TFC Tower APUMP-HE Series User manual

EEI≤0.20

Energy-saving Pipeline Canned

Motor Pump

APUMP-HE Series

Installation and

Operation Manual

TFC Group LLP

Notes:

01. Read the installation manual 11. Some models are not suitable for

carefully before installation and drinking water.

use. 12. The liquid may be high-temperature

02. The manufacturer will not be liable and high-pressure; therefore, the

for any personal injury, pump liquid in the system must be

damage and other property completely drained or the shut-off

damage due to failure to comply valves on both sides must be

with safety warnings closed before moving and

dismantling the pump to prevent

a burn hazard.

03. The installers and operators must

comply with local safety regulations.

13. If removing the exhaust bolt, high-

temperature and high-pressure

liquid will be released. Measures

must be taken to safely contain

any released liquid.

04. The user must confirm that only

qualified personnel with

professional certification and

proficiency of this manual are

permitted to install and maintain this

product.

05. The pump is rated Ip44 and must not

be installed in a place that is damp or

may be splashed by water.

14. Ventilation must be ensured in

summer or high ambient

temperature conditions to avoid

condensation that may cause

electrical malfunctions.

06. For convenient access of

maintaince, a shut-off valve shall be

installed on each side of the pump

15. If there is a risk of frost damage,

install a frost protection thermostat,

or drain down the system in order

to avoid frost damage to the pump

body.

07. The power supply of the pump must

be disconnected before installation

andmaintainace.

08. For domestic hot water, copper or

stainless steel pump body shall be

used.

16. If the pump is left unused for a long

time, please close the pipe valve in

the inlet and outlet of the pump and

disconnect the power supply.

17. If the flexible cord of cable is

damaged, it must be replaced by a

qualified person.

18. Please close the valve at the inlet of

the pump and disconnect power of the

pump immediately if overheating

10. Do not start the pump without

liquid.

01

APUMP-HE

09. In hard water areas use

appropriate water treatment

additives to prevent calcium

deposits, which can block

pipelines and / or the pump

impeller.

or abnormality of motor is detected, and contact your vendor or service center

immediately.

19. If problem cannot be addressed according to the manual, please close the valves

on the inlet and outlet of the pump immediately, cut off power supply and contact

your vendor or service center immediately.

20. This product shall be put in a place out of reach of children. After installation, take

an isolation measures to avoid access of children.

21. This product shall be stored in a dry, well ventilated and cool place under room

temperature.

Warning

Before installation, you must carefully read the installation

and operation manual. The installation and use of the

equipment must comply with local regulation and

applicable operation standards.

Warning

Those who have weak physical strength, react slowly

or lack experience and knowledge (including children) can

use this motor pump only under the monitoring and

direction of his/her safety personnel.

Caution

Note

Warning

Failure to comply with this safety instruction may lead to

personal injury!

Failure to comply with this safety instruction may lead to

equipment malfunction or damage!

Note or instruction for easy and safe operations.

1. Signs

02

APUMP-HE

magnet

2. General

2.1. The APUMP-HE circulation

pump is designed for use

in domestic heating and hot

water systems.

The product is most applicable to the

following systems:

·

system

·variable-temperature pipeline heat

supply system

·heat supply system with night mode

·HVAC system

· Industrial circulation system

domestic heating and domestic

water supply system

This pump is equipped with permanent-

motor and differential pressure

controller, capable of automatically &

continuously adjusting motor performance

to meet the actual needs of the system.

This pump is equipped with control

panel on the front for easy operation

by users.

stable and variable-flow heat supply

·

2.2. Advantages

Easy installation and start-up

(

motor pump needs no adjustment

and can be readily started and

will adjust automatically to meet

the actual needs of the systems.

High-degree comfort

·Low operational noise of motor pump

and whole system.

·Provided with self adaptivc mode

AUTO

Initial setting). In most cases, the

03

APUMP-HE

3.1 Ambient Temperature

Ambient temperature: 0 40

3.2. Relative humidity(RH):

Max. humidity: 95%

3.3. Medium (liquid delivery) temperature

Liquid delivery temperature: +2℃110

To avoid condensation in control box and the stator, the temperature of liquid

pumped by the motor pump must be always higher than ambient temperature.

3.4. System Pressure

Maximum pressure 1.0MPa(10bar).

3.5. Degree of Protection

IP 44

3.6. Inlet Pressure

.

