TitanTec TT-HT230H User manual

INSTRUCTION MANUAL

HEDGE TRIMMER

TT-HT230H

DEAR CUSTOMER

In order to achieve the best performance of your product, please read this instruction manual carefully

before using, and keep it for future reference.

About this instruction

Thank you for purchasing our company

hedge machine.It is honored to provide

you with the hedge machine, which is our

long-term research and development

program, combined with the expertise and

rich experience mastered over the years.

HT230 perfectly combines the latest

technology and ergonomics, light

weight, easy to use, is a professional

tool with a variety of uses.

Some excellent performance of the

hedge trimmer is introduced.These content

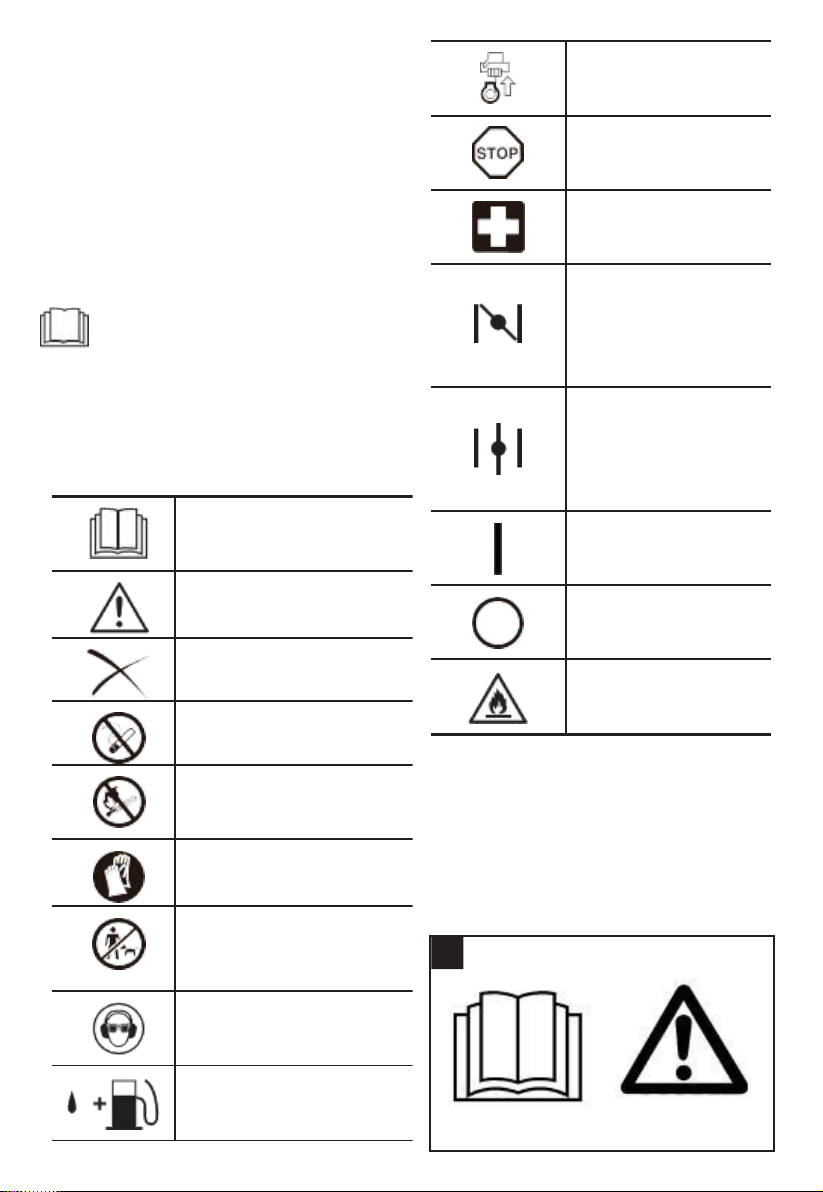

symbol

Warning / dangerous

burning

Read, understand, and follow

operating instruction

prohibit

no smoking

Open flames are strictly

prohibited

Wear protective gloves

All people and pets

Do not enter the operation

area

Wear eye and ear protection

Fuel and mixed oil

Start the engine

manually

emergency stop

give first aid treatment

Indicates that when

the choke switch is

operated in this

direction, the choke

will close

Indicates that when

the choke switch is

operated in this

direction, the choke

will open

Open / start

Turn off / stop

Beware of fire!

Safety instructions

General instructions

-This machine may result in serious

personal injury.Read this guide carefully

for the correct way to operate, prepare,

maintain, start, and stop the machine.Be

familiar with all the control and proper

use of the machine.(A)

A

helps you use your hedge trimmer most

rationally.

Please read carefully and strictly follow this

manual, which details

-It is recommended to only lend hedge

machines to those with experience.The

instruction manual shall also be handed

over together.

-Raw should inform the dealer of basic

instructions and be familiar with the

operation of the hedge machine driven

by the engine.

-Children, and minors under the age of 18,

may not operate a hedge machine.Those

over 16 years of age may use the

equipment for training under the

supervision of qualified trainers.

-The hedge machine should be used with

great care.

-Operating hedge machines only in good

condition.Do all the work with calm and

caution.The user must be responsible to

others.

