Textron Jacobsen Groom Master II 88009 User manual

Parts & Maintenance Manual

Manual de piezas y mantenimiento

When Performance Matters.

™

ADVERTENCIA

Si se usa de forma incorrecta, esta máquina puede causar graves lesiones.

Cualquier persona que use y mantenga esta máquina debe estar entrenada

en su uso correcto, instruida de sus peligros y deberá leer todo el manual

antes de tratar de instalar, operar, ajustar o revisar la máquina.

WARNING

If incorrectly used, this machine can cause severe injury. Those who use

and maintain this machine should be trained in its proper use, warned of its

dangers and should read the entire manual before attempting to set up,

operate, adjust or service the machine

19

17

18

13

6

5

9

15

16

78

10

4

3

11

1-INCLUDESITEMS3 - 16

GB ES

Spain

United

Kingdom

Groom Master II™Sand Trap Rake / Groomer

with ROPS

Rastrilladora de bunkers Groom Master II™

con ROPS

88009,Briggs&Stratton®Vanguard,3WD

88042,Kubota®D722-E3B,3WD

4201266-ES-RevA

© Copyright 2010, Jacobsen, A Textron Company. “All rights

reserved, including the right to reproduce this material or portions

thereof in any form.”

This manual contains adjustment, maintenance,

troubleshooting instructions and parts list for your new

Jacobsen machine. This manual should be stored with the

equipmentforreferenceduringoperation.

Before you operate your machine, you and each operator

youemployshouldreadthemanualcarefullyinitsentirety.

By following the safety, operating and maintenance

instructions,youwillprolongthelifeofyourequipmentand

maintainitsmaximumefficiency.

If additional information is needed, contact your Jacobsen

Dealer.

The serial plate is located on the seat pan. Jacobsen

recommends you record these numbers below for easy

reference.

®

P.O. BOX 7708,

CHARLOTTE,

NC 28241, USA

kg kg kg kW

Jacobsen.com

1-800-848-1636 (US)

en-2

Proposition 65 Warning

Thisproductcontainsoremitschemicals

known to State of California to cause

cancer and birth defects or other

reproductiveharm.

FOREWORD

Suggested Stocking Guide

ToKeepyourequipmentfullyoperationalandproductive,Jacobsensuggestsyoumaintainastockof themorecommonly

usedmaintenanceitems.Wehaveincludedpartnumbersforadditionalsupportmaterialsandtrainingaids.

Toorderanyofthefollowingmaterial:

1. Writeyourfullnameandcompleteaddressonyourorder

form.

2. Explainwhereandhowtomakeshipment:

qUPS qRegularMail

qOvernight q2ndDay

3. Orderbythequantitydesired,thepartnumber,andthe

descriptionofthepart.

4. SendorbringtheordertoyourauthorizedJacobsen

Dealer.

LithoinU.S.A.2-2010

Service Parts

Service Support Material

Qty. Part No. Description Qty. Part No. Description

5000440 GasEngineOilFilter 5002644 DieselEngineOilFilter

5000441 GasEngineAirFilter 5000913 DieselEngineAirFilter

5000436 GasEngineFuelFilter 4209366 DieselEngineFuelFilter

5000913 GasRemoteAirFilter 522972 HydraulicOilFilter

2811450 AlternatorBelt

Qty. Part No. Description

4201264 Safety&OperationManual

4201266 Parts&Maintenance

4189622 DieselEnginePartsManual

4168862 OperatorTrainingVideo

Qty. Part No. Description

2006/42/EC

ThesearetheOriginalinstructionsverifiedbyJacobsenA

TextronCompany.

en-3

Table of Contents

1 Safety

1.1 OperatingSafety......................................... 4

1.2 ImportantSafetyNotes.................................5

2 Specifications

2.1 ProductIdentification................................... 6

2.2 Engine .........................................................6

2.3 Groomer ......................................................7

2.4 WeightsandDimensions..............................7

2.5 Accessories&SupportLiterature .................7

2.6 DeclarationofConformity.............................8

3 Adjustments

3.1 General..................................................... 10

3.2 FanBelt(DieselEngines) ...........................10

3.3 NeutralSwitch............................................10

3.4 NeutralAdjustment(GasUnits) ..................11

3.5 NeutralAdjustment(DieselUnits)...............11

3.6 Parking/ServiceBrake ..............................12

3.7 TorqueSpecification ..................................13

4 Maintenance

4.1 General..................................................... 14

4.2 Engine .......................................................14

4.3 EngineOil ..................................................15

4.4 AirFilter .....................................................15

4.5 GasEngineAirFilter...................................16

4.6 Fuel ...........................................................16

4.7 FuelSystem...............................................16

4.8 Battery .......................................................17

4.9 JumpStarting.............................................17

4.10 ChargingBattery ........................................17

4.11 HydraulicHoses.........................................18

4.12 HydraulicOil ..............................................18

4.13 HydraulicOilFilters ....................................19

4.14 ElectricalSystem .......................................19

4.15 MufflerandExhaust ...................................19

4.16 Tires ..........................................................19

4.17 WheelMountingProcedure........................20

4.18 CareandCleaning .....................................20

4.19 Radiator(DieselEngines) ..........................20

4.20 Storage......................................................21

5 Troubleshooting

5.1 General ..................................................... 22

6 Maintenance & Lubrication Charts

6.1 General ..................................................... 23

6.2 LubricationCHart ......................................24

7 Parts Catalog

7.1 HowToUseThePartsCatalog...................25

7.2 ToOrderParts ...........................................25

7.3 TableOfContents......................................25

1 SAFETY

en-4

1 SAFETY

1.1 OPERATING SAFETY ______________________________________________________

1. Safetyisdependentupontheawareness,concern,and

prudence of those who operate or service the

equipment. Never allow minors to operate any

equipment.

2. It is your responsibility to read this manual and all

publications associated with this equipment (Safety &

Operation Manual, Engine Manual, and attachments/

accessories instruction sheets). If the operator cannot

readEnglishitistheowner’sresponsibilitytoexplainthe

materialcontainedinthismanualtothem.

3. Learn the proper use of the machine, the location and

purpose of all the controls and gauges before you

operate the equipment. Working with unfamiliar

equipmentcanleadtoaccidents.

4. Neverallowanyonetooperateorservicethemachineor

itsattachmentswithoutpropertrainingandinstructions;

orwhileundertheinfluenceofalcoholordrugs.

5. Wearallthenecessaryprotectiveclothingandpersonal

safety devices to protect your head, eyes, ears, hands,

andfeet.Operatethemachineonlyindaylightoringood

artificiallight.

6. Evaluatetheterraintodeterminewhataccessoriesand

attachments are needed to properly and safely perform

the job. Only use accessories and attachments

approvedbyJacobsen.

7. Stay alert for holes in the terrain and other hidden

hazards.

8. Inspecttheareawheretheequipmentwillbeused.Pick

up all the debris you can find before operating. Beware

of overhead obstructions (low tree limbs, electrical

wires,etc.)andalsoundergroundobstacles(sprinklers,

pipes,treeroots,etc.).Enteranewareacautiously.Stay

alertforhiddenhazards.

9. Never direct discharge of material toward bystanders,

nor allow anyone near the machine while in operation.

The owner/operator can prevent and is responsible for

injuries inflicted to themselves, to bystanders, and

damagetoproperty.

10. Do not carry passengers. Keep bystanders and pets a

safedistanceaway.

11. Never operate equipment that is not in perfect working

order or is without decals, guards, shields, discharge

deflectors,orotherprotectivedevicessecurelyfastened

inplace.

12. Neverdisconnectorbypassanyswitch.

13. Donotchangetheenginegovernorsettingoroverspeed

theengine.

14. Carbon monoxide in the exhaust fumes can be fatal

when inhaled. Never operate the engine without proper

ventilationorinanenclosedarea.

15. Fuelishighlyflammable;handlewithcare.

16. Keep the engine clean. Allow the engine to cool before

storingandalwaysremovetheignitionkey.

17. Disengage all drives and engage parking brake before

starting the engine (motor). Start the engine only when

sitting in operator’s seat, never while standing beside

theunit.

18. Equipment must comply with the latest federal, state,

and local requirements when driven or transported on

public roads. Watch out for traffic when crossing or

operatingonornearroads.

19. Localregulationsmayrestricttheageoftheoperator.

20. Never use your hands to search for oil leaks. Hydraulic

fluid under pressure can penetrate the skin and cause

seriousinjury.

21. Operate the machine up and down the face of slopes

(vertically),notacrosstheface(horizontally).

22. To prevent tipping or loss of control, do not start or stop

suddenlyonslopes.Reducespeedwhenmakingsharp

turns.Usecautionwhenchangingdirections.

23. Always use the seat belt when operating mowers

equippedwithaRollOverProtectiveStructure(ROPS).

Never use a seat belt when operating mowers

without a ROPS.

24. Always disconnect battery cables from battery before

performinganyweldingoperationonthegroomer.

