TOPMAQ LGK-80S User manual

Processes

PlasmaArcCutting

Description

Input:Output:

Plasma Arc Cutting Power Source

USER

S

MANUAL

LGK-

80S

INVERTER AIR PLASMA CUTTING MACHINE

Please

read

the

User

s

Manual

carefully

before

use

the

machine.

CONTENTS

IDENTIFYINGSAFETYINFORMATION

●Thesymbolsarebeingusedtoidentifypotentialrisks.

●

When

seen

a

safety

symbol

in

the

manual,

it

must

be

understood

that

there

is

an

injury

risk

and

following

instructions

must

be

read

carefully

to

avoid

potential

risks.

●

While

welding

and

cutting,

keep

the

third

persons

and

especially

the

children

away

from

the

work

area.

UNDERSTANDINGTHESAFETYWARNINGS

Read

carefully

the

manual

and

the

labels

and

the

safety

warnings.

Learntooperatethemachineand howtomakethecontrolsproperly.

Operate

your

machine

in

convenient

work

areas.

Improper

modifications

a

f

fect

the

safety

of

your

machine

negatively

and

shorten

i

t

s

lifetime.

SAFETY

RULES

........................................................................

.................................

....................................

...

.

2

ELECTROMAGNETIC

COM

PA

TIBILIT

Y

......................................................................................................

...

.

6

1.TECHNICALINFORMATIONS........................................................................................................................7

1.1GENERALEXPLANATIONS......................................................................................................................7

1.2APPLICATIONAREA..................................................................................................................................7

1.3SYMBOLANDMEANINGON DATAPLATE...........................................................................................7

1.4ENVIRONMENTALCONDITIONS............................................................................................................8

2.INSTALLATION................................................................................................................................................9

2.1UPONRECEIPTANDCLAIMS..................................................................................................................9

2.2WORKAREA...............................................................................................................................................9

2.3

INS

T

ALL

A

TION

AND

USAGE

OF

THE

MACHINE

................................................

.................................

9

2.3.1CONNECTTHEMACHINETOPOWERSUPPLY.........................................................................10

2.3.2CONNECT OUTPUT( )ANDOUTPUT(+)................................................................................11

2.3.3 CONNECTTOTHEREGULATORANDAIRSUPPLY....................................................................11

3.USAGEINFORMATION...................................................................................................................................11

3.1THEPOWERSOURCEFRONTPANEL.........................................................................................................11

3.2ADJUSTINGTHEGASFLOW...................................................................................................................11

3.3 ARCSTARTINGFOR CUTTING PRESSES..........................................................................................11

3.4ADJUSTINGTHECUTTINGCURRENT..................................................................................................11

4.MAINTENANCEANDTROUBLESHOOTING...............................................................................................12

4.1PERIODICMAINTENANCE......................................................................................................................12

4.2NONPERIODICMAINTENANCE.............................................................................................................12

4.3

BASIC

TROUBLESHOOTING

.....................................................................................................

...

...

.....

...