-Do not stop using the hedge machine

after drinking or taking medication,

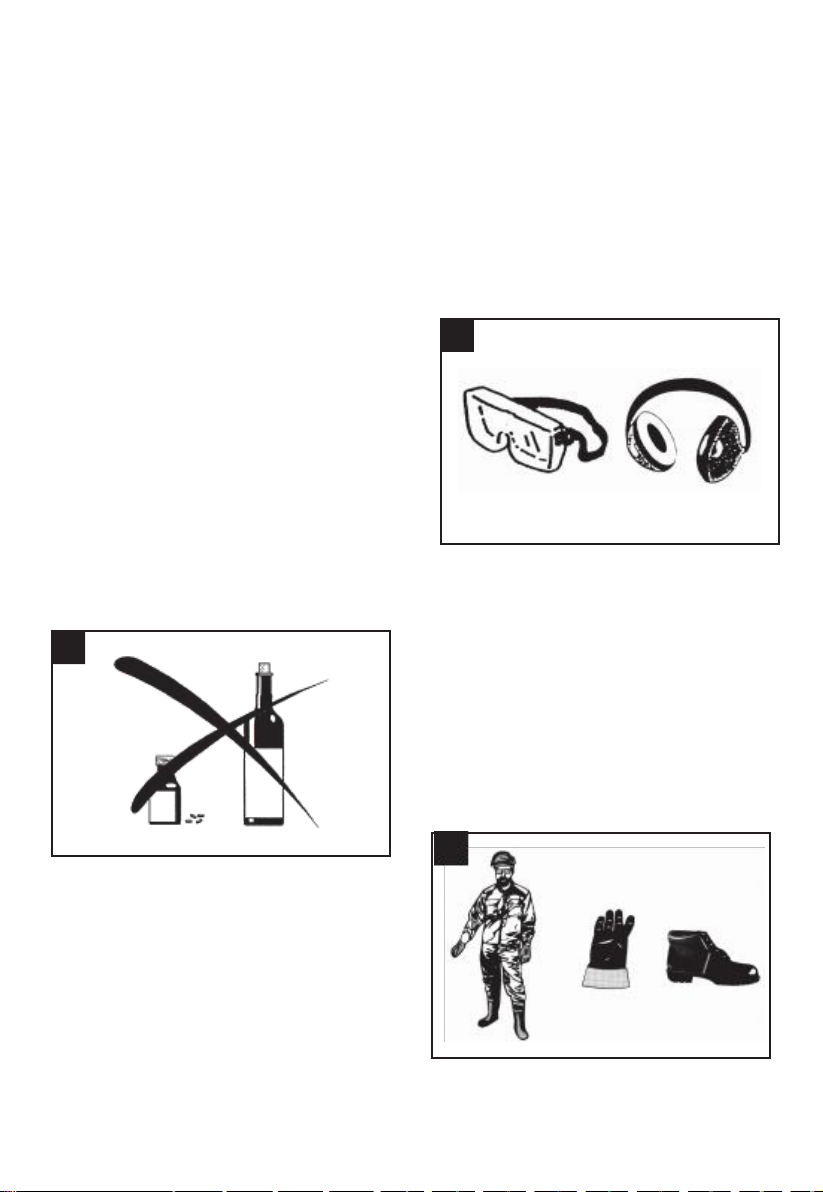

after feeling tired or physically ill.(B)

B

Hedge trimmers are designed for

-The hedge machine is designed to trim

shrubs and hedges and is strictly

prohibited for any other purpose.Do not

use the hedge machines improperly.

personal protective equipment

-Clothes should be appropriate and fit, for

example, close to you but not

inconvenient.Do not wear jewelry or loose

clothing that may be hung by bushes,

bushes or machines.

-In order to avoid damage to the head, eyes,

hands and feet and to protect the hearing,

the following protective equipment and

clothing must be worn during the

operation of the hedge machine.

-Wear protective glasses or goggles to

protect your eyes during the hedge

machine operation.(C)

-It is strongly recommended for users to wear

work clothes.(D)

-Special gloves are made of thick

leather, which are part of the

designated equipment, and must be

worn throughout the operation of the

hedge machine.(D)

-When using a hedge machine, wear

strong shoes with non-slip soles

throughout.This prevents injury and

ensures a firm footing.(D)

