TigerStop Standard Controller 5 User manual

TigerStop®Standard

Controller 5

User Manual

iii

Table of Contents

1 Contact Us

2 Standard Controller Keypad

3 Ready Screen Functions

3 Home Routine

3 Ready ScReen

4 manual movement

4 calculatoR mode

5 Jog

5 incRement

6 Quick calibRation

6 PReSet

8 PaRt liStS

14 backboaRd defecting & oPtimizing

17 Standard Controller Menus

17 acceSSing & navigating tHe menuS

17 menuS oveRview

18 Setup Menu

18 calibRate

18 Home Routine

18 keRf

18 find tHe end limitS

19 auto SetuP

19 minimum limit

19 maximum limit

20 laSH

20 Jog ReveRSe

20 auto detect

21 Scale

22 Offset Menu

22 add/edit an offSet

22 gotoan offSet

23 Options Menu

23 language

23 PaSSwoRd

23 SleeP mode

23 Set unitS

24 SHow unitS

24 millimeteR conveRSion

24 contRaSt

24 PRinteR tyPe

25 PRint cut

25 inkJet offSet

25 Safe zone

25 feed HazaRd

26 diSable Quick calibRation

26 backoff

26 RetRact

26 RetRact offSet

27 RetRact tyPe

28 Part List Menu

28 Head cut

28 tail cut

28 outfeed

28 load offSet

28 unload

29 max SPl

29 waSte

29 PReSetS

29 dRill

30 cleaR all

30 oPtimizeR ScoRe

30 oPtimizeR time

31 oPtimizeR Penalty

31 clamP 1

31 clamP 2

31 Swing clamP

32 infinite

32 download Style

32 PReciSion end tRim

32 banana 1

33 banana 2

33 tigeRmeaSuRe

33 tigeRmeaSuRe offSet

33 millimeteR only

34 Quantity

35 Motion Menu

35 in-SPeed

35 out-SPeed

35 in-acceleRation

35 out-acceleRation

35 in-deceleRation

36 out-deceleRation

36 move delay

iv

36 P gain

36 i gain

36 d gain

37 ditHeR

37 tHRottle lvm

37 tHRottle lvb

37 tHRottle Hvm

37 tHRottle Hvb

37 Stall meP

38 Stall meS

38 Run meP

38 Run meS

39 Timer Menu

39 clamP ondelay

39 Saw ondelay

39 dm off time out

39 cycle time out

40 toP aRboR off time out

40 dm ontime out

40 clamP off delay

40 Saw cycle delay

41 RSd Ready time out

41 PReciSion end tRim delay

41 outfeed delay

41 load delay

42 System Information Menu

42 SeRial numbeR & enable code

42 SoftwaRe veRSion

42 Set zeRo end

42 motoR tyPe

43 Set inteRconnect tyPe

43 baud Rate

43 i/o Panel baud Rate

44 bRake

44 bRake time out

45 Laser Menu

45 laSeR maRking

45 defect only

45 laSeR eRRoR

45 laSeR location

45 laSeR limit

46 laSeR RefeRence

46 cRayon

Table of Contents

46 Pf offSet

46 iR offSet

46 Pf down

47 maRgin

48 Debug Menu

48 dRive teSt

48 i/o teSt

48 i/o maSk

48 debug mode

v

SAFETY FIRST!

IMPORTANT SAFETY INFORMATION. READ ALL WARNINGS BEFORE OPERATING THIS PRODUCT.

WARNING: Installation of your TigerStop® Product must be done by a person trained in the safe design and installation of

automation products, and in the safe operation of power equipment. Ensure that such installation meets all legally required

safety requirements and guidelines, and that proper guarding and safety devices are provided on all sides of the equipment to

preclude unintended access during operation. Consult with and follow the recommendations of a qualified safety engineer.

WARNING: TigerStop® Products are components intended for use in conjunction with potentially dangerous machinery.

The use of TigerStop® Products does not make other machinery safe. TigerStop® Products are not intended to substitute,

in any manner, for safe operating practices in general, or for safety features present in other machines designed to make

those machines as safe as possible. TIGERSTOP® PRODUCTS, IF USED OR INSTALLED IMPROPERLY, MAY CAUSE

PERSONAL INJURY OR DEATH AND SHOULD ONLY BE OPERATED BY PERSONS TRAINED IN THEIR SAFE OPERATING

PROCEDURES. Illustrations of TigerStop® Products in use do not show, and are not intended to show, all safety features and

practices necessary for their safe operation.

