Tone T-3 User manual

T-3 Build Guide

*All product names, trademarks and registered trademarks are property of their respective owners.

Page 2

While many of these procedures are applicable to the T-1

and T-1 Mini jets as well, this guide is specific to the T-3 With Electric Gear Set.

This guide does not cover radio setup, programming or turbine operation. You will

need to refer to the documentation provided with those systems for information on

proper setup and operation.

T-3 ARF Kit:

•Fuselage; Forward, Center, AFT

•Rudder and Stab (Factory Hinged)

•Wings, Factory Hinged Ailerons with Flaps

•Landing Gear with struts and brakes (Electric Comes with Gear and Brake Controller)

•Complete Hardware Package

•Linkage and ball links

•Dual Walled Pipe

•Kevlar Fuel Tank/Smoke Tank Combo with Hysol in fittings

Tips for Success:

•Don’t rush! Allow plenty of time for your build. Take your time, enjoy it, and do it right.

•Don’t be afraid to ask questions! In addition to this document there are several build threads on RC Universe

where you can get input and assistance with your build:

•Complete the latter part of your build on a CG stand…when you’re down to the components that can relocate in

order to adjust CG.

•After your build is complete, have another turbine operator/pilot review your build. A fresh set of THIS s is a

good sanity check.

Specifications:

•Length: 118”

•Wing Span: 103”

•Fuel Tank 256oz

•Smoke Tank 60ozDry Weight 45-48Lbs

•Recommended Engine 180-260

•Center of Gravity: 335mm - 345mm from leading edge of wing root.

•Recommended Aileron Throw: 18-20mm

•Recommended Elevator Throw: 20-25mm

•Recommended Rudder Throw: 25mm

•Recommended Flap Throw: Half flaps = 35mm, Full flaps = 65mm

•Recommended Flap Throw: Half flaps = 45mm, Full flaps = 70mm

Page 3

The kit will come very well packed.

Carefully remove all the parts from the

bubble wrap that they are encased in. Do

not use a knife or razor as you can

inadvertently cut through the packaging

and damage the finish of the parts. Peel or

use scissors to carefully cut and remove

the tape.

Inspect all parts for any shipping damage

and test fit. Check all packaging, parts and

components. It’s good to organize and

identify hardware and components before

you start the build.

You can use some of the packaging

material to place your air-frame parts on to

keep from damaging or scratching during

your build.

Sometimes the painting process results in a

rough edge that might cause binding. This

is easily resolved by using a common emery

board to gently smooth the

underside/inside the flight surface and the

top/outside on the control surface. Use

tape to protect the painted areas on

control surfaces. Go slow and don’t be too

aggressive with the file to avoid removing

too much material.

Equipment Used (Sold Separately)

•Spektrum radio System

•Demon Cortex Gyro

•KingTech K210G2

•KingTech 2X 6.6 3800 Life Packs

•KingTech 9.9 3800 Life Pack

•KingTech 150cc UAT with Holder

•KingTech Smoke Pump

•PRCJ 6mm Poly Fuel Tubing (6 Feet)

•PRCJ XXL 36” Smoke Tube

•PRCJ Large Vents with caps

•PRCJ T-3 E-Gear Wire Harness (PJ-

T3WHRB)

•PRCJ T-3 (8) Pack Savox SA1230SG

•PRCJ Advanced CG Stand

Page 4

AFT Fuselage Zip Tie Mounts & Harness

Installation.

For this process we use self-adhesive Zip

Tie mounts and small Zip Ties to secure the

wire harness in place. Use the photos for

reference on where to install the Zip Tie

mounts and harness. Note: Start wire

harness installation from the AFT forward

leaving at least 2” of wire out of the

fuselage at the connection points for the

stab and rudder.

Once wires are secure use CA or Hysol on

edges of Zip Tie mounts for permanent

adhesion.

Make sure to have no sagging wires. You

can use aluminum tape around

Midbody Fuselage Zip Tie Mount

Installation.

For this process we used the self-adhesive

Zip Tie mounts. Use photos for reference

on where to install the Zip Tie mounts. Use

CA or Hysol on edges of Zip Tie mounts for

permanent adhesion.

Page 5

Midbody & AFT Fuselage Assembly.

