5.9. Checking Firmware Revision...........................................................26

1.1. tarting the Unit Logging.................................................................28

6. Other Functions.......................................................................................29

6.1. View Options....................................................................................29

6.1.1. Clearing the Log......................................................................29

6.1.2. Displaying the Time/Date of events.........................................29

6.1.3. Displaying Log Events.............................................................29

6.2. Reading ettings from TB 12.........................................................29

6.2.1. Displaying the Battery Voltage................................................29

6.2.2. Viewing the Device ID.............................................................30

6.2.3. Viewing the Firmware Version.................................................30

6.2.4. Reading the Date-Time...........................................................30

6.2.5. Reading the LoRa ettings.....................................................30

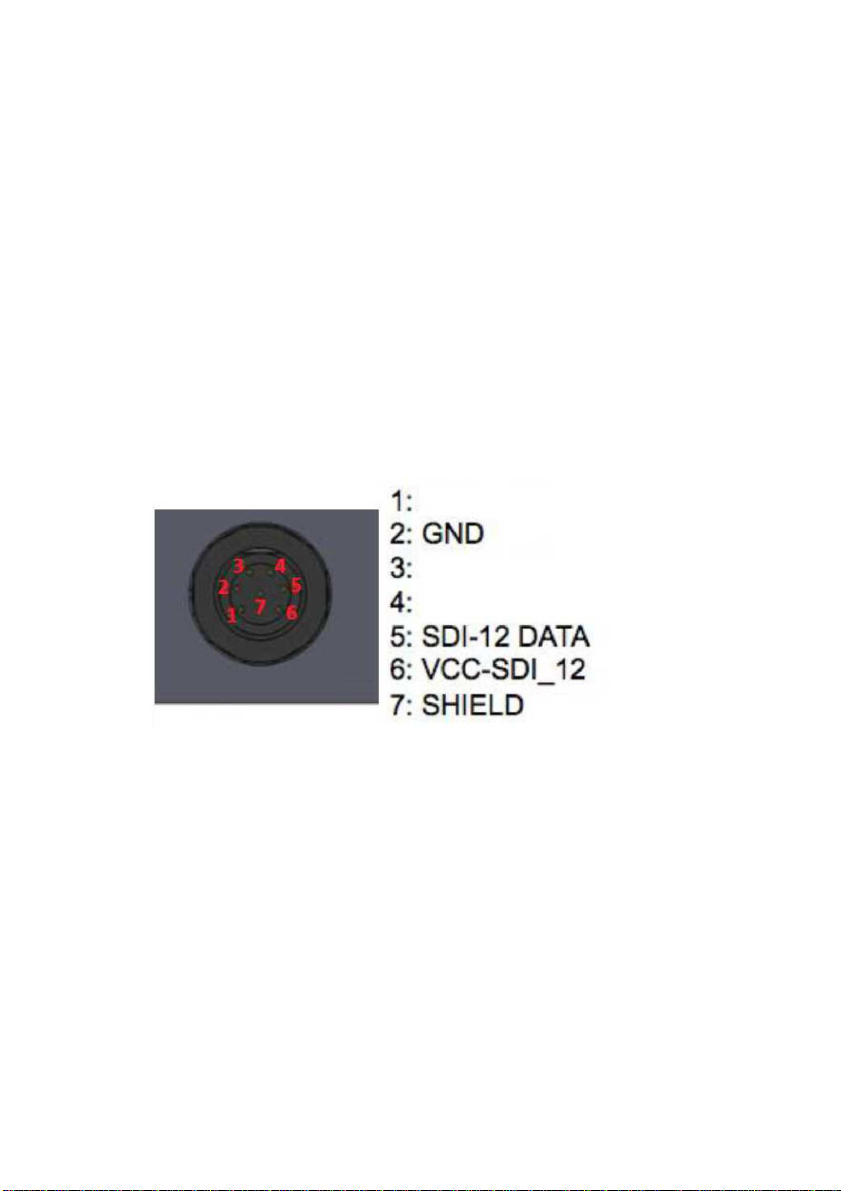

6.2.6. Reading the ensor ettings..................................................30

6.2.7. Reading the chedule ettings...............................................30

7. TB 12 Data format..................................................................................31

7.1. Battery data format..........................................................................31

7.2. ensor data format..........................................................................31

