Topdon ArtiLink300 User manual

Hotline (+86)0755-23576169

Email [email protected]

Website www.topdondiagnostics.com

Facebook @TopdonOcial

Twitter @TopdonOcial

If you have any questions or doubts, please contact

us via

PS

E

ArtiLink300

Code Reader

USER MANUAL

Content

Welcome ......................................................................................1

About............................................................................................1

Package List................................................................................1

Compatibility ...............................................................................1

Notice...........................................................................................1

General Information of OBDII (On-Board Diagnostics II).......... 2

Diagnostic Trouble Codes (DTCs) .............................................. 2

Features.......................................................................................3

Operation Introduction................................................................ 4

Technical Specication.............................................................17

Warranty ...................................................................................17

Warnings....................................................................................18

Cautions.....................................................................................18

FAQ.............................................................................................19

-1-

Thank you for purchasing TOPDON OBD2 scan tool ArtiLink 300.

Please patiently read and understand this User Manual before

operating this product.

About

As designed to work with all OBDII compliant vehicles, including

Controller Area Network (CAN), TOPDON ArtiLink 300 supports all

10 modes of OBDII test for a complete diagnosis. It enables users

to Read/Clear DTCs, run I/M Readiness test, check Live and Freeze

Frame Data etc., with built-in help menus and code denitions.

Package List

1.ArtiLink 300

2.Quick Start Guide

3.User Manual

Welcome

Compatibility

TOPDON ArtiLink 300 is compatible with following protocols:

• KWP2000

• ISO9141

• J1850 VPW

• J1850 PW

• CAN (Controller Area Network)

Notice

ArtiLink 300 may automatically reset while being disturbed by

strong static electricity. THIS IS A NORMAL REACTION.

-2-

Diagnostic Trouble Codes (DTCs)

General Information of OBDII (On-Board

Diagnostics II)

The OBDII system is designed to monitor emission control

systems and key engine components by performing either

continuous or periodic tests of specific components and

vehicle conditions, which will offer three pieces of such

valuable information:

1. Whether the Malfunction Indicator Light (MIL) is

commanded “on” or “off”;

2. Which, if any, Diagnostic Trouble Codes (DTCs) are stored;

3. Readiness Monitor status.

-3-

ArtiLink300CodeReaderUserManual

Features

▼

▲

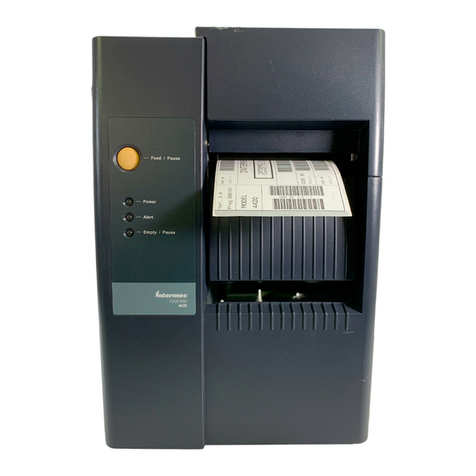

1. LCD - Show test results.

2. OK - To conrm the current operation.

3. EXIT - Back to the previous page.

4. - Move down for selection. Or skip to the next page

when more than one page is displayed.

5. - Move up for selection. Or skip to the previous page

when more than one page is displayed.

6. 16-pin Connector - To connect to the vehicle's DLC (Data

Link Connector).

