Overview

www.ti.com

1 Overview

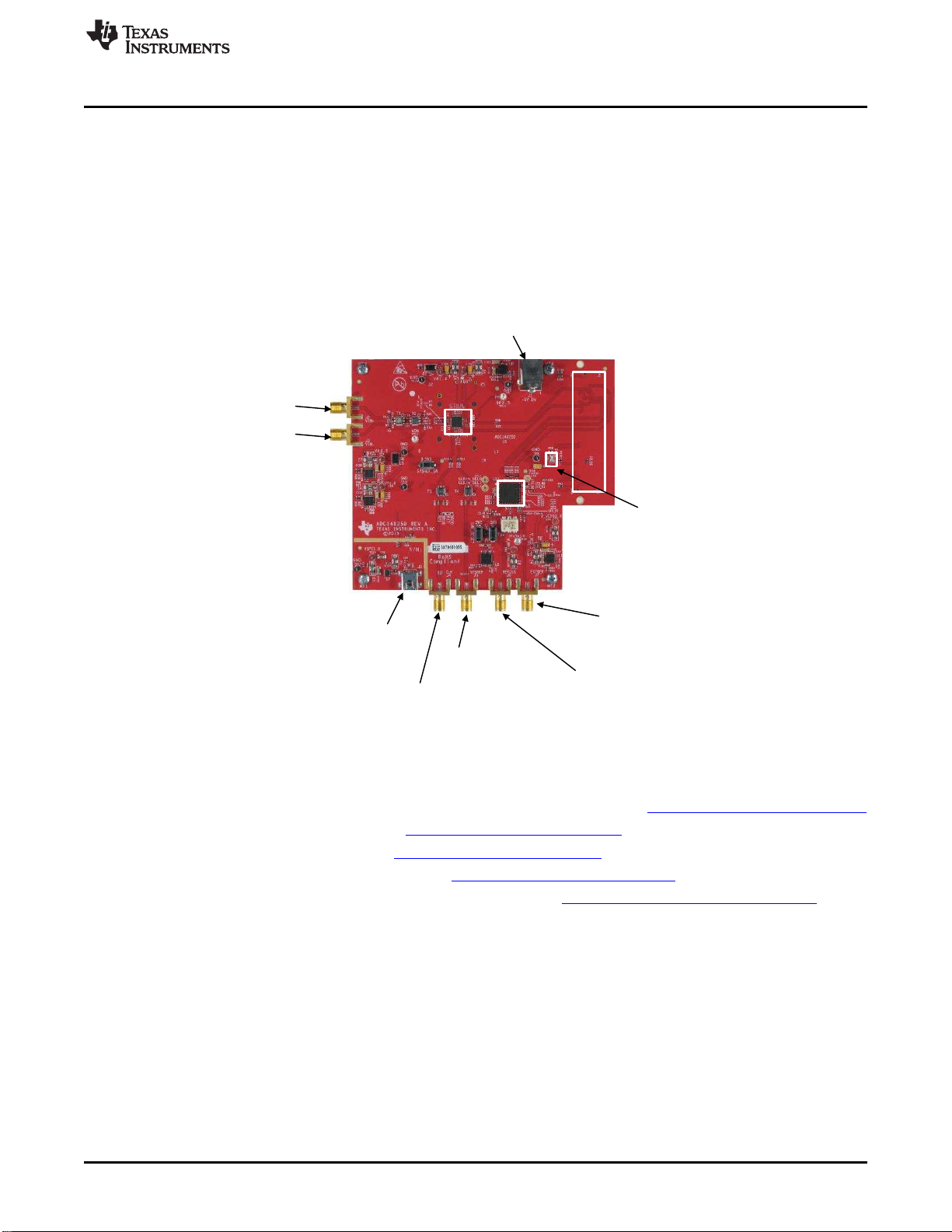

The ADC14X250EVM is an evaluation board used to evaluate the ADC14X250 analog-to-digital converter

(ADC) from Texas Instruments. The ADC14X250 is a single channel, 14-bit analog-to-digital converter

(ADC), capable of operating at sampling rates up to 250 Mega Samples Per Second (MSPS) with outputs

featuring a standard JESD204B high-speed serial interface.

