TOLSEN TOOLS Force Xpress 79575 User manual

79575

HIGH PRESSURE WASHER

INSTRUCTION MANUAL 2000W

SAVE THIS MANUAL !

You will need this manual for safety instructions, operating procedures and warranty.

Put it and the original sales receipt in a safe dry place for future reference.

230V/50Hz

2 SAFETY

IMPORTANT SAFETY INFORMATION

Safety Instructions

1. The appliance has been designed solely for private use outdoors and not for commercial use. Keep this appliance away from

heat, direct sunlight, moisture and rain, ice and sharp edges.

2. Do not allow anybody that has not been trained to use a pressure washer to operate the machine without first reading the

instruction manual.

3. WARNING: High-pressure washers must not be used by children or untrained persons.

4. Before starting your machine, carefully check for defects. If you find any, do not start your machine and contact your local

distributor.

5. In particular, ensure that the electric cable insulation is in perfect condition and free of cracks. If the electric cable is damaged,

an approved local service centre must replace it.

6. WARNING: Hi pressure jets can be dangerous if they are used incorrectly. The jet must not be directed towards persons,

electrical equipment connected to the mains or the appliance itself.

7. WARNING: Do not use the appliance close to other people unless they are wearing protective clothing.

9. CAUTION: Do not direct the jet towards yourself or other persons to clean clothing or shoes.

10. Hold the lance firmly in your hands.

11. he operator and persons within close proximity to the cleaning area must take necessary measures to protect themselves from

dislodged debris when in use.

12. Wear protective gloves and clothing during use.

13. WARNING: The appliance has been designed for use with a cleaning agentsupplied or recommended by the manufacturer.

Using other cleaning products or chemical products may affect the safety of the appliance.

14. WARNING: Disconnect the appliance from the power supply before carrying out any maintenance.

15. CAUTION: To ensure the safety of the appliance, only use spare parts supplied or approved by the manufacturer.

16. Do not use the appliance if the power cable or important parts of the appliance are damaged, for example, the safety device,

high pressure hose and handgun.

17. Do not use the appliance with wet hands. If the appliance is damp or wet, unplug it immediately. Do not place it in water.

18. The tyres and valves on the tyres can be damaged by the high pressure jet and could burst.

19. Never use the machine in an environment where there is a danger of explosion.

20. It is forbidden to clean surfaces containing asbestos at high pressure.

21. This high-pressure washer must not be used in temperatures below 0 ° C.

22. CAUTION - The hoses, accessories and high pressure couplings are important for the safety of the machine. Only use hoses,

accessories and couplings recommended by the manufacturer.

3

SAFETY

23. WARNING: Inadequate extension cables may be dangerous. Cables and spools must always be completely unwound to

avoid letting the cable overheat.

24. If an extension cable is used, the plug and socket must be waterproof and conform to the requirements below regarding the

length and dimensions of the cable.

1,0 mm ² max. 12,5 m 1,5mm²max.20 m

25. If the power cable is damaged, it must be replaced by the manufacturer, their service agent or a qualified professional in

order to avoid any danger.

26. WARNING: This machine is not designed to be used by persons (including children) with reduced physical, sensory or mental

capacities or whose lack experience or knowledge.

27. WARNING: It is advisable that you supervise children to ensure that they do not play with the appliance.

28. CAUTION – Risk of explosion – do not spray flammable liquids, do not direct the jet towards flammable liquids.

29. WARNING: Water that has circulated in the anti-back flow system is not considered drinkable.

30. WARNING: Do not use the appliance if the power cable or important parts of the appliance are damaged, for example, the

safety devices, high pressure hoses and handgun.

31. WARNING: If you have an extension cable, it must be waterproof.

32. WARNING: When you switch on the machine, a recoil movement is produced due to the force of the water jet. Use two hands

to control the lance. Wear safety gloves when using the appliance. Wear suitable protective clothing.

33. In case of accidental contact with detergent, wash with water. If the liquid comes into contact with the eyes, also seek medical

assistance (the detergent can cause irritations or burns).

