TJERNLUND DRAFT INDUCER DJ-3 User manual

Other TJERNLUND Fan manuals

TJERNLUND

TJERNLUND GPAK-J User manual

TJERNLUND

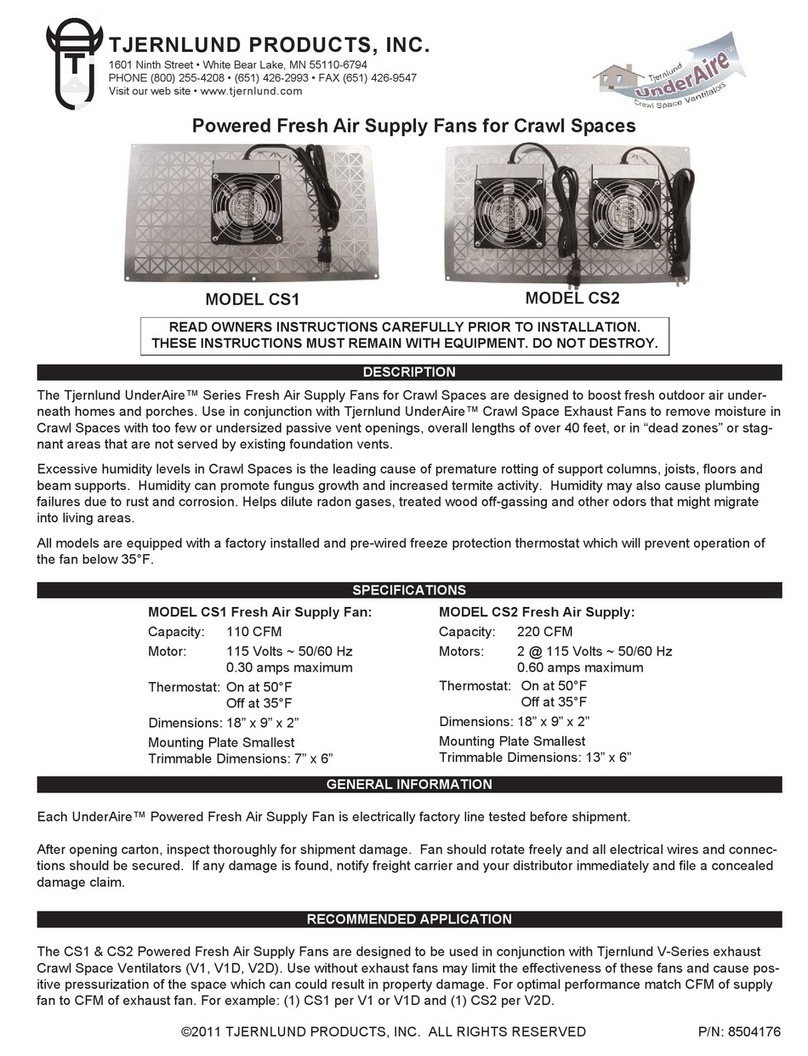

TJERNLUND CS1 User manual

TJERNLUND

TJERNLUND Duct Booster RB10 User manual

TJERNLUND

TJERNLUND SS1 SIDESHOT WITH UC1 UNIVERSAL CONTROL (VERSION X.06) 8504102 REV D... User manual

TJERNLUND

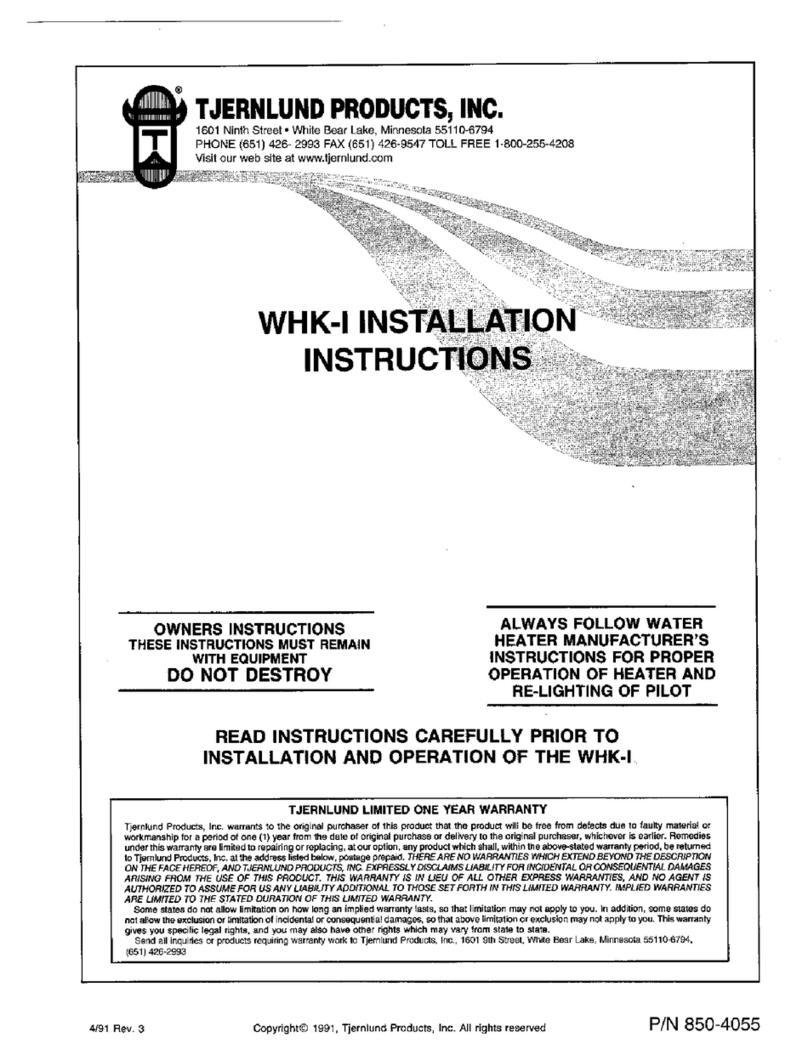

TJERNLUND WHKI MILLIVOLT APPLIANCE INTERLOCK (RECOMMEND WHKE FOR USE WITH UC1) 8504055 REV 3... User manual

TJERNLUND