Make sure the bell mouth is secure and

tight to the pipe. If you plan to use the

PRCJ 36” Smoke Stick, pre-install now at

the top center of the pipe and slide pipe

into AFT Fuselage. Pull your wires through

at the top access area, line up the

AFT/Midbody sections, apply Blue Medium

Thread Locker and install top bolt with the

provided wrench, (Lightly Tighten Bolt)

then loose install the remaining 5 bolts

with Medium Thread Locker. During

tightening, ensure proper alignment of the

AFT and Midbody sections before fully

tightening down the bolts

Securing Pipe and Smoke Tube.

Install the pipe mounting “L” tabs at the

center line of the pipe and secure with

provided hardware, see Photo for

reference. Using your turbine for mock-up,

set the distance and pipe alignment. The

end of the pipe should be flush with the

rear section of the jet as shown in photo.

Once alignment is achieved secure pipe

with provided screws as shown in photo.

Bring smoke tube end out of the rear of the

pipe about 1.5 inches and bend down to

get into the hot exhaust stream. Adjust

rotation of smoke tube and then bend at

the bellmouth area as needed. We used Zip

Ties and mounts to secure smoke tubing.

Wire tie and run smoke tubing forward to

tray.

Page 6

Engine to Pipe Spacing and Installation.

This is a crucial part of any engine

installation. Please refer to your engine

documentation for proper installation and

engine to pipe spacing practices. The

photos show a proper reference for engine

spacing and alignment.

You should have 1” spacing between the

end of the engine tailcone and the

beginning of the pipe inlet

(NOT THE BELL MOUTH)

The tailcone of the engine should be tucked

inside the bellmouth. Once center

alignment and distance is achieved, you

can drill/mount your engine using wood

style screws or bolts with blind/lock nuts.

Fuel Tank Assembly and Installation.

Pre-fit and dry install your fuel tank fittings,

you will drill can vent holes where needed.

NOTE: when locating the vent hole for the

fuel tank, be sure to pay attention to where

the split line is. You must be under the

tank/smoke tank separation line; you can

see inside the main tank for reference.

Carefully clean and Hysol in fittings. Note

fitting directions. Build tank clunk pick-up’s

as seen in photos. Be sure to solder collets

to both ends of the brass tubing. Measure

lengths of tubing as needed and pre-fit

after curing of fittings. Use wire tie to

secure fuel tubing. Pre-drill aluminum

mounting tabs before installing into

Midbody. Use provided wood screws to

install tank. We recommend a bead of

silicone around the front edge of the tank

to the fuel tray for added security.

Tank must be installed in Midbody

before nose section installation!

Page 7

Midbody & Nose Section Assembly.

After the nose gear installation is

completed, line up the Nose/Midbody

sections, apply Medium Thread Locker and

install top 2 bolts with the provided

wrench. (Lightly Tighten Bolts) then loose

install the remaining 5 bolts using Medium

Thread Locker and provided wrench.

Ensure proper alignment of the Nose and

Midbody sections and test canopy fitment

before fully tightening down the bolts. You

can use a straight edge across the fuselage

canopy edge surface to help with

alignment as well. You can use the Zip Tie

mounts to rout gear, steering and door

servo wires to the main tray area on the

right or left side of the nose gear

depending on your install.

TANK MUST BE IN MIDBODY BEFORE PROCEEDING!

Electric Nose Gear Installation.

Locate the nose gear steering horn and

install into strut using Medium Thread

Locker.

Install the steering servo using the

hardware that came with your servo to

mount onto the steering servo plate. Use

Medium Thread Locker

Center up your servo using a servo

centering device, adjust and install the

linkage as shown in photo.

Test fit the nose gear in the nose gear bay.

Verify that there is clearance between all

moving parts in the area such as the gear

door servo, arm, pushrod, and gear door

hinges. Mark hole locations and us a small

pilot drill for the holes then bolt gear into

place.

Page 8

Electric Main Gear Installation.

Feed the main gear and brake wires to the

access area and plug into the wing wire

harness. (Always secure wire connections)

Slide the retract into place and locate the

strut, wheel and brake in the wheel well

making sure that you have equal distances

all the way around the tire and strut as

seen in photo.