35. In the event that the appliance breaks down, do not attempt to repair it yourself but contact a professional technician to avoid

any danger.

Main power connection

The following must be observed when connecting the high pressure washer to the power supply:

36. Connecting the electrical connection should be done by a qualified electrician conforming to 60364-1 CEI

37. It is recommended that the electrical supply to this machine should comprise a residual current device which interrupts the

current if the leakage current exceeds 30 mA for 30ms.

CONNECTING TO THE WATER NETWORK WARNING

According to current guidelines, the unit must never be operated without a system separator on the potable water system. Use

a EN 12729 type BA system separator. Water that passes through a system separator is classified as non-potable.

WARNING: Always connect the system separator to the water supply and never directly to the device!

4SETUP AND SPECIFICATIONS

140bar/2030pis

5.5l/min

2000W

230V~50Hz

5~60℃

Max. pressure

Flow

power

Voltage

Water temperature

SETUP AND SPECIFICATIONS

1. Main ON/OFF switch

2. High-pressure outlet

3. Water connection with filter

4. Coupling section

5. Jet pipe was high-pressure nozzle

Technical data

The Circuitry

First time instructions

This section will explain in details how to make high pressure washer ready for use.

SAFETY DEVICES

The unloader valve can reduce pressure if it exceeds pre-set values.

Locking device on trigger gun (see illustration at the beginning of this manual): The trigger

gun features a locking device. When the knob is activated, the trigger gun cannot be

operated.

THERMAL SENSOR

A thermal sensor protects the motor against overloading. The machine will restart aer a

few minutes when the thermal sensor has cooled.

