Thermo Electron 6540 Operating instructions

Analyze • Detect • Measure • Control™

Model 6540 and 6550 Series

Thelco Oven

Operating and Maintenance Manual

3177885 Rev. I Dated 05MAY06

Thermo Electron CorporationThermo Electron Corporation

MANUAL NUMBER 3177885

I 23443 5/06 Consolidated 230V manual (P/N 3179180) with 120V, no CE ccs

H -- 2/06 Knob part number from 3174902 to 3174903, page 14

G -- 1/06 Part number from 3176708 to 3176738, page 13

F -- 11/05 Part number from 3174892 to 3174903, page 14

E -- 7/05 new manual number (36100120 [34001783]), manufacture location

D -- 8/03 Add temperature control range specification, page 3-4

C -- 11/01 Add “plastics can melt”, page 8

B -- 8/99 Updated for new kit #s, pages 12-14

A -- 6/99 Initial release

REV ECR/ECN DATE DESCRIPTION By

Preface

3177885 Thelco Oven i

Current Model # Previous Model # Voltage

6540 70 120V

6541 70 230V

6545 70D 120V

6546 70D 230V

6550 70M 120V

6551 70M 230V

6555 70DM 120V

6556 70DM 230V

6542 130 120V

6543 130 230V

6547 130D 120V

6548 130D 230V

6552 130M 120V

6553 130M 230V

6557 130DM 120V

6558 130DM 230V

6544 160 230V

6549 160D 230V

6554 160M 230V

6559 160DM 230V

Table 1. Models Covered In This Manual

Thermo Electron Corporationii 3177885 Thelco Oven Thermo Electron Corporation

Preface

Important Read this instruction manual. Failure to read, understand and follow the instructions in this manual

may result in damage to the unit, injury to operating personnel, and poor equipment performance. V

Caution All internal adjustments and maintenance must be performed by qualified service personnel. V

Note The 230V models in this manual were designed specifically for the European market and are supplied with

a European-style power cord. For domestic use, a U.S.-style cord (P/N 3179481) must be ordered separately.

Models 6544, 6549, 6554, 6559 are only available in 230V and are supplied from the factory with both cord

styles. V

Material in this manual is for information purposes only. The contents and the product it describes are subject to

change without notice. Thermo Electron Corporation makes no representations or warranties with respect to this

manual. In no event shall Thermo be held liable for any damages, direct or incidental, arising out of or related to

the use of this manual.

©2003 Thermo Electron Corporation. All rights reserved.

Thermo Electron Corporation 3177885 Thelco Oven iiiThermo Electron Corporation

Preface

Important operating and/or maintenance instructions. Read the accompanying text carefully.

Potential electrical hazards. Only qualified persons should perform procedures associated with this

symbol.

Equipment being maintained or serviced must be turned off and locked off to prevent possible injury.

Hot surface(s) present which may cause burns to unprotected skin, or to materials which may be

damaged by elevated temperatures.

Marking of electrical and electronic equipment, which applies to electrical and electronic equipment

falling under the Directive 2002/96/EC (WEEE) and the equipment that has been put on the market

after 13 August 2005.

This product is required to comply with the European Union’s Waste Electrical & Electronic

Equipment (WEEE) Directive 2002/96/EC. It is marked with the WEEE symbol. Thermo Electron

has contracted with one or more recycling/disposal companies in each EU Member State European

Country, and this product should be disposed of or recycled through them. Further information on

Thermo Electron’s compliance with this directive, the recyclers in your country and information on

Thermo Electron products will be available at www.thermo.com.

Always use the proper protective equipment (clothing, gloves, goggles, etc.)

Always dissipate extreme cold or heat and wear protective clothing.

Always follow good hygiene practices.

Each individual is responsible for his or her own safety.