WARNING: TigerStop® Products must be installed in accordance with all local, state, and federal regulations. Only personnel

properly trained in the safe design and installation of automation machinery and related power equipment should install

TigerStop® Products onto other equipment, to ensure a safe and proper work station. TigerStop® Products should not be

operated without proper training, both in the operation of TigerStop® Products, and in the operation of related equipment.

IMPORTANT CAUTION:

The motor box (compartment) contains DC voltage with potentially FATAL amperage. NEVER attempt any unauthorized actions

inside the motor box.

WARNING: Using a TigerStop® interconnect does not relieve you of the responsibility for making sure that your saw or other

tool has all the necessary safety equipment in place. All installations must meet all legally required safety requirements and

guidelines. Installation and training should be done following the recommendations of a qualified safety engineer.

DANGER: This machine can start, move and stop automatically. Keep hands and loose clothing clear of moving parts while

operating. Moving parts can crush and cut. When used with a saw or other cutting equipment, bodily injury and death may result

if operated without safety guards on all machines. Do not operate with guards removed. Operators must wear adequate eye and

ear protection.

GENERAL WARNINGS

INSTALLATION WARNINGS

INTERCONNECTS

OPERATION

vi

IMPORTANT SAFETY INFORMATION. READ ALL WARNINGS BEFORE OPERATING THIS PRODUCT.

DANGER! Don’t get pinched by the push feeder. Keep your hands away when in motion!

Keep the work area clean and well lighted to avoid accidental injury.

Do not operate near flammable liquids or in gaseous or explosive atmospheres!

Use only 3-wire extension cords that have 3-prong grounding type plugs and 3-pole

receptacles that accept the tools plug for 120VAC. Use only 5-wire cords and plugs

when using 3 phase.

Do not open motor compartment or controller keypad. DC Voltage with potentially

FATAL amperage! Disconnect power before servicing. No user-serviceable parts inside.

DO NOT operate this or any machine under the influence of drugs or alcohol!

No one should operate this machine except for fully qualified personnel.

READ THE MANUAL!

Do not use TigerStop® machines in a dangerous environment. Using power tools in damp

or wet locations or in rain can cause shock or electrocution.

Wear proper apparel, no loose clothes, long hair or jewelry which could get pulled into

moving machinery or materials. Wear non slip footwear, safety glasses, ear protection

and a dust mask.

1

TigerStop®technical support on the web, including manuals and videos:

TigerStop®customer service and technical support by email:

TigerStop®customer service and technical support by phone:

Contact Us

https://www.tigerstop.com/service-center/

service@tigerstop.com (Americas, Australia)

sos@tigerstop.nl (Europe)

1 (360) 448 6102 (Americas, Australia)

00 31 546 575 171 (Europe)

2

Standard Controller Keypad

Sleep: Puts the Standard Controller to sleep to save energy.

Start: Initiates movement of the TigerStop®.

STOP Stop: Ends the current operation/ceases movement/exits the menu.

OK: Confirms an action/initiates a process.

Clear: Cancels an input/exits the menu or process.

Arrows: Moves the cursor/jogs the TigerStop®/navigates menus.

Soft Keys: Executes varied on-screen functions.

*

Math Keys: Performs basic math functions.

6

7

8

9

Number Keys: Inputs numerical values.

3

Ready Screen Functions

Home Routine

Every time a TigerStop®powers-on, it requires the ‘Home Routine’. The Home Routine is a three-step process in

which the TigerStop®moves to its farthest possible position.

Ensure the area is clear. The TigerStop®moves automatically during this routine.

1. Press to run the Home Routine.

2. When movement stops, the TigerStop®controller displays the Ready Screen.

Line 1 displays the “heartbeat”. The heartbeat is a line that rotates and

indicates that the TigerStop®is functioning normally. The letter next to

the heartbeat is the drive indicator. The drive indicator communicates the

motor’s status.

Line 2 shows the current position of the TigerStop®. The position ends with

either ‘in’ or ‘mm’ depending on measurement system.

Drive Indicator

HHolding Still WWaiting

AAccelerating XDrive Disabled

CConstant Speed NCommunication Error

DDecelerating SStopping

LLash JJog

TWaiting for Text

Entry --- ---

Ready ScReen

Line 3 shows the next position of the TigerStop®. This is also where user

input appears.

