pg. II

1. INTRODUCTION ...........................................................................................................................................................................................................

1.1 General guidelines ........................................................................................................................................................................................

1.2 Safety guidelines..........................................................................................................................................................................................

1.3 Standardsandrecommendations ..................................................................................................................................................................

1.4 Transportationand storage...........................................................................................................................................................................

2. TECHNICALCHARACTERISTICS ................................................................................................................................................................................

2.1 Technical data........ .....................................................................................................................................................................................

3. GENERAL DESCRIPTION...........................................................................................................................................................................................

3.1 Operatingtechnology ...................................................................................................................................................................................

3.2 Pellets ..........................................................................................................................................................................................................

3.3 The feedbox................................. ...........................................................................................................................................................

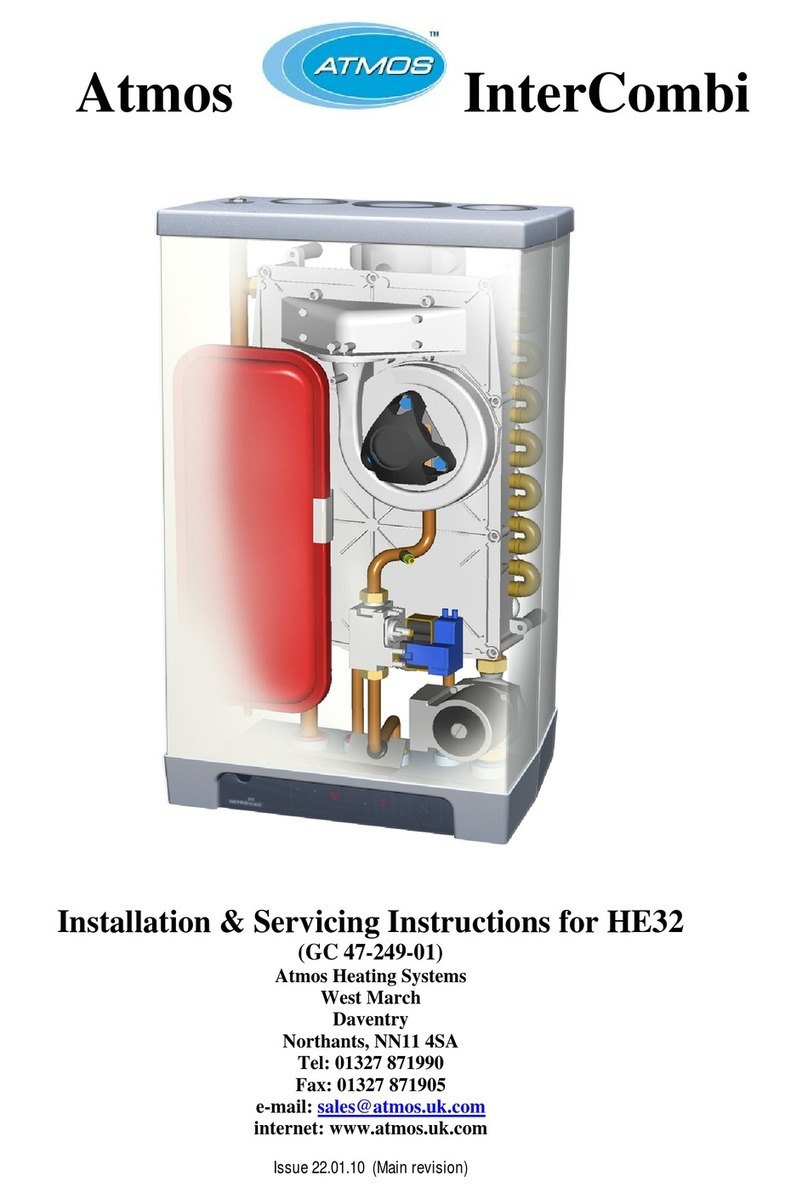

3.4 Main components of heater mod. H2O 25 and boiler mod. Compact 25 . .....................................................................................................

