Top Speed Tunnel Hull User manual

CONGRATULATIONS!

Thank you for choosing the Top Speed Tunnel Hull.This boat has been designed for the intermediate

to advanced boater looking for an easy to assemble, yet high performance tunnel hull. The assembly

is quick and easy, with no special tools or modeling skills required. The Top Speed is a fast, high

performance boat that can be adjusted to differing water conditions to perform at its peak potential.

Please read through this instruction manual in its entirety before beginning assembly. It contains

important instructions and warnings concerning the assembly and use of this model.

Warning! THIS MODEL IS NOT A TOY!

Assembly and operation of this boat must be done by or under the direct supervision of a responsible

adult. If not handled correctly, this model is capable of inflicting serious bodily harm. It is your responsibility

and yours alone to assemble this boat correctly, properly install all R/C components and test and operate it

in a safe and responsible manner.

GPMZ0261 FOR KITS GPMB1050/1055Entire Contents © Copyright 1999

INSTRUCTION

MANUAL

TM

PARTS IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . 3

PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ADDITIONAL ITEMS REQUIRED . . . . . . . . . . . . . . . . . 3

TOOLS REQUIRED. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Assemble the test stand. . . . . . . . . . . . . . . . . . . . . . . 4

Install the radio system . . . . . . . . . . . . . . . . . . . . . . . 4

Prepare the hull. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Prepare the upper tunnel . . . . . . . . . . . . . . . . . . . . . . 7

Engine installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fuel tank installation . . . . . . . . . . . . . . . . . . . . . . . . . 8

Linkage installation . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Radio box cover installation . . . . . . . . . . . . . . . . . . . 11

FINISHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Apply the decals and trim. . . . . . . . . . . . . . . . . . . . . 12

FINAL PREPARATIONS . . . . . . . . . . . . . . . . . . . . . . . 12

Balancing your model. . . . . . . . . . . . . . . . . . . . . . . . 12

Operation check. . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Range check your radio . . . . . . . . . . . . . . . . . . . . . . 13