7.2.1. TB 12 , TB 12B, TB 12 M.................................................31

7.2.2. TB 12PC-F Pulse Count Mode............................................32

7.2.3. TB 12PC-F Flow witch Mode............................................33

8. Backend etup........................................................................................34

8.1. Configuration Requirements............................................................36

9. TB 12 Console Log Files........................................................................38

10. TB 12 Firmware Upgrade.....................................................................39

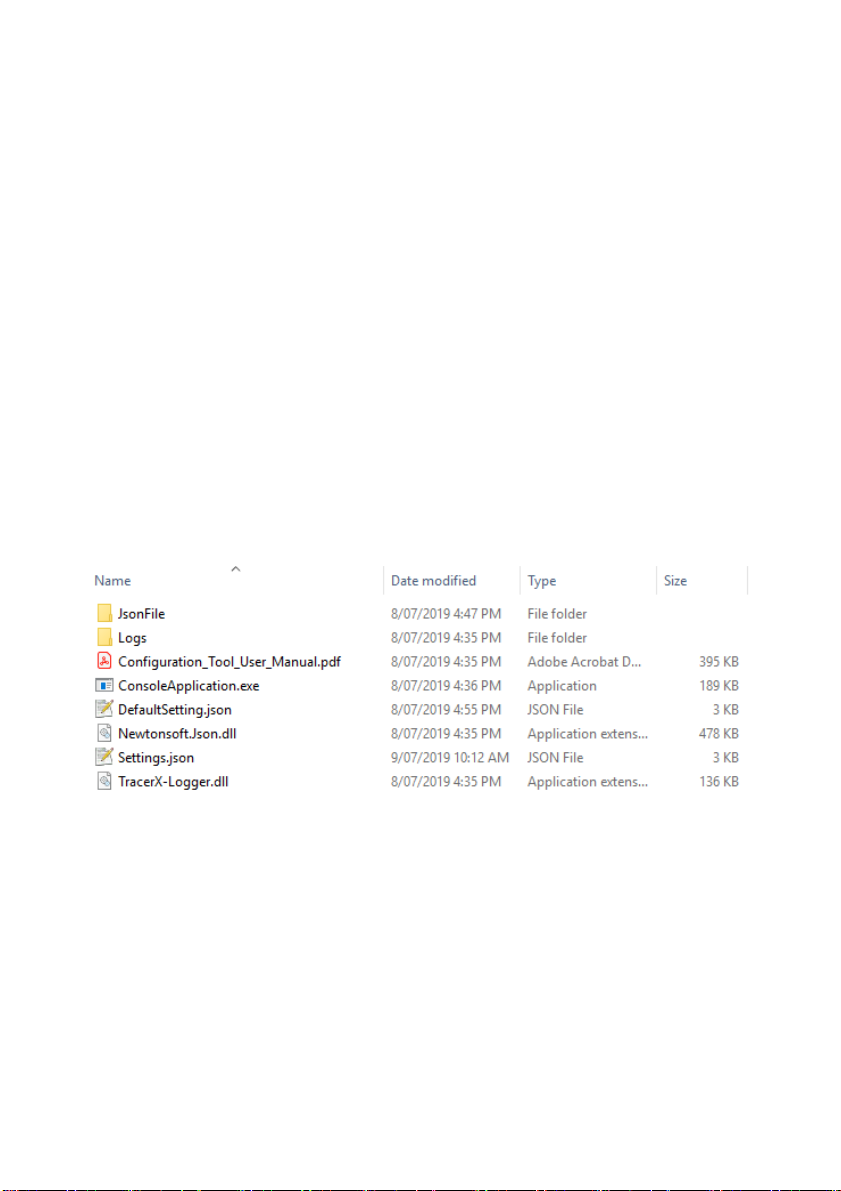

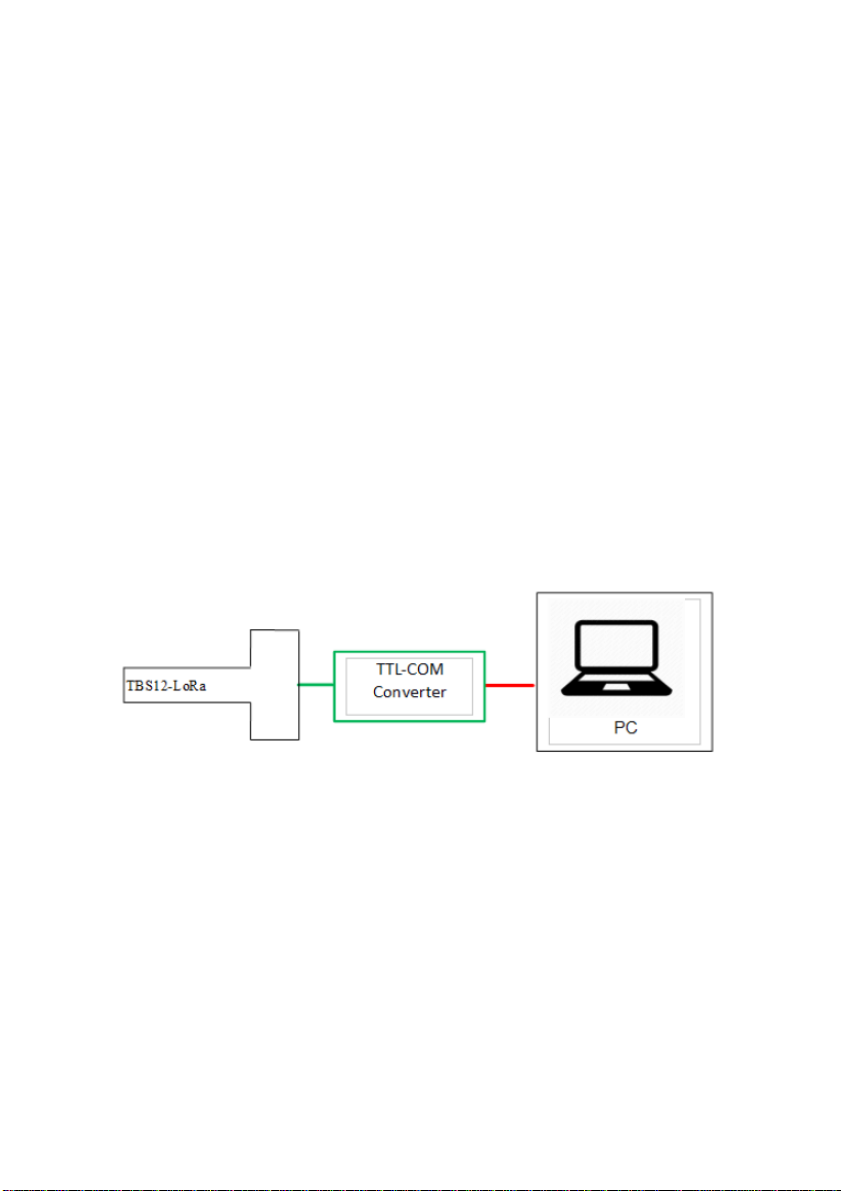

10.1. Equipment Required......................................................................39