The Ready Screen is the starting point for all TigerStop®functions.

The Ready Screen is always accessible by repeatedly pressing STOP or

The Ready Screen has two forms. From the basic Ready Screen, press the

[Show] soft key to display the expanded options.

Press to return to the basic Ready Screen.

4

Ready Screen Functions

Line 4 displays the soft key prompts. These prompts determine what the

soft keys below them do. These change when accessing dierent screens.

manual movement

To manually move the TigerStop®to a stop position, enter a distance from the saw blade or equivalent. Enter this

distance as a whole number, a decimal, or a fractional value.

enteRin g decimalS

1. Start at the Ready Screen.

2. Enter a length at the controller. Use the to put a space between the

whole numbers and the fractional numbers.

Example: To enter 24 1/2 as a fraction, enter

enteRin g FR ac tion S (F t/in on ly)

1. Start at the Ready Screen.

2. Enter a length at the controller.

Example: To enter 24 1/2 as a decimal, enter

3. Press to move the TigerStop®.

3. Press to move the TigerStop®.

The TigerStop®controller displays the position as a decimal after it

moves.

The TigerStop®controller cannot display fractions in the ‘Position’ field.

calculatoR mode

1. Start at the Ready Screen.

The TigerStop®controller has a calculator function for simple math problems.

5

Ready Screen Functions

2. Use the math function keys to enter problems.

Example: Press and appears in the ‘Next’

field.

3. Press and the TigerStop®moves to the calculated position.

4. Use the math function keys to modify the current position.

Example: Subtract 1.5 inches (38 mm) from the current position of 42

inches (1067 mm)-

Press and appears in the ‘Next’ field.

5. Press and the TigerStop®moves to the calculated position.

Jog

1. Start at the Ready Screen.

2. Press and hold or

If the jog buttons move the TigerStop®in the wrong direction, use

the ‘Jog Reverse’ setting in the ‘Setup’ menu to reverse the

movement (page 20).

Manually jog the TigerStop®towards or away from the tool.

incRement

The increment function is a push feed mode that steps the TigerStop®through a series of movements.

Increment:

• Can be a positive length that moves the TigerStop®towards the tool.

• Can be a negative length that moves the TigerStop®away from the tool.

• Compensates for kerf automatically using the ‘Kerf’ setting in the ‘Setup’ menu.

• Stores one increment length at a time.

1. Start at the Ready Screen.

2. Press the [Show] soft key.

3. Press the [Incr] soft key.

6

Ready Screen Functions

4. Enter an increment length and then press

5. Press to begin incrementing.

6. Press STOP to return to the Ready Screen.

Quick calibRation

A short-cut to the calibration setting.

If desired, disable the quick calibration soft key in the Options menu (page 26). Disabling quick calibration

eectively password-protects the calibration function.

1. Start at the Ready Screen.

2. Place sample material against the TigerStop®and cycle the tool.

3. Measure the length of the processed sample.

4. Press the [Calib] soft key.

5. Enter the measured value and then press

6. Press the [Done] soft key.

PReSet

The Preset function is a set of 100 programmable hot keys for quickly accessing common lengths.

Presets are:

• usable in Set Point, Pusher, or Increment mode.

• programmable in Preset slots number 1 - 100.

PReSet PR og R am min g

1. Start at the Ready Screen.

2. Press the [Show] soft key.

7

Ready Screen Functions

3. Press the [PrSet] soft key to access the preset feature.

4. Enter the preset number to program and press the [Edit] soft key.

5. Enter a length for the preset and then press

6. The Preset value is set.

7. Press STOP to go back to the Ready Screen.

PReSet uSe

1. Start at the Ready Screen.

2. Press the [Show] soft key.

3. Press the [PrSet] soft key to access the preset feature.

4. Enter the desired preset number and then press

5. The TigerStop® moves to the preset position.

8

deleti ng PReSetS

1. Start at the Ready Screen.

2. Press the [Show] soft key.

3. Press the [PrSet] soft key to access the preset feature.

4. Enter the preset number for deletion and then press the [Clear] soft key.

5. Press to clear.

PaRt liStS

The list function is the TigerStop®’s versatile part list handler, letting the user run, view, edit, and clear part

list data.

