11

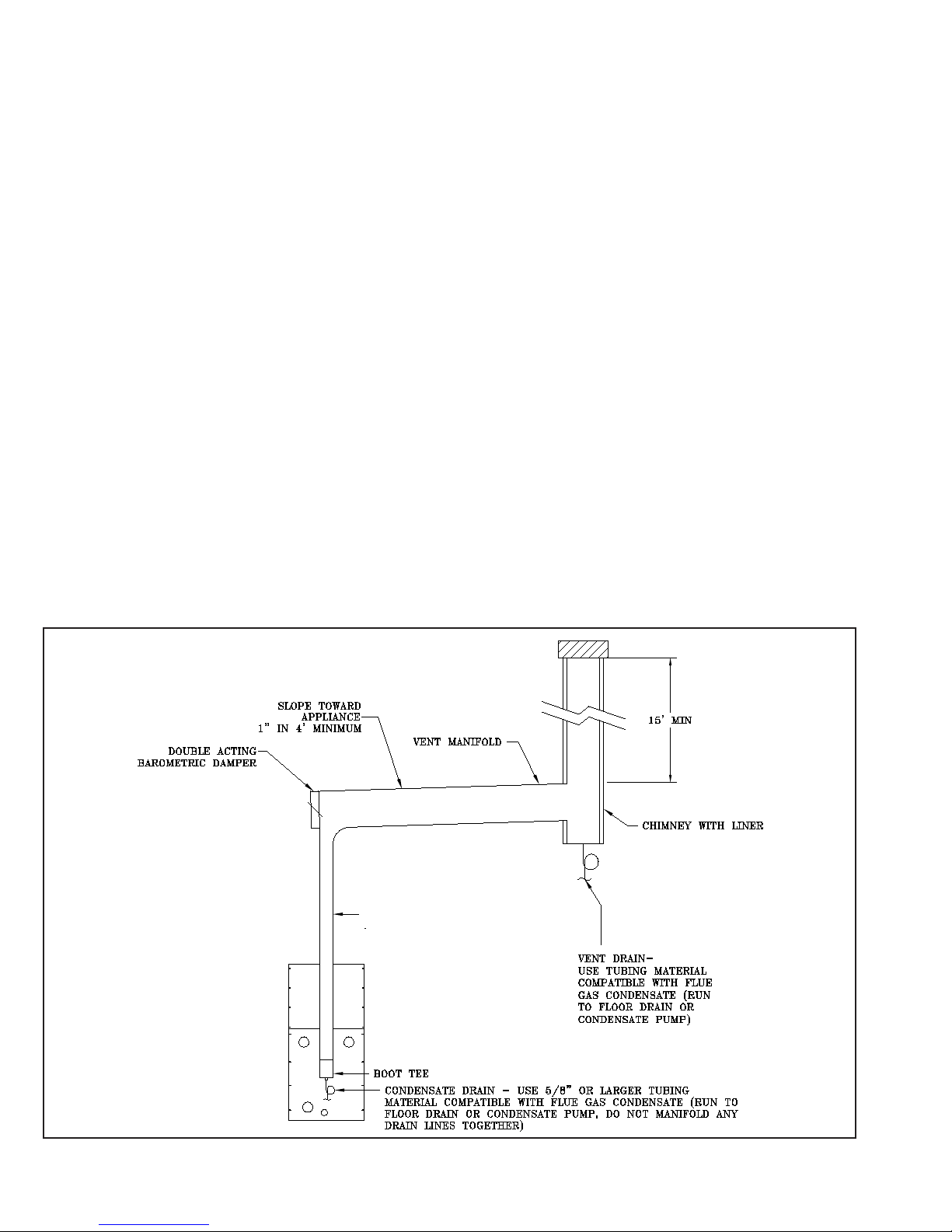

c. The minimum chimney/vertical vent height is 15

feet.

d. Install a condensate drain to collect any

condensate that may form in the lined chimney/

vertical vent.

e. Install a double acting barometric damper with

integraluespillageinterlock.

f. Thechimney/verticalventandueconnectormust

besizedandconguredtoprovideaminimum-0.04

inchw.c.pressure(draft)atthewaterheaterue

outlet.

g. The chimney must be protected from down drafts,

rain and debris by using a chimney cap or star.

h. Start installing vent at vent cap and continue

installation toward the water heater.

i. Theueconnectorandchimneyuediametermay

need to be increased or decreased depending on

the dimensions of the water heater. Consult the

National Fuel Gas Code or Local Codes for sizing.

Waterheaterinput,ueconnectorlateraldistance

andchimneyheightaffecttheueconnectoror

chimneyuediameters.

j. A double acting barometric damper with integral

uespillageinterlockswitchmustbeusedwhen

the water heater is vented conventionally.

4. General Guidelines

a. ThiswaterheaterhasbeencertiedwithAL29-

4C® venting. Select a vent material that is

approvedforusewithcondensinguegasses.

b. Install vent system before installing air intake,

water, gas or electrical connections.

c. For instances where the vent system

manufacturer’s instructions do not make a

specication,refertothebelowpoints.

i. Makesurepipeandttingsarecleanby

swabbing with alcohol. Use Dow Corning 736 or

732 RTV, Polybar #500 RTV or Sil-bond 4500 or

6500 to seal vent pipe.

ii. Refer to the appropriate drawings in this

section of this manual to determine common

acceptablecongurationsofventingsystem.

5. IMPORTANT

The Commonwealth of Massachusetts requires

compliance with regulation 248 CMR 4.00 and

5.00 for installation of side-wall vented gas

appliances as follows:

(a) For all side wall horizontally vented gas

fueled equipment installed in every dwelling,

building or structure used in whole or in part for

residential purposes, including those owned or

operated by the Commonwealth and where the

side wall exhaust vent termination is less than

seven(7)feetabovenishedgradeinthearea

of the venting, including but not limited to decks

and porches, the following requirements shall

besatised:

1. INSTALLATION OF CARBON MONOXIDE

DETECTORS. At the time of installation of

the side wall horizontal vented gas fueled

equipment,theinstallingplumberorgastter

shall observe that a hard wired carbon

monoxide detector with an alarm and battery

back-upisinstalledontheoorlevelwherethe

gas equipment is to be installed. In addition,

theinstallingplumberorgasttershallobserve

that a battery operated or hard wired carbon

monoxide detector with an alarm is installed on

each additional level of the dwelling, building

or structure served by the side wall horizontal

vented gas fueled equipment. It shall be the

responsibility of the property owner to secure

theservicesofqualiedlicensedprofessionals

for the installation of hard wired carbon

monoxide detectors.

a. In the event that the side wall

horizontally vented gas fueled equipment

is installed in a crawl space or an attic, the

hard wired carbon monoxide detector with

alarm and battery back-up may be installed

onthenextadjacentoorlevel.

b. In the event that the requirements of

this subdivision can not be met at the time

of completion of installation, the owner shall

have a period of thirty (30) days to comply

with the above requirements; provided,

however, that during said thirty (30) day

period, a battery operated carbon monoxide

detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE

DETECTORS. Each carbon monoxide detector

as required in accordance with the above

provisions shall comply with NFPA 720 and be

ANSI/UL2034listedandIAScertied.

3. SIGNAGE.Ametalorplasticidentication

plate shall be permanently mounted to the

exterior of the building at a minimum height of

eight (8) feet above grade directly in line with

the exhaust vent terminal for the horizontally

vented gas fueled heating appliance or

equipment. The sign shall read, in print size

no less than one-half (1/2) inch in size, “GAS

VENT DIRECTLY BELOW. KEEP CLEAR OF

ALL OBSTRUCTIONS”.