Engine safety precautions . . . . . . . . . . . . . . . . . . . . 13

Operating procedures . . . . . . . . . . . . . . . . . . . . . . . 13

Operational trimming . . . . . . . . . . . . . . . . . . . . . . . . 14

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

RACING FUN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

PARTS ORDERING INFORMATION . . . . . . . back cover

2

TABLE OF CONTENTS

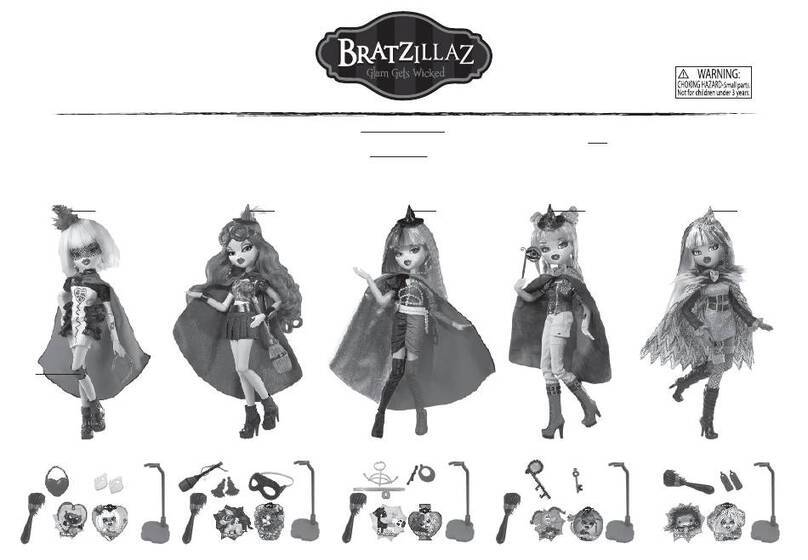

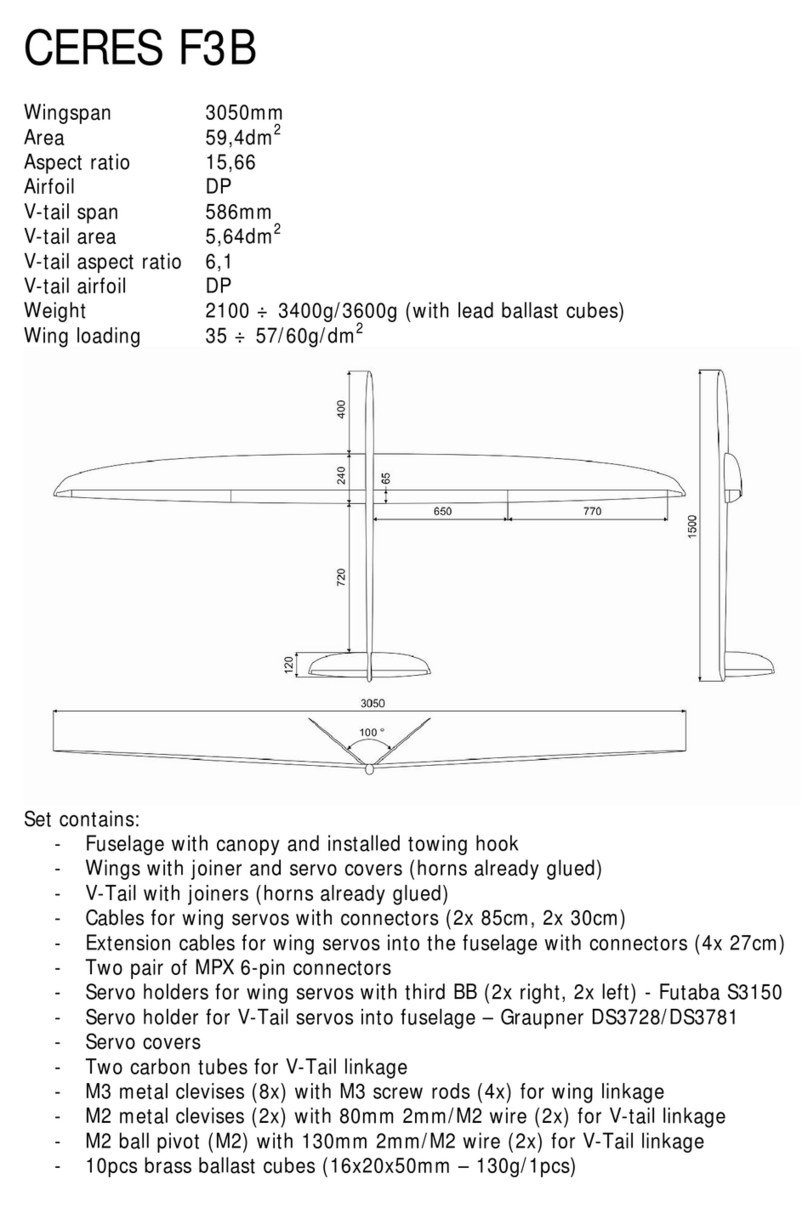

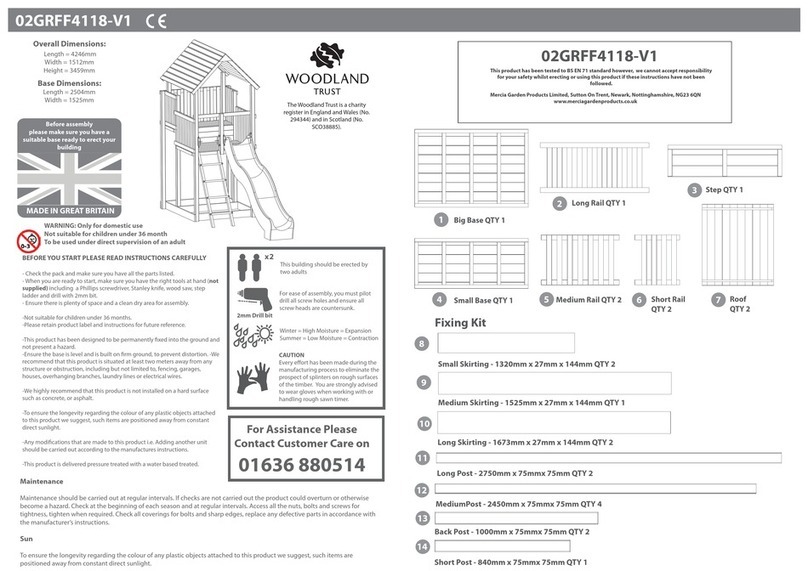

PARTS IDENTIFICATION

1. Hull

2. Radio Box

3. Upper Tunnel

4. Servo Tray

5. Stand Sides

6. Stand Cross Member Large

7. Stand Cross Member Small

8. Fuel Tank

9. Decals

10. Hardware

11. Speed Strips

10

8

3

5

9

11

4

676

1

2

Keep in mind that it is impossible for us to guide you specifically

as to every possible matter that might come up as you

assemble the model. The fun and challenge is to tackle the

problem, using the instructions and photos for resources, as

well as the assistance and advice of fellow modelers and your

local hobby dealer.

The instructions are the basic guide to assembly. Do not alter

or modify the model. Follow the step-by-step instructions

carefully. Read and obey cautions, warnings and directions on

such items as glues, paints and other materials. These are

often TOXIC to the human body in terms of breathing and/or

touch. Be especially cautious of cyanoacrylate glues (also

known as CA glues) that dry almost instantly and bond with

great strength. They require special care since they can be

extremely dangerous if they get into the eyes or on the human

skin. Keep small children and pets away from all building and

finishing materials. Keep your building area safe and clean.

We’ll try to make your boating experience as enjoyable and

“snag-free”as possible.If you find that your kit has any missing

or defective parts, or if you have any questions about building

or operating this model, please call us at (217) 398-8970 and

we’ll be glad to help. If you have problems with or questions

about any accessory items not included in the parts list

(batteries, chargers, radios, fuel, starting equipment, etc.)

please contact the hobby supplier that sold you those items.

❏2-channel radio system with two (2) servos*.The radio

system you use must be on a “surface only”

frequency. Watertight servos are recommended, but

not required.

*NOTE: It is recommended one of the servos have

at least 65 Oz. In. of torque for use as the steering

servo.

❏Waterproof bag for receiver, such as the Kyosho

TR-12 waterproof rubber bag (KYOB6055)

❏Small bottle of CA* glue (GPMR6007)

❏Rubbing alcohol

❏Clear tape

❏Pro thread locking compound (GPMR6060)

❏Shoe-Goo (DTXC2460)

❏6-Minute epoxy (GPMR6045)

❏Weights (GPMQ4485)

❏Mixing sticks (GPMR8055)

*NOTE: In several places, the instructions call for the use of

“CA glue.” The glue used in the Top Speed instruction

manual is GREAT PLANES PRO®CA+ MEDIUM

(GPMR6007) and is available from your local hobby shop).

