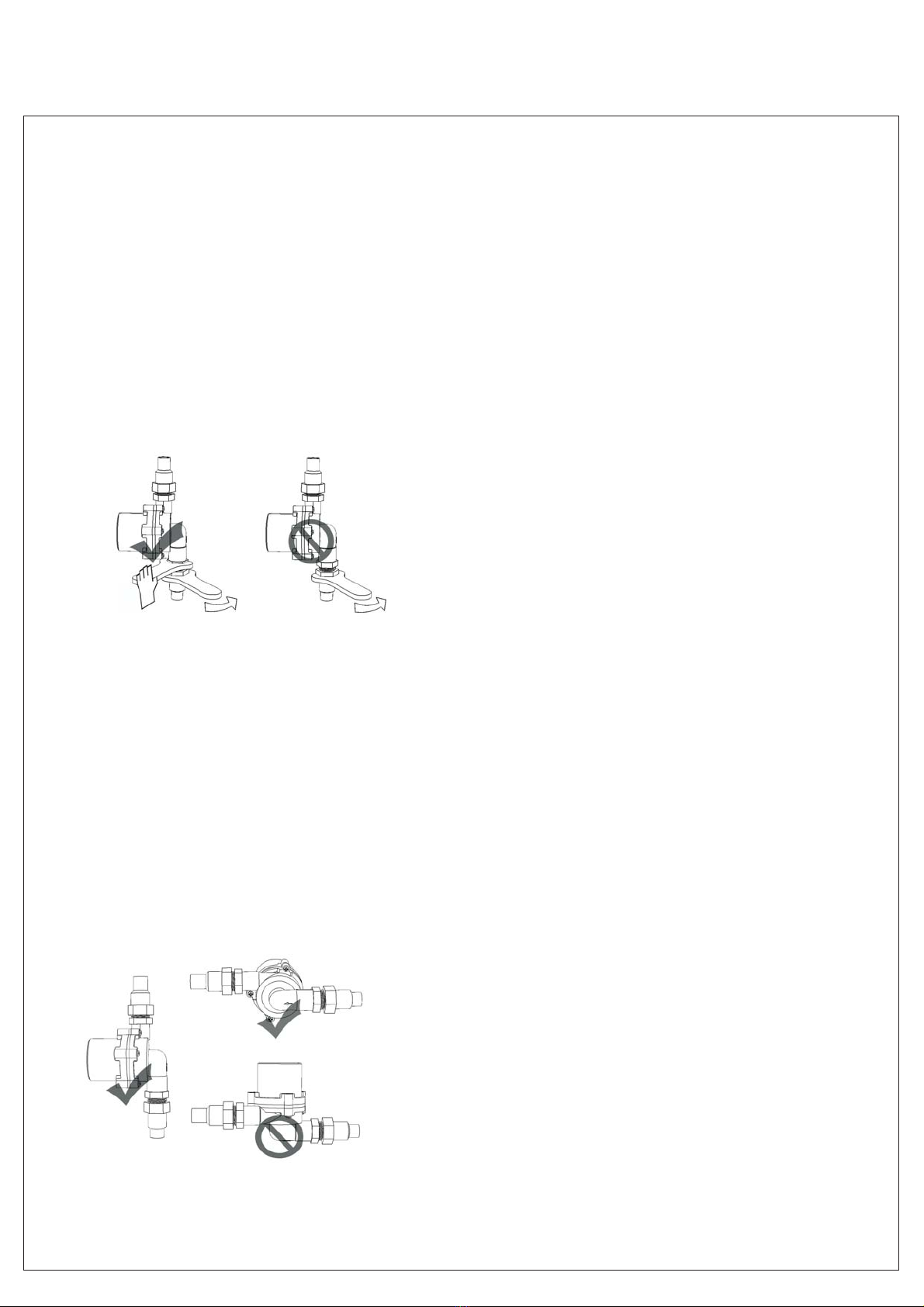

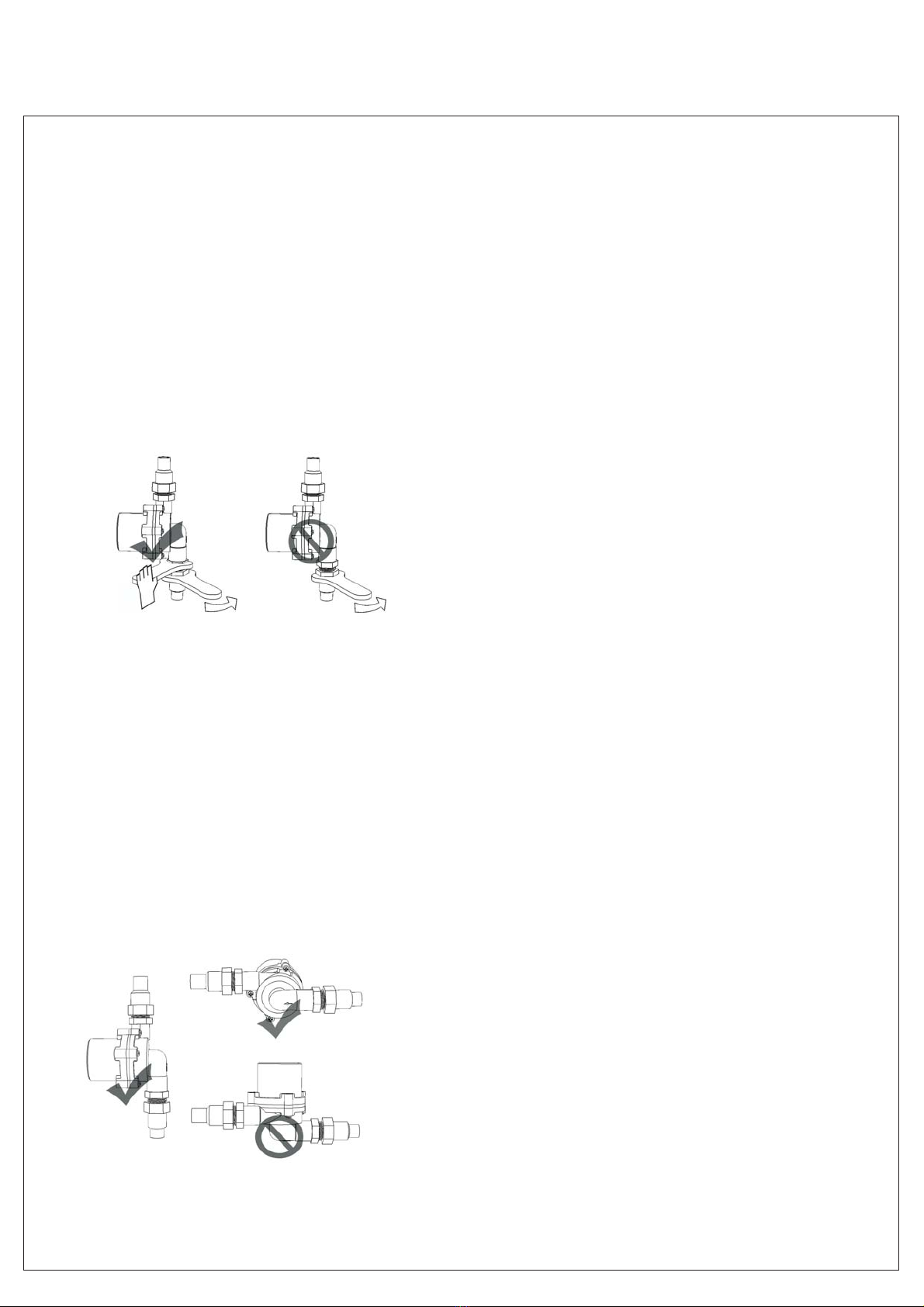

CAUTION!

• Check that the pump body and parts have not been accidentally

damaged or that any bolts or nuts have not been loosened in transit.

• To avoid break the inlet&outlet, when connect and tighten the pipe

connections, it’s necessary to reliably fix the hexagonal nut of

inlet/outlet by wrench. (as shown in the following figure)

• Wires have polarity. Red is plus and black is minus. Wrong polarity

will damage the motor.

• Make certain that the system is filled with liquid and that all air has

been purged before start the pump.

• Be sure the power source conforms to the requirements of pump.

• There is a powerful magnet inside the pump liquid end, do not use

any liquid that contains metallic substances such as iron, nickel, etc.

• To avoid the introduction of water into the electronics, keep the

pump body dry.

• Pump should be drained when subjected to freezing temperatures.

Connecting:

