U S E R G U I D E |B L U E W A V E ®FX-1250 3

Contents

Introduction.................................................................................4

Where to Get Help........................................................................................... 4

Safety...........................................................................................4

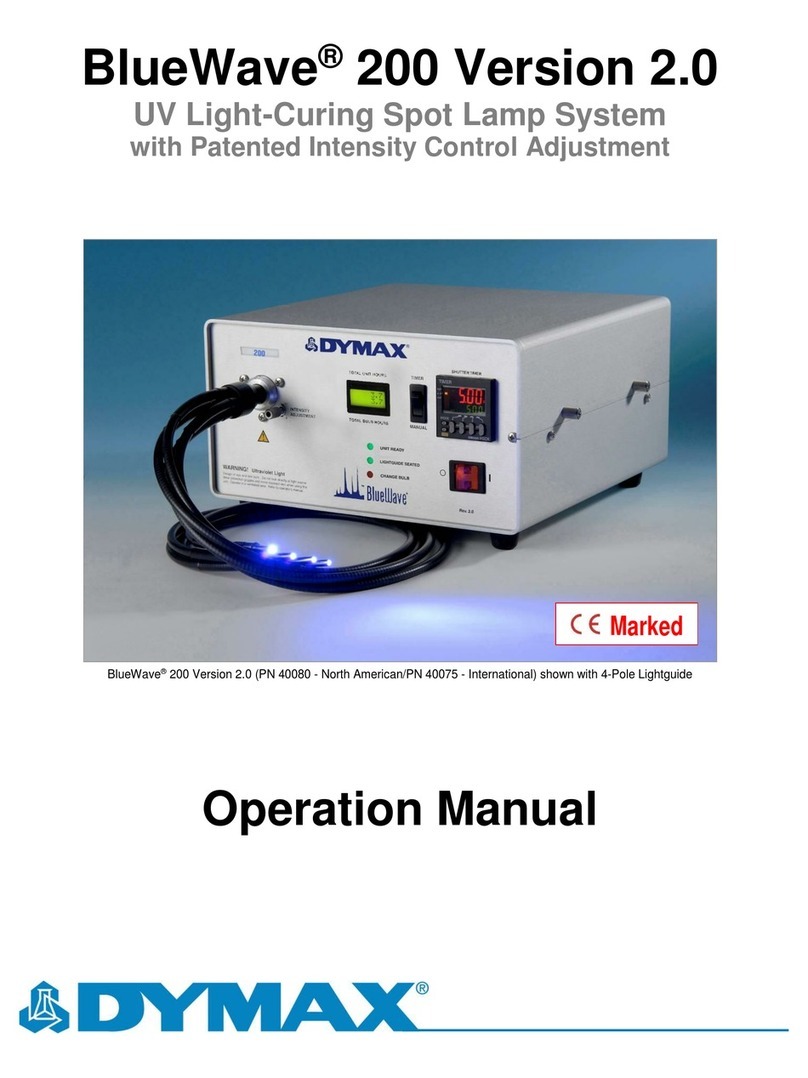

Product Overview .......................................................................5

