled items with dried-on

dirt, use programme 2.

This is selected by pressing pushbutton

(4).

For lightly soiled items with non dried-

on dirt, use programme 1.

This is selected by pressing pushbutton

(3).

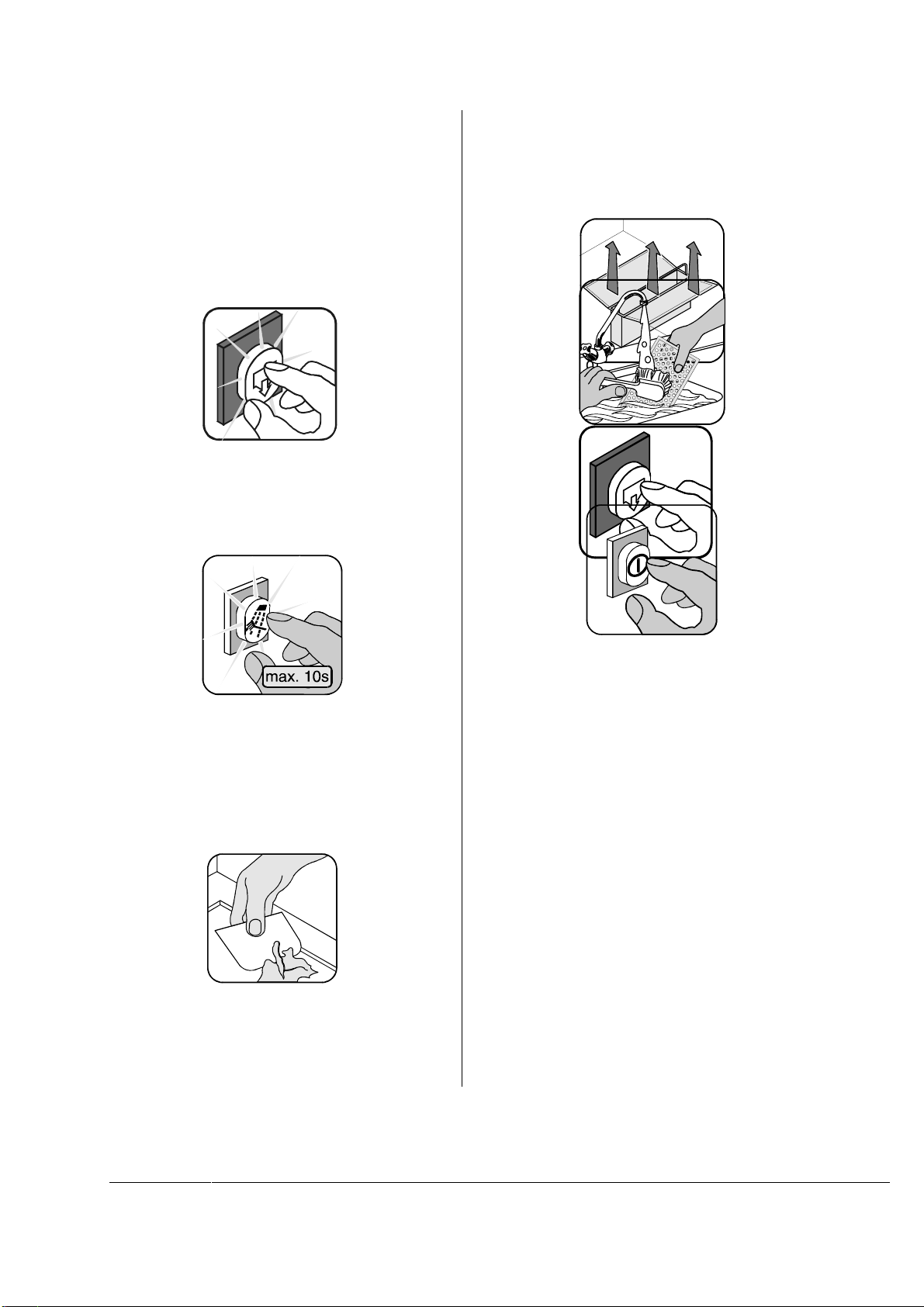

Operating sequence:

•Circulation of detergent solution:

intensive cleaning from above and

below.

•Freshwater rinse with water heated to

85°C (containing rinse aid).

•The indicator lamp in the selected

pushbutton remains illuminated

throughout the programme sequence.

•Once the lamp is extinguished, the

door can be opened and the rack can

be pulled out of the machine onto the

opened lower door to allow removal of

the utensils.

•Do not remove the rack beforehand,

as this will interrupt important stages of

the programme.

•Reload the rack and continue washing

as described above.

•Make sure that the door remains

closed when the machine is not in

operation in order to avoid an un-

necessary waste of energy.