WiPro III + safe.lock Installation Manual – Fiat Ducato X250, Euro 4

7

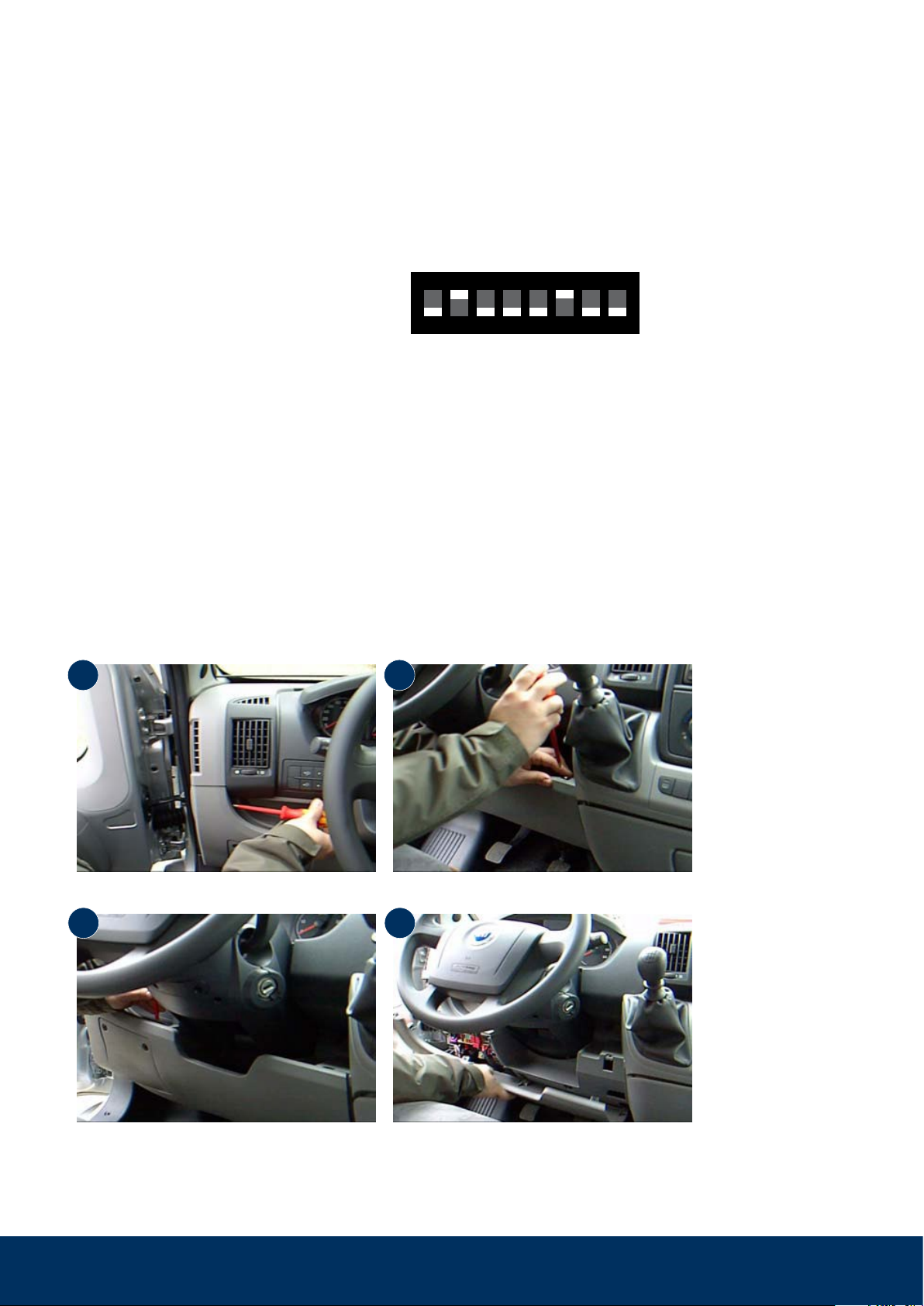

Step 9: Carry out a function test

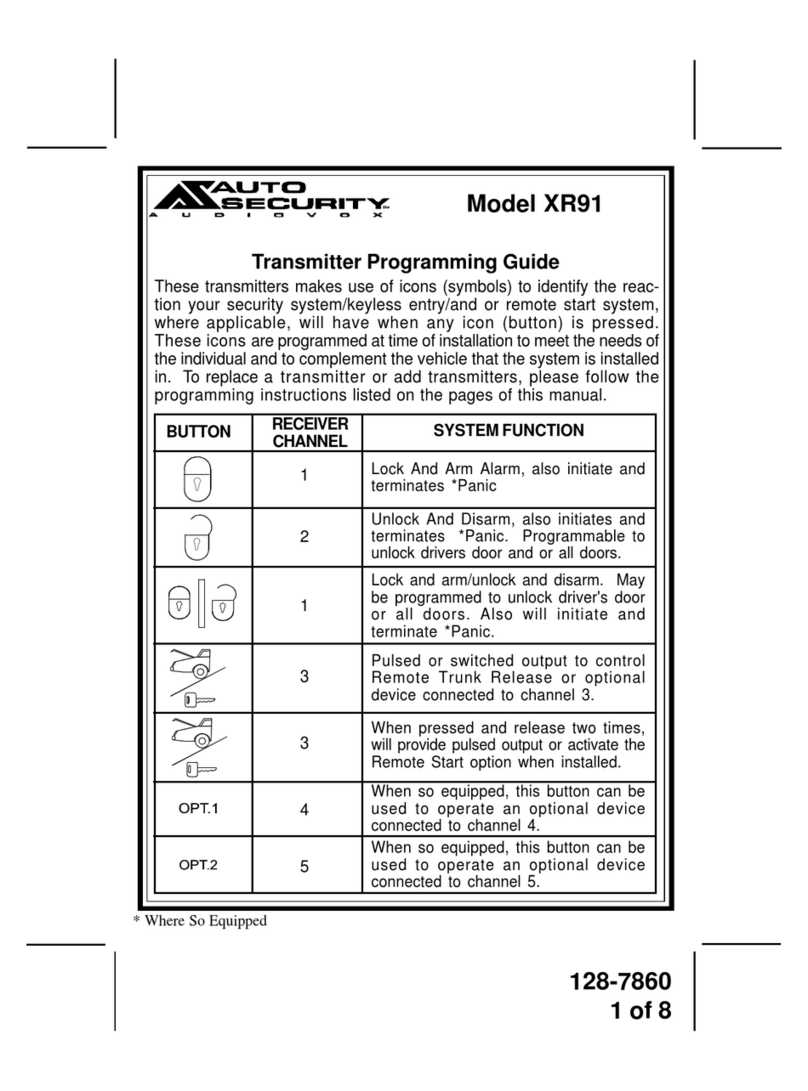

1. The ‘lock’ button on the original vehicle

remote control arms the system.

After installation it may be necessary

to lock and unlock several times until

the system responds as the CAN bus

data first has to be synchronised.

The central control unit acknowledg-

es the activation through a beep and

flashing of the direction indicators. The

status LED flashes.

If a door in the driver’s cab is open, the

vehicle is not locked (on-board func-

tion) and the system is not activated.

2. Trigger the alarm by mechanically

opening the door on the driver’s side –

from the inside with the door handle or

from the outside by unlocking with the

mechanical key and opening the door.

3. The acoustic alarm sounds for approx.

30 seconds. The visual alarm lasts ap-

prox. 180 seconds.

4. The ‘unlock’ button disarms the system

or interrupts the alarm.

Signals during arming

If a series of short beeps is emitted during

locking, one of the taught-in magnetic

contacts is open. However, the system is

armed anyway.

Possible faults

Error

:

The system does not respond to the com-

mands from the wireless key, but emits a

beep when the power supply is applied.

Solution

:

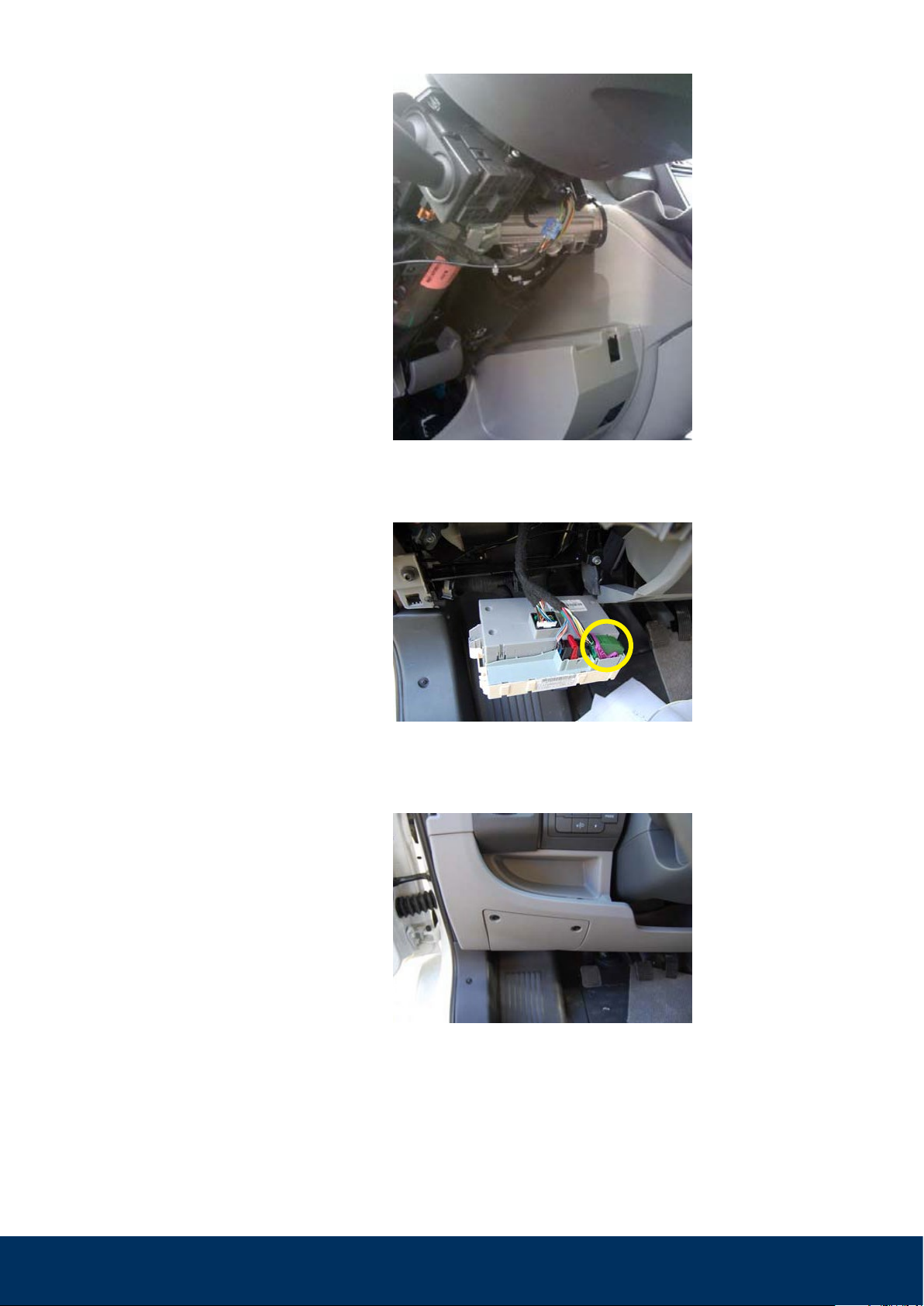

1. Check the CAN connection (white/or-

ange and violet/orange).

2. Briefly press the button on the circuit

board to activate the diagnostics mode.

If the wireless key is being operated or

a different operation is generating data

traffic on the CAN bus, this is indicated

through flickering of the green LED (left

LED). If no data traffic is indicated, the

bus is inactive or the connection has not

been executed correctly.

Error

:

The system does not respond to the

commands from the wireless key and does

not emit a beep when the power supply is

applied.

Solution

:

1. Check the power supply.

2. Is the correct pin on the front connec-

tor occupied?

3. Crimp connection executed correctly?

4. Ignition switched on? The system is

deactivated when the ignition is active.

5. Fuse F39 present and intact?

Error

:

Although all contacts are closed, an open

contact is signalled during arming.

Solution

:

1. Check the distance between the trans-

mitter and the magnet.

2. Open and close all contacts several

times and then arm again.

3. Open contact is still being signalled >

pull out the connector for the power

supply or remove F39 (with closed con-

tacts) > reconnect the power supply.