-4-

ArtiLink300CodeReaderUserManual

Operation Introduction

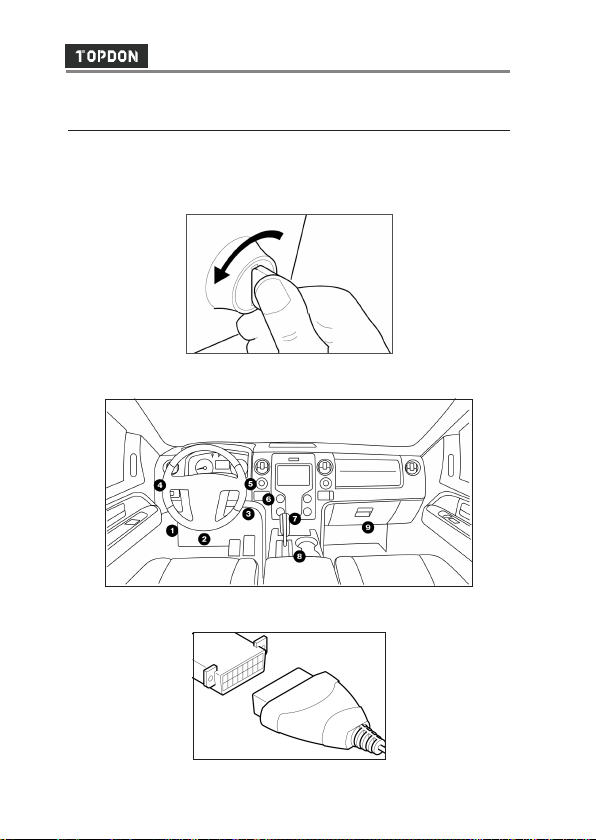

1. Preparation & Connection

1. Turn the ignition off.

2. Locate the vehicle’s DLC socket.

3. Plug the diagnostic cable into the vehicle’s DLC socket.

-5-

4. Turn the ignition on. The engine can be off or running.

5. ArtiLink 300 will start initializing and enter the main menu.

*Note: Don’t connect or disconnect any test equipment with

ignition on or engine running.

2. Diagnose

Select [Diagnose] in Main Menu and press [OK]. The tool will

automatically start a check of the vehicle’s computer.

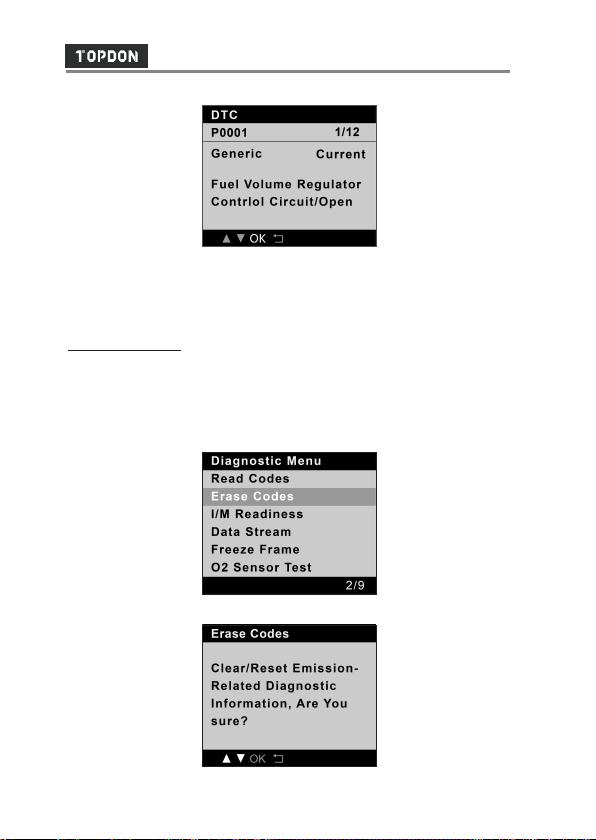

2.1 Read Codes

This option identies which section of the emission control

system has malfunctioned.

Select [Read Codes] and press [OK].

The DTC with its denition will be displayed on screen.

-6-

*Note:NeverreplaceapartbasedonlyontheDTCdenition.

Always refer to the vehicle’s service manual for detailed

testing instructions.

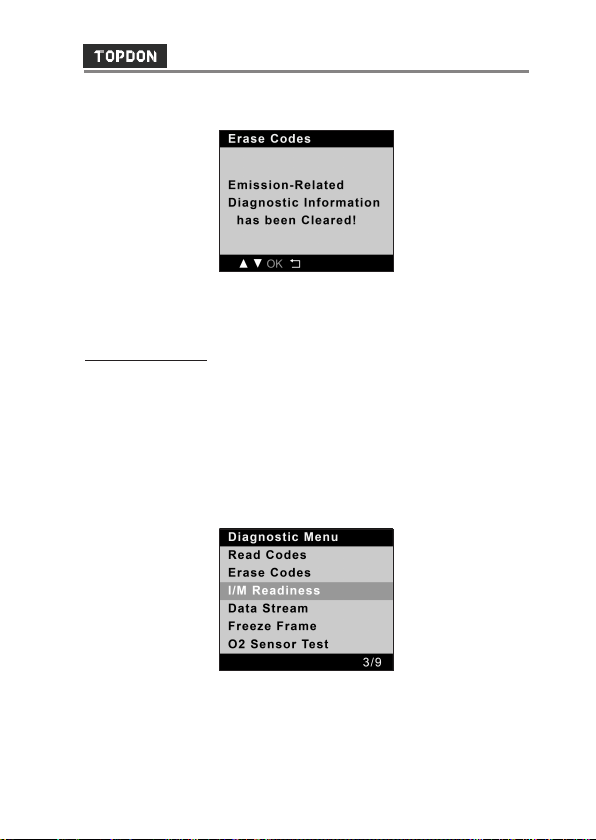

2.2. Erase Codes

This option erases the codes from the vehicle after retrieving

codes from the vehicle, and certain repairs have been carried

out.

