25 July 1996 23 mm Transponder Reference Manual

Page 3of 22

Contents

1. Introduction ................................................................................................................................... 4

2. Transponder Packaging ................................................................................................................. 5

3. Product Codes ............................................................................................................................... 5

4. Function ........................................................................................................................................ 5

4.1 Read (Reading of RO and R/W Transponders) ........................................................................ 5

4.2 Write and Program .................................................................................................................. 8

5. Characteristics of the Pulsed FM System ....................................................................................... 9

5.1 Basic System Data ................................................................................................................... 9

5.2 Reader and System Design Impact .......................................................................................... 10

5.3 System Performance and Functional Reliability Impact ........................................................... 10

5.4 Other Quality Factors of the TIRIS Pulsed FM System ............................................................ 10

6. EMI/EMC Performance ................................................................................................................. 11

6.1 General ................................................................................................................................... 11

6.2 The Automotive Environment and Factors .............................................................................. 11

6.3 TIRIS Pulsed FM Transponder and System Performance ......................................................... 11

7. Measurement Set-Ups .................................................................................................................... 14

7.1 Measurement set-up: Resonance frequency, bandwidth, quality factor ..................................... 14

7.2 Measurement Set-Up: Powering Field Strength ....................................................................... 15

7.3 Measurement set-up: Transponder Signal Strength ................................................................. 17

8. Absolute Maximum Ratings .......................................................................................................... 18

9. Recommended Operating Conditions ............................................................................................. 18

10. Characteristics ............................................................................................................................. 19

11. Environmental Data and Reliability ............................................................................................. 20

12. Memory ....................................................................................................................................... 20

13. Package ....................................................................................................................................... 20

14. Packing Symbolization ................................................................................................................ 21

Appendix A: Conversion Formula ...................................................................................................... 22