℃~+ ℃

~℃

Liquid Temperature

<85℃90℃110℃

Inlet Pressure

0.05bar 0.28bar 1bar

0.5m head 2.8m head

3.7. Pumping Liquid

The pumping liquid includes thin, clean, non-corrosive and non-explosive liquid

which shall not contain any solid particles, fiber or mineral oil, and the pump must

definitely not be used to pump inflammable liquid such as rapeseed oil and gasoline.

If the pump is used in a place with relatively high viscosity, the pump has lower

performance. So when choosing a pump, the viscosity of liquid must be taken into

account.

3. Operating Conditions

10m head

04

APUMP-HE

4.1.

·

pump case indicates the flow direction of liquid through the pump.

·When installing the motor pump in the pipeline, the two gaskets supplied must be

installed at the inlet and outlet.

·During the installation, the motor pump shaft must be horizontal.

Installation

When installing APUMP-HE series circulation pump, the arrow on the motor

4. Installation

05

APUMP-HE

4.2. Position of Junction Box

06

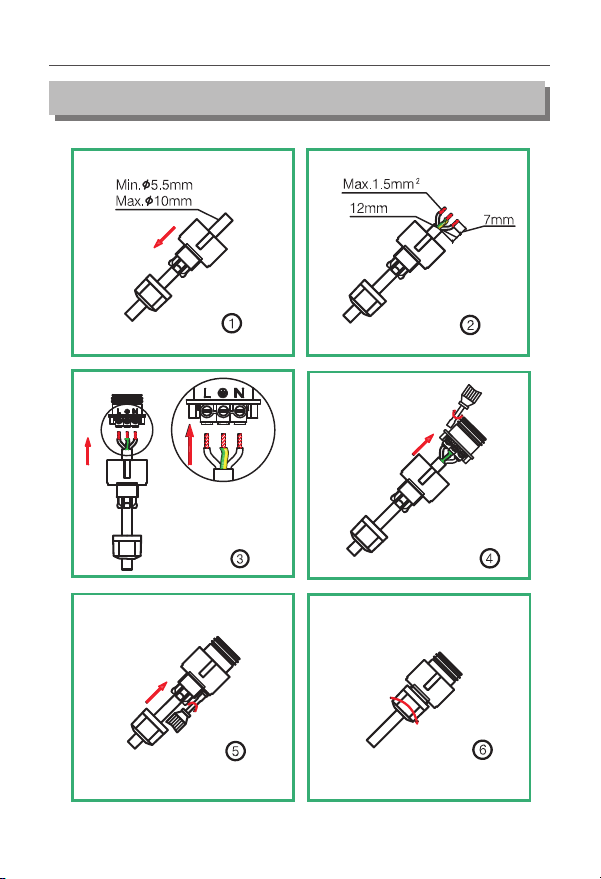

4.3.

The junction box can be rotated in a step of 90°.

The procedures for changing the position of junction box are as follows:

1. Close the valves at the inlet and outlet and release the pressure;

2. Unscrew and remove the four socket head screws that fasten the pump body;

3. Rotate the motor to the required position and align the four screw holes;

4. Install the four socket head screws again and fasten them clockwise making

sure they are fully tightened;

Changing Position of Junction Box

APUMP-HE

5. Open the valves at the inlet and outlet.

Warning

Pumping liquid may be high-temperature and high-pressure;

therefore, the liquid in the system must be completely drained or the

valves on both sides of motor pump must be closed before removing

the socket head screws.

4.4. Thermal Insulation of Motor Pump Body

Limiting the heat loss of motor pump body and pipeline.

Motor pump body and pipeline should be thermally insulated

to reduce their heat loss.

Do not insulate or cover the junction box and control panel.