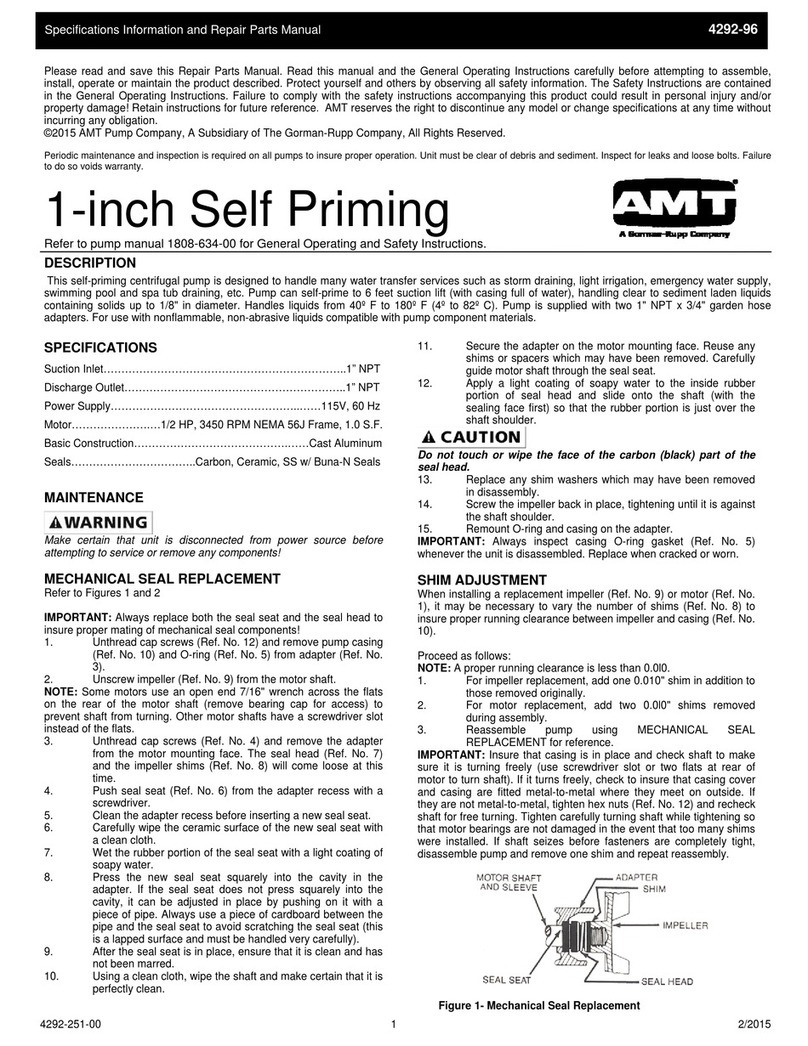

Installation & direction

• It is preferred that the pump always remains in a horizontal

direction and pumping upward. (as shown in the following figure)

• It is acceptable for the pump to be mounted under the piping in a

vertical direction.

• The pump cannot be mounted over the piping in a vertical direction

and any position of the motor is over the pump chamber, this can

cause the pump to run dry leading to premature failure of the pump.

• It is recommended that the pump shall be installed in a position

lower than the liquid level of the tank by at least 12 inches (30 cm). If

this distance is too short, air may enter the pump, causing damage.

• To minimize frictional resistance, the shortest piping possible with a

minimum number of bends should be utilized on the inlet or suction

side of the pump.

• Install a water conditioner if you have hard water.

Installing:

Before start the pump:

• Install the pump in correct direction and position.

• Make certain that the power source conforms to the requirement of

pump.

• Be sure the check valve is installed in the proper direction of flow.

• Make certain that the system is filled with liquid and that the air has

been purged.

Start the pump

• Open the isolation valves and any other valves that may have been

closed during the pump installation

• Plug the pump on

• Power cycling the pump several times accelerates the air removal.

If you hear noise initially, this should abate after a short while as air

is purged from around the impeller

If the pump is noisy there may be air trapped in the system. To

purge the air from the pump, turn the pump off and on several times.

To purge the air from the system open a faucet until all the air in

the line has escaped.

• If the noise does not disappear or decrease substantially, change

the pump’s installation direction or position, and purge the system

once again.

Trouble Shooting

Noise in the System

The pump should run smoothly and quietly, the virtual noise intensity

is relative to the pump consumption. During normal operation, an

occasional air bubble may pass through the pump housing causing

a momentary gurgling noise. However, if noise at the pump persists

for any prolonged period, correct the problem (see below).

• The check valve/non-return valve is mistakenly installed on the inlet

side of pump or in the wrong direction.

• The inlet side shut-off valve is closed or clogged.

• There is air trapped in the pump housing, turn the pump on and off

several times to see if the air pocket can be “bumped” out of the

pump and if not, then open a faucet for manual venting until all the

air in the line has escaped.

• The untight pipe connections permit air into the loop.

• The pump was mounted over the piping in a vertical direction, the

rotor maybe be surrounded by air and no liquid lubricate the bearing,

dry running virtually (change installation direction and purge of air)

• There is sediment or crimps blocking the rotor/impeller.

• The rotor bearing has worn due to dry running causing the rotor to

wobble during operation.

Solar DC Circulation Pump

Installation & Operating

Pump Operating Intermittently or Not at All

• Error in polarity connecting (will damage the motor).

• No or insufficient power to the pump.

• Dry running protection is action, need switch the pump on again.

• Over-temperature protection is working, will resume normal

running when the temperature decreases.

• The ceramic bearing of rotor is worn or damaged, need replace the

rotor/impeller.

• There are sediment or crimps in the recirculation line that would

restrict the flow, please clean the impeller.

If above reason can not resolve the problem, please unplug the

pump several times.