This machine is to be operated and maintained as specified in this manual. It is intended for professional use

and is equipped with attachments designed to move, smooth and loosen sandy materials on golf courses and

sports fields. It is not intended for use with hard compacted soil or gravel.

WARNING

EQUIPMENT OPERATED IMPROPERLY OR BY UNTRAINED PERSONNEL CAN BE DANGEROUS.

Familiarizeyourselfwiththelocationandproperuseofallcontrols.Inexperiencedoperatorsshouldreceiveinstruction

fromsomeonefamiliarwiththeequipmentbeforebeingallowedtooperatethemachine.

!

SAFETY 1

en-5

1.2 IMPORTANT SAFETY NOTES ________________________________________________

This safety alert symbol is used to alert you to potential hazards.

DANGER-Indicatesanimminentlyhazardoussituationwhich,ifnotavoided,WILLresultindeathorseriousinjury.

WARNING-Indicatesapotentiallyhazardoussituationwhich,ifnotavoided,COULDresultindeathorseriousinjury.

CAUTION -Indicatesa potentiallyhazardoussituationwhich,ifnotavoided,MAY resultinminorormoderateinjuryand

propertydamage.Itmayalsobeusedtoalertagainstunsafepractices.

NOTICE-Indicatesapotentiallyhazardoussituationwhich,ifnotavoided,MAY resultinpropertydamage.Itmayalsobe

usedtoalertagainstunsafepractices.

For pictorial clarity, some illustrations in this manual may show shields, guards, or plates open or removed. Under no

circumstances should this equipment be operated without these devices securely fastened in place.

By following all instructions in this manual, you will prolong the life of your machine and maintain its maximum efficiency.

Adjustmentsandmaintenanceshouldalwaysbeperformedbyaqualifiedtechnician.

If additional information or service is needed, contact your Authorized Jacobsen Dealer who is kept informed of the latest

methodstoservicethisequipmentandcanprovidepromptandefficientservice.

WARNING

TheInterlockSystemonthisgroomerpreventsthegroomerfromstartingunless

theparkingbrakeisengagedandtractionpedalisinNeutral.Thesystemwillstop

theengineiftheoperatorleavestheseatwithoutengagingtheparkingbrake.

NEVERoperategroomerunlesstheInterlockSystemisworking.

!

WARNING

1. Beforeleavingtheoperator’spositionforanyreason:

a. ReturntractionpedaltoNeutral.

b. Disengagealldrives.

c. Lowerallimplementstotheground.

d. Engageparkingbrake.

e. Stopengineandremovetheignitionkey.

2. Keep hands, feet, and clothing away from moving parts. Wait for all

movementtostopbeforeyouclean,adjustorservicethemachine.

3. Keeptheareaofoperationclearofallbystandersandpets.

4. Nevercarrypassengers,unlessaseatisprovidedforthem.

!

2 SPECIFICATIONS

en-6

2 SPECIFICATIONS

2.1 PRODUCT IDENTIFICATION_________________________________________________

88010..............................GroomMasterII3-WDGroomer,18

hpgasolineengine.

88042..............................GroomMasterII3-WDGroomer,

16.6hpdieselengine.

SerialNumber .................Anidentificationplate,liketheone

shown,listingtheserialnumber,is

attachedtotheframeofthe

groomerontheseatpan.

Alwaysprovidetheserialnumberoftheunitwhenordering

replacementpartsorrequestingserviceinformation.

2.2 ENGINE__________________________________________________________________

Gasoline Engine

Make...............................Briggs&Stratton

Model..............................VanguardV-TwinOHV

Horsepower ....................18hp(13.5kW)@3600rpm

Note: Actual sustained horsepower will likely be lower

than listed in specifications due to operating limitations

and environmental factors.

Displacement..................34.8cu.In.(570cc)

Torque ............................26ft.lbs.(35Nm)@2600rpm

Fuel:

Type..........................UnleadedGasoline

Rating .......................Min.85Octane

Capacity....................4.5U.S.Gal.(17liters)

Governor.........................FlyweightMechanical

Lubrication:

Capacity....................3.5pints (1.4liters)

Type..........................SAE10W30,SAE30W

APIClassification ......SF,SG,SH

AirFilter...........................ReplaceableDualElement.

Alternator........................16amp

CoolingSystem...............AirCooled

Diesel Engine

Make............................... Kubota

Model.............................. D722-E3B

Horsepower.................... 16.6hp(12.4kW)@3000rpm

Note: Actual sustained horsepower will likely be lower

than listed in specifications due to operating limitations

and environmental factors.

Displacement.................. 43.88cu.In.(719cc)

Torque............................ 33.9ft.lbs.(45.9Nm)@2200rpm

Fuel:

Type.......................... No.2LoworUltraLowSulfurDiesel

Rating....................... Min.Cetanerating45

Capacity.................... 4.5U.S.Gal.(17liters)

Governor......................... BallTypeGovernor

LowIdle .................... 1100RPM

HighIdle.................... 3400RPM

Lubrication:

Capacity.................... 3.4quarts(3.2liter)withfilter

Type.......................... SAE10W30,SAE20W,SAE30W

APIClassification...... CD,CE

AirFilter........................... Drytypewithevacuatorvalveand

serviceindicator.

Alternator........................ 40amp

CoolingSystem............... LiquidCooled

Capacity...................... 3qt.(2.8l)50/50waterethyleneglycol

mix

Product EEC Sound

Power

Operator

Ear

Vibration M/S2

Arms Body

88010

88042 TBD

101.3dB TBD

85.2dB TBD

8.4 TBD

0.507

®

P.O. BOX 7708,

CHARLOTTE,

NC 28241, USA

kg kg kg kW

Jacobsen.com

1-800-848-1636 (US)

88010

GROOMSMASTERII

SANDRAKE

446 13.5

1651

XXXX

NOTICE

Do not use hi-test gasoline or an oil-gasoline mixture.

When using blended fuel, do not use a blend with more

than 10% ethanol. Under no circumstances should you

useablendwithmethanol.

SPECIFICATIONS 2

en-7

2.3 GROOMER _______________________________________________________________

Tires................................20x11-10tubeless

Pressure:.........................3-5psi(0.21-0.34BAR)

Battery:

Type..........................12VoltMaintenanceFree

Group........................24F

ParkingBrake..................Mechanicalrearwheeldisk

Pedalactuated

Speed:

Forward ....................0-9.3mph(16kph)

Reverse .................... 0-3.5mph(8kph)

HydraulicSystem:

Capacity..........................3.29U.S.gal.(12.46liters)

FluidType .......................GreensCare68

Filter................................FullFlow10micron

Steering ..........................Hydrostaticpowersteering

AttachmentLift ................ HydraulicDoubleActingCylinder

2.4 WEIGHTS AND DIMENSIONS ________________________________________________

Dimensions: Inches (mm)

Length(RearRakeandFrontBlade)................. 90 (2286)

Height-SteeringWheelUp............................... 53 (1346)

WheelBase ..................................................... 40 (1016)

Width(WithRearRake)................................. 73.5 (1867)

TurningRadius(CenterofFrontTire)................ 52 (1321)

TurningRadius(InsideRearTire........................ 6 (152)

Weights: Lbs. (kg)

WorkingWeightWithRake,LessOperator

88010............................................................ 984 (446.3)

88042.............................................................xxx (xxx)

2.5 ACCESSORIES & SUPPORT LITERATURE _____________________________________

ContactyourareaJacobsenDealerforacompletelistingofaccessoriesandattachments.

Accesories

AirBlowGun............................................................JAC5098

OrangeTouch-upPaint(12oz.spray) ........................ 554598

RearRake ................................................................. 894134

FrontBlade.................................................................. 88019

FrontBladeHydraulics................................................. 88115

Cultivator..................................................................... 88114

Scarifier..................................................................... 891717

DragMat.................................................................... 891768

PiggyBackFanRake................................................. 891763

Support Literature

Safety&OperationManual.......................................4201264

Parts&MaintenanceManual....................................4201266

DieselEnginePartsCatalog .....................................4189622

OperatorTrainingVideo ...........................................4168862

CAUTION

UseofotherthanJacobsenauthorizedpartsandaccessoriesmaycausepersonalinjuryordamagetotheequipment.

!