This evaluation board also includes the following important features:

• Transformer-coupled signal input network allowing a single-ended signal source

• LMK04828 system clock generator that generates the FPGA reference clock for the high-speed serial

interface

• Default transformer-coupled clock input network to test the ADC performance with a very low-noise

clock

• High-speed serial data output over a standard FMC connector

• Device register programming via USB connector and FTDI USB-to-SPI bus translator

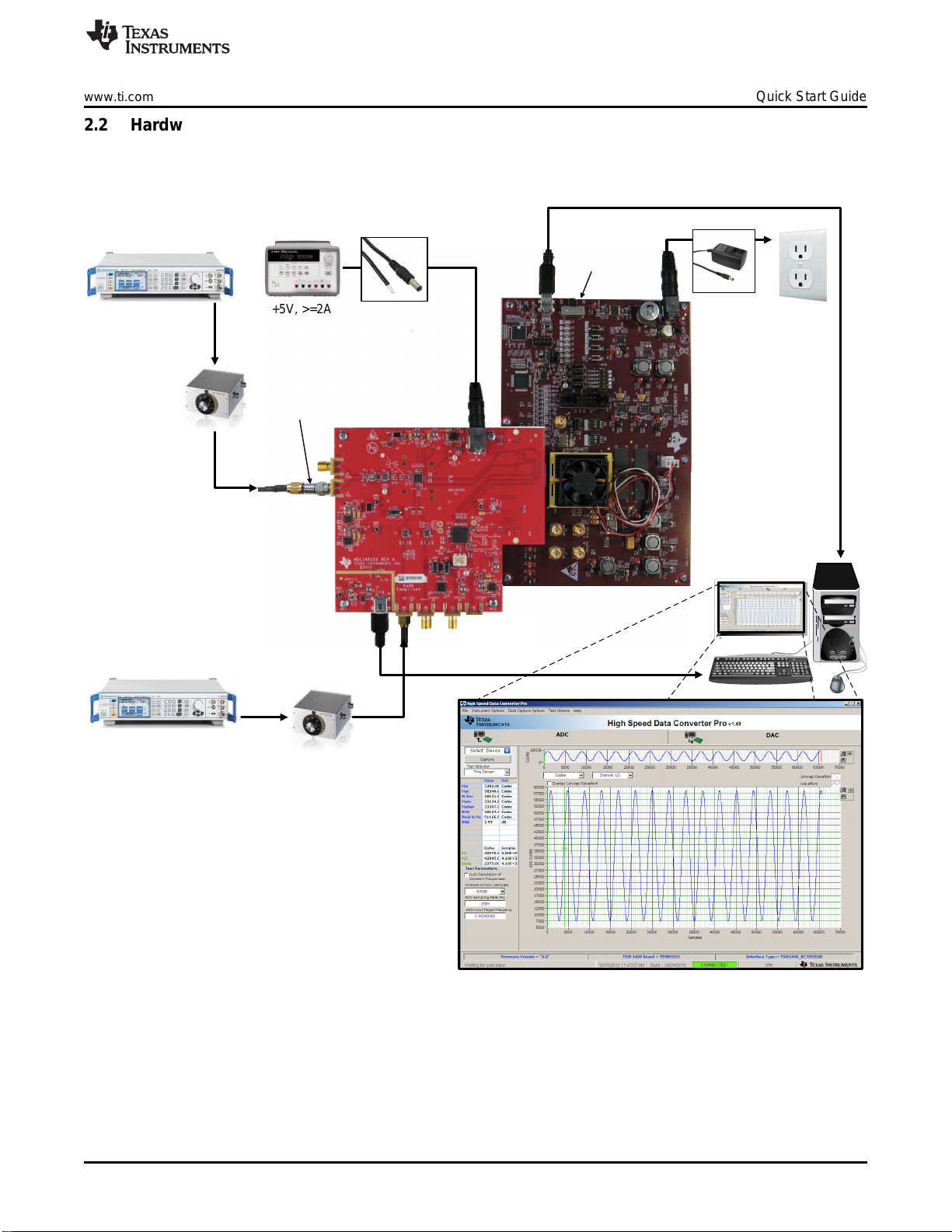

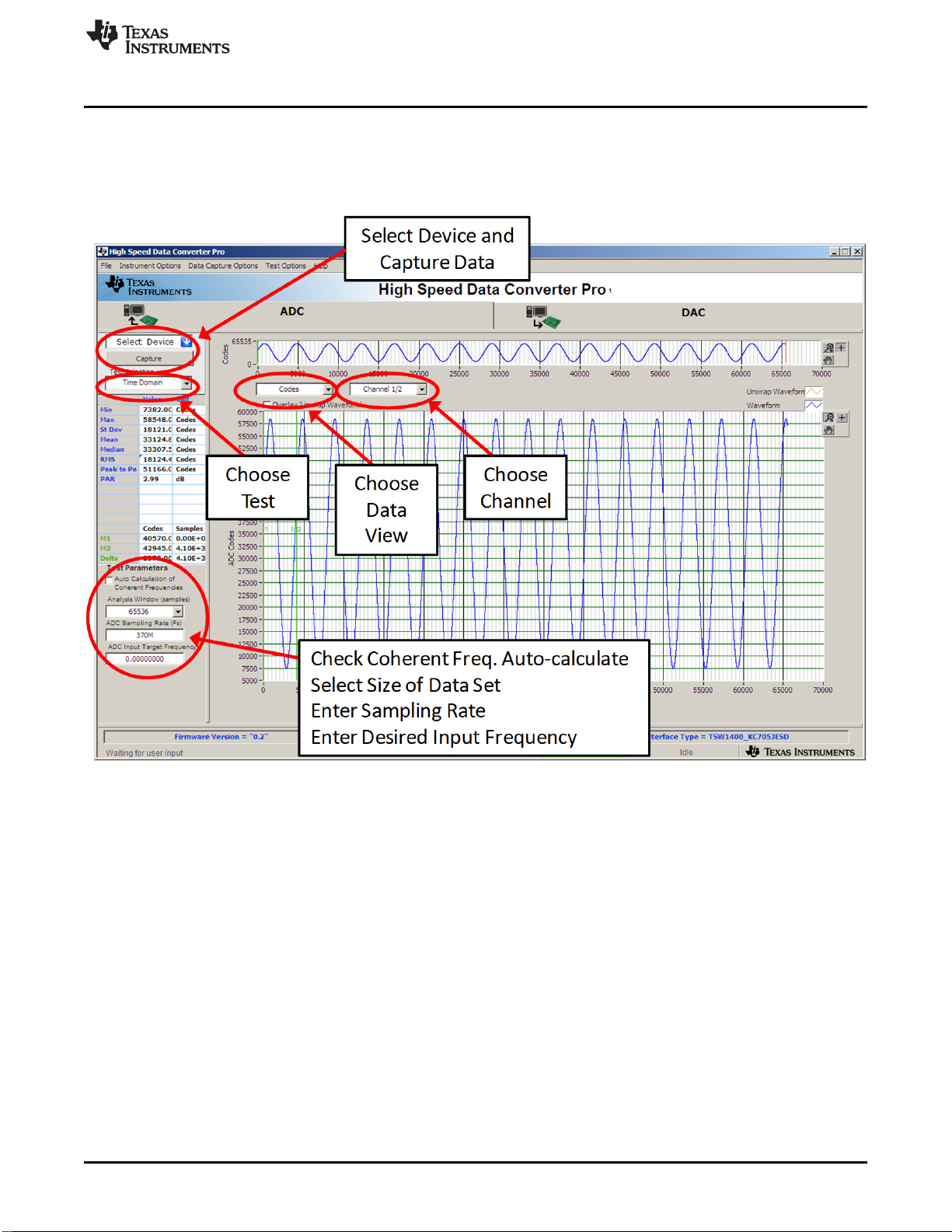

The ADC14X250EVM is designed to work seamlessly with the TSW14J56EVM, Texas Instruments’

JESD204B data capture card and the High Speed Data Converter Pro (HSDCPro) software tool for high-

speed data converter evaluation. The ADC14X250EVM is also compatible with many of the development

kits from leading FPGA vendors that contain an FMC connector.