10.2. Preparation....................................................................................40

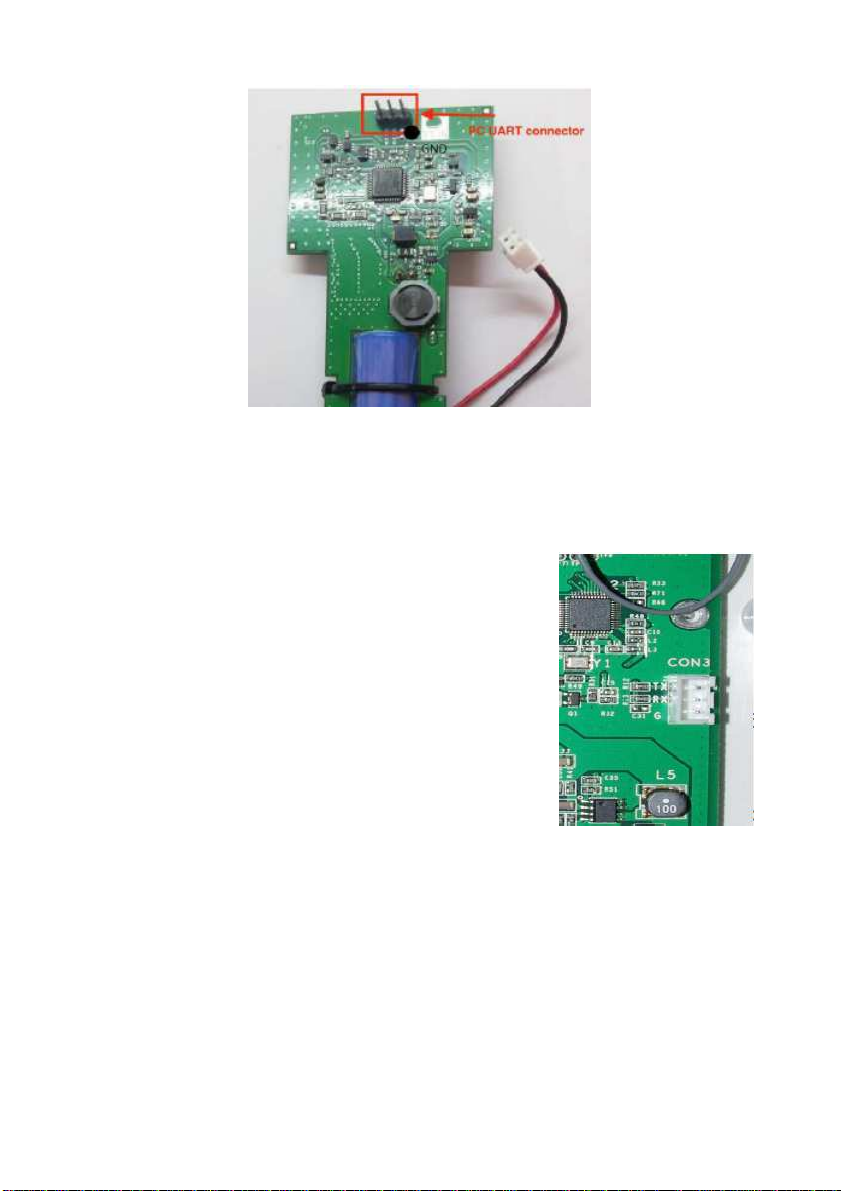

10.2.1. TB 12B, TB 12 , TB 12PC................................................40

10.2.2. TB 12PC/F .........................................................................41

10.3. Firmware Update...........................................................................41

11. Rising HF Modem Firmware Upgrade...................................................43

11.1. Preparation....................................................................................43

11.1.1. TB 12B & TB 12 ................................................................44

11.1.2. TB 12PC/F .........................................................................44

11.2. Upgrade Process...........................................................................45