13

-1-

SAFETY

RULES

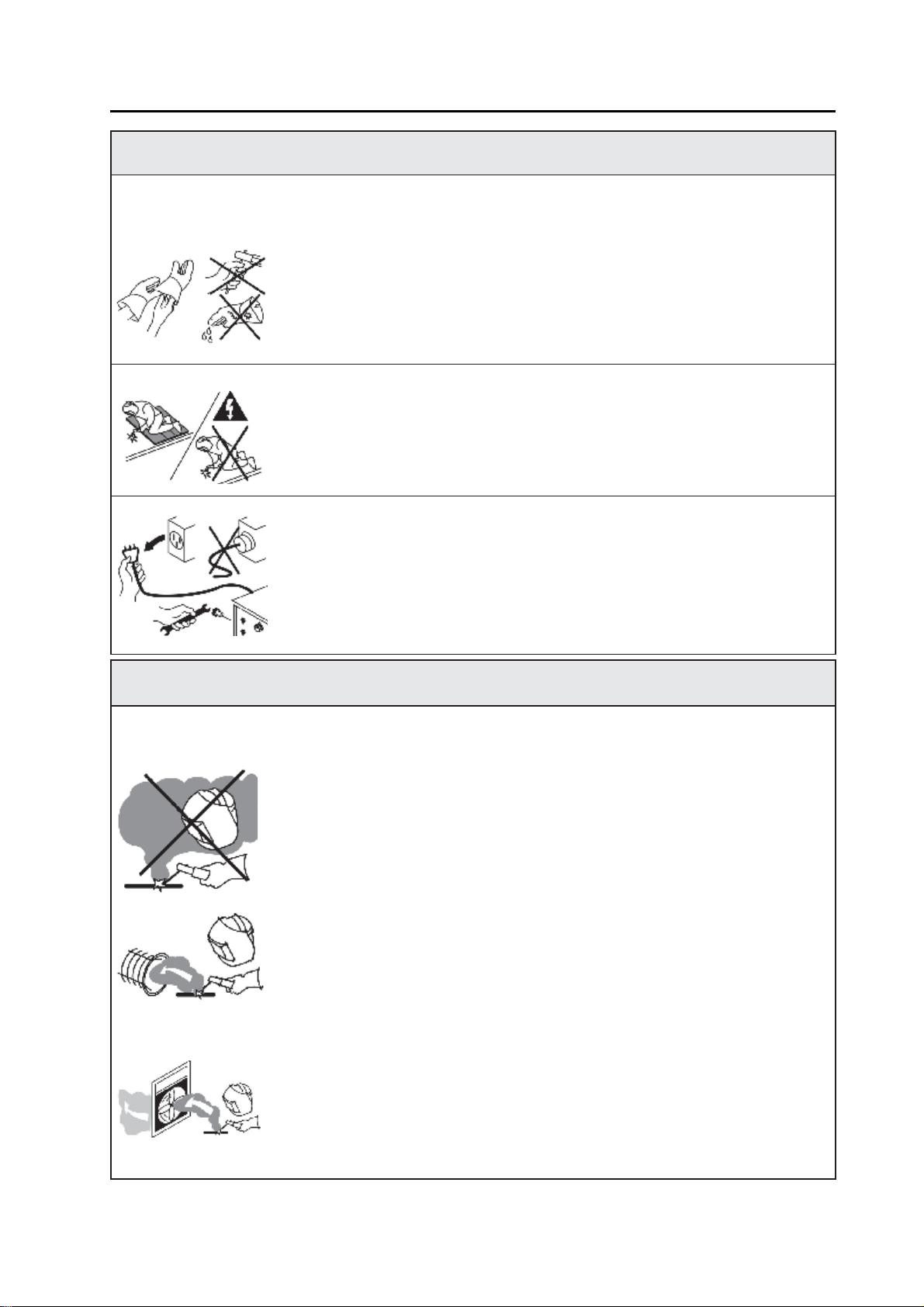

ELECTRICALSHOCKCOULDBEFATAL

Installationproceduremustcomplywithnationalelectricitystandardsandotherrelevantregulations

and

ensure

that

installation

is

performed

by

qualified

persons.

●Weardry,hole-freeinsulatingglovesandbodyprotection.

●

Do

not

touch

electrode

with

bare

hand.

Do

not

wear

wet

or

damaged

gloves

and

bodyprotection.

●Donottouchliveelectricalparts.

●Nevertouchelectrodewhileincontactwithworkingsurface,groundoranother

electrodewhichisconnectedtoadifferentmachine.

●Protectyourselffromelectricshockbyinsulatingyourselffromworkandground.

Usenon-flammable,dryinsulatingmaterialifpossible,orusedryrubbermats,dry

wood

or

plywood,

or

other

dry

insulating

material

big

enough

to

cover

your

full

area

of

contact

with

the

work

or

ground,

and

watch

for

fire.

●Neverconnectupmorethan1electrodesorwirestothemachine.

●Turnoffthemachine,whennotinuse.

●Disconnectinputplugorpowerbeforeworkingonmachine.

●

Frequently

inspect

input

power

cord

for

damage

or

bare

wiring

-

repair

or

replace

cord

immediately

if

damaged.

●

Be

sure

input

ground

wire

is

properly

connected

to

a

ground

terminal

in

disconnect

boxorreceptacle.