Caution

Note

07

APUMP-HE

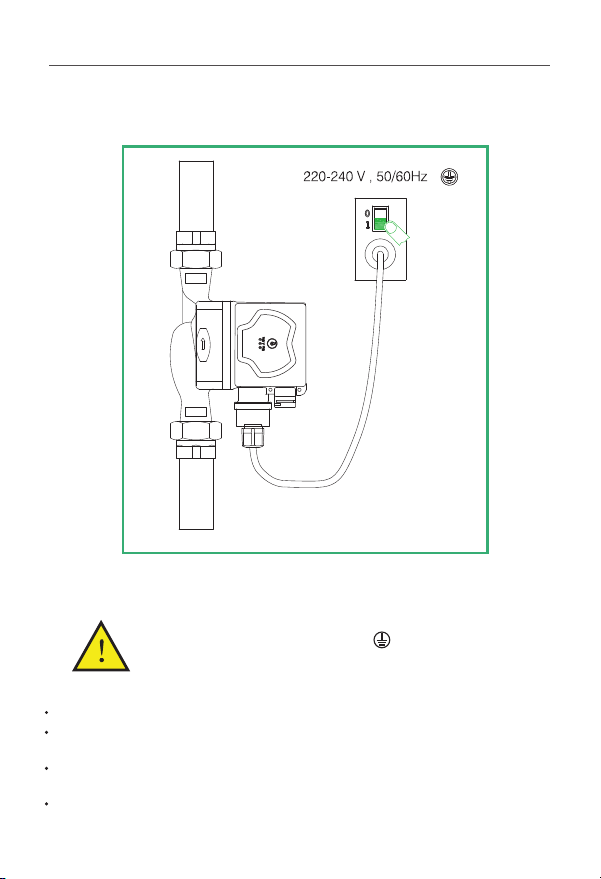

5. Electrical Connection

08

APUMP-HE

Electrical connection and protection shall comply with

local codes and norms.

Warning

The motor pump must be earthed

The motor pump must be connected to an external power switch,

with 3mm minimum contact gap in both poles.

.

·

·Check if the supply voltage and frequency are the same as parameters indicated on the

nameplate of the motor pump.

·Connect the motor pump and power supply with the plug supplied together with the

pump.

·After the power is supplied, the indicator lamp on the control panel is ON.

APUMP-HE series circulation motor pump needs no protection from external motor.

09

APUMP-HE

6. Control Panel

Position

Descriptions

1

2

Indication lamp area of three operation

modes set by motor pump.

Button for setting operation modes of

the motor pump.

6.1. Controls on Control Panel

6.2. Indication Lamp Area of Motor

Pump Setting

APUMP-HE series circulation motor pump has

settings which can be chosen with the button.

The motor pump settings are indicated with

different indication lamp areas.

three

three

10

Button Times

Indication Lamp Area

0

1

2

AUTO ( )

Initial setting

MIN

MAX

Descriptions

Self-adaptive (AUTO)

Constant Speed Curve, Velocity Min

Constant Curve, Velocity MaxSpeed

6.3.

By pressing the button once at 2 seconds interval, the motor pump setting mode will

change to the next in sequence.

A cycle is constituted of every presses on the button. For details, please refer

to Section 6.2.

Button for selecting motor pump settings

three

APUMP-HE

the motor pump setting to other settings.

curve.

11

7. Motor Pump Setting

7.1. Motor Pump Setting Based on System Type

Initial setting AUTO Self-adaptive mode

Recommended and available pump setting

= ( )

·

on the actual heat demand of the system. Self adaptive mode adjusts over time to

find the most effective setting, so before changing the motor pump setting, maintain

AUTO (Self Adaptive Mode) mode setting for at least one week.

· If you select to change back to AUTO (Self Adaptive Mode) mode, the APUMP-HE

motor pump can memorize its last setting in AUTO mode and continue adjusting the

performance automatically.

AUTO (Self Adaptive Mode) mode can adjust the performance of motor pump based

· It may take several minutes or even hours to reach the optimal operation mode after

motor pump setting is changed from the optimal setting (the “Recommended above

mention”) to one of the other optional setting. If the optimal setting of motor pump

fails to enable each room to obtain desired heat distribution, then you should change

· Please refer to Section 8.1 for the relations between pump setting and performance