When proper location is achieved, mark

holes and drill pilot holes, NOTE: Use a drill

stop to set drill depths as to not accidently

drill through wing. Use the (4) provided

screws to mount gear in place. Install gear

cover using provided hardware, slight

trimming may be required for fitment. Use

Aluminum tape to secure brake wires.

Electric Gear Controller Setup.

Each of the three gear units is

independently programmable.

• Long press the mode button to enter

programming mode.

• Short press the mode button to cycle

through the programming options below.

• When the A or B light is blinking, you can

press the + or –button to change the servo

direction. This setting is used if the door is

open when it should be closed or vice

versa.

• When the A and B lights are alternating,

pressing the + or –will increase or

decrease the servo throw on one end of its

movement. This setting is so that you can

adjust the door to open or close all of the

way without excessive binding at the

extents of motion.

Page 9

Electric Gear Controller Setup Continued.

• When the C and D lights are alternating,

pressing the + or –will increase or

decrease the servo throw on one end of its

movement. This setting is so that you can

adjust the door to open or close all of the

way without excessive binding at the

extents of motion.

• The C light blinking alone indicates Mode

1 operation for that gear unit.

• The D light blinking alone indicates Mode

2 operation for that gear unit.

• When you have completed making your

programming adjustments, long press the

mode button to save your changes and exit

programming mode.

Electric Brake Controller Setup.

Connect the two-wire break leads from the

main gear to the “Brake output” port on

the side of the brake controller. Connect

the radio lead from the brake controller to

the appropriate channel that you have

configured for brake operation. Lastly,

connect the power lead to your power

source (7.4V-25.2V). Turn the strength

screw adjustments to their weakest setting

(completely clockwise). You will need to

execute some taxi and brake tests at your

flying location to tune the brake strength

and radio settings that will work best for

you. Ensure that you have your brakes and

landing gear tuned and working prior to

any flight operations.

Page 10

Air Gear Installation.

This is a basic air system setup with a gear

fail safe, dual air valves for gear and door

operations. Brakes system is also a basic

brake control setup. All components

available at www.pacificrcjets.com

Air Gear Installation Photos.

Adhere the two air tanks under the main

board in front of the bulkhead. Use the Zip

Tie mounts to secure your air lines in place.

T off at the center of the fuselage where

the airline to wing area is, use the provided

air line connections and be sure to

bring air lines out minimum 2”

Fuel System Installation

There are different ways to rout your fuel

lines and other location to mount your

UAT, refer to the drawings on the right for

fuel system plumbing along with your

turbine manual. We recommend the PRCJ

Polyurethane tubing and always wire tie

for safety. We also recommend the

Kingtech UAT with PRCJ UAT mount and

ball valve mount.