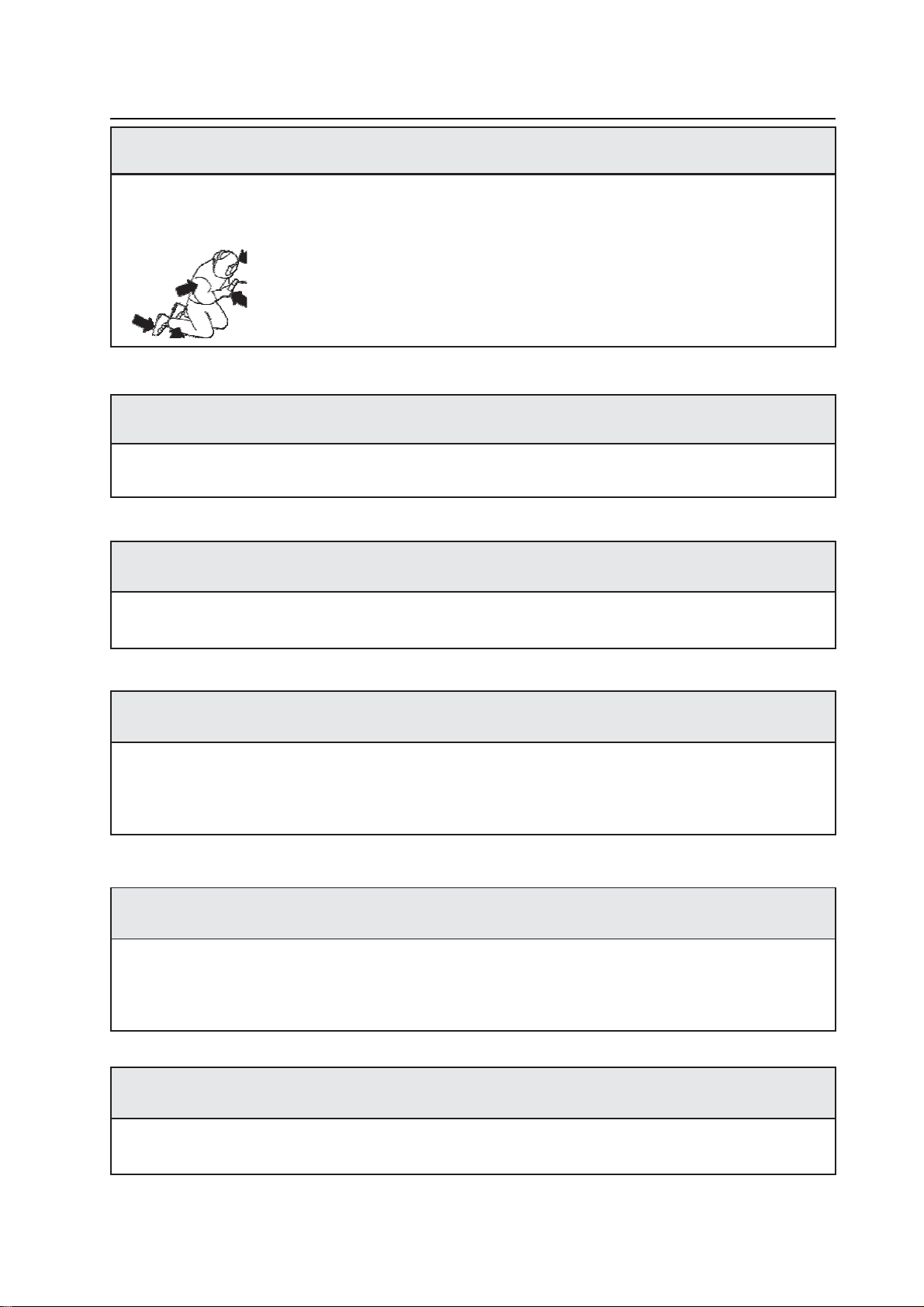

BREATHINGWELDINGFUMESCANBEHAZARDOUSTOYOURHEALTH

Inhalingfumesandgasesoveralongperiodoftime,generatedduringweldingisdangerousand

forbidden.

●Irritationoftheeyes,noseandthroataresymptomsofinadequateventilation.Take

immediatestepstoimproveventilation.Donotcontinueweldingif symptoms

persist.

●Installanaturalorforcedairventilationsystemintheworkarea.

●Installanadequateventilationsystemintheweldingandweldingarea,ifneeded

installasystemthatcanremovethefumeandvaporaccumulatedintheentirework

area,topreventpollutionuseadequatefiltrationindischarge.

●Intheeventofweldingandcuttinginsmall,confinedplaces,orweldinglead,

beryllium,cadmium,zinc,zinccoatedorpaintedmaterials;alsowearafreshair

suppliedrespiratorinadditiontotheabovementionedrules.

●Alwayshaveatrainedwatch-personnearby,whileworkinginsmallconfinedplaces.

Avoid

working

in

such

confined

places

if

possible.

●Ifgascylindersaregroupedinadifferentarea,makesurethatitisawell-ventilated

area.Whennotbeingused,turnoffthecylindervalve.

●Shieldinggassessuchasargonisdenserthanairandwhenbeingusedinconfined

places,canbeinhaledinplaceofair,andthisisdangerousforyourhealth.

●

Do

not

perform

welding

operations

near

chlorinated

hydrocarbon

vapors

produced

by

degreasing

or

painting.

-2-

SAFETY

RULES

ARCRAYSCANBURNEYESANDSKIN

●Useadequateweldinghelmetwithcorrectshadeoffilter(4or13consideringTSEN

379)

to

protect

your

eyes

and

face.

●

Protect

open

parts

of

your

body

(arms,

neck

and

ears)

from

arc

rays

by

adequate

protective

clothing.

●

To

protect

others

by

arc

rays

and

hot

metals,

surround

the

working

area

with

flame

proof

curtains

which

are

higher

than

eye

level

and

put

up

warning

boards.

FLYINGMETALSCANINJUREEYES

●Weldingandcuttingcausesparksandflyingmetal.

●Topreventinjurieswearappropriatesafetyglasseswithsideshieldsevenunderyourweldinghelmet.

NOISECANDAMAGEHEARING

●Noisefromcertainindustrialprocessesorequipmentcandamagehearing.

●

Wear

approved

ear

protection

if

noise

level

is

high.

HOTPARTSCANCAUSESEVEREBURNS

●Donottouchhotparts.

●Allowcoolingtimebeforeservicing.

●

If

needed

to

hold

hot

parts,

use

appropriate

tool,

insulating

gloves

and

fireproof

clothes.

MOVINGPARTSCANCAUSEINJURY

●Keepawayfrommovingparts.

●Keepalldoors,panels,andguardsclosedandsecured.

●

Wear

shoes

with

metal

protection

over

the

fingers.

WORKINGINSMALLANDCONFINEDPLACESCANBEDANGEROUS

●Whileweldingandcuttinginsmall,confinedplaces,alwayshaveatrainedwatch-personnearby.

●Avoidworkinginsuchconfinedplaces.

-3-

SAFETY

RULES

WELDINGWIREMAYCAUSEINJURY

●

Do

not

point

the

gun

toward

any

part

of

a

human

body,

other

persons

or

any

type

of

metal

when

unwinding

welding

wire.

●

While

extracting

the

wire

from

the

spool

by

hand,

it

may

spring

suddenly

and

injure

you

or

a

nearby

person,

protect

especially

your

eyes

and

face.

●

Make

sure

that

there

is

no

one

close.

WELDINGCANCAUSEFIREOREXPLOSION

●Neverweldnearflammablematerial.Itmaycausefireorexplosions.

●Beforestartingtoweldorcut,moveflammablesawayorprotectthemwith

flame-proofcovers.