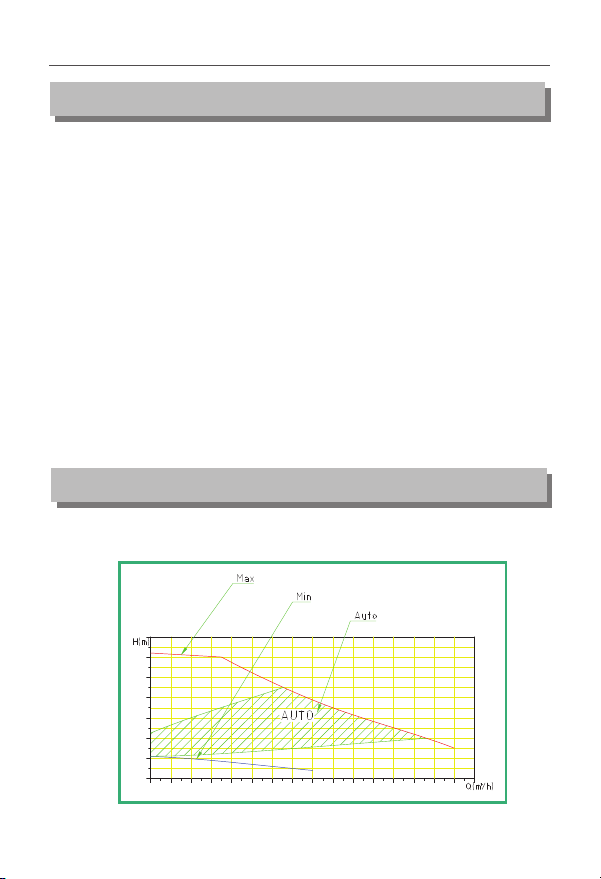

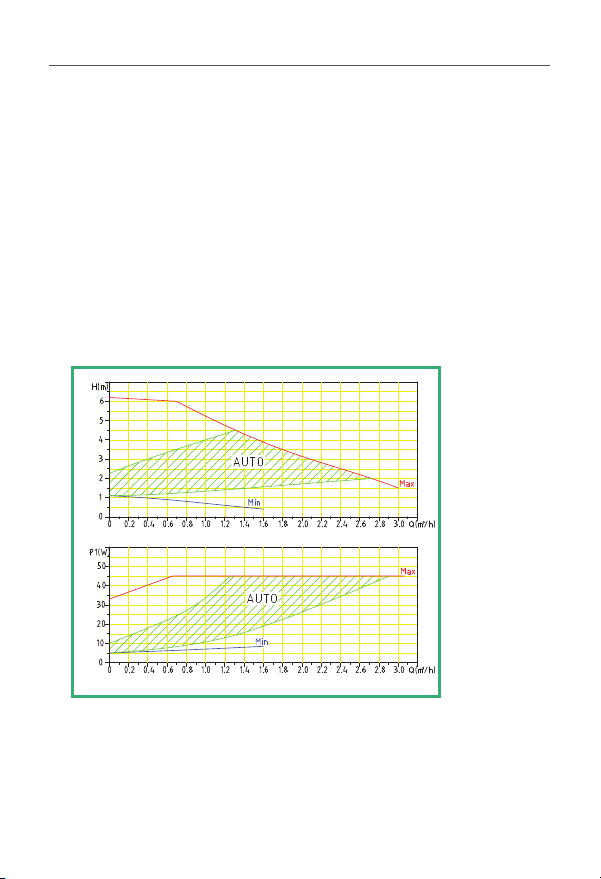

8.1. Relations between Pump Setting and Performance

8. Motor Pump Setting and Performance

APUMP-HE

Proportional

12

AUTO

Setting)

(Initial

AUTO function will automatically control the

pump performance within the specified scope.

adjust pump performance based on system scale;

adjust pump performance based on load variance

within a period of time;

Under the AUTO mode, the pump will be set to

proportional pressure control;

Max

It runs on the constant curve in a constant velocity.

In the Velocity Max mode, the pump is set to work

on the highest curve under all working conditions.

Min Velocity Min

Velocity Max

Highest to

Lowest

Pressure Curve

It runs on the constant curve in a constant velocity.

In the Velocity Min mode, the pump is set to work

on the lowest curveunder all working conditions.

Functions

Setting Pump

Characteristics

Curve

9. Performance Curve

9.1.

Every setting of the motor pump has corresponding performance curve (Q/H curve).

However AUTO (Self Adaptive Mode) mode covers just one performance scope.

The input power curve (P1 curve) belongs to every Q/H curve. Power curve represents

the power consumption of motor pump in given Q/H curve with Watt as the unit.

P1 value corresponds to the readings taken from the monitor of motor pump.

Guide on Performance Curve

APUMP-HE

13

92.

The followings are applicable to the performance curve specified in the APUMP-HE

series manual:

·

· ℃.

· All curves represent averaged value, and shall not be used as guarantee curve. If a

specific performance is needed, then separate measuring shall be conducted.

· Velocity Max, Min curves have all been marked.

· The applicable Kinetic viscosity of the curve υ=0.474 mm²/s(0.474CcST)

.Curve conditions

Test liquid: air-free water.