❏Electric or hand drill

❏Drill Bits:1/16" [1.6mm], 5/64" [2mm], 1/8" [ 3mm],

5/32" [ 4mm], 3/16" [ 4.8mm], 1/4" [ 6mm], 7/16" [11mm]

❏Small screwdrivers (regular and phillips)

❏Pliers

❏Sandpaper (180, 320 and 400 grit)

❏Flat file

❏Hobby knife

❏Scissors

❏Masking tape

❏Clear tape

❏Paper towels

TOOLS REQUIRED

ADDITIONAL ITEMS REQUIRED

PRECAUTIONS

WARNING!

This boat is controlled by radio control, which is subject

to possible interference from other R/C transmitters,

paging systems and many other sources of RF or

electrical noise.When operating this boat, allow a “safety

margin” to avoid an accident in the event you experience

a brief loss of control.Before turning your radio on, make

sure no one else in the area is operating a radio on the

same frequency (channel).

WARNING!

Because of the speed and mass of this boat, it is

capable of inflicting property damage and severe

personal injury if a collision occurs.Never run this boat

in the presence of swimmers or where the possibility

of collision with people or property exists.

WARNING!

The engine is very powerful and spins the propeller

with great torque. Read the instructions manual

included with you engine for proper operating

procedures and safety precautions.

SAFETY WARNINGS

3

NOTE: Notice that the outboard engine protrudes from the

bottom of the hull and is very susceptible to damage.

Therefore, you must use care to avoid setting the boat down

on any surface. In the following steps you will assemble the

“test stand.” Always keep your boat on this stand when it is

not in the water.

❏1. From the two die-cut plywood sheets, remove the

Stand Sides and Cross Members (Large).Save the Servo

Trays from the center of the cross members (L) for use later

in the manual.

❏2. From the remaining die-cut plywood sheet, remove the

Cross Member (Small).

❏3. Sand the outer edges of all the parts to remove any

sharps corners.

❏4. Slide the two cross members (L) onto the sides as

shown in the photo. Slide the cross member (S) onto the

front of the sides (there is a slight upward curve at the front).

❏5. Apply a few drops of medium CA glue to the joints

where the cross members meet the sides. The glue will

penetrate the wood and form a bond within a few minutes.

❏6. Once the CA has fully cured, it is suggested to apply a

coat of clear sealer onto the stand. Top Flite®LustreKote™

Clear (TOPR7200) works extremely well for this purpose.

Applying a coat of clear will prevent water and fuel from

entering the wood, which will weaken the stand prematurely.

❏1. Sand the inside and outside edges of the die-cut ply

servo trays using 320-grit sandpaper.Test fit the servo trays

in the radio box, sanding the edges of the trays as

necessary for a good fit.The servo trays rest on the ledges

molded into the Radio Box.

Install the Radio System

Assemble the Test Stand

ASSEMBLY

4

❏2. Install the rubber grommets and brass eyelets in the

servos using the provided sketch.Do not attach the servo to

the tray yet.

❏3.Test fit your servos into the openings in the servo trays.

If the openings are too small, enlarge the openings with file

or 180-grit sandpaper until there is a 1/32" [.8mm] gap

around the servo.

❏4. Cut four 1/4" x 3/4" servo tray doublers using leftover

plywood from the die-cut sheets.Glue the doublers onto the

servo trays using Medium CA.

❏5.Glue the servo trays into the radio box using Shoe-goo.

Use enough Shoe-goo so it oozes out and slightly onto the

top of the servo tray. The trays are installed so the doubler

is on the bottom of the tray.

❏6.Note the direction of the servo output shafts shown in the

photo.While holding the servos in place, mark the locations for

the servo mounting screws onto the tray. Remove the servos

and drill 1/16" [1.6mm] pilot holes through each mark. Mount

the servos with the screws provided with the servos.

❏7. Read the instructions included with your radio system

and plug together the receiver, servos, on/off switch and

receiver battery. If your system does not come with a NiCd

receiver battery, install batteries in the battery holder

supplied with your radio system. Switch on the transmitter

and receiver (in that order) and check the operation of your

radio system. Center the trims on the transmitter. Switch off

the receiver and transmitter (in that order) when finished.

❏8. Enclose your receiver and receiver battery in waterproof

plastic bags of rubber balloons (the KyoshoTR-12Waterproof

Rubber Bag (KYOB6055) is an excellent choice). Close the

end of the bag where the wires exit using a twist tie or tape.

5

❏9. Place a wad of paper towels in the bottom of the radio

box (to absorb any moisture that may enter), then position

the receiver battery and receiver into the radio box in the

front of the servos.

❏10. Remove the switch plate from the receiver switch.

Attach the switch to the Switch Mounting Plate using the

two screws that were provided with the switch.

❏11. Position the switch assembly in the radio box.

Depending on your choice of radio, the switch may mount

differently than shown. Approximate the location of where

the switch will attach and drill a hole using a 3/16" [4.8mm]

drill bit. Secure the switch using the Switch Retainer.