●Donotweldorcutonandcutclosedtubesorpipes.

●

Before

welding

and

cutting

on

closed

containers,

open

and

clear

them

entirely.

Weldingoperationsonthesepartsmustbeperformedwiththeutmostcaution.

●Neverweldorcutcontainersorpipescontainingorwhichhavecontained

substances

that

could

give

rise

to

explosions.

Welding andcutting equipmentwarmsupsoneverpositionthemonflammable

surfaces.

●

Welding

and

cutting

sparks

can

cause

fire.

For

that

reason,

keep

extinguishing

means,suchasfireextinguishers,waterandsandeasyreach.

●Haveandmaintainsecurityvalves,regulatorsandothervalvesontheflammable,

explosiveandcompressedgascircuitsingoodconditionbyperiodicalcontrols,

usedforweldingandcuttingoperations.

FALLINGUNITCANCAUSEINJURY

Wrong

positioned

power

source

or

other

equipment

may

cause

serious

injury

to

persons

or

damage

to

objects.

●Whilere-positioningthepowersourcealwayscarrybyusingtheliftingeye.Neverpullcable,hoseorGun.

Always

carry

the

gas

cylinders

separately.

●

Before

carrying

the

welding

and

cutting

equipment,

disassemble

all

the

connections

between

and

separately

carry

the

small

ones

by

hand

-

grips

and

the

big

ones

by

lifting

eyes

or

by

using

appropriate

vehicles

like

forklifts.

●

I

nstall

your

machine

on

flat

platforms

having

maximum

10

°

slope

that

it

does

not

fall

over.

Install

it

on

well

ventilated,

non-confined

places

away

from

the

dust,

also

avoiding

the

risk

of

falling

caused

by

cables

and

hoses.

For

gas

cylinders

not

to

fall

over,

attach

it

to

the

mobile

machine

or

to

the

wall

with

a

chain.

●Ensurethatoperatorseasilyreachthecontrolsandconnectionsonthemachine.

-4-

SAFETY

RULES

MAINTENANCEMADEBYUNQUALIFIEDPERSONSMAYCAUSEINJURIES

●

Electrical

devices

should

not

be

repaired

by

unqualified

persons.

Improper

repairs

can

cause

serious

injuries

or

even

death

during

applications.

●

The

components

of

the

gas

circuit

works

under

pressure.

The

service

given

by

unqualified

persons

may

cause

explosions

and

operators

can

be

injured

seriously.

OVERUSECANCAUSEOVERHEATING

●Allowcoolingperiod;followrateddutycycle.

●Reducecurrentorreducedutycyclebeforestartingtoweldagain.

●Donotblockairflowtounit.

●

Do

not

filter

airflow

to

unit

without

the

approval

of

manufacturer.

ARCWELDINGCANCAUSEINTERFERENCE

●

Electromagnetic

energy

arising

during

welding

and

cutting

operations

can

interfere

with

sensitive

electronic

equipment

such

as

microprocessors,

computers,

and

computer-driven

equipment

such

as

robots.

●Besureallequipmentintheweldingareaiselectromagneticallycompatible.

●

To

reduce

possible

interference,

keep

weld

cables

as

short

as

possible,

close

together,

and

down

low,

such

as

on

the

floor.

●

To

avoid

possible

EMC

damages,

locate

welding

operation

as

far

as

possible

(100

meters)

from

any

sensitive

electronic

equipment.

●Besurethisweldingmachineisinstalledandgroundedaccordingtothismanual.

●

If

interference

still

occurs,

the

user

must

take

extra

measures

such

as

moving

the

welding

and

cutting

machine,

using

shielded

cables,

using

line

filters,

or

shielding

the

work

area

.

STATIC(ESD)CANDAMAGEPCBOARDS

●Putongroundedwriststrapbeforehandlingboardsorparts.

●Useproperstatic-proofbagsandboxestostore,move,orshipPCboards.

PROTECTION

●

Do

not

expose

the

welding

machine

to

rain,

protect

from

water

drops

and

vapour.

●

The

lifetime

determined

by

Ministry

of

Industry

and

Trade

is

10

years.

OBEYALLTHESAFETYRULESSTATEDINTHEMANUAL!

-5-

LIFETIME

ELECTROMAGNETIC

COMPATIBILITY

EMC

)

ELECTROMAGNETICEMISSION

●

All

electrical

equipment

generates

small

amounts

of

electromagnetic

emission

due

to

current

transferring

in

the

equipment.

Electrical

emission

may

be

transmitted

through

power

lines

or

radiated

through

space,

similar

to

a

radio

transmitter.

When

emissions

are

received

by

other

equipment,

electrical

interference

may

result

.

Electrical

emissions

may

affect

not

only

welding

machines

but

also

many

kinds

of

electrical

equipment

like

radio

and

TV

reception,

numerical

controlled

machines,

telephone

systems,

computers

etc.

●

Welding

and

cutting

machines

have

been

designed

to

work

for

professional

and

industrial

use;

for

other

applications

to

contact

the

manufacturers.

●

The

user

is

responsible

for

installing

and

using

the

equipment

according

to

the

manufacturer

’

s

instructions.

If

electromagnetic

disturbances

are

detected

then

it

shall

be

the

responsibility

of

the

user

of

the

equipment

to

resolve

the

situation

with

the

technical

assistance

of

the

manufacturer.