Select [Erase Codes] and press [OK].

Press [OK] to conrm erasing.

-7-

The result will be displayed on screen.

*Note: Be sure the vehicle’s ignition key is in the ON position

with the engine off.

2.3 I/M Readiness

This option checks whether or not the various emissions-

related systems on the vehicle are operating properly, and

are ready for Inspection and Maintenance testing.

It is also can be used to confirm that the repair has been

performed correctly, and/or to check for Monitor Run Status,

after the repair of a fault has been performed.

Select [I/M Readiness] and press [OK].

Select an option, and press [OK].

-8-

The result will be displayed on screen.

*Explanation of terms:

• CAT_RDY - Catalyst Monitor Ready?

• HCAT_RDY - Heated Catalyst Monitor Ready?

• EGR_RDY - EGR System Monitor Ready?

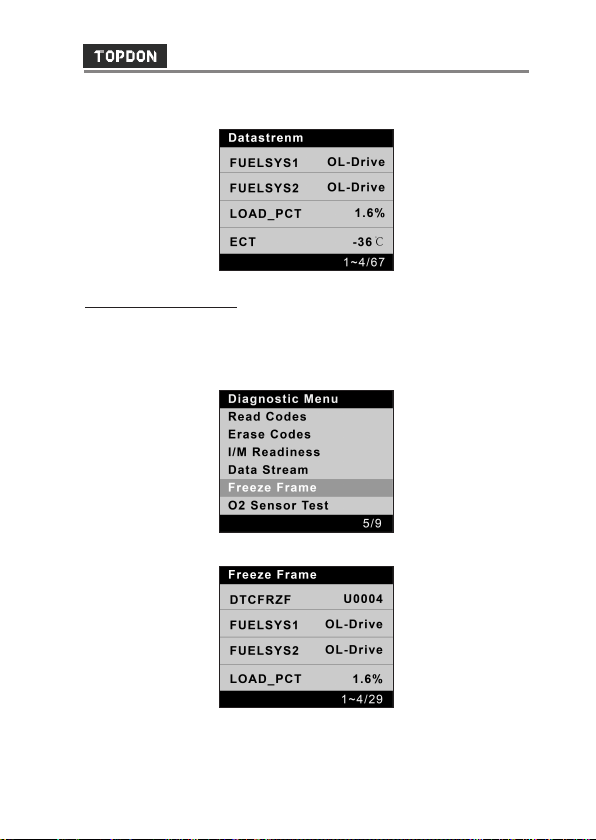

2.4 Data Stream

This option retrieves and displays live data and parameters

from the vehicle’s ECU.

Select [Data Stream] and press [OK].

-9-

The result will be displayed on screen.

2.5 View Freeze Frame

This option takes the snapshot of the operating conditions

when an emission-related fault occurs.

Select [Freeze Frame] and press [OK].

The result will be displayed on screen.

*Note: if DTCs were erased, Freeze Data may not be stored in

vehicle memory depending on vehicle.

-10-

2.6 O2 Sensor Test

This option retrieves O2 sensor monitor test results of the

most recently completed tests from your vehicle’s on-board

computer.

Select [O2 Sensor Test] and press [OK].

Select an option, and press [OK].

Select an option, and press [OK].

The result will be displayed on screen.