D

C

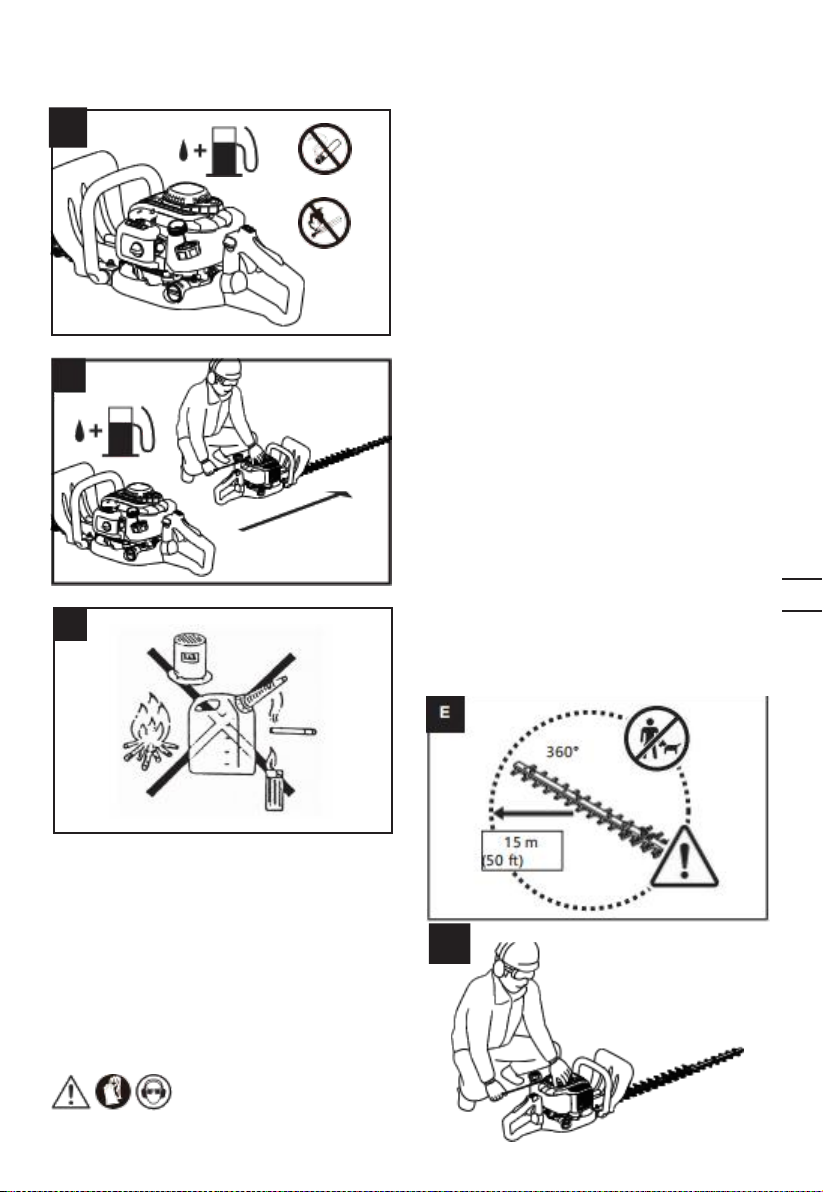

-Make sure that there are no children or

other

people

within

15

meters

of

the

work

area,

and

also

do

not

notice any

animals (E) near the work area.

-Be

sure

to

check

the

operation

safety

of the

hedge

machine

before

using

it.

-Check

the

safety

of

the

throttle

bar.Check

the

smoothness

of

the

throttle

bar

and

Easy to operate.Check that the throttle

bar lock

is

properly

functional.check

up

Whether the handle is clean and dry,

test the function of the I-O switch.

Keep the handle oil-free.

-The hedge machine can be started only as

directed.

360°

15 m

(50 ft)

E

Start the hedge machine

Do not use any other method to start the

engine (F)!

F

-The hedge machine can only be used for

specified purposes.

-Can start the hedge engine only after the

complete assembly.The hedge machine

can be permitted only after all suitable

fitting installation!

-Before starting, make sure that the blade

does not contact any objects, such as

branches, stones, etc.

-If any engine fails, stop the engine

immediately.When operating, hold the

handle with your fingers and hold it front

and back.defend

Handle is clean, free of water, resin, oil or

grease.

-Always stand firm body.Outdoor use only.

-Always look around and be alert to

possible hazards as you may not hear

them due to machine noise.

-Avoid suction gases when operating the

hedge machine.Cannot operate the

engine in a closed space (at risk of

suffocation and gas poisoning).Carbon

monoxide gas is tasteless.Always keep it

well ventilated.(G)

-Stop the engine when resting and

when the hedge trimmer is unattended.

Keep it in a safe place to prevent injury

to others, ignition of combustible

materials, or damage to machinery.

-Do not place hot hedge machines on

hay or on any combustible material.

-To reduce fire hazards, avoid the

absence of debris, leaves, or excessive

lubricants on the engine and muffler.

-Do not operate the engine when the muffler

is faulty.

-Stop the engine (H) during transport.

G

H

-Before stopping the engine:

-Cleaning and blocking

-Check, maintain, or operate the machine.

-When transported by car or truck,

place the hedge machine safely to

avoid oil leakage.

-When transporting the hedge machine,

ensure that the fuel tank is completely

empty and avoid oil leakage.Always

install a blade sheath when transporting

or storing the machine.

Refuel

-Stop the engine before refueling (H), stay

away from the open fire (I), and do not

smoke.

-Do not try to fuel the hot or running engines.

-Avoid skin contact with petroleum

products.Do not inhale fuel

steam.Protective gloves should be worn

all during the refueling process.Change

and clean the protective clothing

regularly.

-Be careful not to spill fuel or lubricating

oil to prevent soil contamination

(environmental protection). Wipe the oil

off the hedge trimmer immediately after

the fuel spills. Dry in a well-ventilated

area before disposing of a rag that has

been wiped with fuel. Otherwise,

spontaneous combustion may occur.

-Do not let the fuel to clothing.If the fuel

splashes on the clothes, change the clothes

immediately (very dangerous).

-Check the tank cover regularly to ensure

that the tank cover is tightly secured.

-Carefully tighten the fuel tank cover.Start

the engine in another place (at least 3 m

from refueling) (J).

-Do not refuel in an enclosed space.Fuel

steam accumulates on the ground (with

an explosion hazard).

-Fuel can only be transported and stored

with approved containers.Make sure

that the child is not exposed to the fuel

being stored.

-When gasoline is mixed with two-stroke

engine oil, only gasoline without ethanol

or alcohol (alcohol) can be used.

-This will help prevent damage to the fuel

lines and other engine components.

method of operation

-Always grasp each handle with both hands

while operating.

-Use a hedge machine only with good

light and visibility.In the cold season,

pay more attention to slippery areas,

snow and ice, etc. (at risk of

slipping).Always stand firm body.

-Do not stand on unstable surfaces or on

steep terrain.

-Do not stand on the ladder and operate

the hedge machine.

-Do not climb to the tree to use the hedge

-To reduce the risk of tripping or runaway,

do not step back while running the

machine.

Be sure to close the engine while cleaning,

repairing the machine, or replacing the

components.

-Do not operate a machine with

damaged or excessively worn

blades.Maintenance instructions

-environmental protection.Minimize noise

and pollution while operating the hedge

machine.In particular, check that the

carburetor is set up correctly.

-Clean the hedge machine regularly and check

that the screws and nuts are fastened.

-Do not repair or store hedge machines

near an open fire or spark, etc.(K)

-Empty the oil pot before storing the hedge

machine.

-No hedge machines near open fires to prevent

fires.

-Store the hedge machine at heights well

ventilated and not touched by children.

I

J

K

3

M

10 ft

-Do not try to repair the machine without

repair qualification.Please comply

with the relevant accident prevention

regulations issued by the relevant

trade associations or insurance

companies.

Do not modify the hedge machine, or it will

endanger your safety.

Maintenance or maintenance work

performed by the user is only the activities

described in this guide.All other work must

be done by an authorized service agent.