Page 11

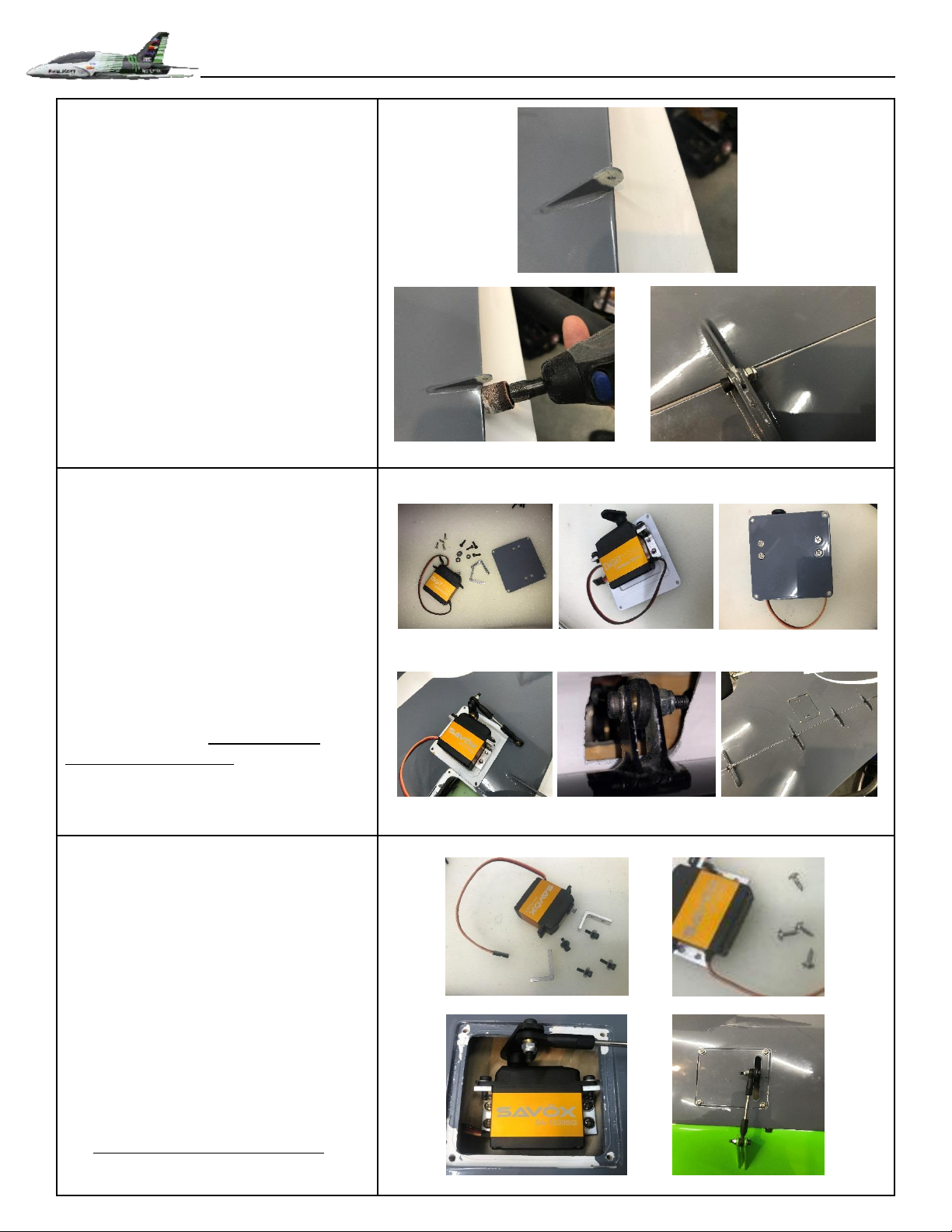

Stab servos Installation

Locate the hardware and servo L brackets.

Mock-up and install the L brackets on the

servo as needed to archive proper

direction and (Best Center) position in the

servo pocket. Use medium Thread locker to

secure.

Plug in your servo extension and use heat

shrink or other methods to secure

connection

Build your servo linkage using 1.0” servo

horns. Use provided ball links and

hardware with threaded control rod. Use

the 35mm threaded rods for Elevators

Center up your servo using a servo

centering device and install servo horn

Locate and install servos using the provided

(SHORT WOOD SCREWS)

Adjust and attach to elevator control horn

and adjust radio as needed to achieve

control throws.

After control setup is complete, remove

ball link from servo horn and install servo

cover using the provided wood screw

Re-attach ball link to control horn and re-

test control throws

Page 12

Flaps and Flap servos Installation

Carefully remove the paint from the hinge

on the wing side. This will allow free

smooth movement of the flaps and

eliminate any binding and or sticking.

Use the supplied lock nuts, bolts and

washers to install flaps.

Check for smooth movement after

installation of flaps.

Flaps and Flap servos Installation

Locate the hardware and servo L brackets.

Mock-up and install the L brackets on the

servo as needed to archive proper

direction and use medium Thread locker.

Use the provided counter sunk machine

screws to attach the servo to the flap servo

cover and use medium Thread locker.

Center up your servo using a servo

centering device. Build linkage using a

shorter ½ servo arm with the provided ball

ends, hardware and 35mm threaded

control rod for the Flaps Adjust and attach

to flap control horn and adjust radio as

needed to achieve max travel.

Repeat process For Other Side

Aileron servos Installation

Locate the hardware and servo L brackets.

Mock-up and install the L brackets on the

servo as needed to archive proper

direction and (Best Center) position in the

servo pocket. Use medium Thread locker to

secure.

Center up your servo using a servo

centering device. Build your servo linkage

using a 1.0” servo arm. Locate and install

servo using the provided (SHORT WOOD

SCREWS) Use provided ball links and

hardware with threaded control rod. Use

the 45mm threaded rods for Ailerons

Repeat process For Other Side

Page 13

Rudder servo Installation

Locate the hardware and servo L brackets.