6. High-pressure hose

7. Gun safe lock

8. Power plug

9. Trigger

6

79

8

Push

Unlock

Push

lock

5

SETUP AND SPECIFICATIONS

1

A

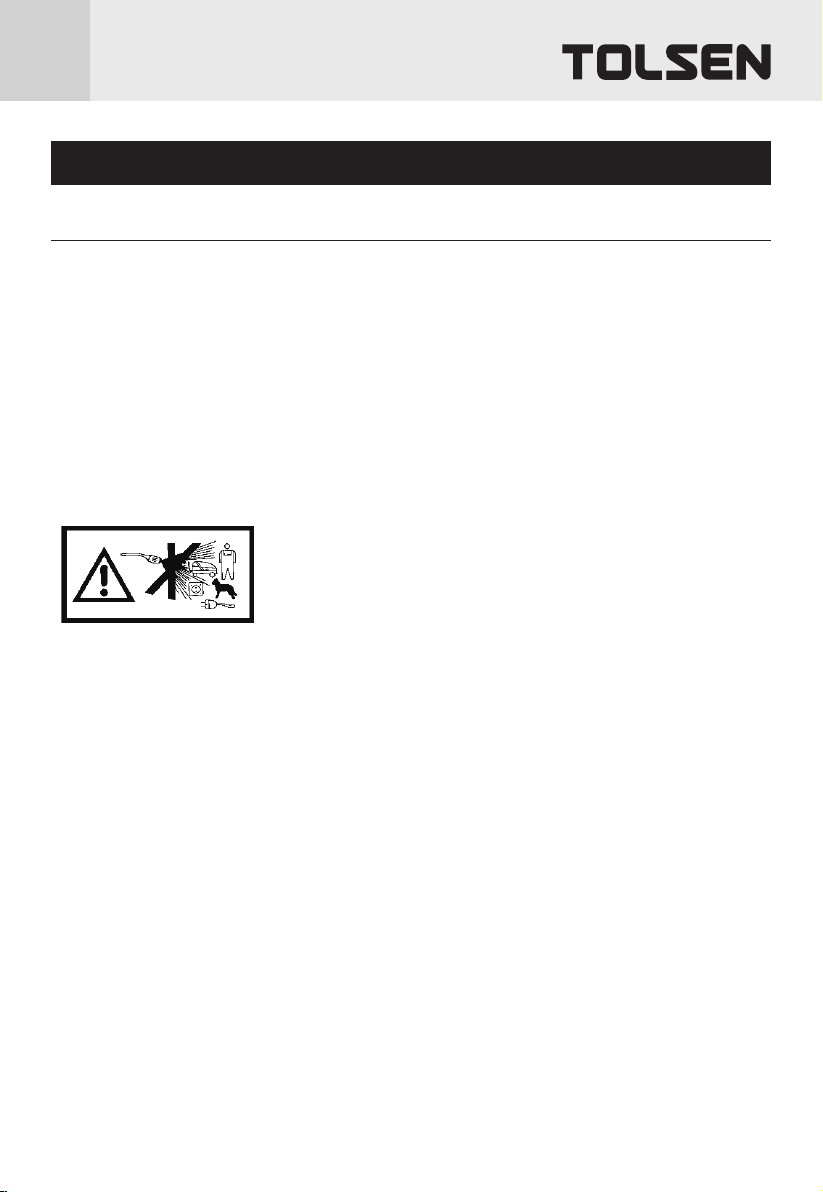

Connection of garden hose

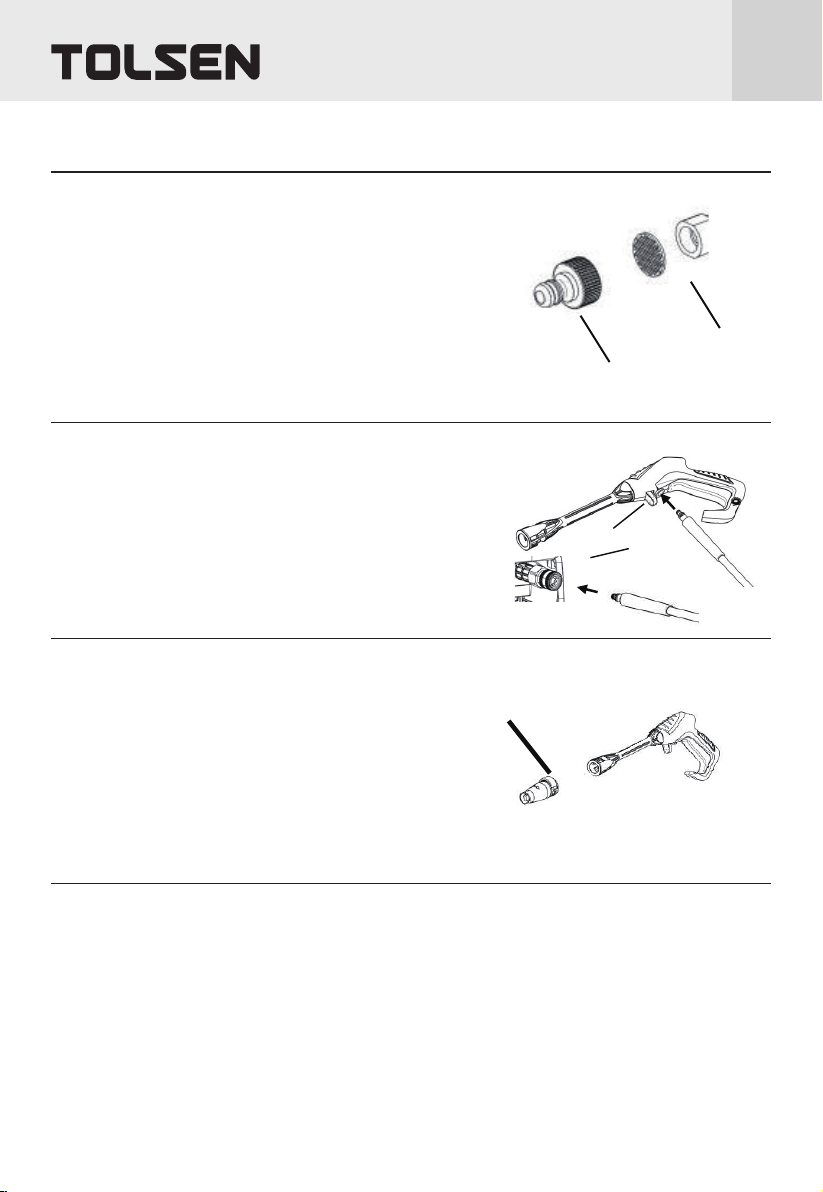

Mounting of high pressure hose

A

B

Screw the water inlet coupling (1) tight on to the water inlet Note:

The inlet filter (A) must always be fitted in the water inlet pipe to filter

out sand, lime stone and other impurities as these will damage the

pump valves.