-11-

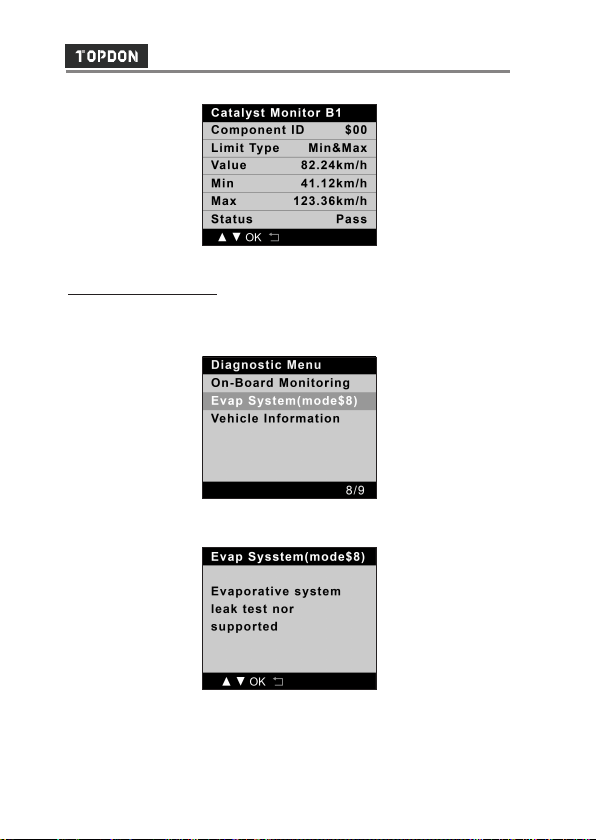

2.7 On-Board Monitor Test

This option retrieves test results for emission-related

powertrain components and systems that are not

continuously monitored. The tests available are determined

by the vehicle manufacturer.

Select [On-Board Monitoring] and press [OK].

Select an option, and press [OK].

The result will be displayed on screen.

-12-

2.8 EVAP System Test

This option initiates a leak test for the vehicle’s EVAP system.

Select [EVAP System (mode$8)] and press [OK].

If the vehicle doesn’t support mode$8, the following result will be

displayed on screen.

*Note: Before using the system test function, refer to the

vehicle’s service repair manual to determine the necessary

procedures.

-13-

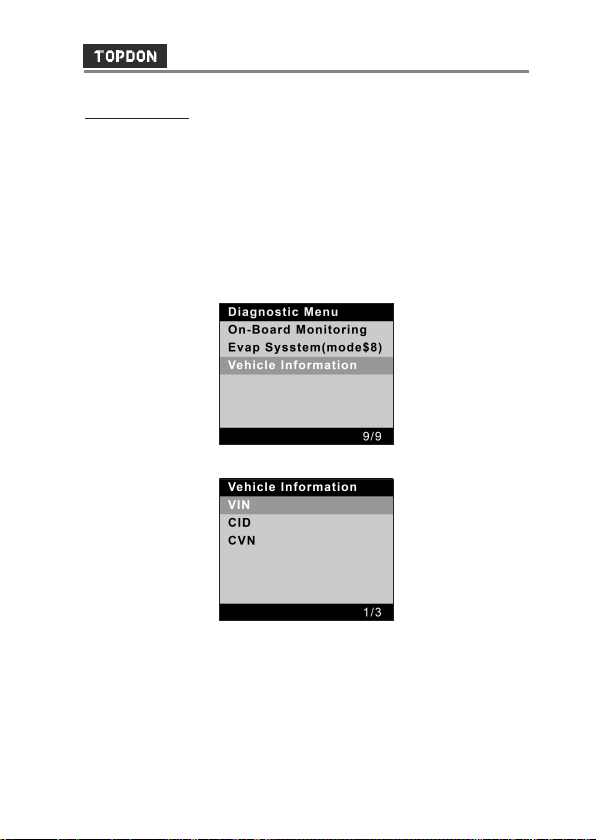

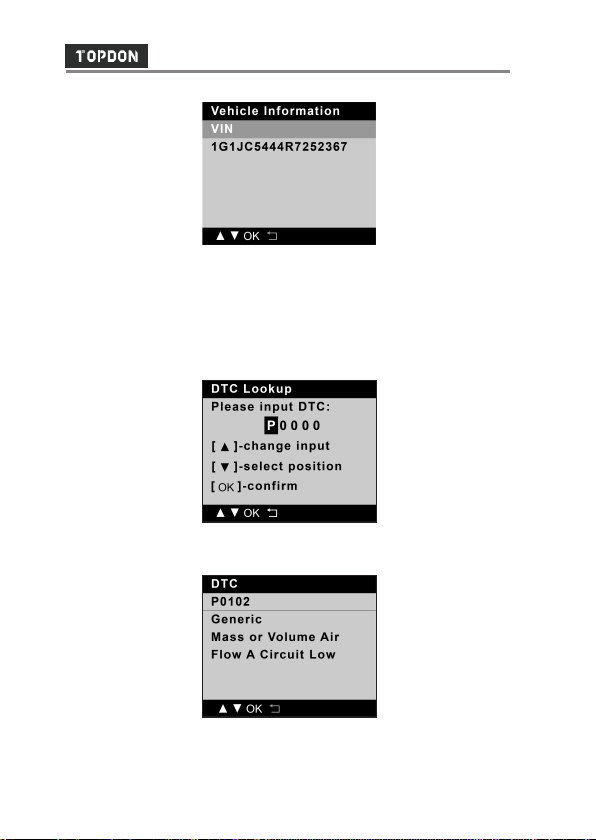

2.9 Vehicle Info

This option retrieves a list of information (provided by the

vehicle manufacturer) from the vehicle’s on-board computer.