Mock-up and install the L brackets on the

servo as needed to archive proper

direction and (Best Center) position in the

servo pocket. Use medium Thread locker to

secure.

Center up your servo using a servo

centering device. Build your servo linkage

using 1.0” servo horns. Locate and install

servo using the provided (SHORT WOOD

SCREWS) Use provided ball links and

hardware with threaded control rod. Use

the 85mm threaded rods for Rudder

Adjust and attach to Rudder control horn

and adjust radio as needed to achieve

control throws.

After control setup is complete, remove

ball link from servo horn and install servo

cover using the provided wood screw.

Re-attach ball link to control horn and re-

test control throws.

Final Component installation Photos

These photos show our basic installation of

components. There are many ways to lay

out and setup your T-3 electronics.

Pacific RC Jets offer many great solutions

for RX, Gear/Brake controllers, Smoke

pumps, Gyros, batteries, wing bags and

other products.

We appreciate your business.

www.pacificrcjets.com

Page 14

Final Component installation Photos

With Electric Retracts

With Air Retracts

Page 15

Congratulations! You have completed the

assembly and configuration of your T-3

turbine sport jet!

Make sure you have another set of eyes give

your aircraft a good looking-over. Quite

often, a problem can be spotted by a fresh,

experienced pair of eyes. It’s better to find

and fix rather than fly and fail.

FLY SAFE AND HAVE FUN!!!

Document:

Version 1.0 –Jan 2019 –Initial composition and release.