Figures

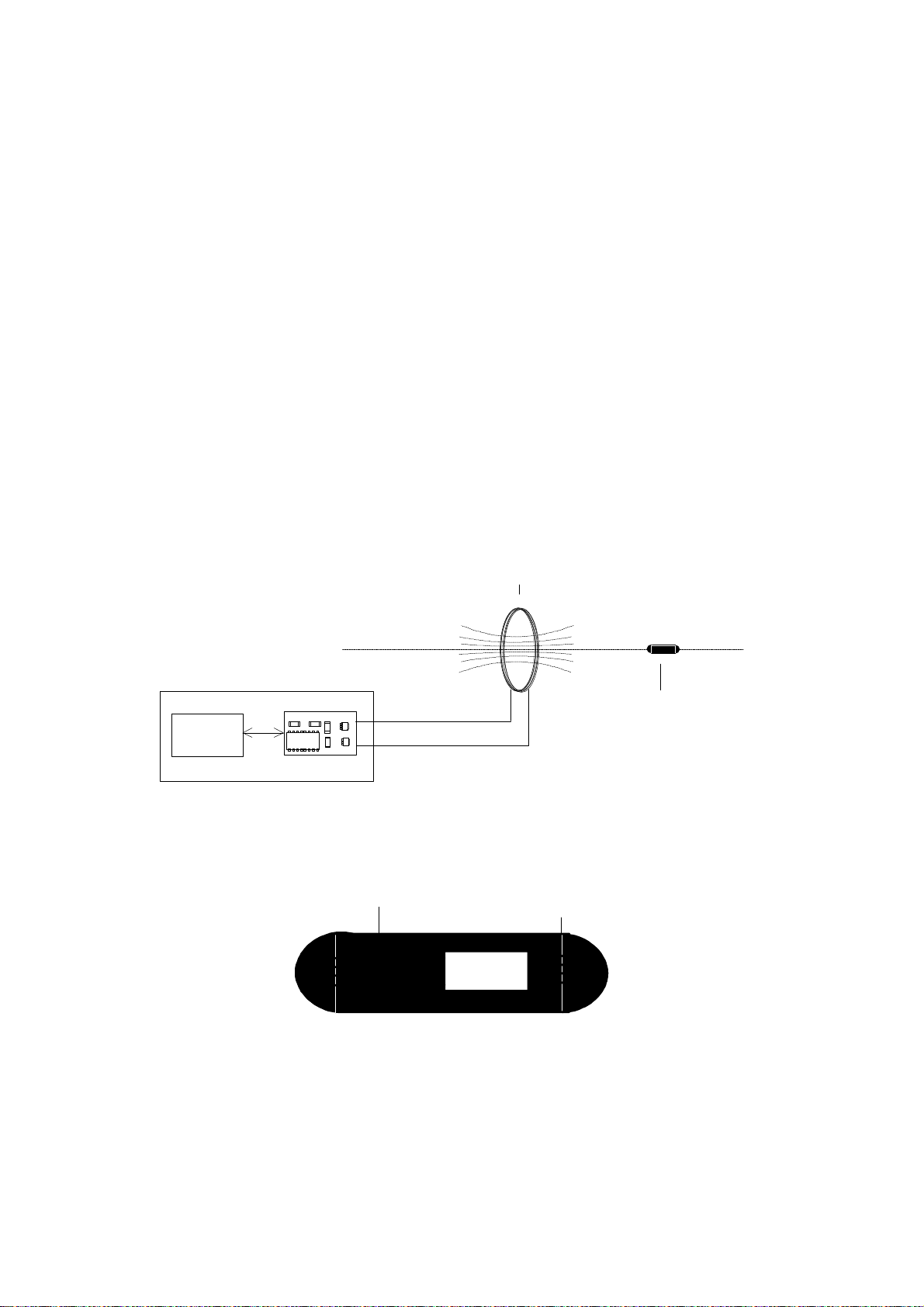

Figure 1: System Configuration Showing the Reader, Antenna and Transponder ................................ 4

Figure 2: Block Diagram of the TIRIS Pulsed FM Transponder .......................................................... 4

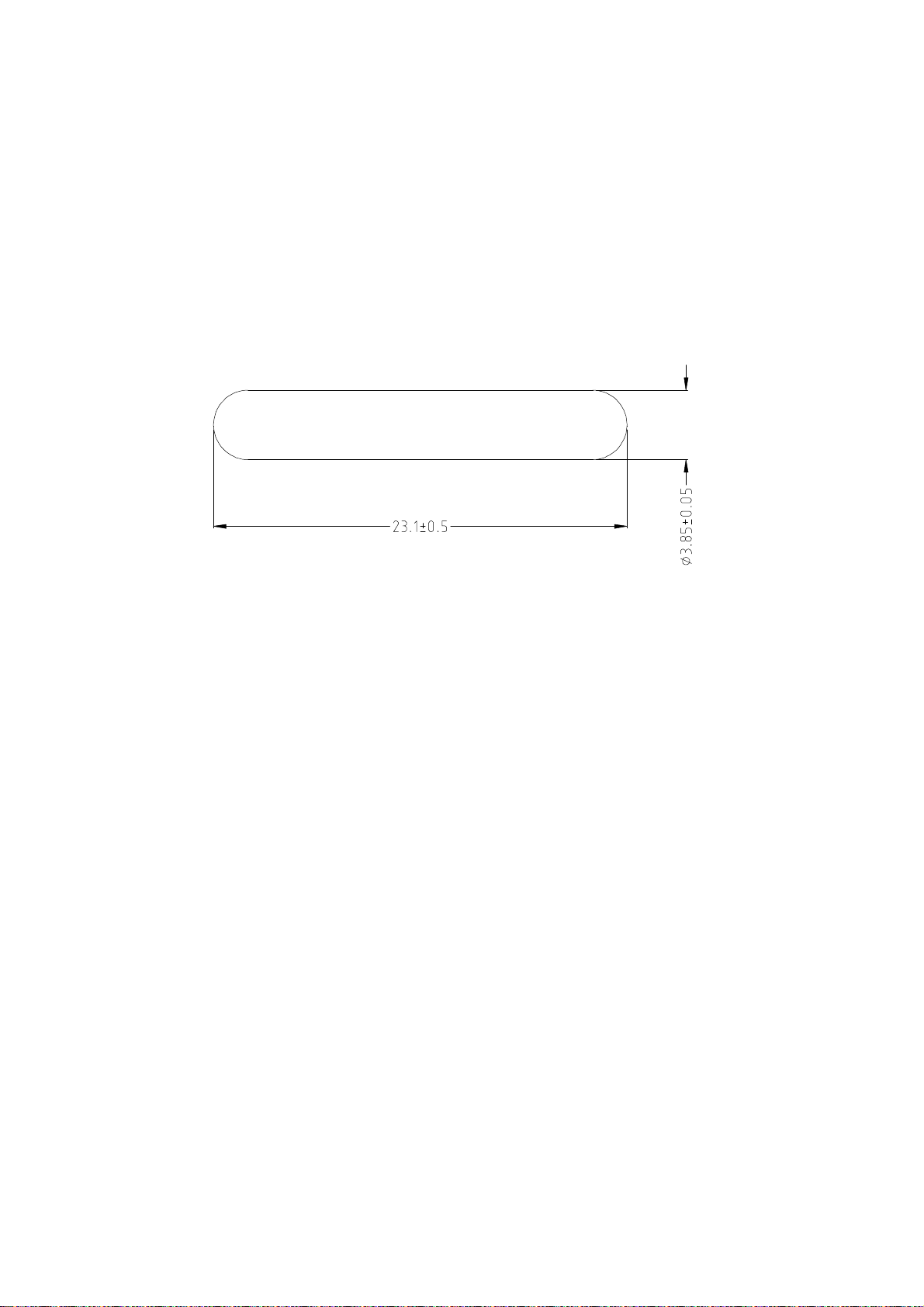

Figure 3: Dimensions of the TIRIS 23 mm Transponder (in mm) ....................................................... 5

