Tornado Dual Internal Air Head Assembly

8

COMPRESSED AIR VACUUM FACTS

1. Use the smallest air jet possible to do the job. The

smaller the jet, the lower the compressed air C.F.M.

required.

2. Use a single venturi unit where liquid recovery is the

primary application. A single venturi will recover liquids

as fast as a double venturi will, yet consumes only one

half as much compressed air.

3. Use a double venturi or quad venturi unit where higher

volume of vacuum air is required. Remember, com-

pressor overload is more likely to occur with a quad

than a double venturi.

4. Use the lowest air line pressure possible per the given

jet size to do the job. The lower the line pressure, the

lower the compressed air consumption.

5. Air line must be maintained at the valve of the venturi

unit. If pressure is not maintained at the unit, vacuum

performance will not be reached. Be sure to use

low line pressure for light liquid recovery, and high

line pressure for liquids, sludge, and other heavy

debris.

6. The air line hose should be as short as possible, and of

maximum inside diameter (single 1/2”, double 3/4”,

quad 1” recommended). Line air losses that occur are

related to hose length and diameter, thus reducing

performance.

7. Any air line moisture (condensation) should be elimin-

ated. Using a water trap in the air line to the venturi unit

will help maintain peak performance.

8. Air line components can reduce performance. Quick

disconnect couplings and line filters, for example, may

reduce compressed air delivery.

9. Factors that affect compressed air supply are com-

pressor horsepower rating, compressor C.F.M. rating,

and system resistance of installed air lines.

Things To Know

AIR COMPRESSOR EVALUATION

Independent of high horsepower or high compressor

C.F.M. rating claims made by individuals, the final evalua-

tion in determining if a compressor is capable of supply-

ing enough compressed air, is to demonstrate the air

vacuum with a pressure gauge at the venturi unit. This

will show the actual pressure being maintained while the

unit is operating (refer to fact #5). This approach will also

compensate for air line system resistance losses. If the

compressor cannot maintain the free air consumption

necessary, the line pressure will drop. Consequently, the

compressed air C.F.M. will also drop, thus reducing the

vacuum or suction performance.

NOTE: The compressed air C.F.M. is not the same as the

vacuum air C.F.M.

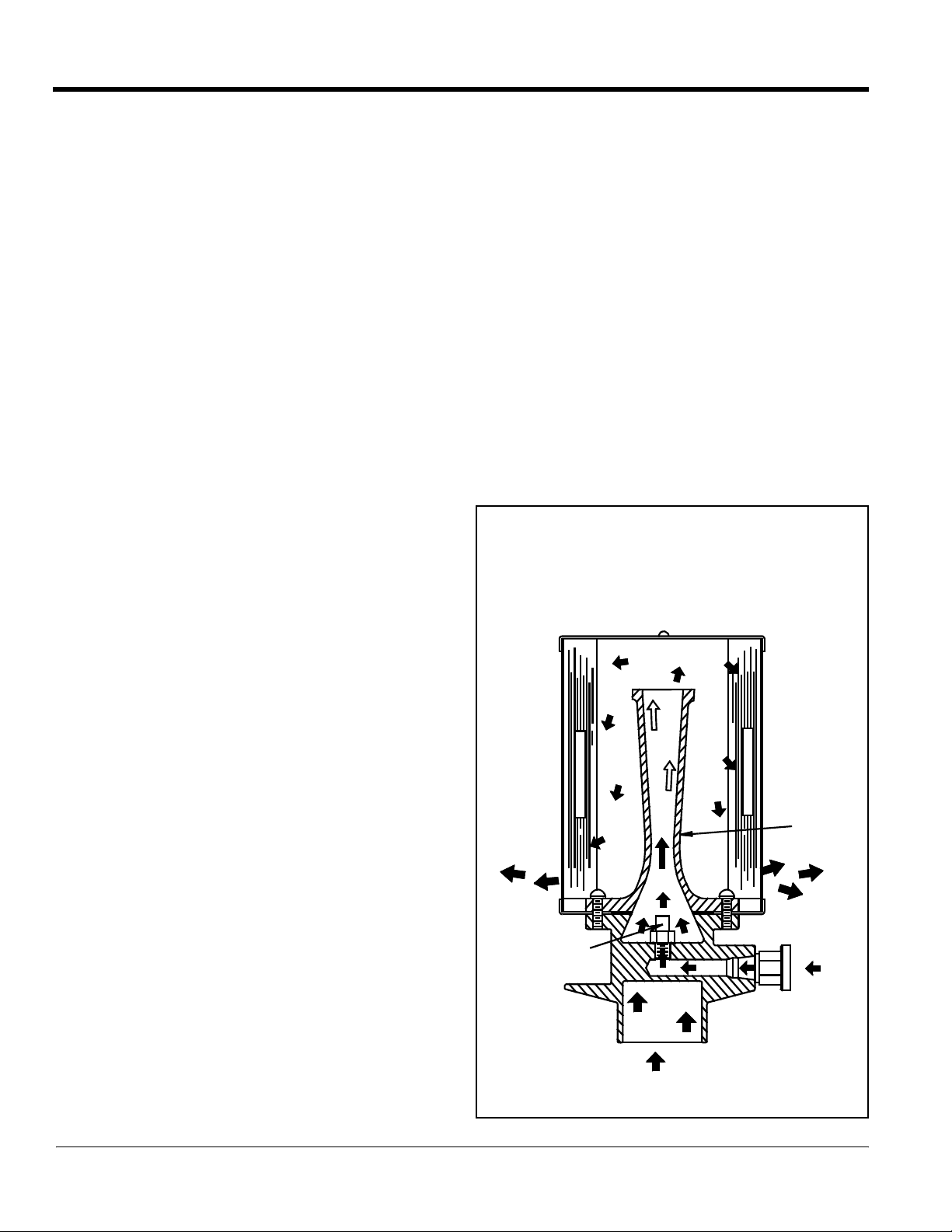

VENTURI

AIR JET

WORKING

VACUUM

AIR FLOW

INTERNAL VENTURI

SILENCER MEDIA

SILENCER MEDIA