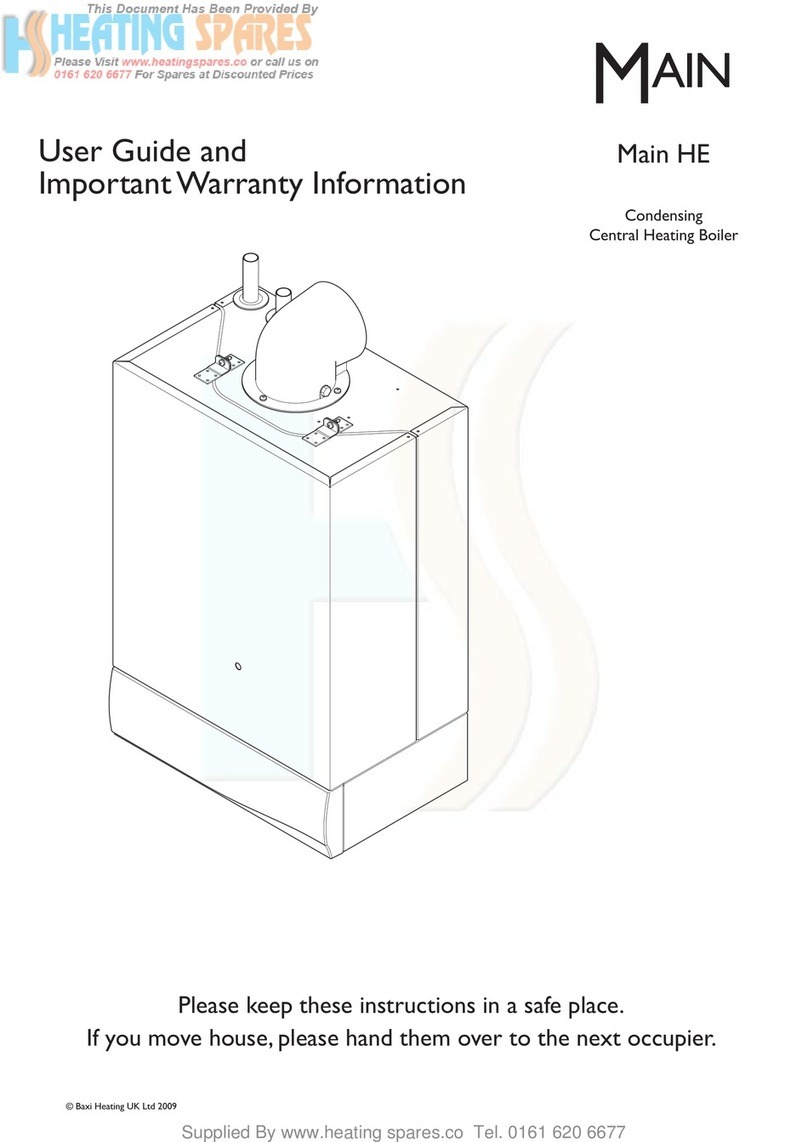

4. INSTALLATION ..............................................................................................................................................................................................................

4.1 Heater / boiler location.......................... ...................................................................................................................................................

4.2 Mounting boiler / heater casing...................................................................................................................................................................

4.2.1 How to mount H2O 25 heater casing............................................................................................................................................................

4.2.3 Howto mountCompact boilercasing............................................................................................................................................................

4.2.4 How to install the additional hopper (optional) with Compact boiler..............................................................................................................

4.2.5 Fasteningadditional hopper(optional) toCompact boiler .............................................................................................................................