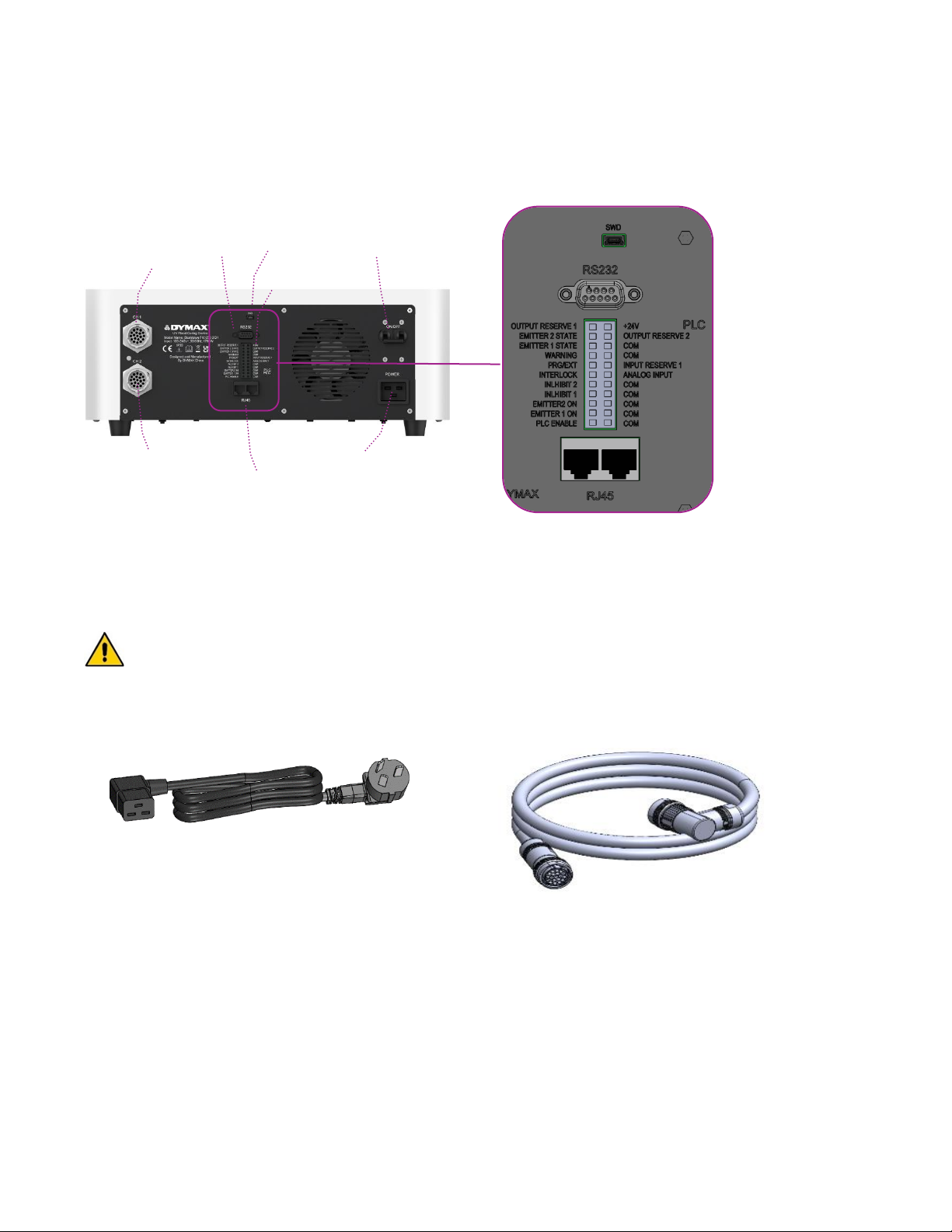

Controller Main Components......................................................................... 6