Caution: Failure to fit the filter will invalidate the guarantee.

Connect the garden hose with a standard quick coupling

Attach the high pressure hose to the trigger gun and machine.

Detach the high pressure hose by pressing the pawl (A) or button (B)

Mounting of lance and nozzle

Push the lance into the trigger gun

When inserted turn it. Caution: Make sure the lance is properly fixed to the

gun

Attach the nozzles. Caution: When attaching the nozzle the button (A) on

the nozzle should come out again. Check before activating the trigger that

the nozzle is properly fixed.

A

Water connection

Connecting the water supply pipe

Follow your water supplier’s instructions .

For connection information, see the data plate/technical specifications

Use a reinforced hose (not supplied) with a standard connection (ext. diameter: 16mm/int. 12mm, maximum length: 25m).

IMPORTANT! Only use water without any impurities. If there is a risk of sand particles in the inlet water (i.e. from your own well), an

additional filter should be mounted.

Let the water run through the water hose before connecting it to the machine to prevent sand and dirt from penetrating the

machine. Note: Check that the filter is fitted in the water inlet pipe and that it is not clogged up.

Connect the water hose to the water supply by means of the quick connector (inlet water, max. pressure: 10 bar, max. temperature:

60°C).

Turn on the water.

6SETUP AND SPECIFICATIONS

Start/stop of the machine

Multi Nozzle

The trigger gun and lance is affected by a thrust during operation - therefore always hold it firmly with both hands.

IMPORTANT: Point the nozzle at the ground.

Check that the machine is in upright position. NOTE: Do not place the machine in high grass!

Release the trigger lock .

Activate the trigger of the trigger gun and let the water run until all air has escaped from the water hose.

Press the Start/stop switch.

Activate the trigger of the trigger gun.

Always adjust the distance and thus the pressure of the nozzle to the surface, which is to be cleaned.

Do not cover the machine during operation or use it in a room without adequate ventilation!

NOTE: If the machine is le or not used for 5 minutes, it must be switched off on the start/stop switch "O":

Press the start/stop switch "O".

Disconnect the electrical plug from the socket.

Shut off the water supply and activate the trigger of the trigger gun to relieve the machine of pressure.

Lock the trigger gun

When releasing the trigger of the trigger gun, the machine automatically stops. The machine will start again when you re- activate

the trigger gun

The pressure can for the multi nozzle be adjusted by

tuning it. WARNING: Do not do this under operation to

avoid that the hand hits the jet.

Aer use instructions

The machine should be stored in a frost-free room!

Pump, hose and accessories should always be emptied of water prior to storing as follows:

Stop the machine (press the start/stop switch “O” and detach water hose, high pressure hose and nozzle

Restart the machine and activate the trigger of the trigger gun Let the machine run until no more water runs through the trigger

gun.

Stop the machine, unplug and wind up hose and cable.

Place trigger gun, lance, nozzles and other accessories in the holders of the machine. The hook can be used for storage of the

hose and cord All accessories can be stored in the washer aer using.

WARNING: Never start up a frozen machine. Frost damages are not covered by the guarantee!

7

SETUP AND SPECIFICATIONS

Environmental protection

Old appliances contain valuable materials that can be recycled. Please arrange for the proper recycling of old appliances. Please

dispose your old appliances using appropriate collection systems.

Maintenance, cleaner and repair

WARNING! Always disconnect the electrical plug from the socket prior to maintenance or cleaning.

To ensure a long and problem free working life, please take the following advice:

Wash out water hose, high pressure hose, spray lance and accessories before mounting.

Clean the connectors of dust and sand.