Thermo Electron Corporationiv 3177885 Thelco Oven Thermo Electron Corporation

Preface

3177885 Thelco Oven vThermo Electron Corporation

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Unpacking and Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Explanation of Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

Periodic Safety Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

Section 1

Section 2

Section 3

Section 4

Section 5

Section 6

Section 7

vi 3177885 Thelco Oven Thermo Electron Corporation

Maintenance and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

Temperature Variance or Fluctuation . . . . . . . . . . . . . . . . . . . . . . . . .8-1

Temperature Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

Calibration (Digital Models Only) . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

Heat Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

Heater Resistance Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

Parts Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Heater Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Heater Wire Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Probe Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

Motor Replacement (Mechanical Models) . . . . . . . . . . . . . . . . . . . . .9-2

Control Replacement (Analog Models) . . . . . . . . . . . . . . . . . . . . . . .9-2

Control Replacement (Digital Models) . . . . . . . . . . . . . . . . . . . . . . .9-3

Door and Latch Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

Door Latch Grabber (on body of oven) . . . . . . . . . . . . . . . . . . . . . . .9-4

Electrical Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

Table of Contents

Section 8

Section 9

Section 10

Section 11

3177885 Thelco Oven 1-1Thermo Electron Corporation

Section 1 Introduction

Your satisfaction and safety are important to Thermo and a complete

understanding of this unit is necessary to attain these objectives.

As the ultimate user of this apparatus, you have the responsibility to

understand the proper function and operational characteristics of your

oven. This instruction manual should be thoroughly read and all operators

given adequate training before attempting to place this unit in service.

Awareness of the stated cautions and warnings, and compliance with

recommended operating parameters — together with maintenance

requirements — are important for safe and satisfactory operation. The unit

should be used for its intended application; alterations or modifications

will void the warranty.

Warning As a routine laboratory precaution, always wear safety glasses

when working with this apparatus. V

Warning This product is not intended, nor can it be used, as a sterile or

patient connected device. In addition, this apparatus is not designed for

use in Class I, II, or III locations as defined by the National Electrical

Code. V

Warning When unpacking this unit, use a mechanical lifting device or

enough people to easily lift the unit and place it in it’s proper location. V

Caution The benchtop, or other mounting surface, must be rigidly

constructed and capable of comfortably supporting the unit weight.

Do not mount this equipment on a flammable surface. V

3177885 Thelco Oven 2-1Thermo Electron Corporation

Section 2 Unpacking and Damage

Save all packing material if apparatus is received damaged. This product

was carefully packed and thoroughly inspected before leaving our factory.

Responsibility for safe delivery was assumed by the carrier upon acceptance

of the shipment; therefore, claims for loss or damage sustained in transit

must be made upon the carrier by the recipient as follows:

1. Visible Loss or Damage: Note any external evidence of loss or damage

on the freight bill or express receipt, and have it signed by the carrier's

agent. Failure to adequately describe such external evidence of loss or

damage may result in the carrier's refusing to honor your damage

claim. The form required to file such claim will be supplied by the

carrier.

2. Concealed Loss or Damage: Concealed loss or damage means loss or

damage which does not become apparent until the merchandise has

been unpacked and inspected. Should either occur, make a written

request for inspection by carrier's agent within 15 days of the delivery

date; then file a claim with the carrier since the damage is the carrier's

responsibility.

If you follow the above instructions carefully, we will guarantee our full

support of your claim to be compensated for loss from concealed damage.

DO NOT — for any reason — return this unit without first obtaining

authorization. In any correspondence to Thermo, please supply the

nameplate data, including catalog number and serial number.

3177885 Thelco Oven 3-1Thermo Electron Corporation

Section 3 General Information

This instruction manual encompasses the following models and their

specific electrical characteristics.

• Models 6540/6541, 6545/6546, 6542/6543, 6547/6548, 6544, and

6549 employ gravity convection as a method of heat transfer. Gravity

convection is defined as the natural tendency for heated air to rise due

to it's change in density and mass.

Air is drawn into the chamber through openings in the bottom of the

oven then heated as it passes over the electric heating coils and up

through the diffuser panel located on the bottom of the inner chamber.

A limited amount of the heated air is exhausted out of the chamber

through the openings in the vent cap located on the top of the oven

and the remaining air recirculates within the chamber.