Only the original parts or accessories

authorized by the Company or provided by

the factory repair center shall be used.

Use of unapproved accessories or tools

increases the risk of accidents and

injury.The Company is not liable for any

accident or damage resulting from the use

of unapproved accessories.

give first aid treatment

In case of accident, ensure there are

well-preserved and standard first aid

kits near the shear operation.

Items removed from the first aid kit should

be replaced immediately.

Provide the following information when asking

for help:

-accident spot

-What accident happened

-Phone number of the injured person

-extent of injury

-surname and personal name

PACK

To prevent damage during transportation, the hedge machine is packaged for protection

Sex in a cardboard box.Cardboard box is a basic raw material,

Can be reused or recycled (waste paper recycling).

12

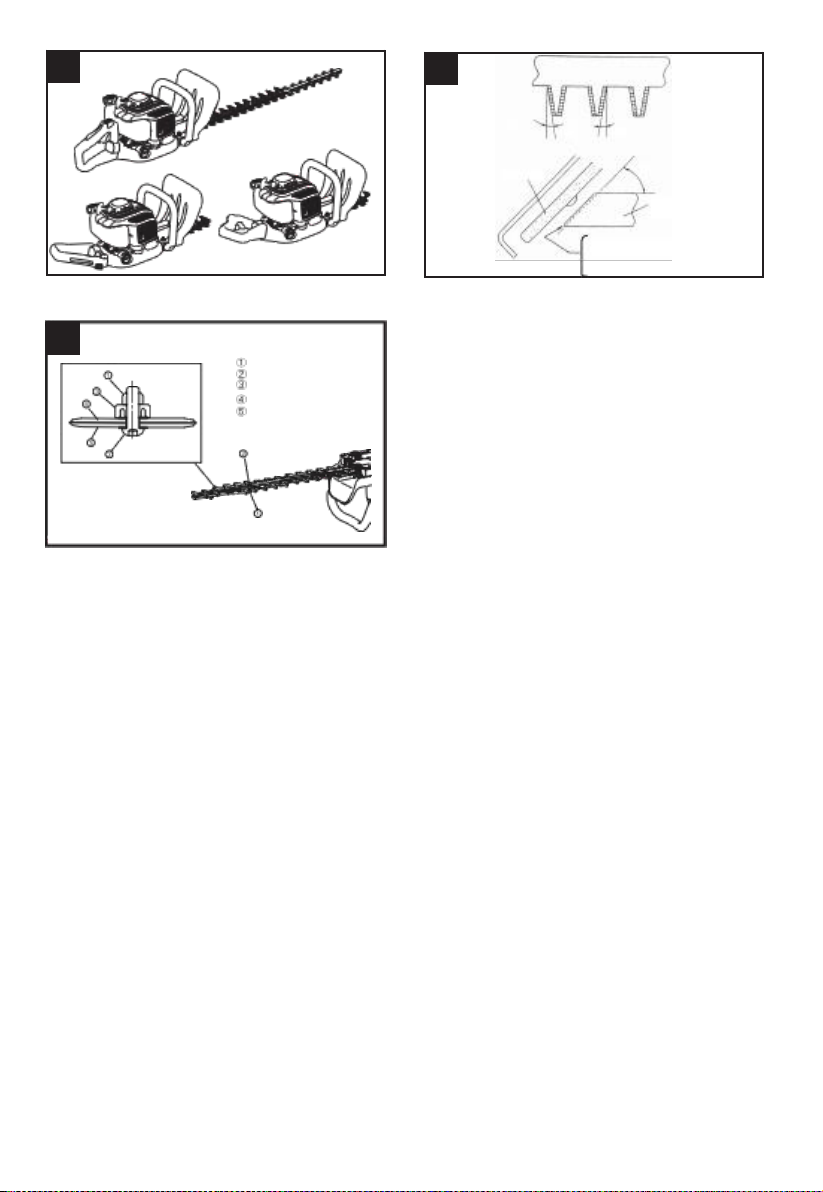

parts

1. The Blade 7. The ar handle

2. Guard plate 8. Turn off the fire switch

3. Front handle 9. Throttle trigger

4. oil-can lid 10. muffler

5. Windgate switch 11. gear case

6. starter 12. Blade sheath

Some of the accessories mentioned in the illustrations or text are not included in the scope of

supply.