Rinse the detergent spraying attachment aer use.

Clean the nozzles.

Any repair should always be made in an authorized workshop with original spare parts.

Cleaning of inlet filter

Clean the water inlet filter regularly once a month or more frequently according to use.

Carefully loosen the filter with a screwdriver and clean it . Check that it is intact before re-mounting it.

The inlet filter must always be fitted inside the water inlet pipe to filter out sand, limestone and other impurities, as they will damage

the pump valves.

CAUTION: Failure to fit the filter will invalidate the warranty

Cleaning of air vents

The machine should be kept clean so as to let cooling air pass freely through the machine vents.

Greasing of couplings

To ensure an easy connection and that o-rings do not dry up; the couplings should be greased regularly.

8

The machine will

not start

Fluctuating pressure

The machine

stops

Fuse blown

Pulsing machine

The machine turns

on and off by itself

The machine is on

but no water

comes out

The machine is not plugged-in

Faulty receptacle

The fuse has blown

Faulty extension cable

The pump is drawing in air

Valves dirty, worn or sticking

The water supply is not sufficient

Pump seals worn

The fuse has blown

Incorrect mains voltage

Thermal sensor activated

Partially blocked jet

Fuse too small

Increase in the amperage

Air in inlet hose / pump

Inadequate supply of water generated

Partially blocked jet

Water filter blocked

Folded pipe

Pump fuse and/or trigger out of order

No water supply

Water filter blocked

Blocked jet

Clean the filter

Clean the jet with a needle and by spraying

water rearwardly through the jet

Contact your nearest service centre

Connect the inflow water.

Allow machine to run with open trigger until

regular working pressure resumes.

Increase water pressure, check for blockages

and / or change the large pipe.

Clean the jet with a needle and by spraying

water rearwardly through the jet

Clean the filter

Unfold the pipe

Replace it with a fuse with higher amp

consumption than the washer.

Try without the extension cable

Replace the fuse

Unplug other appliances

Check that the mains voltage corresponds to the

specifications on the nameplate

Leave the machine to cool for 5 mins

Clean the jet with a needle and by spraying water

rearwardly through the jet

Check that hoses and connections are airtight.

Contact your service centre

Increase water pressure, check for blockages and

/ or change the large pipe.

Contact your nearest service centre

Plug the machine in

Try another receptacle

Replace the fuse Unplug other

appliances

Try without the extension cable

ASSEMBLY DIAGRAM (MACHINE)