Table of contents

Other Tone Toy manuals

Popular Toy manuals by other brands

Tamiya

Tamiya M4 Sherman manual

Faller

Faller 120482 instructions

Black Horse Model

Black Horse Model MIDGET MUSTANG-EP Instruction manual book

Sutcliffe Play

Sutcliffe Play Ladybird Springie SSB160 installation instructions

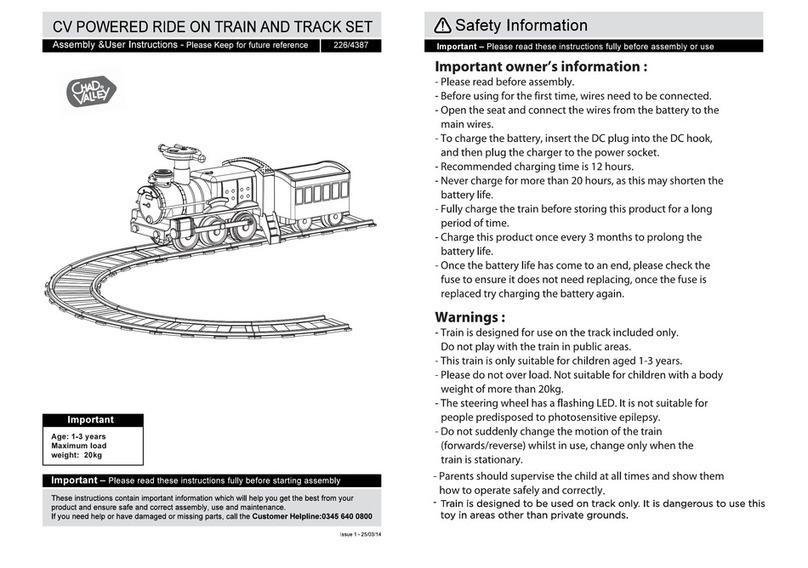

Mattel

Mattel Hot Wheels Slot Car Racing G4186 quick start guide

Hasbro

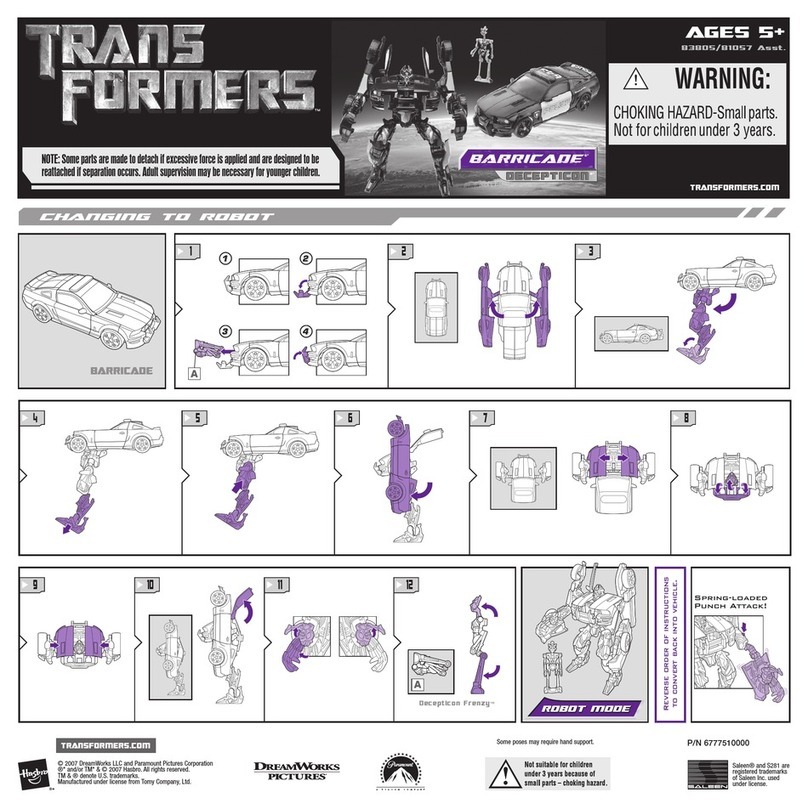

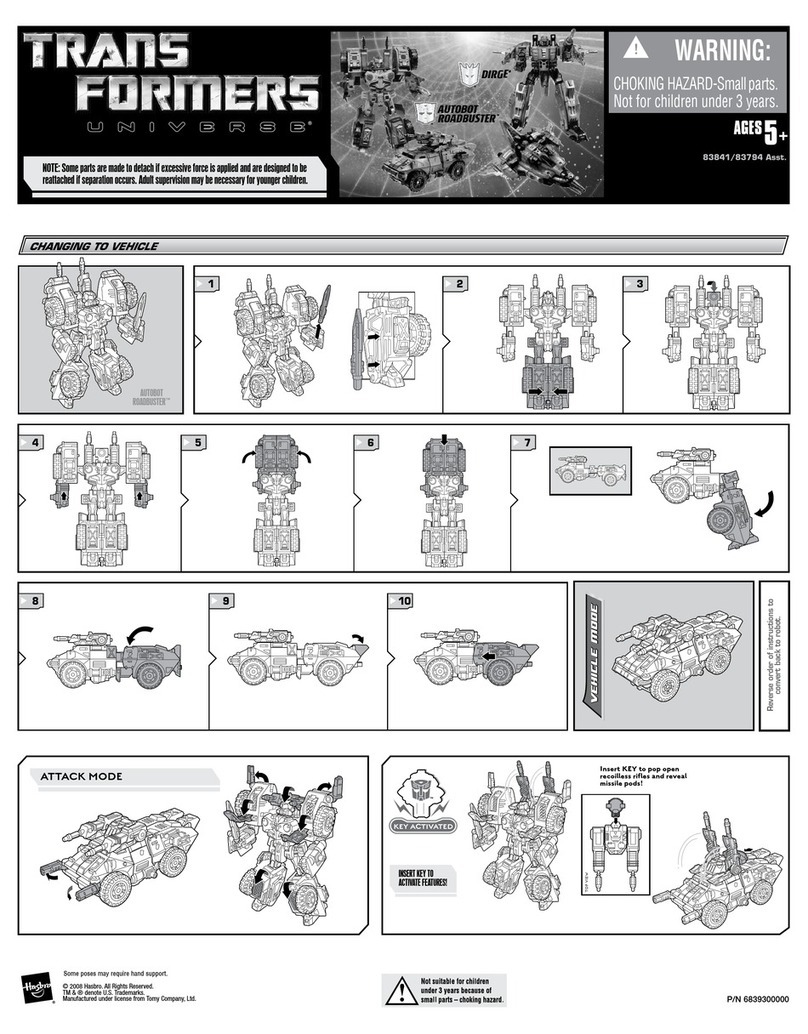

Hasbro Transformers Universe Autobot Roadbuster 83794... installation guide