Gravity convection ovens are ideal where forced air circulation cannot

be tolerated and for situations demanding gentle curing or long term

sample storage under closely controlled conditions. Gravity convection

ovens are ideal for drying powders, soil samples, paper goods,

semiconductors and cosmetics.

• Models 6540/6541, 6542/6543, and 6544 use an analog solid state

temperature control with analog solid state safety thermostat.

• Models 6545/6546, 6547/6548 and 6549 use a microprocessor control

with digital set point, digital display and digital safety thermostat.

• Models 6550/6551, 6552/6553, 6554, 6555/6556, 6557/6558 and

6559 ovens use mechanical convection as a method of heat transfer.

Mechanical convection can be defined as a positive and planned

directional air flow or forced air circulation within the chamber. Air is

drawn into the chamber through a vent tube located in the bottom of

the oven and is heated as it passes over the electric heating coils. The

air is blown through the duct network and forced into the chambers

through calculated, carefully designed openings in the side diffuser

walls.

A limited amount of the heated air is exhausted out the top of the

chamber through the vent shutter cap and the remaining air

recirculates within the chamber.

3-2 3177885 Thelco Oven Thermo Electron Corporation

Section 3

General Information

Mechanical convection ovens provide the most efficient means of heat

transfer as well as the most reproducible test conditions for repeat

operations. Mechanical convection allows for rapid heat up time for

high density loads, shortened recovery periods after door openings and

improved uniformity for extremely heat sensitive materials.

• Models 6550/6551, 6552/6553 and 6554 provide mechanical

convection of heat controlled by an analog solid state control with

analog solid state safety thermostat.

• Models 6555/6556, 6557/6558 and 6559 provide mechanical

convection of heat controlled by a microprocessor with digital set

point, digital display and digital safety thermostat.

• Environmental Conditions -

This instrument is designed to operate safely under the following

conditions:

• Indoor Use Only

• Temperature: 5° to 40° C

• Maximum Relative Humidity: 80% for temperatures to 22°C

• Maximum Altitude 2000 meters

Maximum performance is assured across the following temperature

range:

• 15ºC to 45ºC

3177885 Thelco Oven 4-1Thermo Electron Corporation

Section 4

Specifications

Specifications Gravity Convection

Model

6540/6541

Model

6542/6543 Model 6544 Model

6545/6546

Model

6547/6548 Model 6549

Temperature Control Electronic Microprocessor

Temperature Display 0°C to 250° Thermometer 3 Digit LED

Temperature Control Range 65°C to 250°

Temperature @ 100° C ±4.0 ±3.5

Uniformity @ 200° C ±4.5 ±4.5

Sensitivity ±0.3° C ±0.1°C

Minutes to reach Max.

Temperature 250° 60

*Recovery Time @ 100° C 810 12

(minutes) @ 200° C 510 12

Max. Air Changes/Hr 30 23 15 30 23 15

Chamber Volume cu. ft. 2.5 4.5 5.5 2.5 4.5 5.5

liters 71.5 129 157.5 71.5 129 157.5

Net Weight lbs. 100 130 145 100 130 145

kg 45.3 59 65.8 45.3 59 65.8

Dimensions (D x W x H)

Chamber inches 15-3/4x18-1/2x15 15-3/4x18-1/2x27 15-3/4x18-1/2x33 15-3/4x18-1/2x15 15-3/4x18-1/2x27 15-3/4x18-1/2x33

mm 400x470x381 400x470x686 400x470x838 400x470x381 400x470x686 400x470x838

**Overall inches 21-1/4x24x28 21-1/4x24x40 21-1/4x24x46 21-1/4x24x28 21-1/4x24x40 21-1/4x24x46

mm 540x610x711 540x610x1016 540x610x1168 540x610x711 540x610x1016 540x610x1168

Electrical 50/60 Hz 115V 1200W 10.4A 1700W 14.8A N/A N/A 1200W 10.4A 1700W 14.8A N/A N/A

230V 1200W 5.2A 1700W 7.4A 2000W 8.7A 1200W 5.2A 1700W 7.4A 2000W 8.7A

Shipping Dimensions in. 25x26x31-1/4 25x26x43-1/4 25x26x49-1/4 25x26x31-1/4 25x26x43-1/4 25x26x49-1/4