2 SPECIFICATIONS

en-8

2.6 DECLARATION OF CONFORMITY ____________________________________________

DECLARATION OF CONFORMITY ▪ДЕКЛАРАЦИЯ ЗА СЪОТВЕТСТВИЕ ▪PROHLÁŠENÍ O SHODĚ▪

OVERENSSTEMMELSESERKLÆRING ▪CONFORMITEITSVERKLARING ▪VASTAVUSDEKLARATSIOON ▪

VAATIMUSTENMUKAISUUSVAKUUTUS ▪DECLARATION DE CONFORMITE ▪KONFORMITÄTSERKLÄRUNG ▪

ΔΗΛΩΣΗ ΣΥΜΜΟΡΦΩΣΗΣ ▪MEGFELELŐSÉGI NYILATKOZAT ▪DICHIARAZIONE DI CONFORMITÀ ▪ATBILSTĪBAS

DEKLARĀCIJA ▪ATITIKTIES DEKLARACIJA ▪DIKJARAZZJONI TAL-KONFORMITÀ ▪DEKLARACJA ZGODNOŚCI ▪

DECLARAÇÃO DE CONFORMIDADE ▪DECLARAŢIE DE CONFORMITATE ▪VYHLÁSENIE O ZHODE ▪IZJAVA O

SKLADNOSTI ▪DECLARACIÓN DE CONFORMIDAD ▪DEKLARATION OM ÖVERENSSTÄMMELSE

Business name and full address of the manufacturer ▪Търговско име ипълен адрес на производителя ▪Obchodní jméno a plná adresa výrobce ▪

Producentens firmanavn og fulde adresse ▪Bedrijfsnaam en volledig adres van de fabrikant ▪Tootja ärinimi ja täielik aadress ▪

Valmistajan toiminimi ja täydellinen osoite ▪Nom commercial et adresse complète du fabricant ▪Firmenname und vollständige Adresse des Herstellers ▪

Επωνυμία και ταχυδρομική διεύθυνση κατασκευαστή ▪A gyártó üzleti neve és teljes címe ▪Ragione sociale e indirizzo completo del fabbricante ▪

Uzņēmuma nosaukums un pilna ražotāja adrese ▪Verslo pavadinimas ir pilnas gamintojo adresas ▪Isem kummerċjali u indirizz sħiħtal-fabbrikant ▪

Nazwa firmy i pełny adres producenta ▪Nome da empresa e endereço completo do fabricante ▪Denumirea comercialăşi adresa completăa

producătorului ▪Obchodný názov a úplná adresa výrobcu ▪Naziv podjetja in polni naslov proizvajalca ▪Nombre de la empresa y dirección completa del

fabricante ▪Tillverkarens företagsnamn och kompletta adress

Jacobsen, A Textron Company

11524 Wilmar Blvd.

Charlotte, NC 28273, USA

Product Code ▪Код на продукта ▪Kód výrobku ▪Produktkode ▪Productcode ▪Toote kood ▪Tuotekoodi ▪Code produit ▪Produktcode ▪Κωδικός προϊόντος

▪Termékkód ▪Codice prodotto ▪Produkta kods ▪Produkto kodas ▪Kodiċi tal-Prodott ▪Kod produktu ▪Código do Produto ▪Cod produs ▪Kód výrobku ▪

Oznaka proizvoda ▪Código de producto ▪Produktkod

88042

Machine Name ▪Наименование на машината ▪Název stroje ▪Maskinnavn ▪Machinenaam ▪Masina nimi ▪Laitteen nimi ▪Nom de la machine ▪

Maschinenbezeichnung ▪Ονομασία μηχανήματος ▪Gépnév ▪Denominazione della macchina ▪Iekārtas nosaukums ▪Mašinos pavadinimas ▪Isem tal-

Magna ▪Nazwa urządzenia ▪Nome da Máquina ▪Numele echipamentului ▪Názov stroja ▪Naziv stroja ▪Nombre de la máquina ▪Maskinens namn

Groom Master II Diesel

Designation ▪Предназначение ▪Označení ▪Betegnelse ▪Benaming ▪Nimetus ▪Tyyppimerkintä ▪Pažymėjimas ▪Bezeichnung ▪Χαρακτηρισμός ▪

Megnevezés ▪Funzione ▪Apzīmējums ▪Lithuanian ▪Denominazzjoni ▪Oznaczenie ▪Designação ▪Specificaţie ▪Označenie ▪Namen stroja ▪Descripción

▪Beteckning

Scarifier, Article 13, Item 49

Serial Number ▪Сериен номер ▪Sériové číslo ▪Serienummer ▪Serienummer ▪Seerianumber ▪Valmistusnumero ▪Numéro de série ▪Seriennummer ▪

Σειριακός αριθμός ▪Sorozatszám ▪Numero di serie ▪Sērijas numurs ▪Serijos numeris ▪Numru Serjali ▪Numer seryjny ▪Número de Série ▪Număr de

serie ▪Sériové číslo ▪Serijska številka ▪Número de serie ▪Serienummer

8804201651 - 8804202500

Engine ▪Двигател ▪Motor ▪Motor ▪Motor ▪Mootor ▪Moottori ▪Moteur ▪Motor ▪Μηχανή ▪Modulnév ▪Motore ▪Dzinējs ▪Variklis ▪Saħħa Netta Installata ▪

Silnik ▪Motor ▪Motor ▪Motor ▪Motor ▪Motor ▪Motor Kubota D722-E3B Diesel

Net Installed Power ▪Нетна инсталирана мощност ▪Čistý instalovaný výkon ▪Installeret nettoeffekt ▪Netto geïnstalleerd vermogen ▪Installeeritud

netovõimsus ▪Asennettu nettoteho ▪Puissance nominale nette ▪Installierte Nettoleistung ▪Καθαρή εγκατεστημένη ισχύς ▪Nettó beépített teljesítmény ▪

Potenza netta installata ▪Paredzētātīkla jauda ▪Grynoji galia ▪Wisa’ tal-Qtugħ▪Moc zainstalowana netto ▪Potência instalada ▪Puterea instalatănetă▪

Čistý inštalovaný výkon ▪Neto vgrajena moč▪Potencia instalada neta ▪Nettoeffekt

12,4 kW @ 3000 RPM

Cutting Width ▪Широчина на рязане ▪Šířka řezu ▪Skærebredde ▪Maaibreedte ▪Lõikelaius ▪Leikkuuleveys ▪Largeur de coupe ▪Schnittbreite ▪

Μήκος μισινέζας ▪Vágási szélesség ▪Larghezza di taglio ▪Griešanas platums ▪Pjovimo plotis ▪Tikkonforma mad-Direttivi ▪Szerokość cięcia ▪

Largura de Corte ▪Lăţimea de tăiere ▪Šírka záberu ▪Širina reza ▪Anchura de corte ▪Klippbredd

NA

Conforms to Directives ▪Всъответствие сдирективите ▪Splňuje podmínky směrnic ▪Er i overensstemmelse med direktiver ▪Voldoet aan de richtlijnen ▪

Vastab direktiividele ▪Direktiivien mukainen ▪Conforme aux directives ▪Entspricht Richtlinien ▪Ακολουθήστε πιστά τις Οδηγίες ▪Megfelel az irányelveknek

▪Conforme alle Direttive ▪Atbilst direktīvām ▪Atitinka direktyvųreikalavimus ▪Valutazzjoni tal-Konformità ▪Dyrektywy związane ▪Cumpre as Directivas ▪

RespectăDirectivele ▪Je v súlade so smernicami ▪Skladnost z direktivami ▪Cumple con las Directivas ▪Uppfyller direktiv

2004/108/EC

2006/42/EC

2004/14/EC, 2005/88/EC

2006/66/EC

Conformity Assessment ▪Оценка за съответствие ▪Hodnocení plnění podmínek ▪Overensstemmelsesvurdering ▪Conformiteitsbeoordeling ▪

Vastavushindamine ▪Vaatimustenmukaisuuden arviointi ▪Evaluation de conformité ▪Konformitätsbeurteilung ▪Διαπίστωση Συμμόρφωσης ▪

Megfelelőség-értékelés ▪Valutazione della conformità ▪Atbilstības novērtējums ▪Atitikties įvertinimas ▪Livell tal-Qawwa tal-Ħoss Imkejjel ▪Ocena

zgodności ▪Avaliação de Conformidade ▪Evaluarea conformităţii ▪Vyhodnotenie zhodnosti ▪Ocena skladnosti ▪Evaluación de conformidad ▪

Bedömning av överensstämmelse

Annex VIII

Measured Sound Power Level ▪Измерено ниво на звукова мощност ▪Naměřený akustický výkon ▪Målte lydstyrkeniveau ▪Gemeten geluidsniveau ▪

Mõõdetud helivõimsuse tase ▪Mitattu äänitehotaso ▪Niveau de puissance sonore mesuré ▪Gemessener Schalldruckpegel ▪

Σταθμισμένο επίπεδο ηχητικής ισχύος ▪Mért hangteljesítményszint ▪Livello di potenza sonora misurato ▪Izmērītais skaņas jaudas līmenis ▪

Išmatuotas garso stiprumo lygis ▪Livell tal-Qawwa tal-Ħoss Iggarantit ▪Moc akustyczna mierzona ▪Nível sonoro medido ▪Nivelul măsurat al puterii

acustice ▪Nameraná hladina akustického výkonu ▪Izmerjena raven zvočne moči ▪Nivel de potencia sonora medido ▪Uppmätt ljudeffektsnivå

99.6 dB(A) LWA

Guaranteed Sound Power Level ▪Гарантирано ниво на звукова мощност ▪Garantovaný akustický výkon ▪Garanteret lydstyrkeniveau ▪

Gegarandeerd geluidsniveau ▪Garanteeritud helivõimsuse tase ▪Taattu äänitehotaso ▪Niveau de puissance sonore garanti ▪Garantierter