There are 4 types of lists:

Pusher

A pusher list tells the TigerStop®to push the stock material into the tool. It treats each length entered as an

incremental move. Enter as many parts as desired into a pusher list and the TigerStop®says when it needs

another stock material piece.

Set Point

A set point list tells the TigerStop®to act as a stop. It treats each length entered as an absolute value from

the zero point.

Pattern

A pattern list tells the TigerStop®to process one stock-length’s worth of parts in a push-feed fashion.

It runs the same pattern of parts on one stock-length repeatedly until it’s told to stop.

Pull

A pull list works just like a pattern, except it pulls away from the zero point instead of pushing towards it.

Ready Screen Functions

9

PRo gRa mm i ng aPuSH eR o R Set Point liSt

1. Start at the Ready Screen.

2. Press the [Show] soft key.

3. Press the [List] soft key.

4. Enter the list number to program and then press the [Edit] soft key.

• Choose a number between 1 - 100.

5. Select the [Pusher] or [Setpoint] soft keys.

6. Dynamic Optimization upgrade, only: Press to optimize the list for

maximum material yield. Otherwise, press

7. If prompted: Press to use a global or press to use a local head

& tail cut.

Global - Uses the head & tail cut setting from the Part List menu.

Local - Set a head and tail cut that is used for this list, only.

• Head & tail cuts are trim cuts at the ends of the material.

8. Enter the length of the part to process and press

9. Enter how many parts to process at that length, followed by

Ready Screen Functions

10

Ready Screen Functions

10. Repeat steps 8 & 9 to enter additional part lengths and quantities.

11. Press the [Done] soft key.

12. Press to run the list or to exit.

PRo gRa mm i ng aPatteRn oR Pu ll liSt

1. Start at the Ready Screen.

2. Press the [Show] soft key.

3. Press the [List] soft key.

4. Enter the list number to program and then press the [Edit] soft key.

• Choose a number between 1 - 100.

5. Select the [Pattern] or [Pull] soft keys.

6. Enter the head cut value and press

7. Enter the tail cut value and press

11

Ready Screen Functions

8. Enter the stock length and then press

9. Enter the length of the part to process and then press

10. Enter how many parts to process at that length and then press

11. Repeat steps 9 & 10 to enter additional part lengths and quantities.

• The total length of all parts + quantities cannot exceed the stock

length. The ‘Remainder’ line keeps track of how much stock is

available.

12. Press the [Done] soft key.

13. Press to run the list or to exit.

Runn ing aPuS HeR liSt

1. Start at the Ready Screen.

2. Press the [Show] soft key.

3. Press the [List] soft key.

4. Enter the list number to run and then press

5. Enter the stock length and then press

6. Load the material and then press to begin processing.

7. Repeat steps 5 & 6, as needed.

8. Unload the remaining stock and then press

9. Press to re-run the list or to exit.

12

Ready Screen Functions

Runn ing aSet Po int li St

1. Start at the Ready Screen.

2. Press the [Show] soft key.

3. Press the [List] soft key.

4. Enter the list number to run and then press

5. Dynamic Optimization upgrade, only: Enter the stock length and then

press

6. Load the material, cycle the tool, and then press to move to the

next length. Repeat, as needed.

7. Unload the remaining stock and then press

8. Press to re-run the list or to exit.

Runn ing aPatteR n oR Pu ll li St

1. Start at the Ready Screen.

2. Press the [Show] soft key.

3. Press the [List] soft key.

4. Enter the list number to run and then press

13

Ready Screen Functions

5. Enter the number of times to run the pattern or pull list and then

press Next, press

6. Load the material and then press to begin processing.

7. Complete the pattern or pull list and the ‘Done’ line increments by 1.

Press to continue or STOP to return to the Ready Screen.

• The ‘Done’ line resets to ‘0’ when exiting the list.

editi ng aliSt

1. Start at the Ready Screen.

2. Press the [Show] soft key.

3. Press the [List] soft key.

4. Enter the list number to edit and then press the [Edit] soft key.

5. To edit the part list type, press the [Change] soft key. Otherwise, press

the [Continue] soft key.

6. Dynamic Optimization upgrade, only: To turn on or o the list’s

optimization, press the [Change] soft key. Otherwise, press the

[Continue] soft key.

7. To edit the head or tail cuts, press the [Change] soft key. Otherwise,

press the [Continue] soft key.