Shipping Weight lbs. 125 155 170 125 155 170

Max Number of Shelves 612 15 612 15

***Shelves Supplied 2

Shelf Dimensions in. 15.5 x 18

mm 390 x 455

Catalog Number 115V 3166782 3166784 - - 3166787 3166789 - -

230V 3166783 3166785 3166786 3166788 3166790 3166791

“* Door Open for 30 seconds

** Overall height includes vent cap and adjustable feet

*** Spacing between shelves is 1-7/8” (48mm)

4-2 3177885 Thelco Oven Thermo Electron Corporation

Section 4

Specifications

Specifications Mechanical Convection

Model

6550/6551

Model

6552/6553 Model 6554 Model

6555/6556

Model

6557/6558 Model 6559

Temperature Control Electronic Microprocessor

Temperature Display 0°C to 250° Thermometer 3 Digit LED

Temperature Control Range 40°C to 250°

Temperature @ 100° C ±3.0 ±2.0

Uniformity @ 200° C ±3.5 ±3.0

Sensitivity ±0.3°C ±0.1°C

Minutes to reach Max.

Temperature 250° 70

*Recovery Time @ 100° C 5 7 10 12

(minutes) @ 200° C 5 7 10 12

Max. Air Changes/Hr 52 34 19 52 34 10

Chamber Volume cu. ft. 2.5 4.5 5.5 2.5 4.5 5.5

liters 71.5 129 157.5 71.5 129 157.5

Net Weight lbs. 110 140 155 110 140 155

kg 50 63.5 70.3 50 63.5 70.3

Dimensions (D x W x H)

Chamber inches 15-3/4x18-1/2x15 15-3/4x18-1/2x27 15-3/4x18-1/2x33 15-3/4x18-1/2x15 15-3/4x18-1/2x27 15-3/4x18-1/2x33

mm 400x470x381 400x470x686 400x470x838 400x470x381 400x470x686 400x470x838

**Overall inches 21-1/4x24x28 21-1/4x24x40 21-1/4x24x46 21-1/4x24x28 21-1/4x24x40 21-1/4x24x46

mm 540x610x711 540x610x1016 540x610x1168 540x610x711 540x610x1016 540x610x1168

Electrical 50/60 Hz 115V 1300W 11.3A 1800W 15.6A N/A N/A 1300W 11.3A 1800W 15.6A N/A N/A

230V 1300W 5.6A 1800W 7.8A 2100W 9.1A 1300W 5.6A 1800W 7.8A 2100W 9.1A

Shipping Dimensions in. 25x26x31-1/4 25x26x43-1/4 25x26x49-1/4 25x26x31-1/4 25x26x43-1/4 25x26x49-1/4

Shipping Weight lbs. 135 165 180 135 165 180

Max Number of Shelves 612 15 612 15

***Shelves Supplied 2

Shelf Dimensions in. 15.5 x 18

mm 390 x 455

Catalog Number 115V 3166792 3166794 - - 3166797 3166799 - -

230V 3166793 3166795 3166796 3166798 3166800 3166801

“* Door Open for 30 seconds

** Overall height includes vent cap and adjustable feet

*** Spacing between shelves is 1-7/8” (48mm)

3177885 Thelco Oven 5-1Thermo Electron Corporation

Section 5 Installation

Caution Installation should be completed by qualified instrument

personnel only. V

The most uniform operating conditions will be obtained by placing the

oven in an area remote from drafts, ventilating outlets, radiators, and other

rapidly changing ambient conditions. To assure proper ventilation allow a

minimum of 3 inches of clearance between the rear, top and sides of the

oven and adjacent walls. If two or more ovens are to be placed side by side,

then allow 6 inches between them. The four legs on the bottom of the

oven can be turned to raise or lower the corners of the oven so that it sits

level on the table.

Warning For personal safety, this apparatus must be properly grounded. V

Most units detailed in this manual are equipped with three-pronged

(grounded) plug power cords. These mate with standard three-prong

receptacles to minimize the possibility of electric shock. The user should

have the wall receptacle and circuit checked by a qualified electrician to

make sure the receptacle is properly grounded.