Schalldruckpegel ▪Εγγυημένο επίπεδο ηχητικής ισχύος ▪Szavatolt hangteljesítményszint ▪Livello di potenza sonora garantito ▪Garantētais skaņas

jaudas līmenis ▪Garantuotas garso stiprumo lygis ▪Livell tal-Qawwa tal-Ħoss Iggarantit ▪Moc akustyczna gwarantowana ▪Nível sonoro farantido ▪

Nivelul garantat al puterii acustice ▪Garantovaná hladina akustického výkonu ▪Zajamčena raven zvočne moči ▪Nivel de potencia sonora garantizado ▪

Garanterad ljudeffektsnivå

101.3 dB(A) LWA

Conformity Assessment Procedure (Noise) ▪Оценка за съответствие на процедурата (Шум) ▪Postup hodnocení plnění podmínek (hluk) ▪

Procedure for overensstemmelsesvurdering (Støj) ▪Procedure van de conformiteitsbeoordeling (geluid) ▪Vastavushindamismenetlus (müra) ▪

Vaatimustenmukaisuuden arviointimenettely (Melu) ▪Procédure d’évaluation de conformité (bruit) ▪Konformitätsbeurteilungsverfahren (Geräusch) ▪

Διαδικασία Αξιολόγησης Συμμόρφωσης (Θόρυβος) ▪Megfelelőség-értékelési eljárás (Zaj) ▪Procedura di valutazione della conformità (rumore) ▪

Atbilstības novērtējuma procedūra (troksnis) ▪Atitikties įvertinimo procedūra (garsas) ▪Proċedura tal-Valutazzjoni tal-Konformità (Ħoss) ▪

Procedura oceny zgodności (poziom hałasu) ▪Processo de avaliação de conformidade (nível sonoro) Procedura de evaluare a conformităţii (zgomot) ▪

Postup vyhodnocovania zhodnosti (hluk) ▪Postopek za ugotavljanje skladnosti (hrup) ▪Procedimiento de evaluación de conformidad (ruido) ▪

Procedur för bedömning av överensstämmelse (buller)

2000/14/EC Annex V

UK Notified Body for 2000/14/EC ▪Нотифициран орган вОбединеното кралство за 2000/14/ЕО ▪Úřad certifikovaný podle směrnice č. 2000/14/EC ▪

Det britiske bemyndigede organ for 2001/14/EF ▪Engels adviesorgaan voor 2000/14/EG ▪Ühendkuningriigi teavitatud asutus direktiivi 2000/14/EÜ

mõistes ▪Direktiivin 2000/14/EY mukainen ilmoitettu tarkastuslaitos Isossa-Britanniassa ▪Organisme notifié concernant la directive 2000/14/CE ▪

Britische benannte Stelle für 2000/14/EG ▪Κοινοποιημένος Οργανισμός Ηνωμένου Βασιλείου για 2000/14/ΕΚ ▪

2000/14/EK – egyesült királyságbeli bejelentett szervezet ▪Organismo Notificato in GB per 2000/14/CE ▪2000/14/EK AK reģistrētāorganizācija ▪

JK notifikuotosios įstaigos 2000/14/EC ▪Korp Notifikat tar-Renju Unit għal 2000/14/KE ▪Dopuszczona jednostka badawcza w Wielkiej Brytanii wg 2000/

14/WE ▪Entidade notificada no Reino Unido para 2000/14/CE ▪Organism notificat în Marea Britanie pentru 2000/14/CE ▪

Notifikovaný orgán Spojeného kráľovstva pre smernicu 2000/14/ES ▪Britanski priglašeni organ za 2000/14/ES ▪

Cuerpo notificado en el Reino Unido para 2000/14/CE ▪Anmält organ för 2000/14/EG i Storbritannien

Number: 1088

Sound Research Laboratories Limited

Holbrook House, Little Waldingfield

Sudbury, Suffolk CO10 0TH

Operator Ear Noise Level ▪Оператор на нивото на доловим от ухото шум ▪Hladina hluku v oblasti uší operátora ▪Støjniveau i førers ørehøjde ▪

Geluidsniveau oor bestuurder ▪Müratase operaatori kõrvas ▪Melutaso käyttäjän korvan kohdalla ▪Niveau de bruit à hauteur des oreilles de l’opérateur ▪

Schallpegel am Bedienerohr ▪Επίπεδο θορύβου σε λειτουργία ▪A kezelőfülénél mért zajszint ▪Livello di potenza sonora all’orecchio dell’operatore ▪

Trokšņa līmenis pie operatora auss ▪Dirbančiojo su mašina patiriamo triukšmo lygis ▪Livell tal-Ħoss fil-Widna tal-Operatur ▪

Dopuszczalny poziom hałasu dla operatora ▪Nível sonoro nos ouvidos do operador ▪Nivelul zgomotului la urechea operatorului ▪

Hladina hluku pôsobiaca na sluch operátora ▪Raven hrupa pri ušesu upravljavca ▪Nivel sonoro en el oído del operador ▪Ljudnivå vid förarens öra

85.2 dB

SPECIFICATIONS 2

en-9

Harmonised standards used ▪Използвани хармонизирани стандарти ▪Použité harmonizované normy ▪Brugte harmoniserede standarder ▪

Gebruikte geharmoniseerde standaards ▪Kasutatud ühtlustatud standardid ▪Käytetyt yhdenmukaistetut standardit ▪Normes harmonisées utilisées ▪

Angewandte harmonisierte Normen ▪Εναρμονισμένα πρότυπα που χρησιμοποιήθηκαν ▪Harmonizált szabványok ▪Standard armonizzati applicati ▪

Izmantotie saskaņotie standarti ▪Panaudoti suderinti standartai ▪Standards armonizzati użati ▪Normy spójne powiązane ▪Normas harmonizadas usadas

▪Standardele armonizate utilizate ▪Použité harmonizované normy ▪Uporabljeni usklajeni standardi ▪Estándares armonizados utilizados ▪

Harmoniserade standarder som används

Technical standards and specifications used ▪Използвани технически стандарти испецификации ▪Použité technické normy a specifikace ▪

Brugte tekniske standarder og specifikationer ▪Gebruikte technische standaards en specificaties ▪Kasutatud tehnilised standardid ja spetsifikatsioonid ▪

Käytetyt tekniset standardit ja eritelmät ▪Spécifications et normes techniques utilisées ▪Angewandte technische Normen und Spezifikationen ▪

Τεχνικά πρότυπα και προδιαγραφές που χρησιμοποιήθηκαν ▪Műszaki szabványok és specifikációk ▪Standard tecnici e specifiche applicati ▪

Izmantotie tehniskie standarti un specifikācijas ▪Panaudoti techniniai standartai ir techninėinformacija ▪Standards u speċifikazzjonijiet tekniċi użati ▪

Normy i specyfikacje techniczne powiązane ▪Normas técnicas e especificações usadas ▪Standardele tehnice şi specificaţiile utilizate ▪

Použité technické normy a špecifikácie ▪Uporabljeni tehnični standardi in specifikacije ▪Estándares y especificaciones técnicas utilizadas ▪

Tekniska standarder och specifikationer som används

The place and date of the declaration ▪Място идата на декларацията ▪Místo a datum prohlášení ▪Sted og dato for erklæringen ▪

Plaats en datum van de verklaring ▪Deklaratsiooni väljastamise koht ja kuupäev ▪Vakuutuksen paikka ja päivämäärä ▪Lieu et date de la déclaration ▪

Ort und Datum der Erklärung ▪Τόπος και ημερομηνία δήλωσης ▪A nyilatkozat kelte (hely és idő) ▪Luogo e data della dichiarazione ▪

Deklarācijas vieta un datums ▪Deklaracijos vieta ir data ▪Il-post u d-data tad-dikjarazzjoni ▪Miejsce i data wystawienia deklaracji ▪Local e data da

declaração ▪Locul şi data declaraţiei ▪Miesto a dátum vyhlásenia ▪Kraj in datum izjave ▪Lugar y fecha de la declaración ▪Plats och datum för

deklarationen

Jacobsen, A Textron Company

11524 Wilmar Blvd.

Charlotte, NC 28273, USA

August xx, 2009

Signature of the person empowered to draw up the declaration on behalf of the manufacturer, holds the technical documentation and is authorised to

compile the technical file, and who is established in the Community.

Подпис на човека, упълномощен да състави декларацията от името на производителя, който поддържащ техническата документация ие

оторизиран да изготви техническия файл иерегистриран вобщността.

Podpis osoby oprávněné sestavit prohlášení jménem výrobce, držet technickou dokumentaci a osoby oprávněné sestavit technické soubory a založené v

rámci Evropského společenství.

Underskrift af personen, der har fuldmagt til at udarbejde erklæringen på vegne af producenten, der er indehaver af dokumentationen og er bemyndiget til

at udarbejde den tekniske journal, og som er baseret i nærområdet.

Handtekening van de persoon die bevoegd is de verklaring namens de fabrikant te tekenen, de technische documentatie bewaart en bevoegd is om het

technische bestand samen te stellen, en die is gevestigd in het Woongebied.