This information may include:

• VIN (Vehicle identication Number).

• CID (Calibration ID).

• CVN (Calibration Verication Number).

Select [Vehicle Information] and press [OK].

Select an option, and press [OK].

The result will be displayed on screen.

-14-

ArtiLink300CodeReaderUserManual

3. DTC Lookup

This function enables you to view the detailed definition of

the retrieved DTC.

Select [DTC Lookup] in the Main Menu and press [OK], the

following screen will appear:

After you input the DTC, press [OK] to view its detailed

denition.

-15-

ArtiLink300CodeReaderUserManual

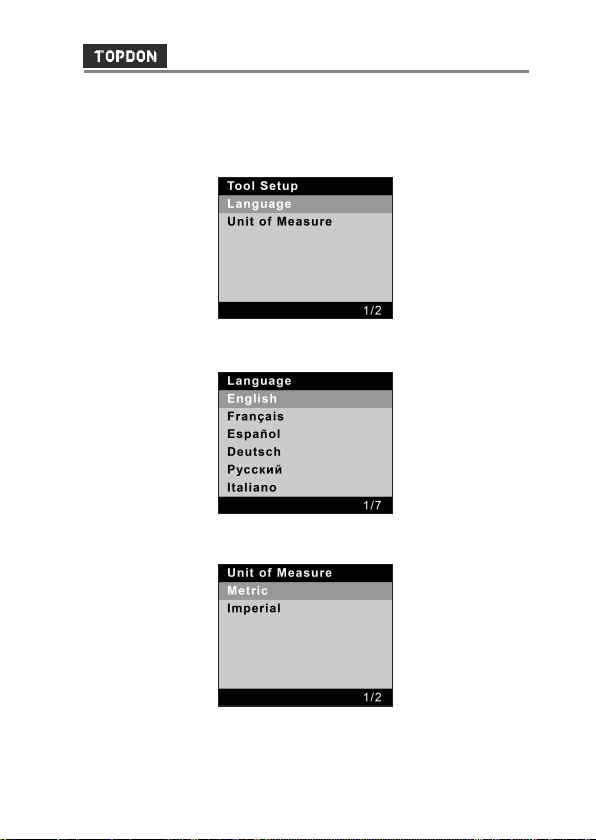

4. Settings

Select [Tool Setup] in the Main menu and press [OK], the

system will enter the tool setup screen.

• Language

This option enables you to set the user interface language.

• Unit of Measure

This option allows you to set measurement unit.

-16-

ArtiLink300CodeReaderUserManual

5. Help

This function enables you to view the tool information and the

OBD introduction.

Select [Help] in the Main menu and then press [OK].

The following options will be displayed on screen.

• About OBD - Relevant introduction information about OBD.

• About Datastream - Relevant introduction information

about Data Stream.

• About I/M - Introduces the full name and detailed

denition of each I/M monitor.

• Tool Information - Displays the related information of your

tool.

-17-

ArtiLink300CodeReaderUserManual

TechnicalSpecication

Display: 1.77”color LCD

Input Voltage Range: 9~18V

Working Temperature: 0 to 50°C (32℉to 122℉)

Storage Temperature: -20 to 70°C (-4℉to 158℉)

Dimensions: 119 * 71.7 * 23.3 mm (4.68 * 2.82 * 0.91 inch)

Weight: 210g (0.46 lb)

Warranty

TOPDONOne Year Limited Warranty

The TOPDON Company warrants to its original purchaser

that TOPDON products will be free from defects in material

and workmanship for 12 months from the date of purchase

(Warranty Period). For the defects reported during the

Warranty Period, TOPDON will, according to the technical

support analysis and conrmation, either repair or replace the

defective part or product.

This limited warranty is void under the following

conditions:

• Misused, disassembled, altered or repaired by a non-

TOPDON technical repair specialist.

• Careless handling and violation of operation.

Table of contents

Other Topdon Barcode Reader manuals