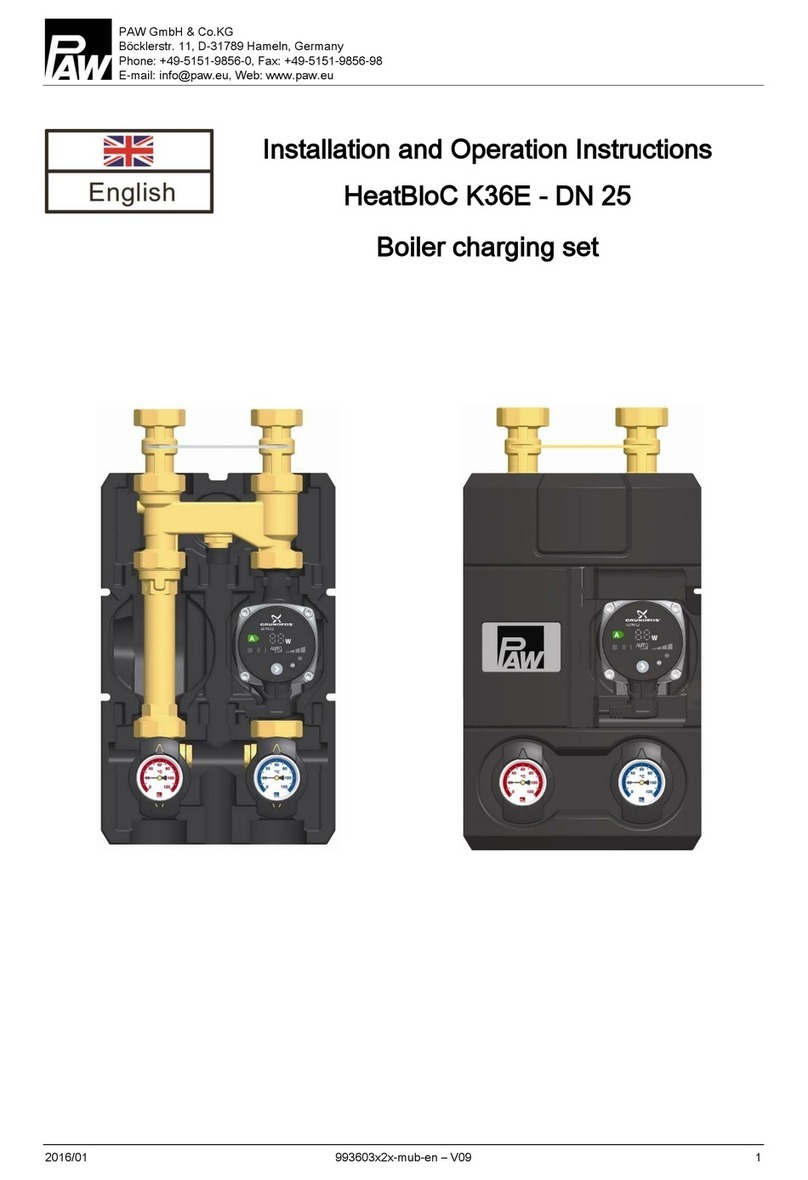

4.3 Hydraulic drawing for heater H2O / Compact ...............................................................................................................................................

4.4 Example of hydraulic drawing for H2O / Compact only heating ....................................................................................................................

4.5 Example of hydraulic drawing H2O / Compact with interspaced boiler coils or boiler coils. ........................................................................

4.6 Example of hydraulic drawing H2O / Compact with boiler coils and use of Thermocontrol (optional) ...........................................................

4.7 Exampleof hydraulicdrawing H2O /Compact +Thermocell (or Thermopuffer)+ additionalThermopuffer + High temperature heatingand

lowtemperature heating. ..............................................................................................................................................................................

4.8 Instructions for executing the hydraulic system closed expansion tank. ....................................................................................................

5. USE OF THE HEATER / BOILER ...............................................................................................................................................................................

5.1 Description of control panel..........................................................................................................................................................................

5.2 Description of rear panel ..............................................................................................................................................................................

5.3 Day and time setting.....................................................................................................................................................................................

5.4 Chronothermostat:ON/OFFprogramming ...................................................................................................................................................

5.5 Languageselection ......................................................................................................................................................................................

5.6 Operating level setting .................................................................................................................................................................................

5.7 Water pressure in the generator...................................................................................................................................................................

5.8 Action temperature setting "Sensor 1 Thermocell" and " Sensor 2 Thermocell " as indicated in the hydraulic drawing para. 4.8 .................

5.9 Information about how the generator works .................................................................................................................................................

5.10 Boiler water pressure control. ......................................................................................................................................................................

5.11Switching on the heater H2O / boiler Compact.............................................................................................................................................

5.12 Adjusting the combustion of the heater H2O / boiler Compact. ....................................................................................................................

5.13 Switching off the heater H2O / boiler Compact.. ..........................................................................................................................................

6. ADDITIONALROOM TEMPERATURETHERMOSTAT AND ADDITIONALCHRONOTHERMOSTAT (NOT SUPPLIED) .............................................

6.1 Operating with the additional room temperature thermostat (not supplied )

6.2 Operating with the additional chronothermostat (not supplied) ....................................................................................................................

7. CLEANING AND MAINTENANCE ..................................................................................................................................................................................

7.1 Foreword ......................................................................................................................................................................................................

7.2 Cleaning andmaintenance ofheater H2O/ boilerCompact ..........................................................................................................................

7.3 Patented self-cleaning burner. .....................................................................................................................................................................

8. SMOKE DISCHARGE TUBE AND COMBUSTIONAIR INTAKE ...................................................................................................................................

8.1 Ventilation of the rooms ................................................................................................................................................................................

8.2 Combustionair intake ...................................................................................................................................................................................

8.3 Smokeoutlet.................................................................................................................................................................................................

9. ALARMS .....................................................................................................................................................................................................................

10. ELECTRICAL WIRING .................................................................................................................................................................................................

11. INFORMATION FOR THE SKILLED TECHNICIAN......................................................................................................................................................

11.1 Main components and their operation...........................................................................................................................................................

11.2 Useful advice for installation and operation .................................................................................................................................................

11.3 Troubleshooting cause - solution ..................................................................................................................................................................

12. SPAREPARTS ................................................................................................................................................................................................................

C O N T E N T SC O N T E N T S

C O N T E N T SC O N T E N T S

C O N T E N T S