© 2020 Thorlabs8

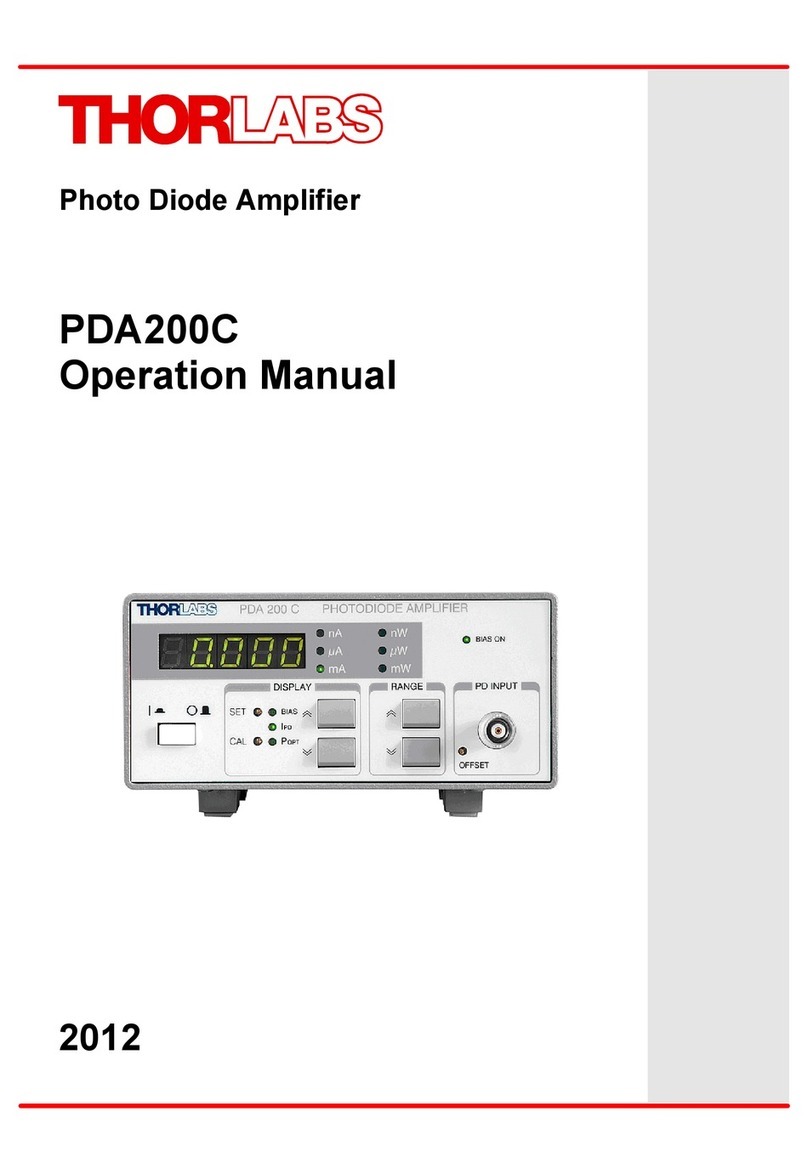

PDA200C

Zeroing the PD's dark current

Connect the photodiode to the input jack "PD INPUT" (F20) and make sure the PD is darkened

completely. It might be useful to ground the photodiode's housing using the supplied grounding

cable, connected to the GND jack R2 on the rear panel

·Select display IPD (F15/ F16).

·Select the required PD current range (F17/ F18).

·Using the screwdriver, turn the potentiometer "OFFSET" (F19) in order to achieve a zero

IPD current in the display.Aftewr th

Note

After changing the IPD current range, the dark current compensation must be carried out again!

3.2.3 Calibration of the Power Display

The PDA200C can be calibrated in order to display the optical power incident to the connected

photodiode. The responsivity of the of the photodiode must not exceed the range 0.05 to 2

A/W. If the connected PD has a responsivity exceeding this eange, please contact Thorlabs for

a solution.

·Connect the photodiode and turn the PDA200C on.

·Expose the photodiode to a well known optical power. Make sure that no additional optical

power enters the photodiode.

·Select display IPD (F15 / F16).

·Select an appropriate current range (F17 / F18) to show the actual photodiode current

with the best possible resolution.

·Select display POPT (F15 / F16).

·Use the screwdriver to adjust the potentiometer "CAL" (F11) in order to get the value of

the optical power POPT displayed equal to the known power level.

This calibration is valid for all current ranges of the PDA200C.

3.2.4 Setting a BIAS Voltage

The PDA200C provides the possibility to apply a reverse voltage of up to ±10 V (bias) to the

photodiode (photo-conductive mode).

·Set the bias switch (R3 ) to “OFF”

·Connect the photodiode and turn on the PDA200C

·Expose the photodiode to light.

·Select the current range (F17 / F18).

If the displayed value is positive (polarity cathode grounded), set the bias switch (R3) to " - CG".

The applied bias voltage is negative.

If the displayed value is negative (polarity anode grounded), set the bias switch (R3) to " + AG".

The applied bias voltage is positive.

·Select Display “Bias” (F15 / F16).

·The bias voltage is displayed in volts.

·Use the screwdriver to set the potentiometer "SET" (F10) to the desired value for the bias

voltage.

6

6