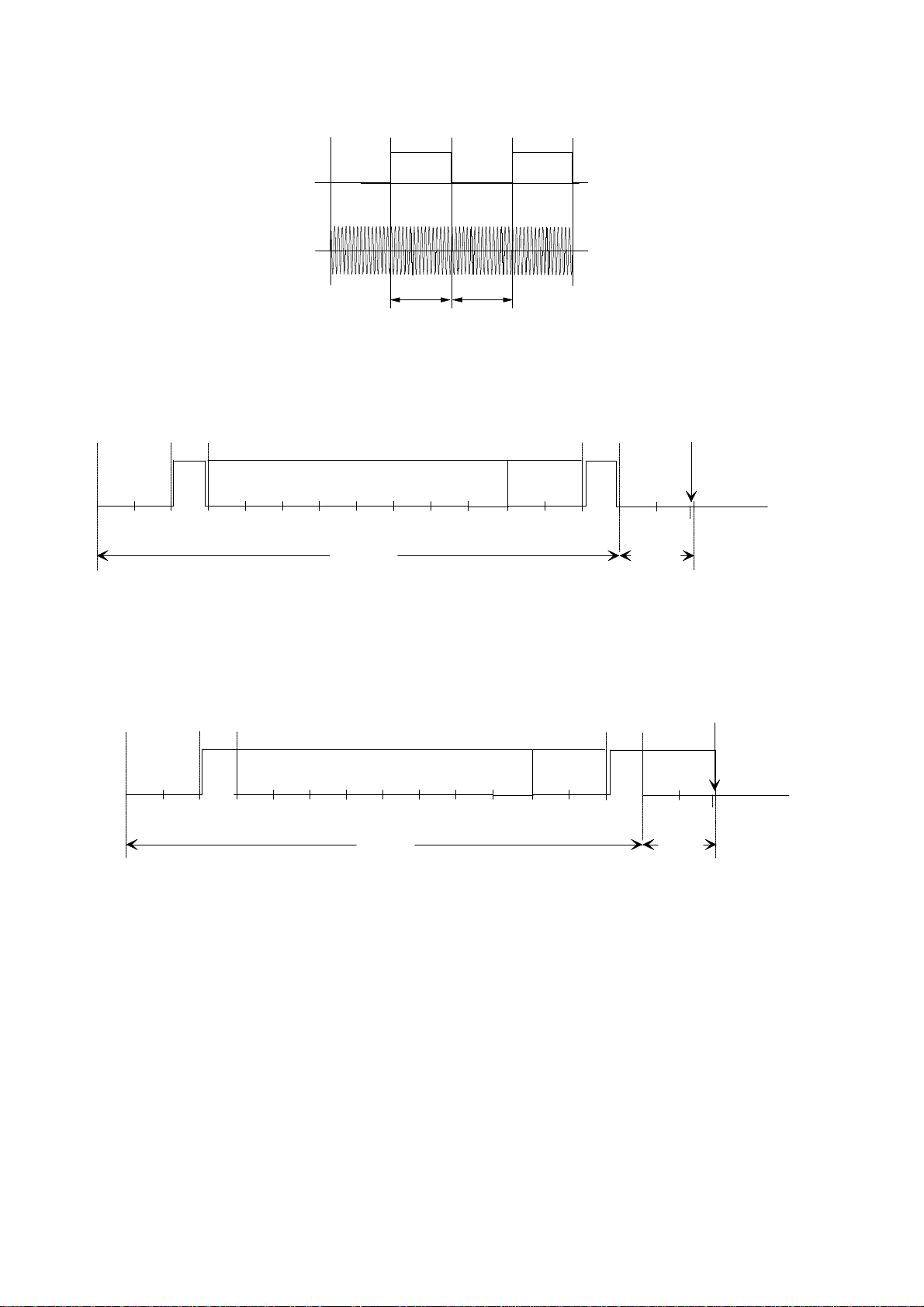

Figure 4: Charge and Read Function of the Transponder .................................................................... 6

Figure 5: FM Principle Used for the Read Function of TIRIS Transponders ........................................ 7

Figure 6a: Read Data Format of TIRIS RO Transponder ..................................................................... 7

Figure 6b: Read Data Format of TIRIS R/W Transponder ................................................................... 7