❏12. Place the Switch Actuator onto the switch with the

hole in the actuator facing towards the radio box side. Slide

the Switch Actuator Lever into the hole in the switch

retainer and thread the lever into the actuator.

Note: Inspect the joint between the upper and lower hull. If

there are any areas that are not securely glued, use

medium CA to glue them together. If there are any large

gaps where water could enter the hull, use Shoe-goo to fill

these gaps.

❏1.Locate the four 7/8" x 1/4" x 1/4" [22mm x 6mm x 6mm]

Hardwood Blocks. Use 6-minute epoxy to glue the blocks

in the locations shown in the photo.

Prepare the Hull

6

❏2. Use a 5/64" [2mm] drill bit to drill holes in the center of

the hardwood blocks. Use caution not to drill through the

bottom of the hull.Also, there are two indentations in the hull

towards the transom. Drill these locations using a 5/64"

[2mm] drill bit.

❏3. Thread the Retaining Hooks into the blocks and hull

as shown in the photo above. Screw them in until the

threads are barely visible.

❏4.Trim the front of the hull 1/4" [6mm] inside the outer edge.

This is where the weight to balance the hull will be placed.

❏1. Locate the Upper Tunnel. Trim the upper tunnel along

the lines scribed onto the tunnel.

❏2. Use a 1/8" [3mm] drill bit to drill four holes into the

upper tunnel at the indentations. Use a 1/4" [6mm] drill to

drill the location for the antenna exit.

❏3. Position the upper tunnel onto the hull.The angled end

of the tunnel faces the bow, or front, of the boat. Hold the

tunnel in position and mark the locations for the tunnel hold

down screws through the 1/8" [3mm] holes in the tunnel.

❏4. Use a 5/64" [2mm] drill bit to drill the four locations for

the tunnel hold down screws.

Prepare the Upper Tunnel

7

❏1.Prepare your engine for installation using the instructions

provided with the engine.

Note: It may be necessary to purchase an engine mount for

your particular engine. The hull has been predrilled to use

either the O.S. .21 XM. or the Du-Bro 3.5cc engine mount.

❏2. Attach your engine to the transom using four #8 x 5/8"

Sheet Metal Screws and four #8 Washers. The washers

are placed between the hull and engine mount, two on each

of the lower screws.This is done to accommodate the seam

where the top and bottom hull are joined.

❏1.Assemble the FuelTank using the instructions included

with the tank. Use the 90-degree tube when assembling the

fuel tank.

❏2. Position the fuel tank as shown in the photo. Use one

Rubber Band to secure the position of the tank. Attach the

rubber band to one of the hooks.Stretch the rubber band to

the other hook, then attach the end to the starting hook.

❏1. Use a 7/16" [11mm] drill bit to enlarge the holes for the

pushrod seal mounts.

❏2. Press the Pushrod Seal Mounts into the holes from

the outside of the radio box. Place two or three drops of

medium CA inside the radio box to secure the mounts to the

radio box.

Linkage Installation

Fuel Tank Installation

Engine Installation

8

❏3. Slide the Pushrod Seals onto the mounts. Use

scissors to trim the end of the seal 1/32" [.8mm] so the

pushrod can exit. Use the rubber O-Rings to secure the

seals onto the mounts.

❏4. Temporarily install the radio box using two rubber

bands as shown in step 7.

❏5.Thread a 2-56 Nut onto each of the 17-1/2" Pushrods.

Add a Silicone Retainer to a Threaded Metal Clevis and

thread the clevis onto the pushrod about 14 turns.

❏6. Remove two of the four arms from a cross servo arm.

Switch your radio system on and center the steering trim.

(See your radio manual for details.) Install the servo arm so

it is 90-degrees to the centerline of the servo. Switch your

radio system off and proceed to the next step.

❏7. Slide a pushrod through one of the pushrod seals in the

radio box. Attach the clevis to the steering arm of the engine.

❏8. Position the engine so it is 90-degrees to the transom.

Enlarge the outer most hole in the servo arm using a 5/64"

[2mm] drill bit. Mark one of the pushrods where it crosses

the servo arm. (Make sure the radio box is fully seated

against the hull before marking the pushrod.)

❏9. Make a 90-degree bend in the pushrod on your mark,

then cut off the excess wire 3/8" [9.5mm] above the bend.

Insert the bent wire into the servo arm, then secure the

linkage using a Nylon FasLink®as shown in the sketch.

Bend the pushrod if necessary to provide clearance around

the fuel tank.

❏10. Locate the 24" [610mm] PushrodTube and cut it to a

length of 11-1/2" [293mm]. Roughen the outside of the tube

using 180-grit sandpaper. Slide the tube 2-1/2" [64mm] into

the remaining hole in the radio box as shown. Use medium

CA to glue the tube to the radio box.

GP

9

❏11.Attach the pushrod tube to the pushrod mount on your

particular engine. It is necessary to have the tube bend as

shown. This will allow for full movement for steering and

reduce the amount of throttle change during steering.

❏12. Locate the 24" [610mm] braided pushrod cable and

the solder clevis. Use the following sequence to solder the

clevis to the braided pushrod cable:

A. Lightly sand the pushrod cable and clean it with

alcohol.

B. Insert the pushrod cable into the non-threaded clevis.

The wire should protrude 1/16" [1.6mm] into the fork

of the clevis.

C. Apply a small amount of soldering flux to the joint.

D.Apply heat evenly to the pushrod cable and the clevis

and then touch the solder to the joint and allow it to flow.