Ühenduse registrisse kantud isiku allkiri, kes on volitatud tootja nimel deklaratsiooni koostama, kes omab tehnilist dokumentatsiooni ja kellel on õigus

koostada tehniline toimik.

Sen henkilön allekirjoitus, jolla on valmistajan valtuutus vakuutuksen laadintaan, jolla on hallussaan tekniset asiakirjat, joka on valtuutettu laatimaan

tekniset asiakirjat ja joka on sijoittautunut yhteisöön.

Signature de la personne habilitée à rédiger la déclaration au nom du fabricant, à détenir la documentation technique, à compiler les fichiers techniques et

qui est implantée dans la Communauté.

Unterschrift der Person, die berechtigt ist, die Erklärung im Namen des Herstellers abzugeben, die die technischen Unterlagen aufbewahrt und berechtigt

ist, die technischen Unterlagen zusammenzustellen, und die in der Gemeinschaft niedergelassen ist.

Υπογραφή ατόμου εξουσιοδοτημένου για την σύνταξη της δήλωσης εκ μέρους του κατασκευαστή, οοποίος κατέχει την τεχνική έκθεση και έχει την

εξουσιοδότηση να ταξινομήσει τον τεχνικό φάκελο και οοποίος είναι διορισμένος στην Κοινότητα.

A gyártó nevében meghatalmazott személy, akinek jogában áll módosítania a nyilatkozatot, a műszaki dokumentációt őrzi, engedéllyel rendelkezik a

műszaki fájl összeállításához, és aki a közösségben letelepedett személy.

Firma della persona autorizzata a redigere la dichiarazione a nome del fabbricante, in possesso Della documentazione tecnica ed autorizzata a costituire

il fascicolo tecnico, che deve essere stabilita nella Comunità.

Tās personas paraksts, kura ir pilnvarota deklarācijas sastādīšanai ražotāja vārdā, kurai ir tehniskādokumentācija, kura ir pilnvarota sagatavot tehnisko

reģistru un kura ir apstiprināta Kopienā.

Asmuo, kuris yra gana žinomas, kuriam gamintojas suteikėįgaliojimus sudaryti šiądeklaraciją, ir kuris jąpasirašė, turi visątechninęinformacijąir yra

įgaliotas sudaryti techninės informacijos dokumentą.

Il-firma tal-persuna awtorizzata li tfassal id-dikjarazzjoni f’isem il-fabbrikant, għandha d-dokumentazzjoni teknika u hija awtorizzata li tikkompila l-fajl

tekniku u li hija stabbilita fil-Komunità.

Podpis osoby upoważnionej do sporządzenia deklaracji w imieniu producenta, przechowującej dokumentacjętechniczną, upoważnionądo stworzenia

dokumentacji technicznej oraz wyznaczonej ds. wspólnotowych.

Assinatura da pessoa com poderes para emitir a declaração em nome do fabricante, que possui a documentação técnica, que está autorizada a compilar

o processo técnico e que está estabelecida na Comunidade.

Semnătura persoanei împuternicite săelaboreze declaraţia în numele producătorului, care deţine documentaţia tehnică, este autorizatăsăcompileze

dosarul tehnic şi este stabilităîn Comunitate.

Podpis osoby poverenej vystavením vyhlásenia v mene výrobcu, ktorá má technickú dokumentáciu a je oprávnená spracovaťtechnické podklady a ktorá

je umiestnená v Spoločenstve.

Podpis osebe, pooblaščene za izdelavo izjave v imenu proizvajalca, ki ima tehnično dokumentacijo in lahko sestavlja spis tehnične dokumentacije, ter ima

sedež v Skupnosti.

Firma de la persona responsable de la declaración en nombre del fabricante, que posee la documentación técnica y está autorizada para recopilar el

archivo técnico y que está establecido en la Comunidad.

Undertecknas av den som bemyndigad att upprätta deklarationen å tillverkarens vägnar, innehar den tekniska dokumentationen och är bemyndigad att

sammanställa den tekniska informationen och som är etablerad i gemenskapen.

Ryan Weeks

VP of Engineering

January 29th, 2010

Jacobsen, A Textron Company

11524 Wilmar Blvd,

Charlotte, NC 28273, USA

Certificate Number ▪Номер на сертификат ▪Číslo osvědčení ▪Certifikatnummer ▪Certificaatnummer ▪Sertifikaadi number ▪Hyväksyntänumero ▪

Numéro de certificat ▪Bescheinigungsnummer ▪Αριθμός Πιστοποιητικού ▪Hitelesítési szám ▪Numero del certificato ▪Sertifikāta numurs ▪

Sertifikato numeris ▪Numru taċ-Ċertifikat ▪Numer certyfikatu ▪Número do Certificado ▪Număr certificat ▪Číslo osvedčenia ▪Številka certifikata ▪

Número de certificado ▪Certifikatsnummer

4201266 Rev A

GB BG CZ DK NL EE FI FR DE GR HU

IT LV LT MT PL PT RO SK SI ES SE

българскиEnglish čeština dansk Nederlands eesti suomi français Deutsch Ελληνικά magyar

latviešu

valoda

italiano lietuvių

kalba

Malki polski português Română slovenčina slovenščina Ελληνικά Svenska

3 ADJUSTMENTS

en-10

3 ADJUSTMENTS

3.1 GENERAL________________________________________________________________

1. Adjustments and maintenance should always be

performed by a qualified technician. If proper

adjustment cannot be made, contact an authorized

JacobsenDealer.

2. Replace,donotadjust,wornordamagedcomponents.

3. Long hair, jewelry, or loose fitting clothing may get

tangledinmovingparts.

4. Do not change governor settings or overspeed the

engine.

3.2 FAN BELT (DIESEL ENGINES) _______________________________________________

Inspectandadjustnewbeltafterfirsttenhoursofoperation.

Adjustevery100hoursthereafter.

1. Adjustalternatorpulleysobelt(B)deflects9/32to11/32

in. (7 to 9 mm) with a 22 lb. (10 kgf) push at midspan

betweenpulleys.

2. Iftensionisincorrect,loosenalternatormounting bolts

(A) and adjust alternator until proper belt tension is

achieved.Tightenhardware(A).

Figure 3A

3.3 NEUTRAL SWITCH ________________________________________________________

1. PlacetractionpedalinNeutralposition,engageparking

brake.

2. Adjust switch (C) and bracket (D) as required until

sensing portion of switch is centered under damper

mountinghardware.

3. Use a meter to be certain switch contacts are closed

with pedal in Neutral position and open when pedal is

depressedineithertheforwardorreversedirection.

Figure 3B

WARNING

To prevent injury, lower implements to the ground,

disengage all drives, engage parking brake, stop

engine, and remove key from ignition switch before

makinganyadjustmentsorperformingmaintenance.

Make sure the groomer is parked on a solid and level

surface.Neverworkonagroomerthatissupportedonly

bythejack.Alwaysusejackstands.

If only the front or rear of the groomer is raised, place

chocks in front of and behind the wheels that are not

raised.

!

CAUTION

Becarefultoprevententrapmentofthehandsand

fingersbetweenmovingandfixedcomponentsofthe

machine.

!

A

B

C

D

ADJUSTMENTS 3

en-11

3.4 NEUTRAL ADJUSTMENT (GAS UNITS) ________________________________________

1. Allow engine and hydraulic system to reach normal

operating temperature. Move unit to a flat and level

surface.

2. Withenginerunningatfullthrottle,andtractionpedalin

Neutral,releaseparkingbrake.Unitshouldnot“creep”

ineitherdirection.

3. Ifunitcreepsinforwarddirection,removehardware(E)

and turn rod ends (F) clockwise (Shorten rod) as

required.

4. Ifunitcreepsinreversedirection,removehardware(E)

and turn rod ends (F) counter-clockwise (Lengthen

rod)asrequired.

Figure 3C

3.5 NEUTRAL ADJUSTMENT (DIESEL UNITS) _____________________________________

1. Allow engine and hydraulic system to reach normal

operating temperature. Move unit to a flat and level

surface.

2. Withenginerunningatfullthrottle,andtractionpedalin

Neutral,releaseparkingbrake.Unitshouldnot“creep”

ineitherdirection.

3. Ifunitcreepsinforwarddirection,removehardware(E)

and turn rod ends (F) counter-clockwise (Lengthen

rod)asrequired.

4. Ifunitcreepsinreversedirection,removehardware(E)

and turn rod ends (F) clockwise (Shorten rod) as

required.

