WWW.JASIC.CO.UK 6

Product Overview

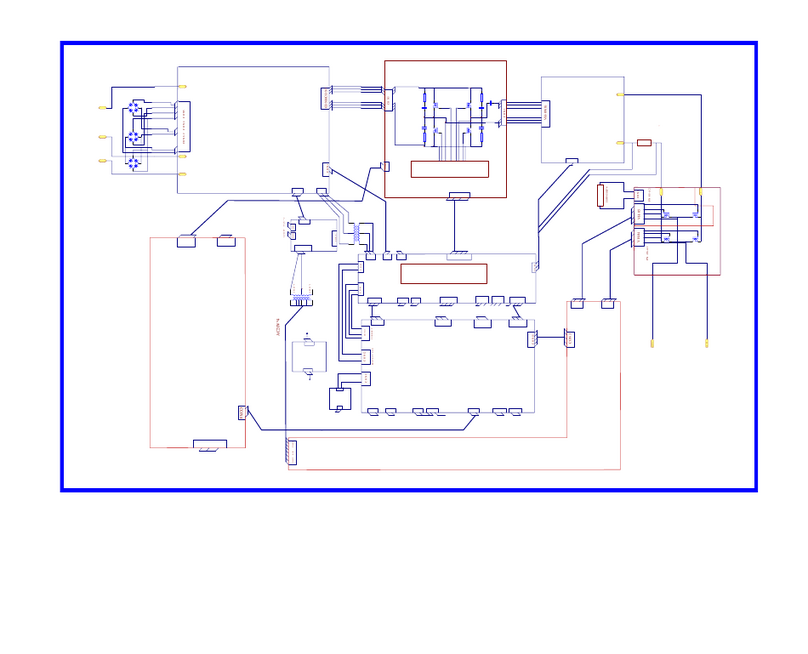

The main circuit of this product uses full-bridge converng

technology based on the tradional PWM (pulse width

modulaon) and current control mode, It uses insulated gate

bipolar transistors (IGBT) as its switching devices. By

adopng advanced so switching technology, the switching

loss of the switching device is greatly reduced, thereby the

product eciency is increased, and consequently the

reliability and stability of this machine is improved. By

adopng internaonally advanced DSP digital technology

and with abundant funcons and good performance, this

machine is an all-digital inverter welder with pulse MIG/

MAG and standard MIG/MAG. When compared with the

tradional welding machine, it mainly has the following

characteriscs.

Abundant funcons: This product has many welding modes

available, such as MIG/MAG, pulse MIG/MAG and double-

pulse MIG/MAG, etc. At the same me, there are many

oponal operaon modes under each welding mode, such as

spot welding, 2T and 4T, etc. Welding wires of dierent

diameters between 0.8mm and 1.6mm are all applicable to

this product. Users may choose welding wires of dierent

materials and dierent diameters to weld dierent metals

and alloys according to dierent welding requirements. In

addion, parameters such as welding current, welding

voltage, ignion current, crater lling current, ignion me,

crater lling me and pulse frequency can be set via the easy

to use computer interface.

High precision and good consistency: The composion

characterisc of the tradional welding machines

determines that their performance completely depends on

the parameters of their components. That is to say, the

inconsistency in the parameters of components directly

leads to the inconsistency in the performance of the welding

machines. However, it cannot be guaranteed that the

components made by any manufacturers are completely

consistent in their parameters. Besides, highly precise

control cannot be obtained due to non-ideal features of the

operaonal amplier. Therefore, even for the welding

machines of the same brand, they oen dier from each

other. In addion, welding performance of the machine may

change to some extent, since parameters of the components

may vary according to the environment such as temperature

and humidity, etc.

This product uses a digital circuit, for which most of the

parameters are set via soware, and it is insensive to the

change of the parameters of the components. Therefore, the

consistency and stability of digital welding machine is beer

than that of tradional welding machine.

High reliability: Overheang protecon, overcurrent

protecon and input under voltage/overvoltage protecon

are all available for this product, which contributes a lot to

the reliability improvement of this product, and meanwhile

facilitates the maintenance and repair of this product.

Excellent welding performance: In order to improve the

welding performance to meet the higher requirements of

welding process, experts at home and abroad have done a

lot of work and put forward many excellent mathemacal

control models. However, such complicated mathemacal

models are very dicult to implement on the tradional

analog welding machines. Instead, they are well applied in

the digital welding machines.

Convenient opmizaon and upgrade of welding

performance: With the development and improvement of

the welding process, it is certainly required that our welding

machine has an excellent welding performance. All the

welding performance of this product is achieved by

soware. Therefore, the welding performance of this

welding machine can be opmized and upgraded by

upgrading the soware without changing any hardware

circuits.

User-friendly design: Dierences in user and using occasion

were taken into consideraon when designing this product,

so as to meet the personalized requirements of users to the

largest extent. For example, this product provides a variety

of welding torch operang modes and user-dened modes.

This product adopts synergic design. That is to say, users

only need to adjust one of the parameters, and other related

parameters would change respecvely to achieve the

opmal matching. It is unnecessary to set each parameter

independently. For example, when the user changes the

welding current, parameters such as welding voltage, wire

feed speed and base metal thickness would change

respecvely. Of course, users can make ne-tuning on

certain parameters such as welding voltage to adapt to their

welding habits.

Energy-saving and small size: This machine adopts

advanced IGBT inverter technology, which reduces the

volume and weight of the welding source and the whole

machine, improves the eciency and power factor of the

power supply, and brings signicant energy saving eect.