14

Ready Screen Functions

8. Use and to scroll through the parts to find one to edit.

9. Enter a new length and then press

10. Enter a new quantity and then press

11. Press the [Done] soft key to save.

12. Press to run the list or to exit.

deleti ng aliSt

1. Start at the Ready Screen.

2. Press the [Show] soft key.

3. Press the [List] soft key.

4. Enter the list number to delete and then press the [Clear] soft key.

5. Review the list’s details. Press to confirm deletion.

backboaRd deFecting & oPtimizing

Backboard Defecting & Optimizing is a process that allows quick and easy cutting around material defects

while optimizing the clear stock for better material yield. It is accomplished using a standard Set Point list (page

9), the Dynamic Optimization upgrade, and a Back-Fence Ruler.

Runn ing tHe li St

1. Start at the Ready Screen.

2. Press the [Show] soft key.

Table of contents

Popular Controllers manuals by other brands

National Instruments

National Instruments NI cDAQTM-9138 user manual

QD

QD Pi HSC505-32 LCD User's information guide

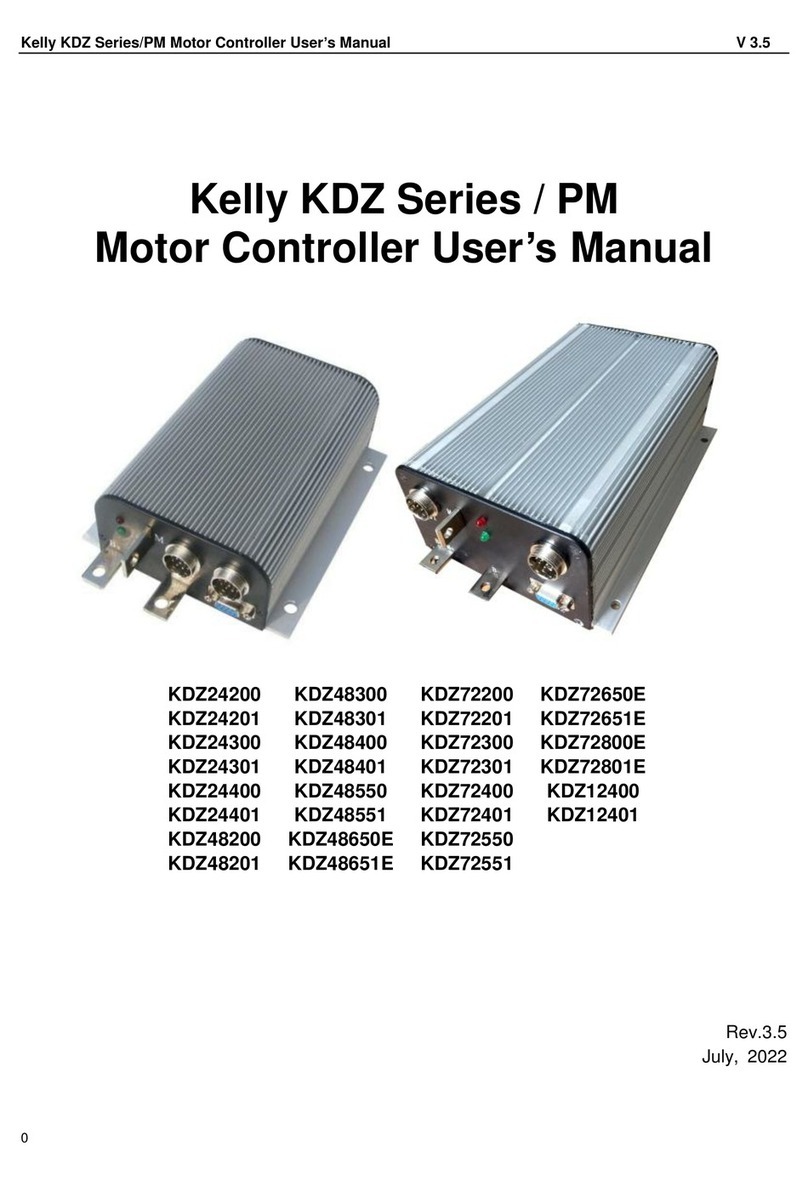

Kelly

Kelly KDZ72650E user manual

PRECISION DIGITAL

PRECISION DIGITAL PD6210-6R2 instruction manual

GOLINK

GOLINK VD2605 instruction manual

Tornatech

Tornatech GFX Installation and maintenance manual