technical parameter

product model

TT-HT230H

product description

Hedge Trimmer

size 106*25*25

weight 7kg

Effective cut length 650mm

Fuel tank volume 580ml

engine type TT-1E32F-2

Power (maximum) 0.65kw/7500rpm

idling speed 3000±300rpm

high speed 10000±500rpm

Fuel mixing ratio 25:1

gear ratio 10:45

+

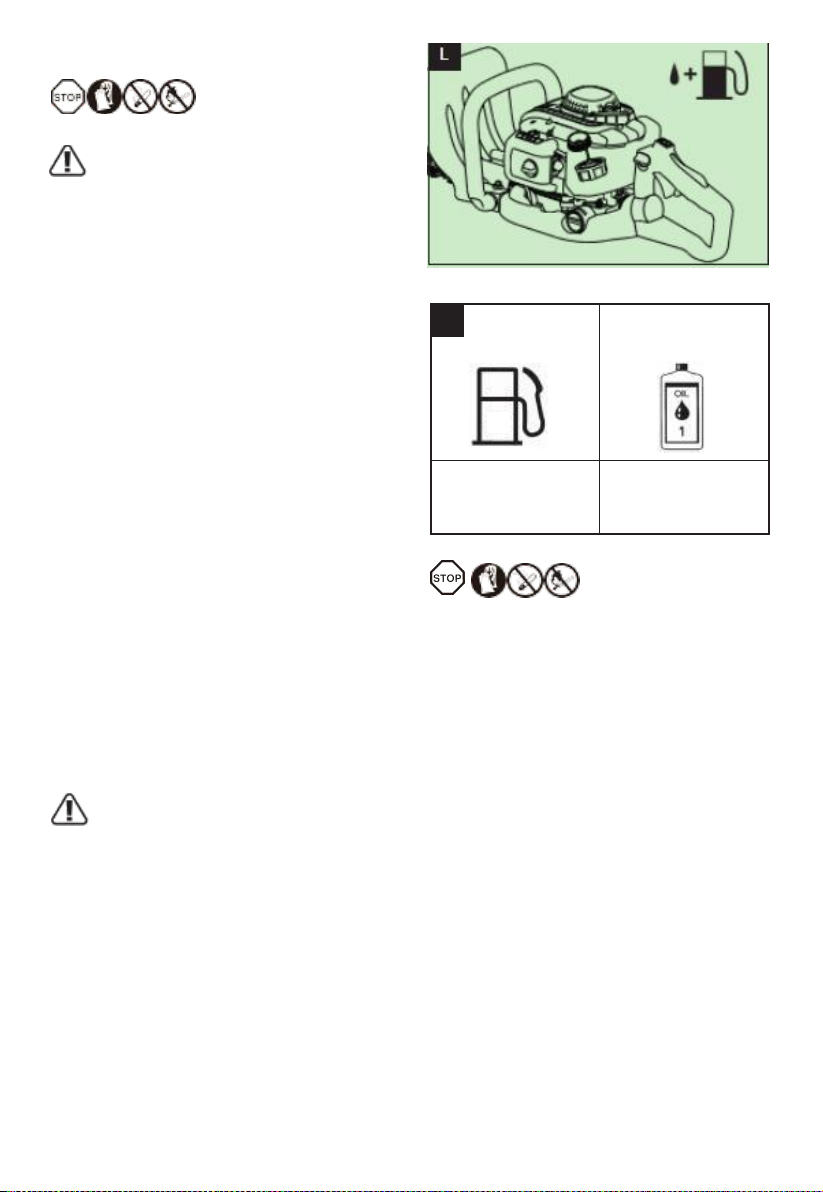

Fuel / refueling

Fuel and mixed oil (L) (M)

Follow the Safety Instructions " operation

-The hedge engine uses an efficient two-

stroke engine.It uses a mixture of fuel oil

and two-stroke engine oil.The engine

was designed to use unleaded-free

conventional fuel.

If not, have a higher octane can be fuel

instead.This will not damage the engine,

but will cause low operation efficiency.

Similar situations can also be caused by the

use of a leaded fuel oil.

For optimal engine performance and to

protect your health and environment, use

only leaded-free fuel!

-For lubrication, the engine uses two-stroke

engine oil, which is added to the fuel.

The engine design is combined with two-

stroke engine oil with a mixing ratio of

40:1 to protect the environment.In

addition, it can guarantee a long service

life, reliable operation and minimum

exhaust emissions.Strict adherence to the

25:1 mix ratio (two-stroke engine oil) is

essential, otherwise reliable hedge

function is not guaranteed.

-Correct mix ratio:

Gasoline: Engine oil = 25:1

recommended

pay attention to:

When preparing oil mixing, first mix all the

engine oil with half of the required fuel in

the approved container.The container shall

meet or exceed all local regulations.Then

add the remaining fuel fuel.Shake and mix

the oil thoroughly before pouring it into

the hedge machine fuel tank.

To ensure safe operation, do not add the

specified oil to the engine.That will only

produce more combustion residue, pollute

the environment, and block the discharge

channels of cylinders and silencers.

Mengine oil

1,000 cm3(1 L)

5,000 cm3 (5 L)

10,000 cm3 (10 L)

50 cm3

250 cm3

500 cm3

Refueling (N) (O) (P)

Stop the engine when refueling, keep

away from open flames, and no smoking.

Do not spill fuel on the engine. If fuel is

spilled, wipe it up.

If fuel is spilled on clothing, change

clothing immediately (to prevent clothing

from catching fire).

Carefully tighten the fuel tank cap. Start

the engine in a different place (at least 3

meters away from the place where the fuel

is added).

Never refuel in an enclosed space. Fuel

vapors accumulate on the ground.

(explosion hazard)

Make sure that children do not have

access to stored fuel.

Unscrew the fuel tank cap and fill the

tank with fuel. Use a mesh funnel to filter

the fuel.

Tighten the fuel tank cap (hand only).

gas

olin

2 5 :1

-Clean the screw plug and the area around

the tank after refueling.

-Always erase spilled fuel to prevent fire.

Store fuel

-Fuel oil cannot be stored indefinitely.

-Only purchase the amount of oil required for

the 4-week operation period.

-Fuel can only be stored with

approved

containers.PrecBefore Start

(E) (R)

-Make sure that there are no children or

other personnel working at 15 m.Pay

special attention to the animals near the

work area.

-Always check the operation safety of the

hedge machine: check that the blade is

damaged, whether the control lever is

easy to operate, and whether the I-O

switch is properly functional.

-Make sure that the blade is not running with

the engine idling.

-If doubtful, please consult the dealer

about the adjustments.Check the handle

for clean and dry and test the function of

the I-O switch.

-The hedge machine can be started only

as directed.Do not use any other

method to start the engine!(See Startup)

-The engine can only be started after the

complete assembly.Engine operation is

allowed only after installing all suitable

accessories.Otherwise, there is a danger

of injury.

-Before starting, make sure that the blade

does not contact any objects, such as

branches, stones, etc.

-Before trimming, check the cables, glass,

or other external objects that will

contact the blade.

-electric shock.Notice all of the wires and

hedges.Before cutting, check the wires in

all areas.

P

8

N

O

R

S

T

U

V

W

At least 3 meters away from the refueling

position.Place the hedge machine on the

clean floor.Make sure that the blade does

not touch the ground or any other items.

Cold start: (when the engine cooled or

stops for more than 15 minutes or when

fuel has been added to the engine.)