Figure 3D

EF

EF

3 ADJUSTMENTS

en-12

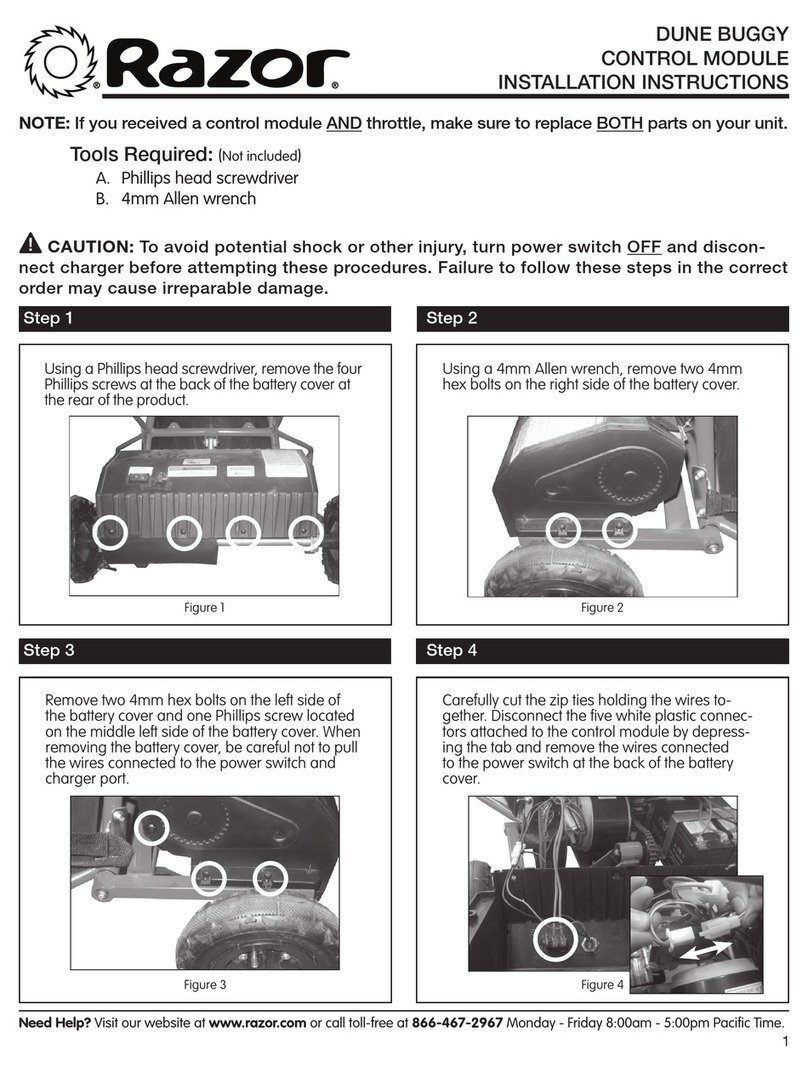

3.6 PARKING / SERVICE BRAKE ________________________________________________

Inspectbrakespads:

wheneverwheelsareremoved,

ifgroomercreepsonhillswithparkingbrakeapplied,

orthereisanoticeableincreaseinstoppingdistance.

To adjust brake cables:

1. Raisegroomerandsupporttheunitusingjackstandsor

blockssothatallthreewheelsareslightlyraisedoffthe

ground.

2. Backoffnut(G).

3. Withthebrakepedalallthewayup(disengaged)turnin

adjusting nut (H) and spin wheels slowly by hand until

youfeelbrakesengageandwheelsbegintobind.

4. Backoffadjusternut(H) slightlyuntilwheelsagainturn

freely.

5. Tightennut(G) tolockadjustmentinplace.

6. Repeatforsecondcable.

Before returning unit to operation, drive groomer in a flat,

openareaandcheckoperationofbrakestomakesurethey

areoperatingcorrectly.Checkparkingbraketomakesureit

engages properly and prevents the groomer from rolling

downhill.

Figure 3E

H

G

ADJUSTMENTS 3

en-13

3.7 TORQUE SPECIFICATION ___________________________________________________

JacobsenusesGrade5boltsasstandard,unlessotherwisenoted.

NOTICE

Alltorquevaluesincludedinthesechartsareapproximateandareforreferenceonly.Useofthesetorquevaluesisatyour

solerisk.Jacobsenisnotresponsibleforanyloss,claim,ordamagearisingfromtheuseofthesecharts.Extreme

caution should always be used when using any torque value.

AMERICAN NATIONAL STANDARD FASTENERS

SIZE UNITS GRADE 5 GRADE 8

#6-32 in-lbs(Nm) 20(2.3) –

#8-32 in-lbs(Nm) 24(2.7) 30(3.4)

#10-24 in-lbs(Nm) 35(4.0) 45(5.1)

#10-32 in-lbs(Nm) 40(4.5) 50(5.7)

#12-24 in-lbs(Nm) 50(5.7) 65(7.3)

1/4-20 in-lbs(Nm) 95(10.7) 125(14.1)

1/4-28 in-lbs(Nm) 95(10.7) 150(17.0)

5/16-18 in-lbs(Nm) 200(22.6) 270(30.5)

5/16-24 in-lbs(Nm) 240(27.1) 300(33.9)

3/8-16 ft-lbs(Nm) 30(40.7) 40(54.2)

3/8-24 ft-lbs(Nm) 35(47.5) 45(61.0)

7/16-14 ft-lbs(Nm) 50(67.8) 65(88.1)

7/16-20 ft-lbs(Nm) 55(74.6) 70(94.9)

1/2-13 ft-lbs(Nm) 75(101.7) 100(135.6)

1/2-20 ft-lbs(Nm) 85(115.3) 110(149.2)

9/16-12 ft-lbs(Nm) 105(142.4) 135(183.1)

9/16-18 ft-lbs(Nm) 115(155.9) 150(203.4)

5/8-11 ft-lbs(Nm) 150(203.4) 195(264.4)

5/8-18 ft-lbs(Nm) 160(217.0) 210(284.8)

3/4-10 ft-lbs(Nm) 170(230.5) 220(298.3)

3/4-16 ft-lbs(Nm) 175(237.3) 225(305.1)

7/8-14 ft-lbs(Nm) 300(406.8) 400(542.4)

AMERICAN NATIONAL STANDARD FASTENERS

SIZE UNITS GRADE 5 GRADE 8

METRIC FASTENERS

SIZE UNITS

NonCritical

Fastenersinto

Aluminum

M4 Nm(in-lbs) 1.2(11) 1.7(15) 2.9(26) 4.1(36) 5.0(44) 2.0(18)

M5 Nm(in-lbs) 2.5(22) 3.2(28) 5.8(51) 8.1(72) 9.7(86) 4.0(35)

M6 Nm(in-lbs) 4.3(38) 5.7(50) 9.9(88) 14.0(124) 16.5(146) 6.8(60)

M8 Nm(in-lbs) 10.5(93) 13.6(120) 24.4(216) 33.9(300) 40.7(360) 17.0(150)

M10 Nm(ft-lbs) 21.7(16) 27.1(20) 47.5(35) 66.4(49) 81.4(60) 33.9(25)

M12 Nm(ft-lbs) 36.6(27) 47.5(35) 82.7(61) 116.6(86) 139.7(103) 61.0(45)

M14 Nm(ft-lbs) 58.3(43) 76.4(55) 131.5(97) 184.4(136) 219.7(162) 94.9(70)

4.8

5.8

8.8

10.9

12.9

4 MAINTENANCE

en-14

4 MAINTENANCE

4.1 GENERAL________________________________________________________________

1. Adjustment and maintenance should always be

performed by a qualified technician. If proper

adjustments cannot be made, contact an Authorized

JacobsenDealer.

2. Inspect the equipment on a regular basis, establish a

maintenancescheduleandkeepdetailedrecords.

a. Keeptheequipmentclean.

b. Keep all moving parts properly adjusted and lubri-

cated.

c. Replace worn or damaged parts before operating

themachine.

d. Keepallfluidsattheirproperlevels.

e. Keep shields in place and all hardware securely

fastened.

f. Keeptiresproperlyinflated.

3. Long hair, jewelry, or loose fitting clothing may get

tangledinmovingparts.

4. Use the illustrations in the Parts Catalog as reference

forthedisassemblyandreassemblyofcomponents.

5. Recycle or dispose of all hazardous materials

(batteries, fuel, lubricants, anti-freeze, etc.) according

tolocal,state,orfederalregulations.

4.2 ENGINE _________________________________________________________________

IMPORTANT: A separate Engine Manual, prepared by

the engine manufacturer, is supplied with this

groomer.Read the engine manual carefully until you

are familiar with the operation and maintenance of

the engine. Proper attention to the engine

manufacturer’s directions will assure maximum

service life of the engine. To order replacement

engine manuals contact the engine manufacturer.

The proper break-in of a new engine can make a

considerable difference to the performance and life of the

engine.

Note: The groomer is designed to operate most

efficiently at the preset governor setting. Do not change

the engine governor settings or overspeed the engine.

During the break-in period, Jacobsen recommends the

following:

Diesel Engine:

1. During the first 50 hours of operation, a new engine

shouldbeallowedtoreachanoperatingtemperatureof

atleast140°F(60°C)priortooperationatfullload.

2. Checktheengine oilleveltwicedailyduringthefirst50

hoursofoperation.Higherthannormaloilconsumption

isnotuncommonduringtheinitialbreak-inperiod.

3. Change engine oil and oil filter element after first 50

hoursofoperation.

4. Checkandadjustfanandalternatorbelts.

5. Refer to Section 5 and Engine Manual for specific

maintenanceintervals.