9

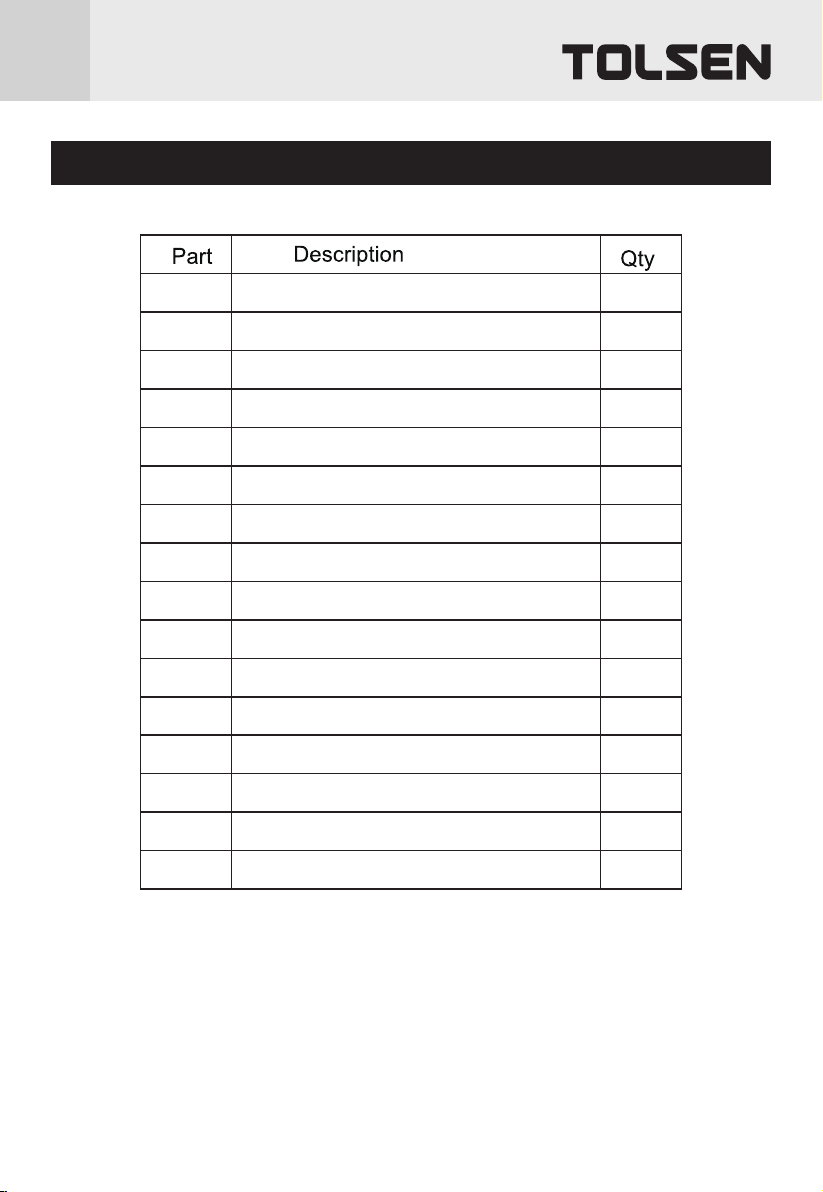

10 PARTS LIST

PARTS LIST (MACHINE)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Tapping screw