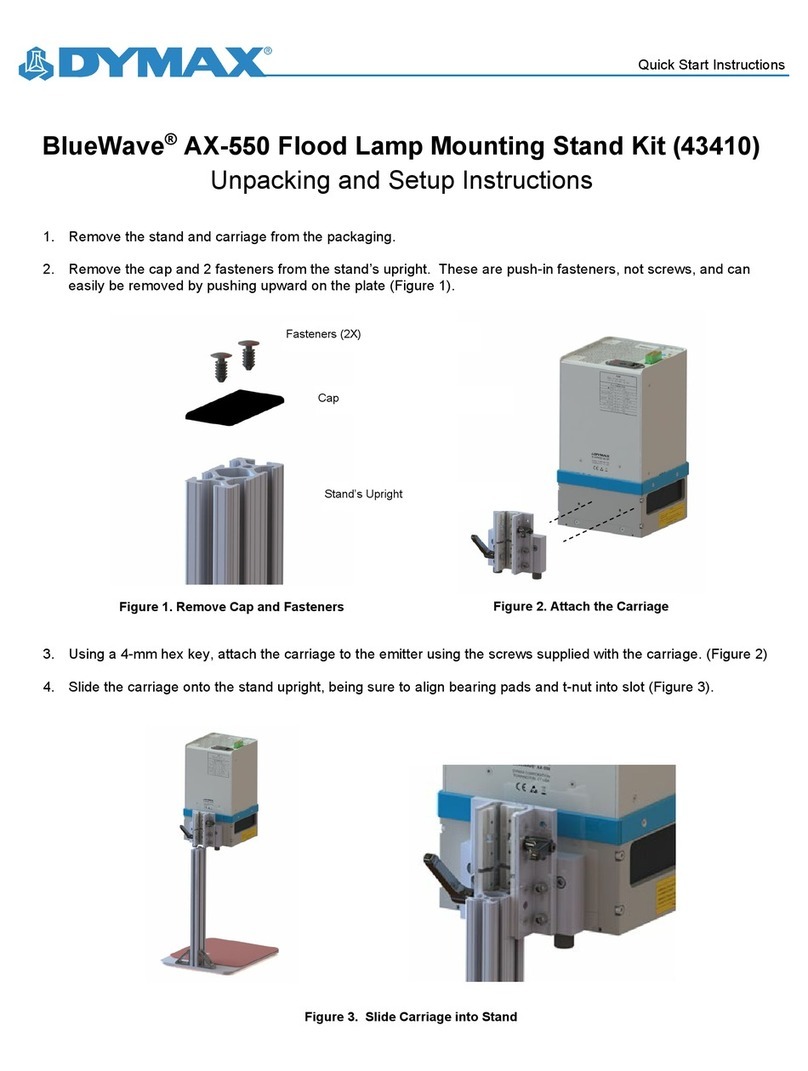

Unpacking ...................................................................................8

Unpacking and Inspecting Your Shipment................................................... 8

Parts Included .................................................................................................. 8