In

some

cases

this

remedial

action

may

be

as

simple

as

earthing

the

welding

the

welding

circuit,

in

other

cases

it

could

involve

constructing

an

electromagnetic

screen

enclosing

the

power

source

and

the

work

complete

with

associated

input

filters.

In

all

cases

electromagnetic

disturbances

must

be

reduced

to

the

point

where

they

are

no

longer

troublesome.

●

The

circuit

may

or

may

not

be

earthed

for

safety

reasons.

Changing

the

earthing

arrangements

should

only

be

authorized

by

a

person

who

is

competent

to

assess

whether

the

changes

will

increase

the

risk

of

injury,

e.g.

by

allowing

parallel

welding

current

return

paths

which

may

damage

the

earth

circuits

of

other

equipment.

●Extraprecautionmayberequiredwhentheweldingpowersourceisusedinadomesticestablishment.

●SpecialmeasuresshallbetakentoachievecompliancewithweldingpowersourceincludingHFfrequencyfor

arcignitionandstabilizing;itmayberequireduseofshieldedcablesandinanycasetoresolvetheparticular

implementation(e.g.withrobot,computerandanyotherelectricalandelectronicequipmentconnectedto

weldingpowersource)tocallthetechnicalassistanceofthemanufacturer.

●EMCisClassAaccordingtoCISPRII.

ASSESMENTOFTHESURROUNDINGAREA

Beforeinstallingtheweldingandcuttingequipment,theusershallmakeanassessmentofpotential

electromagneticproblemsinthesurroundingarea.Thefollowingshallbetakenintoaccount-ifneeded

arrangetheworkinghoursthatnotcoincidewiththose.

●

Other

supply

cables,

control

cables,

signaling

and

telephone

cables;

above,

below

and

adjacent

to

the

welding

and

cutting

equipment,

●Radioandtelevisiontransmittersandreceivers,

●Computerandothercontrolequipment,

●Safetycriticalequipment,

●Presenceofheartbeatregulators,heartcells,hearingdevicesoretc.nearby,

●Equipmentusedforcalibrationormeasurement,

●

The

immunity

of

other

equipment

in

the

environment.

Theusershallensurethatotherequipmentbeingusedintheenvironmentiscompatible.Thismay

requireadditionalprotectionmeasures.

METHODSOFREDUCINGEMISSIONS

●Cuttingequipmentshouldbeconnectedtothemainssupplyaccordingtothemanufacturer’srecommendations.

Ourweldingmachinesarefilteredagainstemissionaccordingtostandards.Ifinterferencestilloccurs,itmay

benecessarytotakeadditionalprecautionssuchasfilteringofthemainssupply.

●

The

equipment

should

be

routinely

maintained

according

to

the

manufacturer

’

s

recommendations.

The

welding

and

cutting

equipment

should

not

be

modified

without

the

approval

of

manufacturer.

●

The

welding

and

cutting

cables

should

be

kept

as

short

as

possible

and

should

be

positioned

close

together,

running

at

or

close

to

the

floor

level.

Power

cables

and

signal

cables

should

be

kept

separately.

●Keepingcablesintheshapeof-8-andtapingtogetherreduceemission.

●

Connect

earth

clamp

to

work

-

piece

as

close

to

the

weld

as

possible.

But

the

user

should

be

control

whether

this

situation

damage

to

people

and

equipment

or

not.

-6-

TECHNICAL

INFORM

A

TION

1.TECHNICALINFORMATIONS

1.1GENERALEXPLANATIONS

●Thiscuttingmachineismanufacturedwithadvancedinvertertechnology.Withhigh-powercomponentIGBTand

byadoptingPWMtechnology.TheinverterconverttheDCvoltage,whichisrectifiedfrominputACvoltage,to

high20KHzfrequencyACvoltage.Asaconsequence,thevoltageistransformedandrectified.Therefore,itresults

themuchmoresmall-sizedofthepowersourceandlighterinweightoftheinvertercuttingmachine,whichratesthe

performanceofcuttingby30%.Thehighfrequencyoscillation,whichenablestheoutputofthehighfrequencyDC,

isemployedinthearc-startingsystem.Thefeaturesofthisproductareasfollowing:stablethecuttingcurrent

output,reliable,completelyportable,efficientandlownoisegeneratedwhilecuttingisperformed.

●CuttingProcessisavailablefor LGK-80S.

●Duringtheperformanceofcutting,thiscuttingequipmentisfeaturedwiththestabilityofcurrentoutputandthat

thecuttingcurrentoutputdoesnotvarywithvariationofthelengthofarc.

●Guaranteeofmaintenanceformainengineisoneyear,excludingotherspareparts.

●Duringtheguaranteemaintenanceperiod,allmaintenanceisfreeofcharge,excludingthedeliberateddamageto

thiscuttingequipment.

●Onlyqualifiedtechnicianareauthorizedtocarryouttherepairstaskofthiscuttingmachineincaseofmachine

fault.

●THEMAINTECHNICALSPECIFICATIONSorDATAPLATEonthecuttingmachine.

1.2APPLICATIONAREA

1.3SYMBOLANDMEANINGONDATAPLATE

threephaseinputACpower supply,RectifierDCcurrentor voltage output

Output Characteristicsofthecuttingpowersourceisconstantcurrent(CC)outputfor LGK-80S.

Norm:Applicationstandards,forexample,EN60974-1orIEC60974-1.