If the injection pump, injectors, or the fuel system require

service,contactanauthorizedJacobsenDealer.

Gasoline Engine:

1. Drivemodestlyforthe first 25 hoursat reducedengine

speed.

2. Avoidfullthrottlestartsandrapidacceleration.

3. Allow the engine to reach operating temperature

beforeoperatingatfullload.

4. Change the oil and filter after the first 8 hours of

operation.

5. Refer to Section 6.1 and Engine Manual for specific

maintenanceintervals.

WARNING

Before you clean, adjust, or repair this equipment,

disengage all drives, lower implements to the ground,

engageparkingbrake,stopengineandremovekeyfrom

ignitionswitchtopreventinjuries.

Make sure the groomer is parked on a solid and level

surface.Neverworkonagroomerthatissupportedonly

bythejack.Alwaysusejackstands.

!

MAINTENANCE 4

en-15

4.3 ENGINE OIL ______________________________________________________________

Checktheengineoilatthestartofeachday,beforestarting

theengine.Iftheoillevelislow,removeoilfillercapandadd

oilasrequired.

Diesel Engine:

Performinitialoilchangeafterfirst50hoursofoperationand

every75hoursthereafter.SeeEngineManual.

UseonlyengineoilswithAPIclassificationCD/CE.

Gas Engine:

Performinitialoilchangeafterthefirst8hoursofoperation.

Changeoilevery50hoursthereafter.

See the Engine Manual for detailed service

information.

Afteraddingorchangingoil,startandrunengineatidlewith

alldrivesdisengagedfor30seconds.Shutengineoff.Wait

30 seconds and check oil level. Add oil to bring up to FULL

markondipstick.

UseonlyengineoilswithAPIclassificationSF,SG,orSH.

Figure 4A

Figure 4B

4.4 AIR FILTER _______________________________________________________________

ThegasolinepoweredGroomMasterIIusesatwostageair

filtration system. The first stage consists of a heavy duty

filter equipped with a filter indicator to alert the operator

when a filter change is required. The second stage,

mounted to the engine includes a pleated paper element

and foam pre-cleaner. Diesel units use only a single stage

heavydutyfilterwithindicator.

Do not remove the element for inspection or

cleaning. Unnecessary removal of the filter increases the

riskofinjectingdustandotherimpuritiesintotheengine.

When serviceis required, firstclean the outsideof thefilter

housing,thenremovetheoldelementasgentlyaspossible

anddiscard.

1. Carefully clean the inside of the filter housing without

allowingdustintotheairintake.

2. Inspect the new element. Do not use a damaged

elementandneveruseanincorrectelement.

3. Assemble the new element and make sure it seats

properly.

4. Reassemble cap making sure it seals completely

around the filter housing. Dust evacuator must be

facingdown.

5. Checkallhosesandairducts.Tightenhoseclamps.

Above77°F(25°C) SAE30WorSAE10W30/10W40

32to77°F(0to25°C) SAE20WorSAE10W30/10W40

Below32°(0°C) SAE10WorSAE10W30/10W40

Above40°F(5°C) SAE30W

0to40°F(-18to5°C) SAE5W30orSAE10W30

Diesel Engine Dipstick

Safe Operating Range

⎧

⎨

⎪

⎪

⎪

⎪

⎩

Gas Engine Dipstick

ADD

FULL

4 MAINTENANCE

en-16

4.5 GAS ENGINE AIR FILTER ___________________________________________________

1. Removeandservicethefoampre-cleaner(A) every25

hours.Replaceifdirtyordamaged.

To service pre-cleaner, wash in a liquid detergent and

water. Squeeze dry in a clean cloth. Saturate in clean

engine oil, and squeeze out excess oil in a clean,

absorbentcloth.

2. Replace the air cleaner cartridge every 100 hours,

moreoftenwhenoperatingindustyconditions.

Note: Donotusepetroleumsolventssuchaskerosene

to clean cartridge. Do not use pressurized air to clean

cartridge.

See the Engine Manual for detailed service

information.

Figure 4C

4.6 FUEL ____________________________________________________________________

Handle fuel with care - it is highly flammable. Usean

approved container, the spout must fit inside the fuel filler

neck.Avoidusingcansandfunnelstotransferfuel.

• Fillthefueltanktowithin1in.(25mm)ofthebottomofthe

fillerneck.

• Store fuel according to local, state or federal ordinances

andrecommendationsfromyourfuelsupplier.

• Neveroverfillorallowthetanktobecomeempty.

• Checkfuellinesandclampsevery50hours.Replacefuel

linesandclampsatthefirstsignofdamage.

Diesel Engine:

• Use clean, fresh, #2 low or ultra low sulfur Diesel fuel.

Minimum Cetane rating 45. Refer to Engine Manual for

additionalinformation.

Gas Engine:

•Use clean, fresh, regular grade, unleaded gasoline

minimum85Octane.

4.7 FUEL SYSTEM ____________________________________________________________

RefertoSection 6.1forspecificmaintenanceintervals.

Before replacing any filter, thoroughly clean the filter

housing and the area around the filter. Dirt must not be

allowedtoenterintofuelsystem.

For diesel engines, turn the ignition switch to the ON

position to start the fuel pump, and bleed the fuel system if

thefuelfilterandlines have been removed, or thefueltank

hasbecomeempty.SeeEngineManual.

A

WARNING

Neverremovethefuelcapfromthefueltank,oraddfuel,

whentheengineisrunning,orwhiletheengineishot.

Do not smoke when handling fuel. Never fill or drain the

fueltankindoors.

Donotspillfuelandcleanspilledfuelimmediately.

Neverhandleorstorefuelcontainersnearanopenflame

oranydevicethatmaycreatesparksandignitethefuelor

fuelvapors.

Besuretoreinstallandtightenfuelcapsecurely.

!

NOTICE

Do not use hi-test gasoline or an oil-gasoline mixture.

When using blended fuel, do not use a blend with more

than 10% ethanol. Under no circumstances should you

useablendwithmethanol.

MAINTENANCE 4

en-17

4.8 BATTERY ________________________________________________________________

Make absolutely certain the ignition switch is OFF and the

keyhasbeenremovedbeforeservicingthebattery.

Tighten cables securely to battery terminals and apply a

lightcoatofsiliconedielectricgreasetoterminalsandcable

ends to prevent corrosion. Keep vent caps and terminal

coversinplace.

Always disconnect battery cables from battery before

performinganyweldingoperationonthegroomer.

Checktheelectrolytelevelevery100hours.Keepthecable

ends,batteryandbatterypostsclean.

Verify battery polarity before connecting or disconnecting

thebatterycables.

1. Wheninstallingthebattery,alwaysassembletheRED,

positive(+)batterycablefirst,andtheground,BLACK,

negative(-)cablelast.

2. When removing the battery, always remove the

ground, BLACK, negative (-) cable first, and the RED,

positive(+)cablelast.

3. Make sure battery is properly installed and secured to

thebatterytray.

4.9 JUMP STARTING __________________________________________________________

Before attempting to “jump start” the groomer, check the

conditionofthedischargedbattery.Section 4.8

When connecting jumper cables:

1. Stoptheengineonthevehiclewithagoodbattery.

2. Connect RED jumper cable to the positive (+) terminal

on the good battery and to the positive (+) terminal on

the“discharged”battery.

3. ConnecttheBLACKjumpercablefromthenegative (-

) terminal on the good battery to the frame of the

groomerwiththedischargedbattery.

After cables have been connected, start the engine on the

vehiclewiththegoodbatterythenstartthegroomer.

4.10 CHARGING BATTERY _____________________________________________________

1. Refer to Section 4.8.ReadtheBatteryandCharger’s

manualforspecificinstructions.

2. Whenever possible, remove the battery from the

groomerbeforecharging.Ifbatteryisnotsealed,check

thattheelectrolytecoverstheplatesinallthecells.

3. Make sure the charger is OFF. Then connect the

charger to the battery terminals as specified in the

charger’smanual.

4. Always turn the charger OFF before disconnecting

chargerfromthebatteryterminals.

CAUTION

Always use insulated tools, wear protective glasses or

goggles, and protective clothing when working with

batteries. You must read and obey all battery

manufacturer'sinstructions.

!

WARNING

Batteries generate explosive hydrogen gas. To reduce

the chance of an explosion, avoid creating sparks near

battery.Alwaysconnectthenegativejumpercabletothe

frameofthegroomerwiththedischargedbattery,away

fromthebattery.

!

WARNING

Charge battery in a well ventilated area. Batteries

generate explosive gases. To prevent an explosion,

keepanydevicethatmaycreate sparksorflamesaway

fromthebattery.

To prevent injury, stand away from battery when the

chargeristurnedon.Adamagedbatterycouldexplode.

!

4 MAINTENANCE

en-18

4.11 HYDRAULIC HOSES _______________________________________________________

1. Always lower implements to ground, disengage all

drives,engageparkingbrake,stopengine,andremove

key before inspecting or disconnecting hydraulic lines

orhoses.