Applicable density of curve ρ=983.2 kg/m³, and liquid temperature +60

9.3. Performance Curve

APUMP-HE

APUMP-HE

14

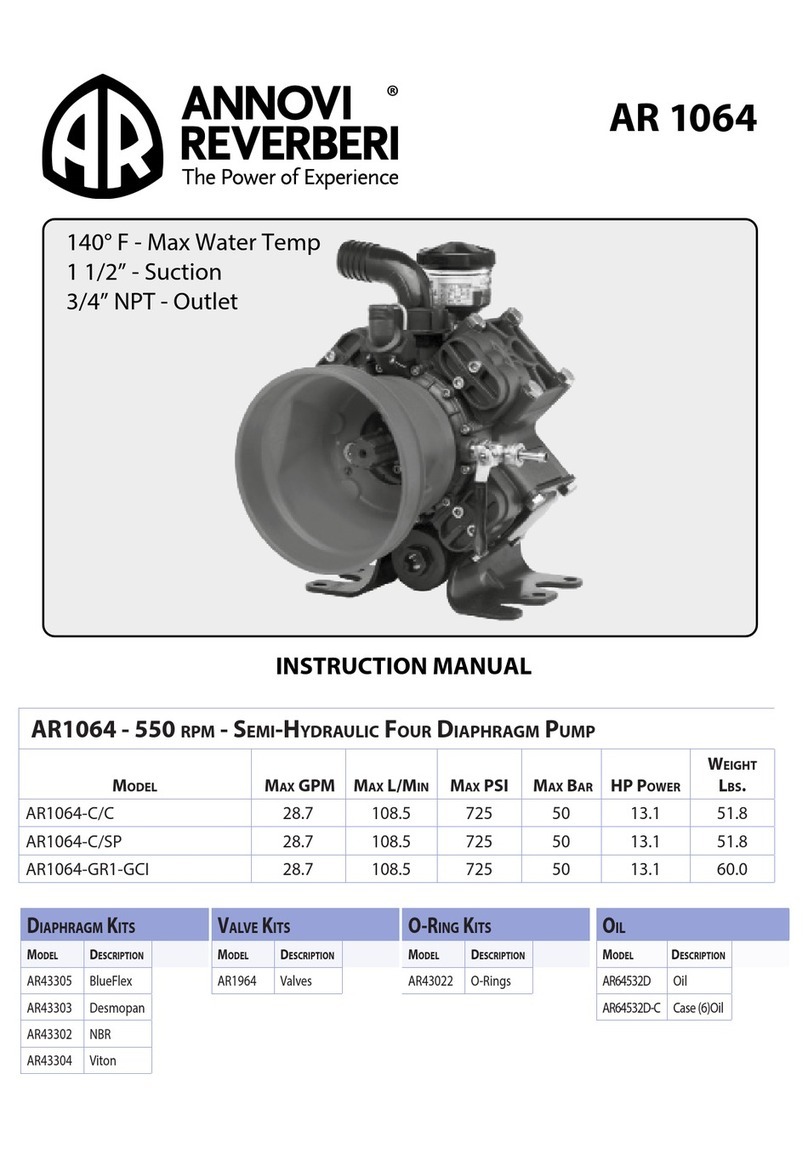

APUMP-HE 21030001

10. Features

No.

Descriptions

1

2

3

4

Company name (brand)

Pump Type

Date of manufacture: the first six numbers

Serial number: the rest four numbers

5

Number

6

7

8

Highest Liquid Temperature

Certification Mark

Rotation Direction

9

Protection Grade

10

Insulation class

11

Energy Index

12

Frequency (Hz)

13

Voltage (v)

Power

(Watt)

Electricity

(ampere)

Minimum power input in minimum pattern

Minimum flow in minimum pattern

Maximum system load bearing (Mpa)