Le machine body

4 corners of gasket

filter

connector gastket

O-ring

water inlet connector

quick connector

quick connector gastket

Top cover

soket head cap screw

Flat gasket

right machine body

tension disc

Pump

Rubber front pad

1

1

1

1

1

1

1

1

1

1

4

4

1

1

1

7

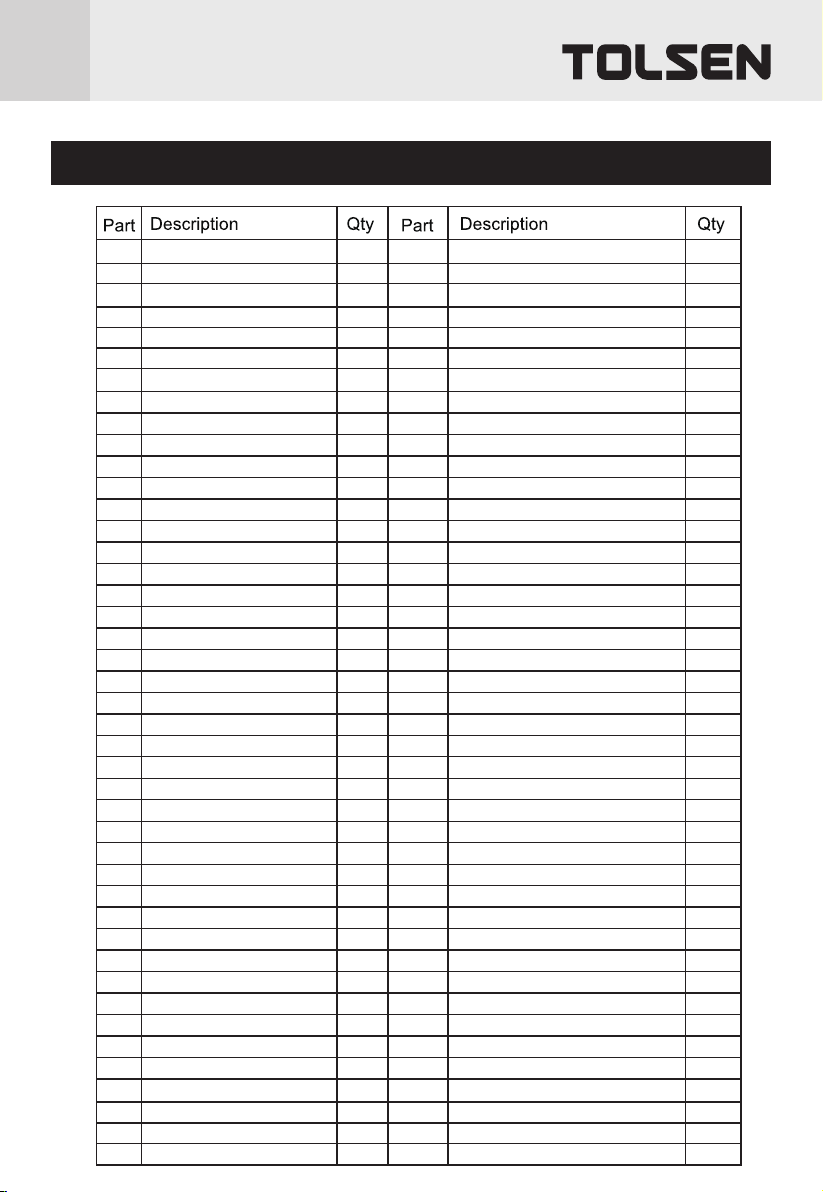

ASSEMBLY DIAGRAM PART-B (PUMP)

11

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

B17

B18

B19

B20

B21

B22

B23

B24

B25

B26

B27

B28

B29

B30

B31

B32

B33

B34

B35

B36

B37

B38

B39

B40

B41

B42

B43

7

11

1

1

6

6

6

6

6

1

4

1

3

3

3

3

3

3

1

1

1

1

1

1

6

2

2

1

1

1

1

1

1

1

1

4

4

1

1

1

1

1

2

6

1

1

4

1

1

1

2

4

4

1

2

1

1

2

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

B44

B45

B46

B47

B48

B49

B50

B51

B52

B53

B54

B55

B56

B57

B58

B59

B60

B61

B62

B63

B64

B65

B66

B67

B68

B69

B70

B71

B72

B73

B74

B75

B76

B77

B78

B79

B80

B81

B82

B83

B84

B85

Cross element machine screw

Cross flat - ended spindle screw

Switch box cover

High and low screw

main switch

Waterproof cover pressing plate

Waterproof cover pressing plate

High and low screw

wire connector

connector sleeve

cable hose

Cable cover

ground terminal

micro wire

High and low screw

micro wire cover

micro switch

O-ring

pressure release valve end screw

O-ring

O-ring

clamping ring

O-ring

pressure release valve core

O-ring

pressure release valve cover

pressure release valve spring

pressure release valve handle

O-ring

O-ring

pressure holder valve body

O-ring

plunger ring

pressure holder valve handle

pressure holder valve spring

pressure holder valve cover

pressure holder valve spring

headless screw

Cross leveling screw

out water pump connector

Special sealing

o-ring

soket head cap screw

spring shim

water inlet connector

Triangle ring

K1200 one way valve seat

o-ring

one way valve core

one way valve spring

K 1200 one way valve body

Pump head

soket head cap screw

Mid-pump

sealing

guide sleeve

sealing

BCNT piston

BCNT piston spring

Plunger baffle

o-ring

soket head cap screw

Spring shim

Flat gasket

Flat gasket

Swash plate

Hexagon self-locking nut

Rubber foot

soket head cap screw

Flat gasket

Motor

Front cover of Motor

Motor cover

Back cover of Motor

wind page

wind scooper

wind scooper

hexagon screw

Pan head screws with cross

Motor le bracket

Motor right bracket

sealing gasket

switch box

Capacitance

Wire groove

12 PARTS LIST

PARTS LIST PART-B (PUMP)

NOTE

NOTE

NOTE

TOLSEN is a trademark or

registered trademark of TOLSEN

TOOLS. All rights reserved.

MADE IN CHINA

TOLSEN TOOLS

CO.,LIMITED

www.tolsentools.com

Table of contents

Other TOLSEN TOOLS Pressure Washer manuals