E. Allow the pushrod and clevis to cool before continuing.

❏13.Install a brass Screw-lock Connector with the 4-40 x

1/8" Cap Screw on the throttle arm. Snap the Nylon

Retainer onto the screw-lock connector post on the

opposite side of the throttle arm.

❏14.Slide a silicone clevis retainer onto the clevis.Slide the

cable into the pushrod housing, starting from inside the

radio box. As the cable exits the tube, guide it through the

pushrod connector on the throttle arm.

❏15.With the radio switched on, install the servo arm onto

the throttle servo as shown in the photo. Manually close the

throttle on the carburetor completely.Tighten the cap screw

on the screw-lock pushrod connector. Check the throttle

operation with the radio and make adjustments to the

linkages as necessary for smooth operation. Use the

appropriate holes in the throttle servo arm to provide the

correct amount of throttle movement and to prevent the

servo from binding at its end points.

❏16.Once the throttle has been adjusted, slide the silicone

clevis retainer in position. Cut a mixing stick to fit inside the

radio box as shown. Use medium CA to glue the stick in

position. Glue the throttle tube to the stick, being careful not

to get any glue inside the pushrod tube.

10

❏1.Temporarily tape the Radio Box Cover to the radio box.

❏2. Measure and record the position of the switch.Transfer

this measurement onto the upper tunnel and drill a 3/16"

[4.8mm] hole at the location.Use a hobby knife to “fine tune”

the location of the hole if necessary.

❏3. Place the tunnel in position.Using a pen or leftover from

the steering pushrod, mark the location of the antenna exit

through the hole in the upper tunnel onto the radio box cover.

❏4.Remove the radio box cover and use a 5/32" [4mm] drill

bit to drill a hole for the antenna in the radio box cover.

❏5. Sand the end of the Antenna Tube to a slight taper

(this will permit you to thread the hex nut on).

❏6. Grasp the antenna tube firmly and thread one of the

6-32 Hex Nuts 1/4" [6mm] onto the tube with a pliers.HINT:

If you find it difficult to turn the nut, try holding the tube with

another pliers, locking the tube in a vise (use light pressure

to avoid crushing the tube), or having someone else hold

the antenna tube with two hands while you turn the nut.

❏7. Insert the antenna tube into the hole drilled in the radio

box cover and secure it with another 6-32 hex nut.

❏8. Route the receiver antenna through the antenna tube

so approximately 2" of the antenna protrudes out the top of

the tube.Do not cut off any excess antenna length. Wrap

the excess together and place it inside the radio box.

Radio Box Cover Installation

11

❏9.Install the radio box cover onto the radio box using clear

tape. Make sure the tape fully seals the radio box cover so

water does not enter the radio box.

❏10. Secure the radio box to the hull using a total of eight

rubber bands.

❏11. Attach the fuel lines from the fuel tank to the engine.

(See the instructions that came with your engine for more

details.) Allow enough slack in the lines to allow the engine

to move fully to the right and left without pulling on the lines,

possibly causing them to come off during operation.The fuel

tank is filled using the line connected to the carburetor.

When the tank is full, the excess fuel will come out of the

fuel line connected to the muffler.

❏12.Attach the upper tunnel to the hull using four #4 x 1/2"

Sheet Metal Screws and four #4 Washers.

❏13. Using 400-grit sandpaper, lightly sand the bottom of

the sponson and one side of the Speed Strip. Use a paper

towel and rubbing alcohol to remove any dirt or oil from the

sponson and speed strip. Position the speed strip so it

slightly overhangs the edges of the sponson. Glue the

speed strip onto the bottom of the sponson using medium

CA. Use the photos on the box for further positioning of the

speed strips.

NOTE: DO NOT reshape the speed strips. They are

designed to slightly overhang the edges of the sponson.

The sharp edge on the speed strip forces the water to

“break free” of the sponsor, rather than cling to it during

operation. This reduces the amount of water friction,

allowing the boat to “get up on plane” faster and operate at

a higher speed than without the speed strips. The only

modification to the speed strip would be to lightly sand the

edges to re-sharpen them if your Top Speed encounters

anything that damages the edges of the speed strip.

❏1. Using a scissors or a hobby knife, cut out the Decals.

❏2. Clean the exterior of your boat thoroughly with warm,

soapy water. Rinse and dry thoroughly.

❏3.Peel off the protective backing and apply the self-adhesive

decals, referring to the photos on the box label.HINT:To apply

large decals, peel only a small portion of the backing from one

end. Cut off the backing with a scissors. Then, position the

decal carefully. Press down the exposed portion of the decal

and remove the rest of the backing.Working from the attached

end, carefully press down the rest of the decal, working any air

bubbles out as you go.

Note: This section is VERY important and must NOT be

omitted! A model that is not properly balanced will be

unstable and possibly flip over during operation.

❏1. The balance point (C.G.) is located 7-1/2" [193mm]

forward of the transom.This is the balance point at which your

model should balance for your first runs.After initial trim runs

and when you become more acquainted with your Top

Speed, you may wish to experiment by shifting the balance

forward or backward to change its operating characteristics.

Changing the location of the CG will change the handling

characteristics of your boat.Read the “Operational Trimming”

section at the end of the manual thoroughly to “fine tune” the

performance of your boat.