-7-

●LGK-80S cuttingmachinesare threephase,

380V,50Hz,constantcurrent(CC)outputpower

sourcesespeciallydesignedfortheairplasmaarc

cutting.

●Allthecontrolsandadjustmentknobofthecutting

powersourceareplacedontothefrontpanelforeasy

operation.

●CuttingCable,the torch, EarthCableand gas

hose canbe easyconnectedto thepowersource.

●Outputcurrentofthe LGK-80S cuttingmachine

canbeadjustedbyacuttingcurrentadjustment

knob.

●LGK-80S isverygoodselectionformedium

thicknessmetals(upto20mm)cutting.It isalsoa

verygoodchoiceforstainlesssteelandmetalscutting.

Thismachineshouldbeselectedforhighdutycycle

cuttingapplications.

TECHNICAL

INFORM

A

TION

U1:RatedACinputvoltageofthecuttingpowersource,3~,380V,etc.

I1max:Max.inputcurrent.

I1eff:Max.effectiveinputcurrent.

50HZ:RatedfrequencyofsinglephaseACpowersupply.

X: Rated dutycycle.Itistheratiobetweentheloaddurationtimeandthefullcycletime.

Note1: Thisratioisbetween0~100%.

Note2: Forthisstandard,onefullcycletimeis10min.Forexample,iftherateis60%,theloadedtimeshallbe6

minutesandresttimeshallbe4minutes.

Dutycycleisbasedonatenminuteperiod.Thismeansthatthearcmaybedrawnfortwominutesoutof

eachtenminuteperiodwithoutanydangerofoverheating.Ifitisusedmorethantwominutesduringseveral

successivetenminutesperiods,itmayoverheat.

U0:No-loadvoltage

Itistheopen-circuitoutput voltageofthecuttingpowersource.

I2:outputcurrentorcuttingcurrent

U2:Outputloadvoltageorcuttingvoltage. Theratedloadedoutputvoltage U2=80+0.04I2forPlasmaCutting.

A/V A/V:Theadjustablerangeofcurrentanditscorrespondingloadvoltage.

S1:TheratedInputPower,KVA

IP:Protectiongrade.Forexample,IP21S,approvingthecuttingmachineassuitableforuseindoors;IP23S,.

approvingthecuttingmachineassuitableforuseoutdoorsintherain.

Suitableforhazardousenvironments.

Class:H Insulationgrade.

1.4Environmentalconditions

Thepowersourceshallbecapableofdeliveringtheirratedoutputwhenthefollowingenvironmental

conditionsprevail:

e)baseoftheweldingpowersourceinclinedupto10°

-

8

-

S

INS

T

ALL

A

TION

2.INSTALLATION

2.1UPONRECEIPTANDCLAIMS

2.2WORKAREA

2.3INSTALLATIONANDUSAGEOFTHEMACHINE

Onlyqualifiedpersonsshouldinstall,useorservicethisequipment.Protectyourselfandothers

frompossibleseriousinjuryordeath.

WARNING: Donotoperatewithcoversremoved.Disconnectinputpowerbeforeservicing.

Donottouchelectricallyliveparts.

●Beforestartingtheinstallation,checkwiththepowercompanytobesureyourpowersupplyisadequate

forthevoltage,amperes,phase,andfrequencyspecifiedonthecuttingmachinenameplate,Alsobesurethe

-

9

-

●Besurethatyouhavereceivedalltheitemsthatyou

haveordered.Incaseofanyitemsaremissingordamaged,

contactyoursupplierimmediately.

●Besurethatnoneofthefollowing4items are

missing

in

the

box.

Power Source

EarthClampandCable

CuttingTorch

UserManual

●Make sure that your line voltage is

threePhase,380V,50Hz andyouhaveaneutraland

earthlinepresentatyourworkplace.

●Inordertocooldownthemachineandhave

anefficientwork,keepthemachineatleast30

cmawayfromthesurroundingobjects.Donot

placeanyheatsource,asoven,tofrontsideof

themachinewherethecoolingair istakenfrom.

●Donotplacethemachineinsmalland narrow

places.Bewareofexcessivedustanddirt.

●Keepyourmachineawayfromwetand humid

places.

●Donotoperatethemachineunderdirectsunlight,rain

andwind.Machinesshouldbeoperatedon lower

capacities whenambientairtemperatureexceeds40ºC.

●Pleaseuseasuitableexhaustsystemforgases

andcuttingvapour.Usebreathingapparatusifthereisa

riskofinhalinganyweldingorcuttingvapour.

●Avoidcuttingwhereair-flowishigh.Protect

thecuttingareawithcurtainsormobilescreens.

●Transportandplacethedeviceonfirmand

levelgroundsothatitmaynotfallover.The

maximumpermissibleangleofinclination

fortransportandassemblyis10°.

●Thismachineisprotectedelectronically

againstoverloading.Donotusestrongerfuses

thanthosestatedonthetypeplateofthe

device.

●Ensurethattheearthclamphasgoodand

directcontactnearthecuttinglocation.Do

notdirectcuttingcurrentoverchains,ball

bearings,steelcables,protectionconductors

etc.,Otherwisetheymaymelt.

●Ensurethatoperatorscaneasilyreachthe

machine

controls

and

equipment

connections.

●Useliftingeyesforliftingthemachine.

Donotliftthemachinebyusingafork-liftora

similar vehicle.