TJERNLUND 1 User manual

TJERNLUND

TJERNLUND Cool Breeze CB14 User manual

TJERNLUND

TJERNLUND SS2 SIDESHOT WITH UC1 UNIVERSAL CONTROL (VERSION X.04) 8504105 REV B... User manual

TJERNLUND

TJERNLUND RV2 User manual

TJERNLUND

TJERNLUND AIRESHARE AS2 User manual

TJERNLUND

TJERNLUND IN-FORCER PAI-3 User manual

TJERNLUND

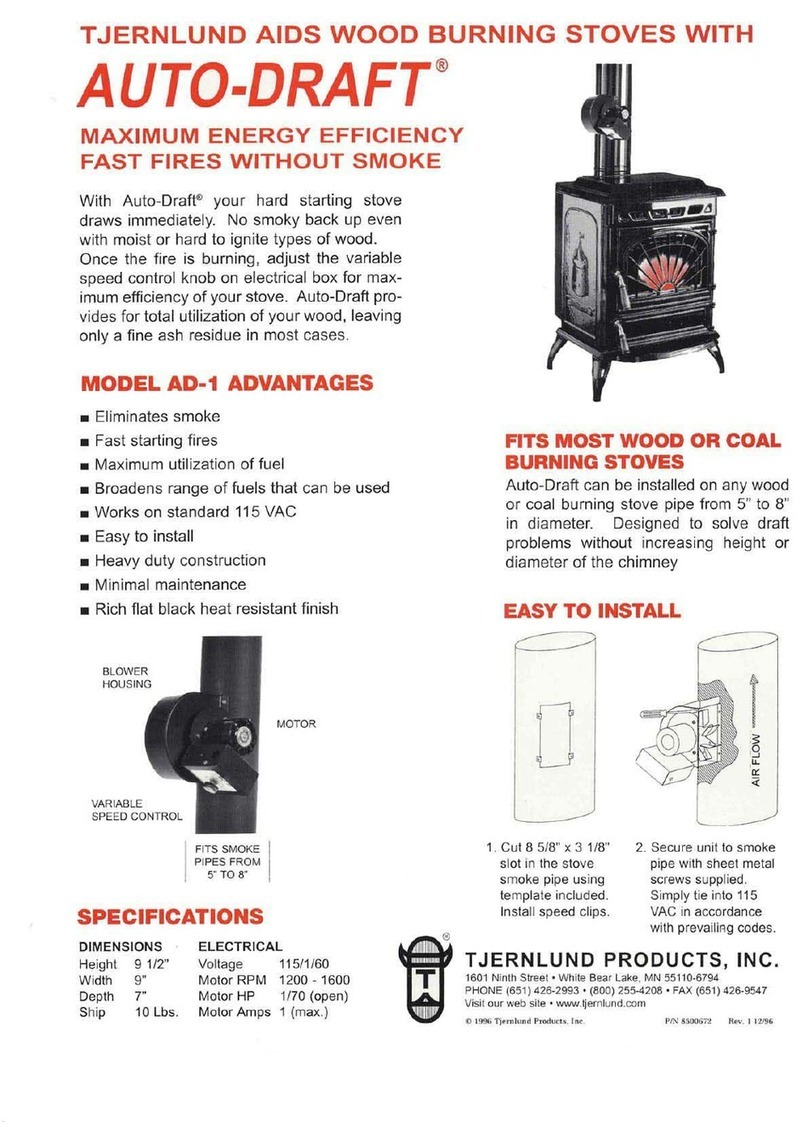

TJERNLUND AD-1 DRAFT INDUCER FOR WOOD BURNING STOVES 8500672 REV. 1... User manual

TJERNLUND

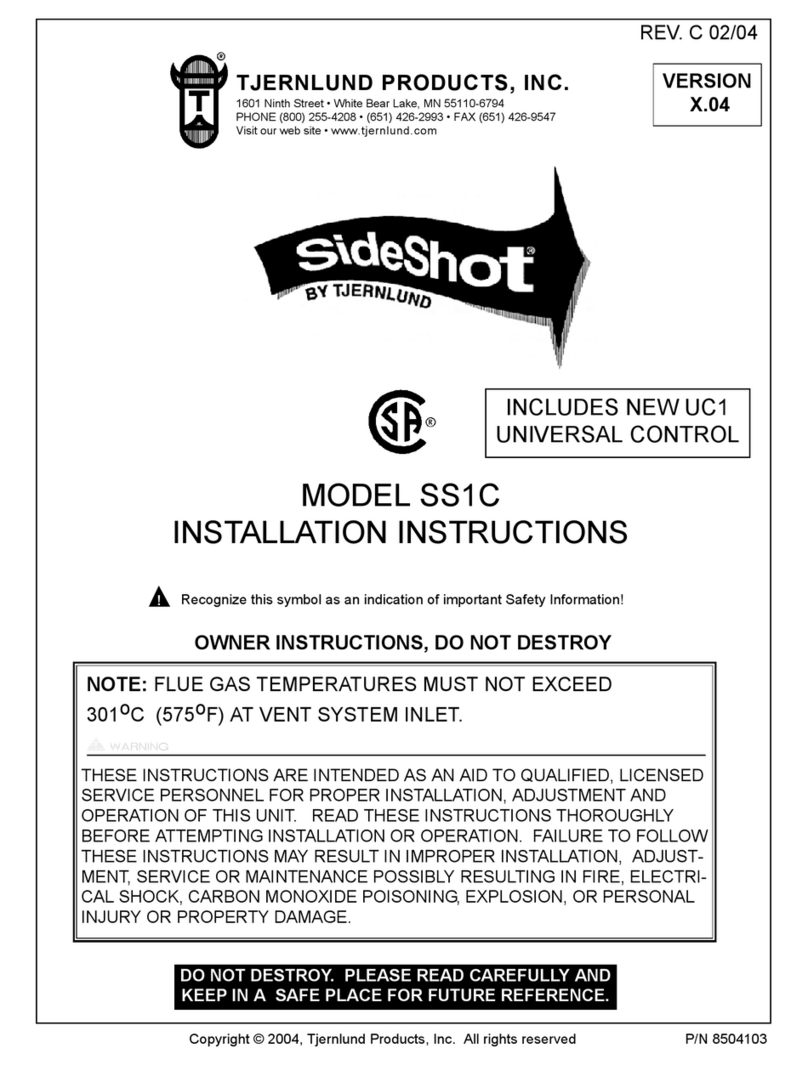