2. Check visible hoses and tubes daily. Look for wet

hoses or oil spots. Replace worn or damaged hoses

andtubesbeforeoperatingthemachine.

3. The replacement tube or hoses must be routed in the

same path as the existing hose, do not move clamps,

brackets,andtiestoanewlocation.

4. Thoroughly inspect all tubes, hoses, and connections

every250hours.

IMPORTANT: The hydraulic system can be

permanently damaged if the oil becomes

contaminated. Before disconnecting any hydraulic

component, clean the area around the fittings and the

hoseendstokeepimpuritiesoutofthesystem.

a. Before disconnecting any hydraulic component,

tagormarkthelocationofeachhosethencleanthe

areaaroundthefittings.

b. As you disconnect the component, be preparedto

assembleplugsorcapstothehoseendsandopen

ports. This will keep impurities out of the hydraulic

systemandalsopreventoilspills.

c. Makesure“O”ringsarecleanandhosefittingsare

properlyseatedbeforetightening.

d. Keep the hose from twisting. Twisted hoses can

causecouplerstoloosenasthehoseflexesduring

operationresultinginoilleaks.

e. Kinked or twisted hoses can restrict the oil flow

causing the system to malfunction and the oil to

overheatandalsoleadtohosefailure.

4.12 HYDRAULIC OIL __________________________________________________________

RefertoSection 6.1forspecificmaintenanceintervals.

Drainandreplacethehydraulicoilafteramajorcomponent

failure,orifyounotice the presenceof water or foaminthe

oil,orarancidodor(indicatingexcessiveheat).

Alwaysreplacethehydraulicfilterwhenchangingoil.

To change hydraulic oil:

1. Cleantheareaaroundtheoil cap to preventimpurities

fromenteringandcontaminatingthesystem.

a. Oil temperature should be at 60° to 90°F (16° -

32°C).Donotcheckoillevelwhenoilishot.

b. Theoil levelinthehydraulictankshouldalwaysbe

atorabovethefulllevelmark.

2. Drain and replace the hydraulic oil every 200 hours or

after a major component failure, or if you notice the

presenceofwater,foam,orarancidodor.

3. Remove drain plug from bottom of main tank and

loosen or remove breather cap. Check and clean the

breathercap,replaceasnecessary.

4. After oil has drained install drain plug and fill with

JacobsenHydraulicoil.

5. Purgeairfromsystem.

a. Operate all groomer functions for about 5 minutes

to purge air out of the system and stabilize the oil

level.

b. Oncethelevelhasstabilizedandtheairis purged,

fillthehydraulictanktotheFULLlevel.

WARNING

To prevent serious injury from hot, high pressure oil,

neveruseyourhandstocheckforoilleaks,usepaperor

cardboard.

Hydraulic fluid escaping under pressure can have

sufficient force to penetrate skin. If fluid is injected into

theskinitmustbesurgicallyremovedwithinafewhours

by a doctor familiar with this form of injury or gangrene

mayresult.

!

MAINTENANCE 4

en-19

4.13 HYDRAULIC OIL FILTERS___________________________________________________

Thehydraulicsystemisprotectedbyone10micronfilter.

To replace hydraulic oil filter:

1. Removetheoldfilter.

2. Fillnewfilterwithoiltheninstallnewfilter.Handtighten

only.

3. Operate engine at idle speed with hydraulic system in

Neutralforfiveminutes.

4. Check hydraulic oil level in reservoir and fill to FULL

markondipstick.

4.14 ELECTRICAL SYSTEM _____________________________________________________

General precautions that can be taken to reduce electrical

problemsarelistedbelow.

1. Make certain all terminals and connections are clean

andproperlysecured.

2. ChecktheInterlockSystemandfusesregularly.

If the Interlock System does not function properly and

theproblemcannotbecorrected,contactanauthorized

JacobsenDealer.

3. Keep the wire harness and all individual wires away

frommovingpartstopreventdamage.

4. Makesuretheseat switchharnessisconnectedtothe

mainwireharness.

5. Checkthebatteryandbatterychargingcircuit.

6. Do not wash or pressure spray around electrical

connectionsandcomponents.

4.15 MUFFLER AND EXHAUST___________________________________________________

To protect from carbon monoxide poisoning, inspect the

complete exhaust system regularly, and always replace a

defectivemuffler.

If you notice a change in thecolor orsound of the exhaust,

stoptheengineimmediately.Identifytheproblemandhave

thesystemrepaired.

Torque all exhaust manifold hardware evenly. Tighten or

replaceexhaustclamps.

4.16 TIRES ___________________________________________________________________

1. Keep tires properly inflated to prolong tire life. Check

inflationpressurewhilethetiresarecool.Inspecttread

wear.

2. Checkthepressure with an accurate,lowpressure tire

gauge.

3. Keeptiresinflatedto3-5psi-(0.21-0.34BAR).

CAUTION

Always turn the ignition switch off and remove the

negative battery cable (Black) before inspecting or

workingontheelectricalsystem.

!

WARNING

Exhaust fumes contain carbon monoxide that is toxic

andcanbefatalwheninhaled.

NEVERoperateanenginewithoutproperventilation.

!

CAUTION

Unless you have the proper training, tools, and

experience, DO NOT attempt to mount a tire on a rim.

Improper mounting can produce an explosion which

mayresultinseriousinjury.

!

4 MAINTENANCE

en-20

4.17 WHEEL MOUNTING PROCEDURE____________________________________________

1. Remove dirt, grease, and oil from stud thread. Do not

lubricatethreads.

2. Positionwheelonhubandinspecttoinsurefullcontact

between mounting surface of wheel and hub or brake

drum.

3. Finger tighten all hardware then torque hardware in

criss-cross order; always tighten nuts in the top

position.

4. Checkandretorquedailyuntiltorqueismaintained,85-

95ft.lbs.(115-128Nm).

4.18 CARE AND CLEANING _____________________________________________________

Wash the groomer and implements after each use. Keep

theequipmentclean.

Note: Do not wash any portion of the equipment while it

is hot. Do not use high pressure spray or steam. Use cold

water and automotive cleaners.

1. Usecompressedairtocleanengineandradiatorfins.A

special blow gun is available through your Jacobsen

Dealer.

2. Useonlyfreshwaterforcleaningyourequipment.

Note: Use of salt water or effluent water has been known

to encourage rust and corrosion of metal parts resulting

in premature deterioration or failure. Damage of this

nature is not covered by the factory warranty.

3. Do not spray water directly at the instrument panel,

ignition switch, controller, or any other electrical

components,oratbearinghousingsandseals.

4. Cleanallplasticorrubbertrimwithamildsoapsolution

orusecommerciallyavailablevinyl/rubbercleaners.

Repair damaged metal surfaces and use Jacobsen touch-

uppaint.Waxtheequipmentformaximumpaintprotection.

4.19 RADIATOR (DIESEL ENGINES) ______________________________________________

Check coolant level daily. Radiator should be FULL and

recoverybottleshouldbeuptotheCOLD mark.

Drainandrefillannually.Removetheradiatorcap,openthe

engineblockdrainandtheradiator drain. Empty and clean

therecoverybottle.

Mix clean water with ethylene glycol based anti-freeze for

the coldest ambient temperature. Read and follow the

instructions on the anti-freeze container and Engine

Manual.

Keepradiatorairpassagesclean.Use compressedair (30

psimaximum)tocleanthefins.

Checkand tighten thefanbelt.Replace clamps and hoses

everytwoyears.

If you have to add coolant more than oncea month, or add

morethanonequartatatime,haveanauthorizedJacobsen

Dealercheckthecoolingsystem.

WARNING

Make sure the groomer is parked on a solid and level

surface.Neverworkonagroomerthatissupportedonly

bythejack.Alwaysusejackstands.

If only the front or rear of the groomer is raised, place

chocks in front of and behind the wheels that are not

raised.

!

CAUTION

Clean grass and debris from attachments, drives,

muffler,andenginetopreventfires.

WARNING

NEVER use your hands to clean attachments, use a

brush. Attachment edges can be extremely sharp and

cancauseseriousinjuries.

!

!

WARNING

To prevent serious bodily injury from hot coolant or

steam blow-out, never attempt to remove the radiator

capwhiletheengineisrunning.Stoptheengineandwait

until it is cool. Even then, use extreme care when

removingthecap.

CAUTION

Donotpourcoldwaterintoahotradiator.Donotoperate

enginewithoutapropercoolantmixture.Installcapand

tightensecurely.

!

!

This manual suits for next models

1

Table of contents

Languages:

Other Textron Utility Vehicle manuals

Textron

Textron Ezgo 628442-G User manual

Textron

Textron CUSHMAN ELECTRIC TUG E-Z-GO XI 340 Guide

Textron

Textron E-Z-GO Cushman TITAN LD 2014 User manual

Textron

Textron ST480 User manual

Textron

Textron Jacobsen 3500 User manual

Textron

Textron RANSOMES User manual

Textron

Textron EZGO User manual

Textron

Textron Jacobsen Hauler 800 2004 User manual