Balancing Your Model

FINAL PREPARATIONS

Apply the Decals & Trim

FINISHING

12

❏2. With all the parts of the model installed (ready to run)

and an empty fuel tank, lift the model at the balance point.

If the transom of the boat drops, the model is “tail heavy”

and you must add weight to the front to balance the model.

If the bow drops, it is “nose heavy”and you must add weight

to the rear of the boat to balance the model.

Inspect your radio installation and confirm that all the

controls respond correctly to the transmitter inputs. The

engine operation must also be checked by confirming that

the engine idles reliably, transitions smoothly and rapidly to

full power and maintains full power, indefinitely. The engine

must be “broken-in” following the engine manufacturer’s

recommendations. Make sure that all screws remain tight,

that the linkages are secure and that the prop is on tight.

Whenever you go to the pond, check the operational range of

the radio before the first run of the day.First, make sure no one

else is on your frequency (channel).With your transmitter and

receiver on, you should be able to walk at least 100 feet away

from the model and still have control. While you work the

controls, have a helper stand by your model and tell you what

the control surfaces are doing. If the control surfaces are not

always responding correctly, do not run your boat! Find and

correct the problem first. Look for loose servo connections or

corrosion, loose bolts that may cause vibration, a defective

on/off switch, low battery voltage or a defective receiver battery,

a damaged receiver antenna, or a receiver crystal that may

have been damaged.

Note: Failure to follow these safety precautions may result

in severe injury to yourself and others.

Keep all engine fuel in a safe place, away from high heat,

sparks or flames, as fuel is very flammable. Do not smoke

near the engine or fuel; and remember that the engine

exhaust gives off a great deal of deadly carbon monoxide.

Do not run the engine in a closed room or garage.

Get help from an experienced modeler when learning to

operate engines.

Use safety glasses when starting or running engines. Do

not run the engine in an area of loose gravel or sand; the

propeller may throw such material in your face or eyes.

Keep your face and body as well as all spectators away

from the plane of rotation of the propeller as you start and

run the engine.

Keep these items away from the prop: loose clothing, shirt

sleeves, ties, scarfs, long hair or loose objects such as

pencils or screwdrivers that may fall out of shirt or jacket

pockets into the prop.

Use an electric starter to start the engine. Do not use your

fingers to flip the flywheel. Make certain the glow plug clip

or connector is secure so that it will not pop off or otherwise

get into the running propeller.

Make sure that any wires from your glow plug clip or starter

are clear of the propeller before starting the engine.

The engine gets hot! Do not touch it during or right after

operation.Make sure fuel lines are in good condition so fuel

will not leak onto a hot engine, causing a fire.

To stop a glow engine, cut off the fuel supply by closing off

the fuel line or following the engine manufacturer’s

recommendations. Do not use hands, fingers or any other

body part to try to stop the engine. Do not throw anything

into the propeller of a running engine.

If you have followed all of the previous instructions and find

everything to be operating properly, your Top Speed should

now be ready to run! Here is the procedure that should be

followed (some of these steps may already be completed):

❏1.If your radio system has rechargeable batteries, charge

the transmitter and receiver batteries, according to the radio

manufacturer’s instructions.

❏2.Turn on the transmitter and receiver (in that order).

❏3. Check to make sure the throttle and steering are

operating properly. NOTE: Looking at the boat from the rear,

the aft edge of the engine must move to the right when the

transmitter steering wheel/stick is turned right (clockwise).

❏4. Ask yourself, “If the boat becomes dead in the water,

will I be able to retrieve it either by waiting for the wind to

blow it in to shore, or by using a retrieval boat?” There is

always a chance of something going wrong and the boat

going “dead”; therefore, you should always have a plan for

retrieval in that event.

Caution: If you go out in a boat to retrieve a model boat, be

sure to wear an approved floatation device. Never swim or

wade in the water to retrieve a model boat!

Operating Procedures

Engine Safety Precautions

Range Check Your Radio

Operation Check

13

❏5. Start and adjust the engine following the procedures

outlined in the instructions included with your particular engine.

❏6. Place the boat in water that is at least 8 inches deep

and free of debris that may tangle or damage the prop.

❏7. Advance the throttle and note if the boat has a

tendency to turn right or left. Adjust the steering trim tab on

your transmitter until the boat runs in a straight line when the

wheel/stick is neutralized.

❏8. Try some turns to the right and left. First, make big

gentle turn and gradually make tighter turns to see how your

Top Speed handles. If your Top Speed “spins out” or is on

the verge of flipping over in tight turns, you can reduce the

steering movement by making adjustments on your

transmitter (if you have a transmitter that allows this type of

“endpoint adjustment”.) To prevent swamping, avoid making

tight turns in rough water.

❏9. Total run time of the Top Speed is approximately 5-6

minutes on a full tank of fuel. It is suggested to use a timer

to time your Top Speed to prevent it from stopping while in

the middle of your pond or lake.

❏10. After operating your Top Speed, place it on the stand.

Use paper towels to dry off the hull. Remove the upper

tunnel and check the radio box to see if any water has

entered.If so, remove the radio box cover and dry the inside

of the box. Check the propeller for weeds or other debris.

Remove any foreign material which may have become

entangled. WARNING: If, during operation, you notice the

boat suddenly slow down or loose power, it probably means

that weeds or other debris have tangled around the

propeller. This could cause excessive overheating of the

engine, therefore, you should immediately bring the boat to

shore, shut off the engine and inspect the engine and

propeller for any foreign matter and remove it.