TJERNLUND SS1C SIDESHOT WITH UC1 UNIVERSAL CONTROL (VERSION X.04) 8504103 REV C... User manual

TJERNLUND

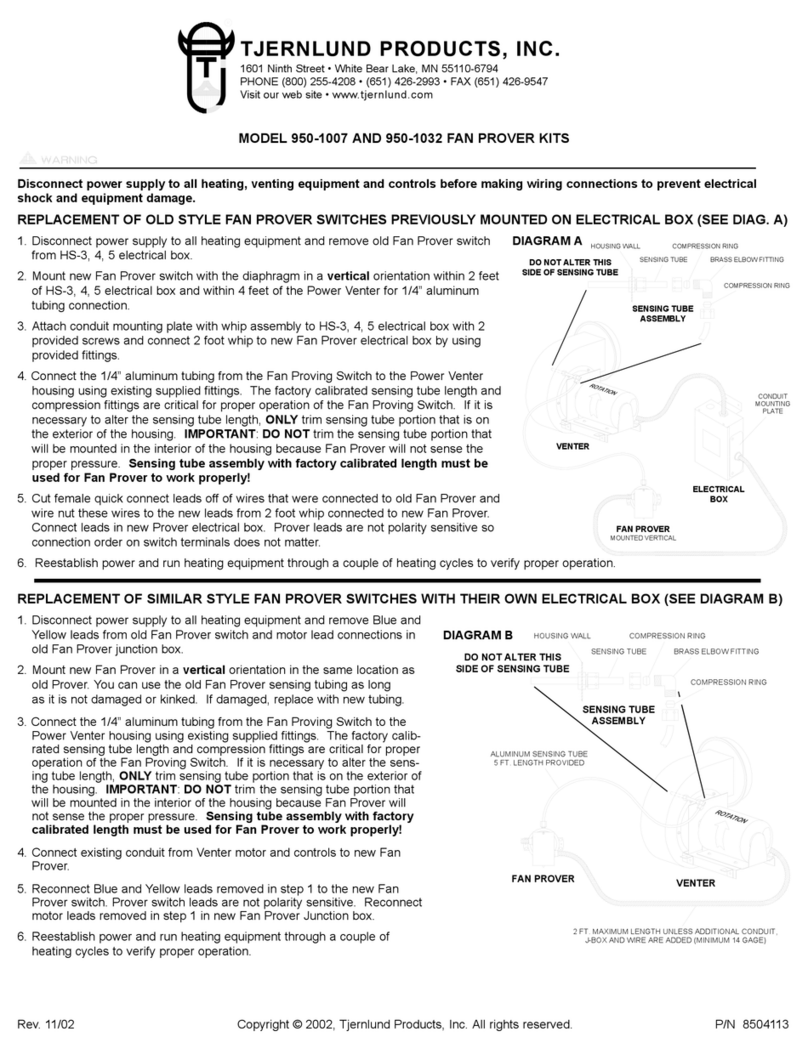

TJERNLUND 950-1007 FAN PROVER KIT 8504113 User manual

TJERNLUND

TJERNLUND HSJ User guide

TJERNLUND

TJERNLUND 950-2420 24SP200 SPILLAGE KIT 8504056 REV 1... User manual

TJERNLUND

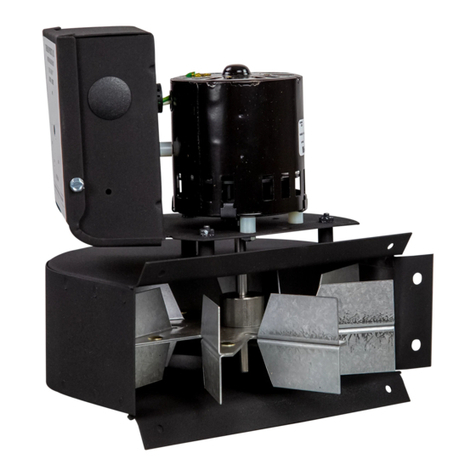

TJERNLUND SS2G SIDESHOT (DISCONTINUED) 8504075 REV 1... User manual

TJERNLUND

TJERNLUND HS115-3 User manual

TJERNLUND

TJERNLUND AD-1 FOR WOOD OR COAL STOVES 8504012 REV A... User manual

TJERNLUND

TJERNLUND SS2 SIDESHOT WITH UC1 UNIVERSAL CONTROL (VERSION X.06) 8504105 REV C... User manual

Popular Fan manuals by other brands

Harbor Breeze

Harbor Breeze RLG52NWZ5L manual

Allen + Roth

Allen + Roth L1405 instruction manual

ViM

ViM KUBAIR F400 ECOWATT Technical manual

HIDRIA

HIDRIA R10R-56LPS-ES50B-04C10 user guide

BLAUBERG Ventilatoren

BLAUBERG Ventilatoren CENTRO-M 100 L user manual

Triangle Engineering

Triangle Engineering HEAT BUSTER SPL Series owner's manual