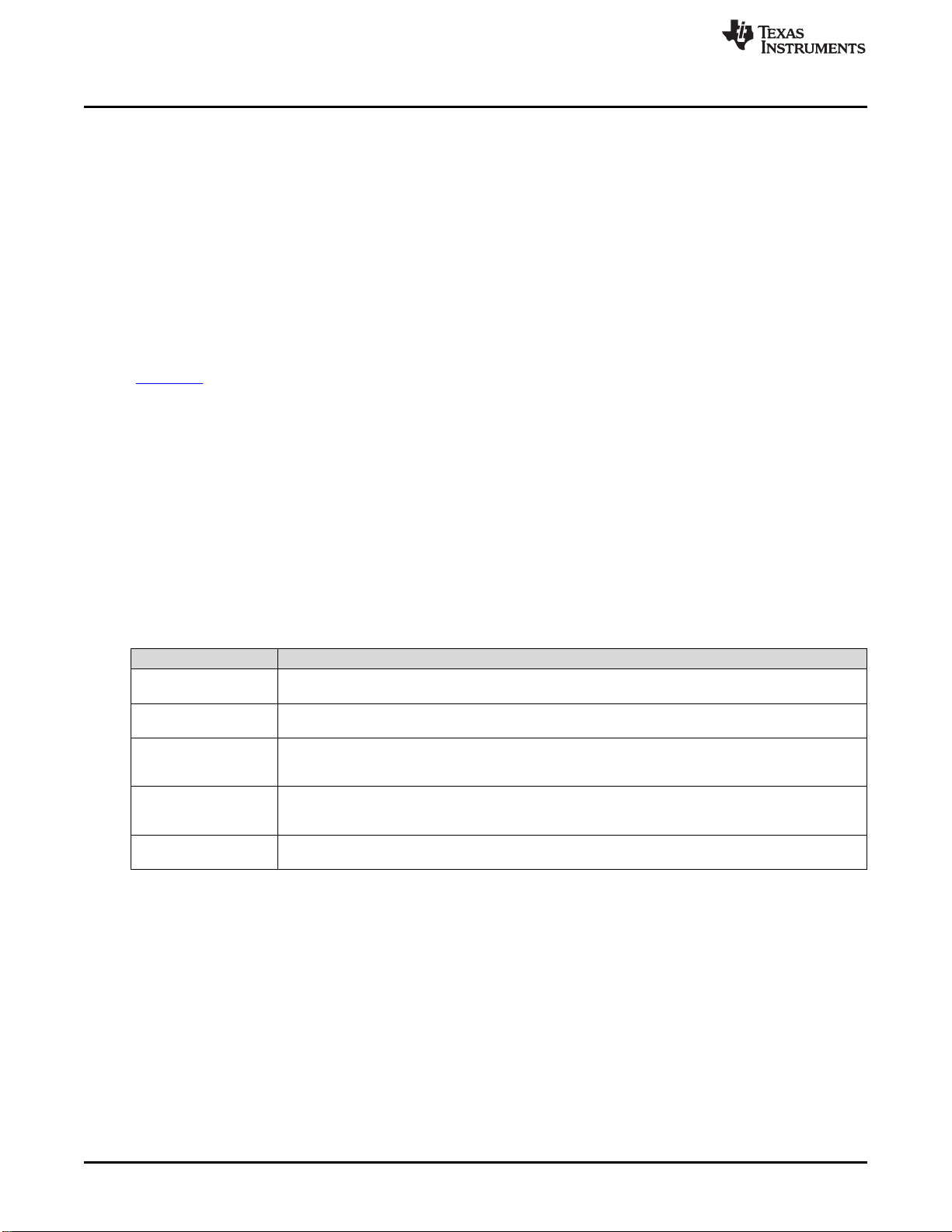

1.1 Required Hardware

The following equipment is included in the EVM evaluation kit:

• ADC14X250EVM evaluation board (EVM)

• Flying lead-to-barrel connector power supply cable

• Mini-USB cable

The following list of equipment are items that are not included in the EVM evaluation kit but are items

required for evaluation of this product to achieve the best performance:

• TSW14J56EVM Kit: Data capture board, 5-V power supply and mini-USB cable

• 5-V power supply capable of sourcing 2 A

• Computer running Microsoft®Windows®7 or Windows XP

• Two (2) low-noise signal generators

Recommendations:

– RF generator, > 17 dBm, < –40-dBc harmonics, < 500 fs jitter 20 kHz–20 MHz, 10 MHz–2 GHz

frequency range

– Examples: TSW2170EVM, HP HP8644B, Rohde and Schwarz SMA100A

• Bandpass filter for analog input (between 125–250 MHz).

Recommendations:

– Bandpass filter, ≥60-dB harmonic attenuation, ≤5% bandwidth, > 18-dBm power, < 5-dB insertion

loss

– Examples: Trilithic 5VH-series Tunable BPF, K&L BT-series Tunable BPF, TTE KC6 or KC7-series

Fixed BPF

• Bandpass filter for clock input (250 MHz)

Recommendations:

– Bandpass filter, ≥60-dB harmonic attenuation, ≤5% bandwidth, > 18-dBm power, < 5-dB insertion

loss

– Examples: Trilithic 5VH-series Tunable BPF, K&L BT-series Tunable BPF, TTE KC6 or KC7-series

Fixed BPF

• Signal path cables, SMA and/or BNC with BNC-to-SMA adapters

2ADC14X250EVM Evaluation Module SLAU625–November 2015

Submit Documentation Feedback

Copyright © 2015, Texas Instruments Incorporated