14

Minimum power input in maximum pattern

Minimum flow in maximum pattern

APUMP-HE

15

11. Technical Parameters and Installation Dimensions

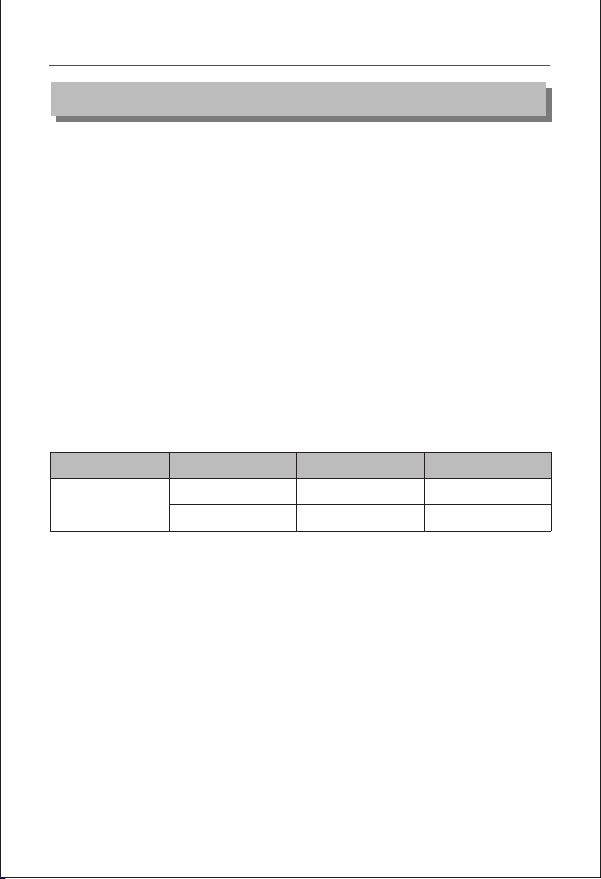

11.1. Technical Parameters

Power Supply Voltage

Motor Protection

Degree of Protection

Insulation Class

Relative Humidity(RH)

System Load Bearing

Suction Port Pressure

EMC Standard

Sound Pressure Class

Ambient Temperature

Temperature Grade

Surface Temperature

Liquid Temperature

Liquid Temperature

2

10

20

30

35

40

Min. (℃)

Ambient

Temperature (℃)

0

10

20

30

35

40

220V-240V,50/60Hz,PE

The pump needs no external protection

IP 44

H

Max. 95%

1.0 MPa

Liquid Temperature

≤+ ℃85

≤+ ℃90

≤+ ℃110

The sound pressure level of pump is lower than 42dB(A)

0 40~+℃

TF110

The maximum surface temperature is not higher than +125℃

+~+℃2 110

Minimum Inlet Pressure

0.005 MPa

0.028 MPa

0.100 MPa

110

110

110

110

90

70

Max. (℃)

To prevent condensation in the junction box and rotor, the temperature of pumping

liquid of the motor pump must be always higher than ambient temperature.

For domestic hot water, it is suggested that water temperature should remains below

65℃ to reduce scaling.

EN61000-3-2 and EN61000-3-3 EN55014-1 and EN55014-2

APUMP-HE

16

11.2. Installation Dimensions

Material of

Pump Body

45

Product

Model

Power

(W)

Cast

Iron

Plastic

Copper

SS

Dimension (mm)

L1

65

L2 B1 B2 H1 H2 G

● ●●

130

82 130103130 1½"

APUMP-HE

APUMP-HE

17

Corrective Action

Symptom

Control Panel

Indication

lamp “Off”

12. Trouble-Shooting Schedule

Warning

Before conducting any maintenance and repair of the motor pump,

ensure that power supply has been cut off and will not be connected

accidentally.

Cause

Flicker two time

Motor pump

cannot

be started

Equipment fuse burned Replace the fuse

The circuit breaker of

current control or voltage control

opens

Connect the circuit

breaker

Failure of motor pump

Return to factory maintenance

Under voltage Check whether power

supply is in specified range

PCB component failure or

motor failure

Return to factory maintenance

Flicker one time High voltage

Check whether power supply

is in specified range

Flicker six time No water in the pump Open the valve and supply

water to the pump

Flicker four time Missing phase protection Return to factory

maintenance

Flicker five time Rotor blocked Remove the pump housing

and clean the rotor

Flicker three time

APUMP-HE

Table of contents

Popular Water Pump manuals by other brands

GORMAN-RUPP

GORMAN-RUPP SFEV3C Installation, operation and maintenance manual

Gardena

Gardena 13000 aquasensor Operator's manual

Sulzer

Sulzer Piranha S10 Installation, Operating and Maintenance Instruction

Edwards

Edwards STP-301 Series instruction manual

Crane

Crane Barnes 3SE-HD Series manual

SAMES KREMLIN

SAMES KREMLIN REXSON 2B453 user manual

Ingersoll-Rand

Ingersoll-Rand ARO PF20R-X Operator's manual

Medela

Medela Vario 8 c/i Service manual

Barmesa Pumps

Barmesa Pumps BMV Series Installation, operation & maintenance manual

GETINGE GROUP

GETINGE GROUP ARJOHUNTLEIGH ALPHA ACTIVE 4 Instructions for use

Agilent Technologies

Agilent Technologies 1290 infinity user manual

Becker

Becker KDT 3.100 operating instructions