1 Push the I-O switch (1) to the "I"

position.

2 Push the oil bubble repeatedly (2) (7 to

10 times) until the fuel enters the oil

bubble.

3 Push the air valve switch (3) to the ""

position.

4 Hold the hedge machine down to avoid

out of control when starting the

engine.Failure to do so may cause

serious personal injury or property loss

from contact with the blade.

5 Slowly pull the starter handle 10 to 15cm

until resistance is felt.

6 Pull the starter handle and feel

resistance to start the engine.

7 Turn the damswitch when the engine

starts, eops, or stops

(4) Place it in "".

8 Add to full speed and run the engine for

about 1 minute at medium speed.

Start the machine (S) (T) (U) (V) (W)

4

Notes for body rebound:

Body rebound refers to the high-speed

rotating blade in the stone, trees, concrete,

piles, pillars and other hard fixed objects,

because of the reverse force, the body in a

moment of violent shaking

phenomenon.When the rebound occurs, the

body will suddenly appear in an unexpected

vibration, which may cause the operator to

be unable to operate normally.To prevent a

rebound, observe the following:

-Be careful not to expose the blade to

hard objects, posts, wire, and rock to

avoid damage to the blade.

-When working, always shake hands and do

not hold other parts.

-When working, keep your eyes on the

blade.When you need to leave the blade,

release the throttle trigger and return to

the start speed position (when the blade

stops in motion).

-Do not raise the blade close to your feet

or just above the waist.

Stop the Machine (X)

-Release the throttle trigger completely.

-Push the I-O switch (1) to the "O"

position.The engine will slow down and

stop.

Operation hedge machine (Y) (Z) (A1)

-Do not operate the hedge machine during

a light grip.

-Never contact the blade when the

engine is starting or operating.

-Avoid suction gases when operating the

hedge machine.Cannot operate the

engine in a closed space (at risk of gas

poisoning).Carbon monoxide gas is

tasteless.

-All protective facilities, such as guards,

must be used during operation.

-Do not operate the engine if the muffler is

faulty or missing.

-Use a hedge machine only with good light

and visibility.

X

1

-In winter, pay more attention to slippery

areas, snow and ice, etc. (at risk of

slipping).Always stand firm body.

-Do not stand on the ladder and operate

the hedge machine.Let all your feet

stand on the ground.

-Do not climb to the tree to use the hedge

machine.

-Do not perform operations on unstable surfaces.

-Remove sand, nails, wires, etc.External

objects may damage the blade.

-Cut branches 8 mm or thicker before

cutting.

-The blade must reach full speed before starting

the cutting.

-Always hold your hands firmly on the handle

of the hedge machine.

-Form a firm clip with your thumb and

other fingers around the handle.

-It takes time to stop after the throttle

trigger is release.

-Do not operate the hedge machine at

high speed.If the idling speed is too

high, the cutting speed cannot be

adjusted by the throttle control.

-When cutting, hold the hedge machine

and let the blade form a 15-30° angle

with the cutting line.

-Pay special attention when the cut hedges

are close to or against the barbed wire.

-Do not touch hard objects with razor

blades, such as barbed wire, stone, or

ground, etc.This may cause the blade to

crack, break or break.

-If the blade touches a rock or other hard

object, turn off the engine and check

the blade.Replace the damaged blade

before reoperation.

-Take regular breaks. A 10 to 20 minute break

is recommended for every 50 minutes of use.

Shut off the engine immediately if the engine

fails.

-Reduce the noise and pollution while

operating the hedge machine.Also check

that the carburetor and fuel / engine oil

ratio is set correctly.

-Do not remove the blocked cut material

when the blade runs.Put the machine

down, turn it off, and remove the dust.

Y

Z

A1

Adjust the rear handle angle (B1)

The rear handle can turn left or right for 90° and

each set at 45°.

switchback:

-Press the release lever to release the lock.

-Turn the handle to an angle of 0°, 45°, or

90°.

-Make sure that the release lever returns to

the initial position to engage and lock.

-Do not pull the throttle trigger when

releasing the lock.

-Do not release the lock while working.

maintenance instruction

-Shut off the engine and remove the spark

plug cap before cleaning / replacing /

grinding the blade or performing any

maintenance.

-Do not straighten or weld the damaged blades.

-Check the damage to the blade frequently

(under engine shutdown).

-Keep the blade sharp.

-Clean the hedge machine regularly and

check the tightening of all screws and

nuts.

-Never repair hedge machines near open fires to

prevent fires.

-Cortical gloves are always worn when

holding or polished due to the sharp

blade.

Grishing blade (C1)

If the blade edge becomes blunt and does not

cut very well, polish the shadows in the picture

component.The contact surface (sliding

surface) of the top and bottom edge edges

shall not be polished.

-Before grinding, hold the blade firmly,

close the engine and remove the spark

plug cap.

-Wear gloves, goggles, etc.

-Don't polish too much material.That

would lose hardness and the blade

would become blunt.

Adjust the blade spacing (D1)

Upper / lower blade wear.If the blade

does not cut well even if it is sharp,

adjust the spacing as follows.

1 Release screw and remove the extension

blunt teeth.

2 Release the nut (1) using the box or open

wrench.

3 Gently tighten the truss bolt (2) with a

hexagon wrench until it stops and turn a

quarter circle.

4 Tighten the nuts (1) and secure the truss

bolts (2).

5

Apply light oil on the friction surface of the

blade.

6 Start the engine, open and close the throttle

trigger for one minute.

7 Measure the time required for the blade to

stop after releasing the throttle trigger.If it is

two seconds or more, stop the engine and

repeat steps 2 through 7.

8 Stop the engine and touch the blade surface.

If they are not quite too much

D1

Blade

guide,

upper

blade,

truss

bolt

nut

B1

1

C1

10° 10°

strai ght whee l 45 °

The blade

passes through the part

Keep the disc wheel at

45° and polish the

blade to the point to

sharpen the blunt edge.