❏11.When you have finished for the day, dry the boat inside

and out and recharge the batteries. Place the boat on its

stand for storage.Periodically (and for long term storage) you

should also remove the radio box cover, wipe it off and clean

out the inside of the radio box. You should also read the

instructions included with your engine for any procedures to

prepare the engine for long term storage.

IMPORTANT NOTE: If, for whatever reason, your boat takes

on a large amount of water, swamps or sinks, causing the

radio equipment to get wet, you must do the following:

Immediately remove all batteries and radio equipment from

the boat. Open the receiver (if water has entered the plastic

bag) and servo cases (if not watertight servos) and dry all

components completely before reassembling. To dry

electrical components, use a paper towel to absorb the water

droplets. Then, use a hair dryer to make sure they are

completely dry. Dry the inside of the radio box and reinstall

the components and check for proper operation before

running the boat in water.

Because the outboard engine can be adjusted in both

vertical positioning and angle, the following trimming guide

will give you a rough overview on how to adjust your Top

Speed to pick up some additional speed:

ENGINE ANGLE

Changing the angle of the engine in relationship to the

transom will change the angle of the hull in relationship to

the water. By rotating the engine so the lower end is farther

away from the transom will lift the front (bow) of the boat out

of the water. By rotating the engine so the lower end is

closer to the transom will force the bow of the boat into the

water. The angle of the engine should be adjusted so the

sponson rides level when cornering.

CENTER OF GRAVITY

Changing the center of gravity will also alter the angle of the

hull in the water. Adding weight to the bow of the boat

(moving the CG forward) will push the bow into the water.

Adding weight to the transom of the boat (moving the CG

aft) will lift the bow of the boat out of the water. Adjust the

CG as necessary so the boat rides level in the water.

ENGINE HEIGHT

Moving the position of the engine vertically on the transom

will change the vertical positioning of the hull in relationship

to the water. By moving the engine downward on the

transom, the hull will ride higher in the water. Moving the

engine upward will cause the hull to ride lower, or more in

the water. Begin by positioning the engine so the mounting

screws are in the middle of the adjustment range of the

engine. On smooth water, run your Top Speed and observe

the positioning of the hull in relationship to the water. The

best positioning of the Top Speed is to have it “skim” slightly

out of the water.

In addition to the items listed under “Top Speed Operating

Procedures,” you should also check the following regularly:

❏1. Periodically check to see if the engine is securely

attached to the transom. Because of the amount of force

applied to the hull during operation, it is possible these

screws may loosen.

❏2. Periodically check the steering linkages for free

movement. In time, the engine may accumulate debris

between the mount plate and outboard unit. If this happens,

remove the outboard unit (following the manufacturers

instructions) and clean both the mount plate and outboard

unit. Reassemble and check for free movement.

❏3. After running in salt water, clean the boat thoroughly

with fresh water. Follow the manufacturers instructions on

cleaning and maintenance for your particular engine.

Maintenance

Operational Trimming

14

Although it is very enjoyable to go out alone and “hot dog”

with yourTop speed, we think the real fun and excitement is

experienced when you get involved in RACING!

Racing does not have to be an organized and sanctioned

competition to be fun. In fact, small, informal races can be

very exciting without the stress that comes with the more

formal ones.

Following are some suggestions for setting up a simple race

course for electric boats:

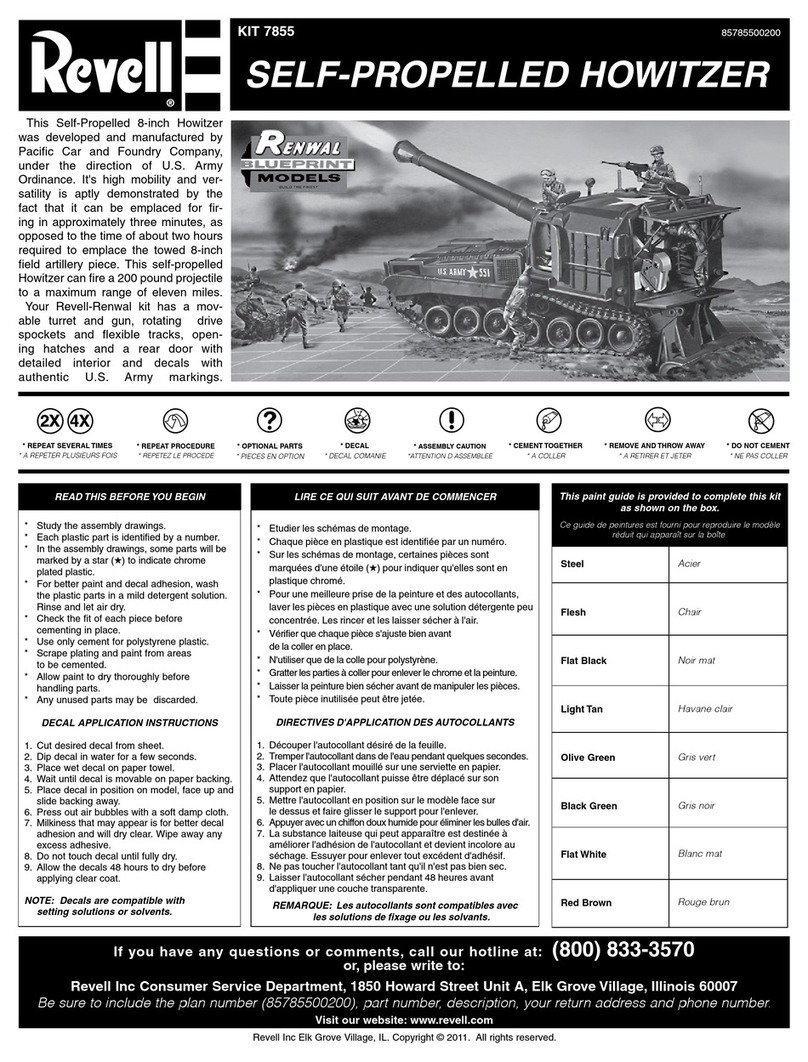

1. Make 2, 3 or 4 simple and inexpensive “marker buoys”

with empty milk jugs, string and heavy objects for anchors,

similar to the above sketch.

2. For “drag racing” place the buoys in a pattern similar to

the above sketch.

3. For “oval racing” place the buoys in a pattern similar to

the above sketch.

NOTE: The above patterns are “about right” for racing

electric boats, and they are not based on any official

standards; therefore, you can set up courses any way you

desire, using your imagination to make the races more

interesting. Usually the smaller courses will provide more

action and excitement.

Races will be more exciting if the boats are closely matched

in performance. Two or three Top speeds in the same race

can be a lot of fun, especially if they are all using battery

packs having the same number of cells. If you must race

boats having large speed differences, try giving the slower

boats a “handicap.” For instance, give the slower boats a

1/2-lap or 10 second head start (more or less, depending on

the speed difference and length of the race).

The length of the race can be determined by a set

number of laps around the buoys (for example, the first boat

to complete 5 laps is the winner); or by time (for example,

whoever is leading at the end of 2 minutes is the winner).

The RBRC Battery

Recycling Seal on the

nickel-cadmium (NiCd)

battery that should be

used in our product,

indicates Hobbico is

voluntarily participating in

an industry program to

collect and recycle these

batteries at the end of

their useful life, when

taken out of service in the United States or Canada. The

RBRC program provides a convenient alternative to placing

used NiCd batteries into the trash or the municipal waste

system, which is illegal in some areas. Please call 1-800-

822-8837 for information on Ni-Cd battery recycling in your

area. Hobbico's involvement in this program is part of our

commitment to preserving our environment and conserving

our natural resources.

RECYCLING

RACING FUN WITH YOUR TOP SPEED

15

GPMQ4103 1 Fuel tank

GPMZ0261 1 Instruction manual

METAL013 2 2-56 Threaded clevis

METAL030 1 Solder clevis

METAL056 1 Quick connector

METAL076 6 Cup hooks

NUTS005 2 2-56 Hex nut

NUTS010 2 6-32 Hex nut

NYLON177 1 Kwik switch 203-B

NYLON178 1 Waterproof pushrod seal

NYLON85C 1 Retainer

NYLON91 2 Faslink pushrod keeper

PLTB012 1 11-3/4" Tube white

PLTB020 1 24" Pushrod tube

PLTB021 3 Clevis retainer

PLTB028 1 Fuel tubing

SCRW004 4 #4x1/2" Sheet metal screw

SCRW054 4 #8x5/8" Truss head sheet metal screw

SCRW100 1 4-40x1/8" Socket head cap screw

TPSD001 1 Radio cover

TPSDD01 1 Decal 1

TPSDD02 1 Decal 2

TPSPDDC01 2 3x30" Speed strip

TPSPDDC02 1 Stand support

TPSPDDC03 2 Stand sides

WIRES11 2 17-1/2" Pushrod treaded one end

WIRES73 1 24" Cable

WSHR005 4 #4 Flat washer

WSHR011 4 #8 Flat washer

PARTS ORDERING INFORMATION

❑PAYMENT ENCLOSED SUB-TOTAL

❑PLEASE SEND C.O.D. S & H $4.50

❑VISA ❑M/C C.O.D. ADD $5.00

CARD # 2ND DAY AIR ADD $10.00

EXP DATE / NEXT DAY AIR ADD $20.00

❑PLEASE SEND CATALOG IL. RES. ADD 7.25%TAX

TOTAL

NAME __________________________________________

ADDRESS_______________________________________

CITY_________________________ST____ZIP_________

PHONE # ________________________

SEND TO:

Great Planes Model Mfg.

P.O. BOX 788, Urbana, IL 61803

or Phone (217) 398-8970 for C.O.D. orders

We do accept MasterCard and Visa credit cards.

Please print clearly on all orders. Note: Parts and

prices are subject to change without notice.

Printed in USA

CALL OR WRITE FOR CURRENT PRICES

HAND-CRANK FUEL PUMP............................HCAP3015

Uniquely geared for smooth, efficient, long-lasting

operation, this pump delivers 1/4-oz. of glow fuel with every

turn of the handle. It fills or drains with equal ease. The

durable nylon case includes flanges for easy field box

attachment. Fuel tubing is also included.

HOBBICO®TORQMASTER™STARTER........HCAP3200

TorqMasters include easy-press start switch, turned

aluminum starter cone w/grooved silicone insert and 5’input

cord. *TorqMaster 90* starts engines up to .90; *TorqMaster

180*, engines up to 1.8 cu. in.

Table of contents