Where a standard two-prong wall receptacle is encountered, it is the

personal responsibility and obligation of the user to have it replaced with a

properly grounded three-prong wall receptacle.

Warning Do not, under any circumstances, cut or remove the third

(ground) prong from the power cord. Do not use a two-prong adapter. V

Determine the total amount of current being used by other apparatus

connected to the circuit that will be used for this apparatus. It is critical

that the added current demand (see nameplate) of this and other

equipment used on the same circuit does not exceed the rating of the fuse

or circuit breaker.

Location

Electrical

Connections

5-2 3177885 Thelco Oven Thermo Electron Corporation

Section 5

Installation

Caution Be sure that the power supply is of the same voltage as specified

on the nameplate. V

Caution Be sure the wall receptacle is readily identifiable and easily reached

to disconnect the unit from the power source. V

Model 6557 115-volt units (Cat. No. 3166789) are equipped with non-

standard plugs (one horizontal and one vertical blade) and will require

installation of a special matching receptacle. To be in compliance with the

National Electrical Code, non-standard plugs and receptacles are required

to accommodate higher current draw.

The aforementioned models are rated at 15.6 amps.

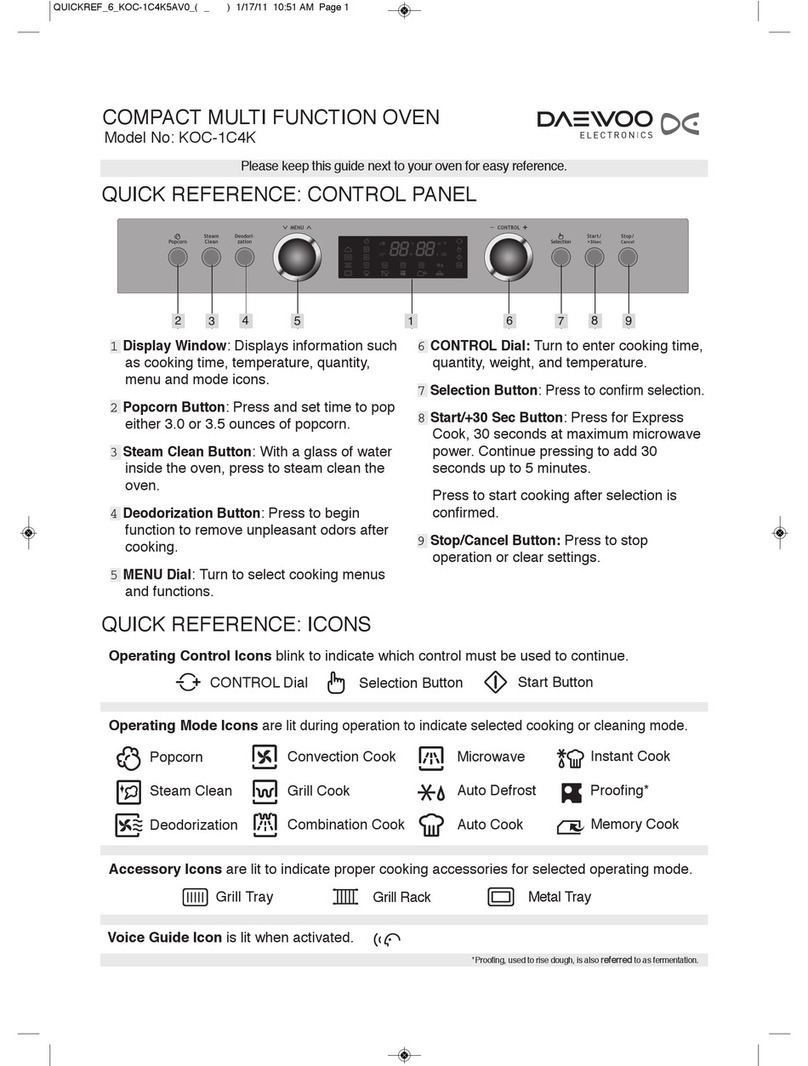

Section 6 Explanation of Controls

Models 6540/6541, 6550/6551, 6542/6543,

6552/6553, 6544, and 6554

On/Off Switch - The on/off switch controls the flow of all electric power

to the oven. The blower motor in the mechanically convected models

will only be in operation with the power switch ON, and the timer not

at setting "0".