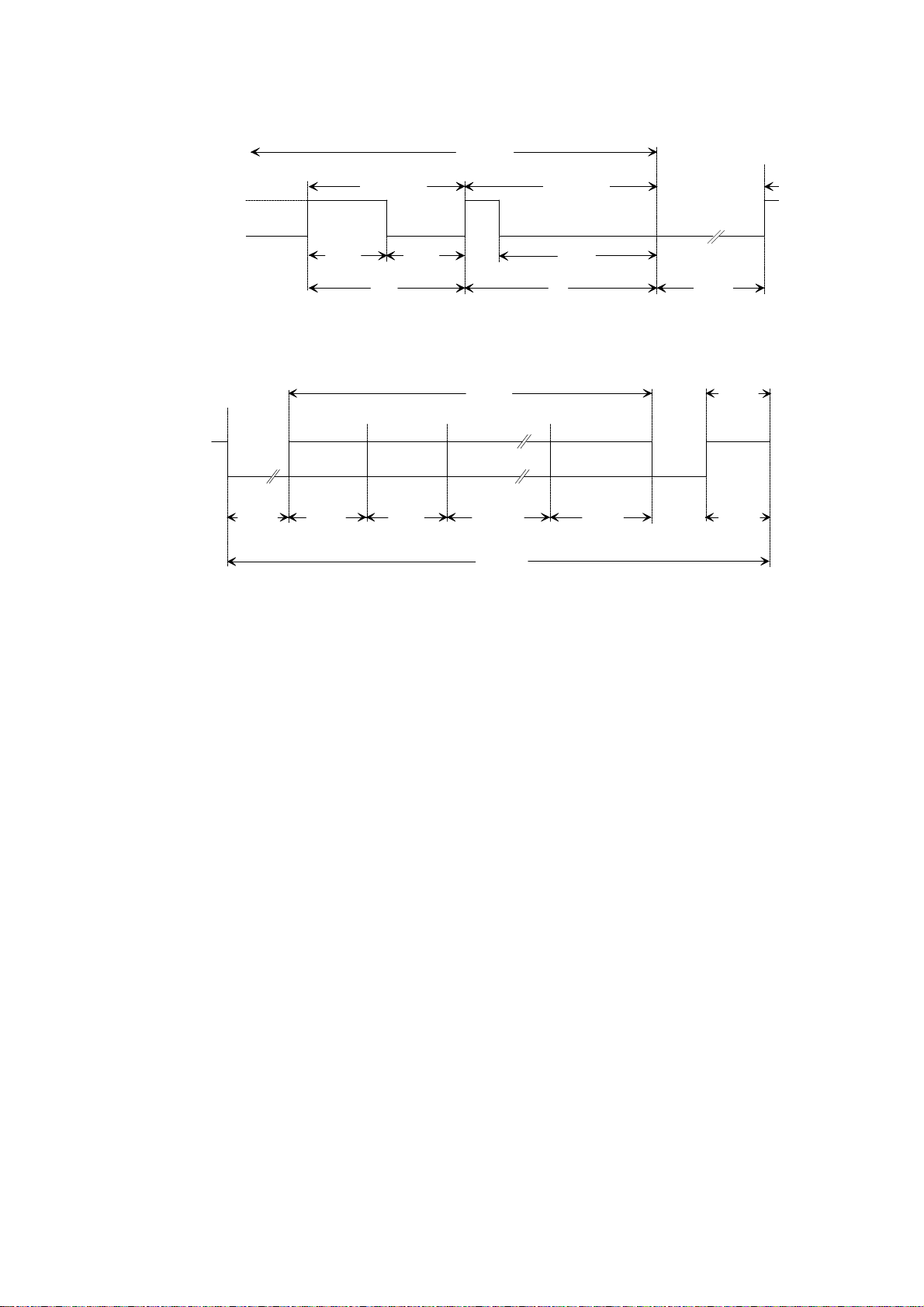

Figure 7: Charge, Write and Program Principle used for TIRIS .......................................................... 8

Figure 8: The Write and Program Function ........................................................................................ 9

Figure 9: Write Data Format for Programming Function .................................................................... 9

Figure 10: EMI Performance Test of the TIRIS System. ..................................................................... 12

Figure 11: EMI performance in automotive environment. ................................................................... 13

Figure 12: Reading range under broad band noise (white noise) conditions ........................................ 13

Figure 13: Measurement for transponder resonance, bandwidth & quality factor ............................... 14

Figure 14: Determination of resonance and -3dB by monitoring pick-up coil voltage .......................... 15

Figure 15: Test set-up for powering field strength determination ........................................................ 15

Figure 16: Received signal at the pick up coil, if power field strength is sufficient .............................. 16

Figure 17: Determination of the transponder signal strength with Helmholtz aperture ........................ 17

Figure 18: Monitored signal voltage at the spectrum analyzer (time domain mode) ............................ 17