INS

T

ALL

A

TION

plannedinstallationwillmeetalllocalandnationalcoderequirements.Somecuttingmachinesmaybe

operatedfromasinglephaselineorfromonephaseofatwoorthreephaseline.

●Beforeconnectingtheinputcabletothepowersupply,checkthatthepower(on-off)switchoperatesin

thepositioncorrespondingtotheinputvoltagethatthemachinewillbeconnectedto.

CAUTION:Ifthepowerswitchsettingdoesnotmatchtheinputpowervoltage,youmayburnupthe

cuttingmachine!

●Connectthe “PE”or green/yellowgroundingwire intheinputcordtoasystemgroundperthe

applicablenationalandlocalcodes.

2.3.1CONNECTTHEMACHINETOPOWERSUPPLY

●Theconnectiontothemainlinesismadebytheenduser.Ithastobeperformedbyqualifiedelectriciansorby

thepeopletrainedinthisarea.

●Power supply cable tothemachine mustbeconnectedto themain power supply switch.Themain power

supplyhasbeenlabeledinthe nameplateof themachine,forexample,3~,50Hz,380VAC.

●The4x2.5mm²power supply cable shouldbeused.

●Beforeturningonthemain power supply switch usermustcheckcarefullytheseconnections ofthepower

supply cable andearth cable (Yellow/Green) tothemachine.

Besurethatconnectionsarefastenedtightly.Looseorincorrectfasteningmaycause

theconnectiontooverheator burn.Unexpectedresultsmayoccurifamistakeismade

inthenetworkconnection.Payattentionthattheconnection of the “PE”or green/yellow

groundingwireoftheinputcordtoasystemground.

Figure1:The front panel ofthe cutting powersource

POWER Pilotlightof andLED1forthe power supply

O.H PilotlightofLED2forOverheating protection

CUTTINGCURRENT Cuttingcurrentadjustmentknob

LOWINPUT PilotlightofLED3forlow power supplyvoltageorlowvoltage protection.

SwitchofCUTTINGorCHECKAIR CUTTINGorCHECKAIRSelectionSwitch

-1

0

-

Adjustmentofthe

cuttingcurrent

INS

T

ALL

A

TION

2.3.2CONNECT OUTPUT(-)ANDOUTPUT(+)

●Connectthework-piece to Output(+), notLoose.

●ConnecttheCuttingtorchto Output( )or connectoroftheCuttingtorch, notLoose.

●Connecttheairtubetothecoppernozzleoftheback panel.Theairsupplysystemshouldbewellconnectedin

ordertokeepairoutput,whichisofcriticalimportanceforcuttingoperation.

●BesurethatconnectionsarecorrectandnotLoose.

●Turnon thepower supply ON/OFFswitch.

●SetCHECKAIR,CheckAir flow andpressure!

●SetCUTTING,thecuttingprocesswillbecarriedoutbyusingthe torch switch.

●Toincreasethequalityofcutting,earthclampontheworkpieceshouldbeclampedtightlyandasclosetothe

cuttingareaaspossible.

2.3.3CONNECTTOTHEREGULATORANDAIRSUPPLY

●ConnecttheairregulatortotheCuttingmachine.Connecttheairregulatortotheairsupply.

●Connectoneendoftheairregulatortotheairsupplyinletofthecuttingpowersource.Theotherendisfor

connectingthehosetotheairsupply.

●Screwtheairhosepressureregulatorandopen the airsupply.

●SettingoftheAirflowwiththeadjustment valveoftheregulator. Usually,thevalveisabout0.17m3/min.

3.USAGEINFORMATION

3.1THEPOWERSOURCEFRONTPANEL

●Onthefrontcontrolpanelofthecuttingpowersource,therearePilotlights,checkairandcuttingswitch,Cutting

currentcontroller,etc.

●A:Cuttingcurrent adjustmentknob orcontroller.

●LED1(POWER):PilotlightofthepowersupplyintheON/OFFpowersourceswitch.TheLED1islighted

whenthe switchisON.

●LED2(O.H):PilotlightofOver-heating,Overcurrentorvoltage.TheLED2islightedwiththermaloverload

protectionorovercurrent.LED2ison,incasethatthiscuttingequipmentisofoverheatingprotectionstatus.

Overheatingarisesifthiscuttingpowersourceisoverloaded.Thiscuttingequipmentautomaticallyrestarts

whenthetemperatureinsideofthiscuttingequipmenthasfallen,andpilotlampisoff.

●LED3(LOWINPUT):Pilotlightoflow power supplyvoltageorlowvoltage protection.TheLED3islighted

whenthe power supplyvoltage is low.

CAUTION:Incasethatthiscuttingequipmentisofovercurrentorvoltageprotectionstatus,LED2ison.At

thistime,Switchofthecuttingpowersourcemustbeturnoff,andthenSwitchshouldbeturnon,thecuttingpower

sourcewould beabletocut.

3.2ADJUSTINGTHEAIRFLOWFORTHECUTTINGPROCESS

●SettingoftheAirflowwiththeadjustment valve. Usually,thevalveisabove0.17m3/min.

3.3 Arcstartingforthecuttingprocess

Pressthetorchswitch.Thearcismadebetweentheworkandthecuttingtorch,andcuttingoperationis

accessible.

3.4ADJUSTINGTHECUTTINGCURRENT

Thecuttingcurrentisselectedaccordingtothethicknessoftheworkpiece.