Temperature Control Knobs - Two control knobs, Temperature Control

and High Temperature Limit set the operating temperature and safety

set points respectively. The numerical graduations do not refer to any

specific temperature, but are simply for reference.

Temperature Control Pilot Lamps - These lamps indicate the status of the

controls. When the lamp above the Temperature Control is illuminated,

this indicates electric current is being applied to the heater. It is normal

for this lamp to cycle on and off during the operation of the oven. The

lamp above the High Temperature Limit is illuminated only when first

set. If this lamp is ON, it indicates that oven is controlling on the High

Temperature Limit thermostat which has taken over control of from the

Temperature Control thermostat.

When the High Temperature Limit lamp comes on it is due to either a

Temperature Control thermostat failure or that the High Temperature

Limit thermostat is set too close in value to the temperature control. In

this case a slight turn clockwise for the High Temperature Knob should

increase the span between them.

Timer - The timer controls how long the oven will stay on if a predeter-

mined time between one to twelve hours is desired. With the Timer set

to the HOLD position the oven will run continuously. If the Timer

knob is first turned past two hours then set to some value the oven will

then turn off after that value has timed out.

Glass Thermometer - Used to indicate oven temperature and determine

proper thermostat settings.

Light Switch - Turns interior lamp on and off.

3177885 Thelco Oven 6-1Thermo Electron Corporation

Models 6545/6546, 6555/6556, 6547/6548,

6557/6558, 6549, and 6559

On/Off Switch - The on-off switch controls the flow of all electric power

to the oven. The blower motor in the mechanically convected models

will always be in operation with the power switch "ON".

Digital Displays - Three digital displays show actual temperature, set point

temperature and hours.

Arrows - The arrow buttons will allow you to increment (^) or decrement

(v) the displayed temperature or time set point values.

Temp - The Temp button will allow you to select a set point value for

desired temperature.

High Limit - The High Limit button will allow you to select a set point

value for the desired high temperature limit.

Set - The Set button will allow you to enter the value you have selected

with the arrow buttons when you are either in Temp or High Limit

mode.

Mute - The Mute button will silence the audible alarm if activated.

Timer - The Timer Button will put the oven into either Continuous or

Timed mode, as indicated by the Hours digital display. When in

Continuous mode, the display will show -- (dashes); the Continuous

lamp is illuminated, and the oven runs constantly. When in Timed

mode, the display will show a numeral.

Start/Stop Button - The Start/Stop button is used to start the Timed oper-

ation or to interrupt the Timed cycle. When the Timed lamp is illumi-

nated, the oven will remain at the set point temperature for the time dis-

played. When the lamp is not illuminated, the oven is not heating and

the length of running time can be selected in hour increments using the

arrow buttons.

Light On/Off - The Light ON/OFF switch operates the interior chamber

lamp.

6-2 3177885 Thelco Oven Thermo Electron Corporation

Section 6

Explanation of Controls

Section 7 Operation

Warning This equipment has reachable hot surfaces. The operator should

take any precaution to avoid contact with these parts. V

Fully open the exhaust vent shutter cap on the top of the oven and keep it

open at all times. However, if the running the oven at the maximum rated

temperature it may be necessary to turn the cap to a more closed position

to retain heat.

Insert shelf supports into the holes punched in the side walls of the inner

chamber. Insert the shelves into the shelf supports and try to keep an equal

distance between shelves whenever possible. Try to position the shelves so

they can be withdrawn more than halfway without falling. Never cover the

shelves with foil or reduce their open surface area by more than 75%, this

will greatly reduce convection and hence uniformity and control will

suffer.

3177885 Thelco Oven 7-1Thermo Electron Corporation

This manual suits for next models

19

Table of contents