Hot, you can touch, it means that it has

been adjusted.If hot to touch, rotate the

truss bolts (2) and repeat steps 6 to 8.

9 Tighten the screw and

install the blunt teeth.

pay attention to:

Before adjusting, stop the engine and wait for

the blade to stop.

The blade has a slot next to the screw (2).If

dust is found at the end of the groove,

clean it.

Check and adjust the idling speed (E1)

The blade should not run when the engine is

idling.

-The idling speed shall be set at 3000 r/min

(rpm).

-If required, adjust the idling screw (the

blade does not operate when the engine

is idling).

-Blade running while idling-Turn the

idling screw counterclockwise to

reduce the idling speed.

-Engine stops while idling-Turn the

idling screw clockwise to increase the

idling speed.

-If the blade is still running idle after

adjustment, contact your nearest

authorized repair agent.

-The clutch shall be engaged at 4000

r/min (rpm) or higher.

-Check for the normal operation of the

I-O switch, lock lever, and throttle

trigger.

Clean the empty filter (F1)

danger:

Check and clean the air filter once daily or

every 10 working hours.

-Turn the damper switch to the full off

position and close the carburetor to

avoid entering dust or dirt.

-Release the empty filter lock mother.

-Pull out the tail of the empty filter and

move forward to remove it.

-If oil is stuck to the filter element (sponge),

apply force cleaning.

-For heavy pollution:

-Remove the filter element (sponge),

dip the element in warm water or

water-diluted neutral detergent, and

dry it thoroughly.

-Clean the filter element (linoleum)

with gasoline and dry it thoroughly.

-Make sure that the filter element is fully

dried before installing it.Insufficient dry

filter elements may be difficult to start.

-Wipe the oil from the empty filter with

waste cloth.

-After cleaning, install the empty filter

cover immediately and secure with the

retaining bolts.(When reinstalling, install

the grab hook first.)

Important matters handling empty filter

elements

-If the dust is particularly high on the filter

element, it should be cleaned multiple

times in a day.

-If the operation continues without

removing the oil from the filter element,

the oil in the empty filter may fall outside,

causing oil contamination.

E1

F1

T

Flammable

products are

Loc

k

On

the hook

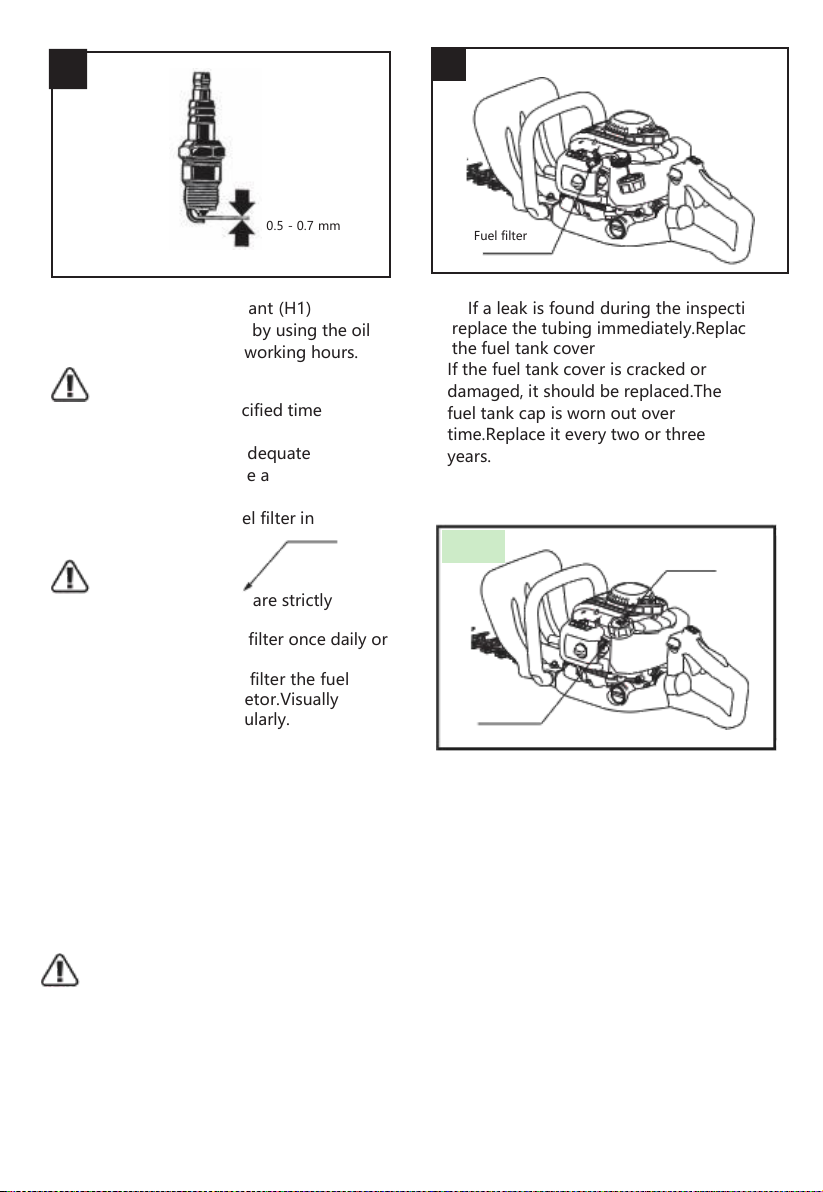

Check the spark plug (G1)

Check and clean the spark plugs daily or every 8

working hours.

-Only remove or install the spark plug using the

attached universal wrench.

-The spacing between the two electrodes of

the spark plug shall be 0.5-0.7 mm.If the

spacing is too wide or too narrow, adjust.If

the spark plugs are carbon-blocked or

contaminated, they should be thoroughly

cleaned or replaced.Make an accurate

replacement.