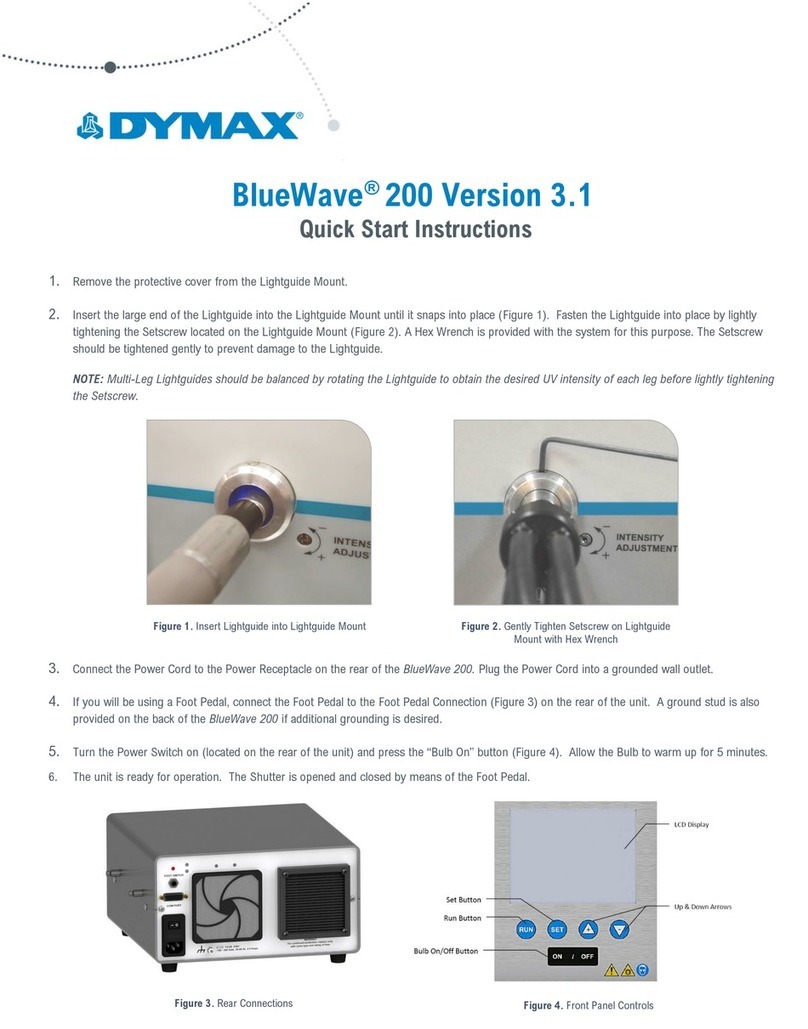

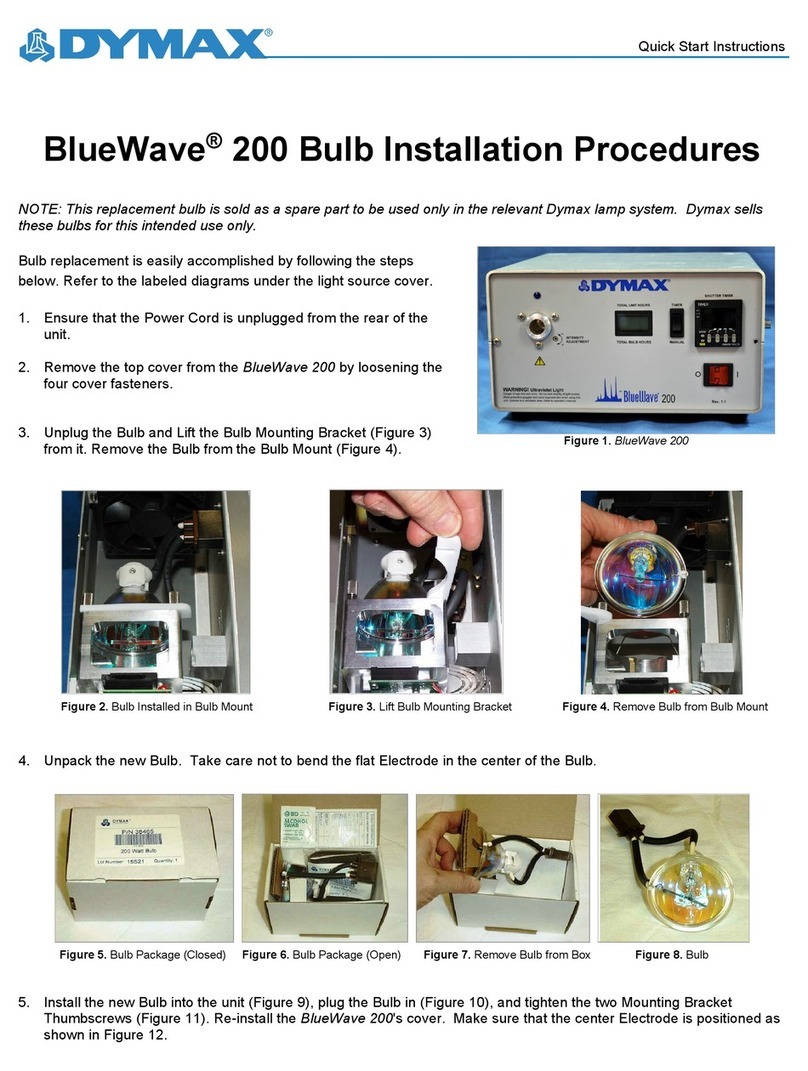

System Installation .....................................................................9

System Assembly............................................................................................ 9

System Cooling................................................................................................ 9

Wiring and Connections ...............................................................................10

Connections ...................................................................................................11

I/O Interface Summary .............................................................12

PLC UV Control .............................................................................................13

Status Output.................................................................................................14

Operation...................................................................................15

Start Up...........................................................................................................15

Main Window Settings ..................................................................................15

Setting the Power ..........................................................................................17

Setting the Cure Time...................................................................................17

Running the System......................................................................................17

Program Setting.............................................................................................18

Settings......................................................................................19

Brightness.......................................................................................................19

Clock and Calendar Settings .......................................................................20

Resetting the Emitters’ LED ON Time.........................................................20

Changing the Password................................................................................20

System Reset .................................................................................................20

System Log ....................................................................................................21

PLC Mode ..................................................................................22

Spare Parts & Accessories ......................................................24

Specifications ...........................................................................25

Declaration of Conformity........................................................28

Validation...................................................................................30

Warranty....................................................................................31