-1

1

-

MAINTENANCEANDTROUBLESHOOTING

4.MAINTENANCEANDTROUBLESHOOTING

Onlyqualifiedpersonsshouldinstall,useorservicethisequipment.Protectyourselfandothers

frompossibleseriousinjuryordeath.

WARNING: Donotoperatewithcoversremoved.Disconnectinputpowerbeforeservicing.

Donottouchelectricallyliveparts.

WARNING: Beforeremovinganyscrewonthemachineformaintenance,powersupplymustbe

disconnectedfromtheelectriclinesandenoughtimeshouldbeallowedforcapacitordischarging.During

maintenance,payattentiontothemovingpartsinthemachine.

4.1PERIODICMAINTENANCE

Onceeverythreemonths

●Cleanthelabelsonthemachine.Repairorreplacethewornoutlabels.

●Repairorreplacethewornoutcuttingcables.

●Cleanandtightenweldterminals.

●CheckGun,earthclampandtheircables.

●Checkthemainconnectionsinsidethemachine.

Onceeverysixmonths

●Openthecoversofthemachineandcleanwithdryair.

NOTE: Theaboverecommendedmaintenanceperiodsareindicativeaccordingtoour

generalexperience,thesemayvaryfromworkshoptoworkshopandtheconditionsofthe

cuttingsite.

4.2NONPERIODICMAINTENANCE

●Thecuttingpowersource mustbecleanedwithdryair.

●

Nozzleonthetorchhavetobecleanedregularlyandchangedifrequired.Contacttips

mustbeingoodcondition,longertipsgenerallygivebetterresults.

Exposuretoextremelydusty,damp,orcorrosiveairisdamagingtothecuttingmachine.Inordertopreventany

possiblefailureorfaultofthiscuttingequipment,cleanthedustatregularintervalswithcleananddrycompressed

airofrequiredpressure.

Pleasenotethat:lackofmaintenancecanspelltotheunavailabilityandcancellationoftheguarantee;the

guaranteeofthiscuttingequipmentwillbenolongeravailableincasethatithasbeenattemptedtotakethe

machineapartoropenthefactory-madesealingofthemachine.

-

12

-

MAINTENANCE

AND

TROUBLESHOOTING

4.3BASICTROUBLESHOOTING

FaultSymptoms Rectification

1.Thecuttingequipment

isoperated,LED1lampis

off,nooutput,thebuilt-in

fanunavailable.

1.Possiblefunctionfailureofpowerswitch.Compensateitifnecessary.

2.Possibleunavailabilityofinput.Compensateitifnecessary.

3.Possibleshortcircuitofinputcable,Compensateitifnecessary.

2.Whilethisequipmentis

operated,LED1ison,no

output,thebuilt-infan

unavailable.

1.Possibleunavailabilityoftheconnectionofswitch.Reconnectit.

2.PCBispossiblydamaged.Replaceitifnecessary.

3.Whilethisequipmentis

operated,thebuilt-infan

functions,LED2isoff,no

HFelectricityreleasing,

arcstartingunavailable.

1.PCBispossiblydamaged.Replaceitifnecessary.

2.Possibleelectricityleakageofcapacitors,replacethemifnecessary.

3.Checktheconnectionwhetherisavailable.Iffaultcannotberectified,please

contactthesupplierforfurtheradvice.

4.Possibledamageofthecuttingtorch.Replaceitifnecessary.

4.LED2isoff,andcutting

currentoutputis

unavailable.

1.Possibledisconnectionofcuttingtorchcable.

2.Possibledisconnectionofearthcable,orunavailabilityofconnectionoftheearth

cableandworkpiece.

3.Theconnectionbetweenpositiveoutputterminalortheairorelectricityoutput

terminalandthiscuttingequipmentispossiblyunavailable.Reconnectthem.

5.Whileisthiscutting

equipmentisoperated,

LED2isoff,noelectricity

releasing,andthearc

startingavailable.

1.ThecableconnectionbetweenthetransformerofarcstartingandpowerPCBis

possiblyunavailable.Checkandreconnectit.

2.Possibleoxidizationofthesparkgappartsoccurs.Orthedistanceislargerthan

themaximumdistanceavailable.Removetheoxidizationofthesepartsandadjust

thedistanceofthesparkgappartsto1mm.

3.Possibledamagetoswitch.Replacethemifnecessary.

4.HFarcstartingcircuitarepossiblydamaged.Checkandreplacethemif

necessary.

6.Whilethiscutting

equipmentisoperated,

LED2ison,andthereis

nooutput.

1.Itispossibleofover-currentprotectionstatus.WaittilltheLED2isoff,andrestart

thiscuttingequipment.

2.PossiblefaultwithInvertercircuit.DisconnecttheplugofPCB.Andrestartthis

cuttingequipment.

3.PCBispossiblydefective.Replaceit.

4.PossibledamageoftransformerofcenterPCB.Replaceitifnecessary.

5.Iftheindicatorisoff,possibledamageofsecondaryrectifieroftransformer.

Replaceitifnecessary.

6.Possibledamageoffeedbackcircuit.Replaceitifnecessary.

7.Unstablecurrent is

unavailable.

1.Possibledamageofthecurrentcontroller.Replaceitifnecessary.

2.Theconnectionofthiscuttingequipmentisnotavailable.

-

13

-

Table of contents