Rebricating oil and lubricant (H1)

Grease was replenished by using the oil

injection port every 50 working hours.

pay attention to:

Be sure to follow the specified time

and grease supplement

amount.Otherwise, an inadequate

supply of grease will cause a

machine failure.

Clean the oil filter (the fuel filter in

the oil tank) (I1)

warn:

Flammable products are strictly

prohibited

Check and clean the fuel filter once daily or

every 50 working hours.

Fuel filter (1) is used to filter the fuel

required for the carburetor.Visually

check the fuel filter regularly.

When checking the fuel filter, open the

tank cap and hook the fuel filter from the

tank hole.

Change the fuel filter if it becomes hard,

contaminated, or blocked.Change the fuel

filter at least once a quarter to ensure

adequate oil supply to the

carburetor.Inadequate oil supply can

cause an engine start failure and limit the

maximum speed.

Replacement (J1)

pay attention to:

Flammable products are strictly prohibited

Check and clean the tubing once daily or

every 10 working hours.Change the

tubing once every 200 working hours or

every year (regardless of working

frequency).Otherwise, the oil spill may

cause a fire.

If a leak is found during the inspection,

replace the tubing immediately.Replace

the fuel tank cover

If the fuel tank cover is cracked or

damaged, it should be replaced.The

fuel tank cap is worn out over

time.Replace it every two or three

years.

For maintenance or adjustment not

described in this manual, consult your local

authorized repair center.

Routine inspection and maintenance

To ensure a long service life and avoid

damage to the equipment, the following

maintenance operations shall be performed

regularly.

Before use:

Check screws on hedge machine for

loose or missing parts.Pay special

attention to the tightening degree of

the blade screws.

Check whether the cooling air channel

and the cylinder heat sink are

blocked.Clean it up as required.

Clean and check the tank for oil leaks

or foreign objects falling into the tank.

I1

Fuel filter

0.5 - 0.7 mm

G1

-

J1

Table of contents

Other TitanTec Trimmer manuals

Popular Trimmer manuals by other brands

Tanaka

Tanaka TBC-230 series Handling instructions

Flymo

Flymo Mini Trim ET21 Important information

GreenWorks Commercial

GreenWorks Commercial 82TB161 Operator's manual

Makita

Makita DUR142L instruction manual

Craftsman

Craftsman WEEDWACKER 316.745400 Operator's manual

Scheppach

Scheppach RT2300-Li18V operating manual

Little Wonder

Little Wonder 1910 Owner's manual and safety instructions

iSP

iSP DeLuxe Stitcher T3000 Instructions and parts manual

Craftsman

Craftsman INCREDI.PULL 316.79204.0 Operator's manual

VEVOR

VEVOR TM24 manual

Dolmar

Dolmar HT-43 instruction manual

Qualcast

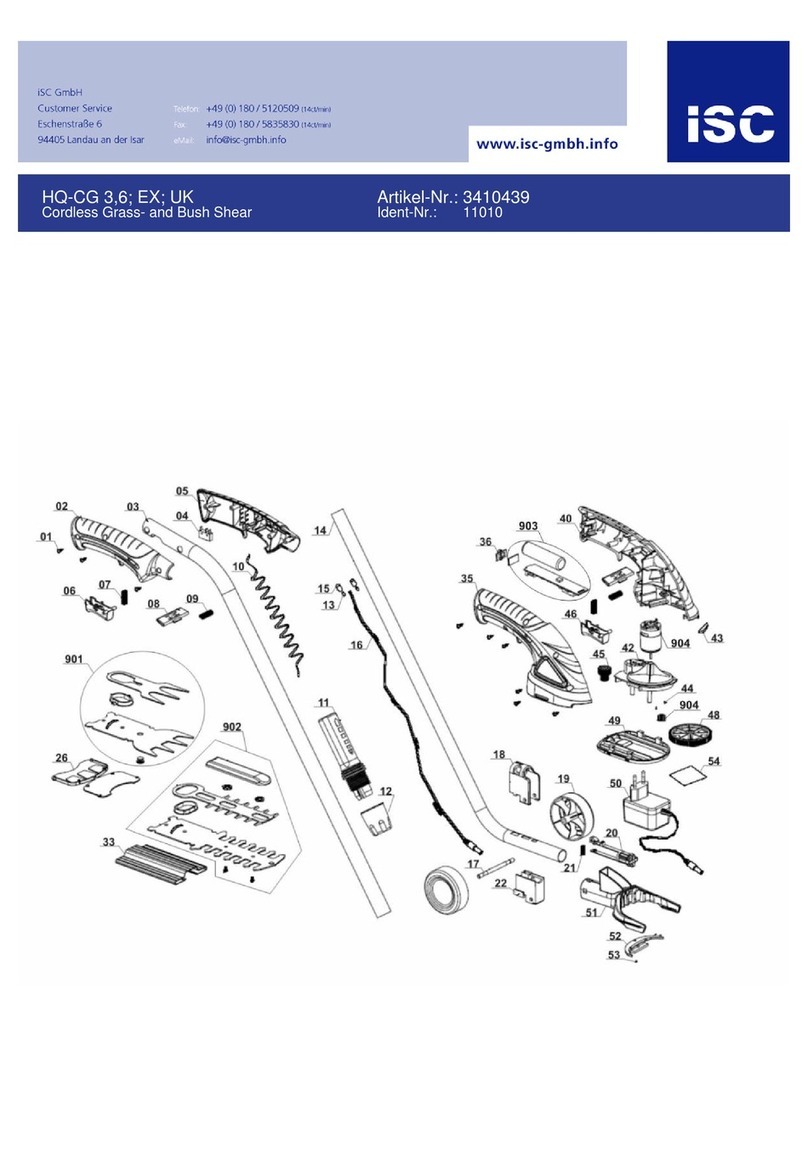

Qualcast HQ-CG 3.6 Original operating instructions